《1 Introduction》

1 Introduction

The safety performance and assurance capacity of bridges is vital to the smooth passage of transportation arteries. Any damage will seriously affect the normal development of transportation functions and impact the security of people’s lives and property or worse, cause complete failure of key arteries or urban transportations.

Bridges, along with other similar and important elements of transportation infrastructure that experience long-term environmental impacts, are subject to performance weakening or disasters (physical disasters such as seismic events, debris flow, ice and snow freezing-thawing effects, and human disasters such as terrorist attacks, regional wars, and vehicle collisions). Features of disasters that can take place at any station point, route or region are suddenness, unexpectedness, and dispersion, while their occurrence results in extensive damage to or loss of transportation life lines, human life, and property, with negative societal impacts. Hence, research on bridge structural safety assurance is of great significance to building an intelligent and modern transportation system in China.

《2 Current status and problems of bridge safety》

2 Current status and problems of bridge safety

《2.1 Current development of bridges in China》

2.1 Current development of bridges in China

Due to more than 20 years of extensive transportation infrastructure construction in China, by the end of the year 2016 the national road bridge quantity attained 8×105 , while the railway bridge quantity attained 2×105 . By the end of the year 2020, approximately 2×104 –3×104 new bridges are planned to be constructed [1]. Road and railway bridges tend to be located in areas of complex terrain, geology, and hydrogeology where the weather conditions are changeable and various disasters such as landslides and debris flow are frequent, due to the existence of seismic faults and fragmentary zones. In addition, because of recent increases in traffic volume and the impact of overloading, overweight, and natural aging of bridge structures, the potential hazards affecting bridge safety are extensive; as a result, bridge structural safety risks and hazards will attract people’s attention more and more. It is therefore urgent to establish a rational mechanism for forecasting, monitoring, evaluating, and assuring safety, so as to improve the resistance of bridges to risks and ensure bridge safety during their operation phase [1].

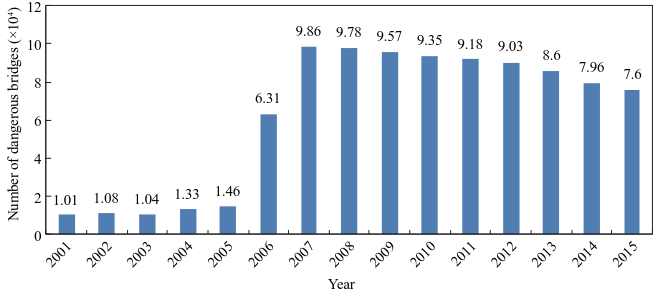

According to the Statistics Bulletin of Transportation Industry Development issued from 2001 to 2005 by the Ministry of Transport, a greater number of dangerous bridges in the national road network are reported, as shown in Fig. 1.

《Fig. 1》

Fig. 1. Number of dangerous bridges in China from 2001 to 2015.

Fig. 1 indicates that with the rapid development of traffic volume in recent years, a large number of bridge structures are in poor or perilous conditions, due to the impacts of overloading, overweight, natural aging of the bridge itself, and other factors. According to statistics resulting from inspection data of the Ministry of Railways, national railway bridges and culverts of deterioration class up to class A (serious) account for 24.8% and 7.8% of total bridges, respectively, proving that the safety condition of aged railway bridges is unsatisfactory.

《2.2 Influences on bridge safety》

2.2 Influences on bridge safety

Influences on bridge safety are numerous; overall, they can be generalized into two major types, namely human influence and natural influence. Human influences comprise errors in design and work execution, equipment collisions, overloading, purposeful damage, and so on. Natural influences include seismic events, flooding, storms, strikes by drifting objects, adverse environments, and other unknown influences.

2.2.1 Earthquakes

Seismic disaster is one of the primary natural disasters faced by human beings. Under seismic pressure, the substructures of bridges are prone to fractures and defects that can cause further damage and collapse the superstructures of bridges. Furthermore, due to their unpredictability, seismic events cause greater damage to bridges than any other type of physical disaster.

2.2.2 Geological disasters (collapse, landslides, debris flow, and other similar events)

China is a country with very active and frequent debris flow activity. Debris flow areas are scattered extensively throughout mountainous regions in Southwest, Northwest, and Southern China. According to statistics, areas of active debris flow activity can be as vast as 4.80×106 km2 , with a total of 1583 counties (cities) being subjected to debris flow disasters over long periods [2].

2.2.3 Climatic disasters (flooding, wind disasters)

During the rainy season, the mountain torrent generated by intense rainfall and geological disasters causes extremely large threats to local highways, bridges, and other infrastructure. According to incomplete statistics recorded since 1975, damages to bridges and culverts caused by flood-type geological disasters have incurred economic losses of hundreds of millions in RMB, with such economic losses increasing on a yearly basis.

2.2.4 Collisions of traffic equipment and strikes from drifting objects

Since the serious collision of equipment with a bridge that took place in 1987, there has been on average one collision per year in China. There has been a tendency toward a steady increase in collision frequency in recent years.

2.2.5 Irrational design and construction

Since bridge sites encompass complex geographical conditions and surroundings, bridge accidents can happen when a single factor of design or construction is underestimated.

2.2.6 Bridge structural aging, inadequate maintenance, and overloading

Under the influence of years of cold winds and hot summers, storms, burning heat from the sun, flood erosion, and vehicle and equipment collisions, many bridges acquire defects and damages of varying degrees. Such defects and damages include damaged decks, fractured railings, damaged expansion joints, voided foundations of piers and abutments, erosion-induced collapses of the subgrade at abutments, overturned riverbed coverings, and serious movement or changes in the river channel due to long-term erosion that endangers the subgrade at abutments, all of which seriously impede the normal service of bridges. These negative events also endanger the security of passengers and passing vehicles, in addition to shortening the service life of the affected bridges considerably.

《2.3 Investigation of and analysis of bridge accidents in China and abroad》

2.3 Investigation of and analysis of bridge accidents in China and abroad

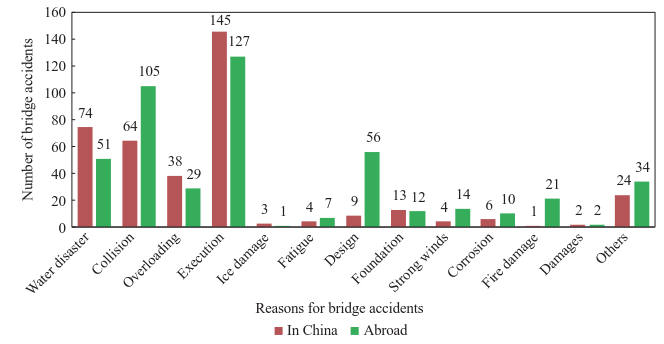

By consulting a large quantity of literature, documents, and relevant books in order to analyze various adverse causes of bridge accidents, material regarding 916 bridge accidents in China and abroad was collected, of which 376 cases concerned national bridges and 540 cases concerned bridges abroad; a preliminary statistical analysis of the data was then conducted [3,4].

Fig. 2 shows that design, construction, collision, water disaster, and overloading constitute the main triggers of accidents and that the causes of bridge accidents tend to be the result of the influence of multiple factors.

《Fig. 2》

Fig. 2. Statistics of bridge accidents [3,4].

The causes of bridge accidents in the country and abroad are essentially identical. Construction, overloading, and water disasters are the main contributors. From the analysis of national bridge cases, it can be seen that bridge accidents induced by construction, overloading, and water disasters account for a higher proportion in China than in foreign countries, highlighting the fact that China is faced with a heavy task in handling the tough problem of bridge accidents.

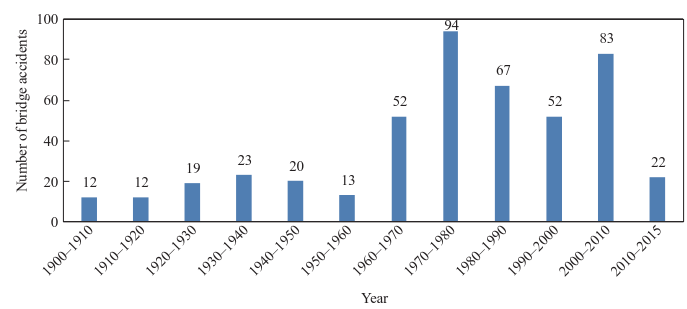

Fig. 3 provides statistics for occurrences of bridge accidents abroad since 1900 and shows that with large-scale transportation infrastructure construction following World War II, the occurrences of bridge accidents clearly increased.

《Fig. 3》

Fig. 3. Bridge accident occurrences abroad for the period 1900–2015 [3,4].

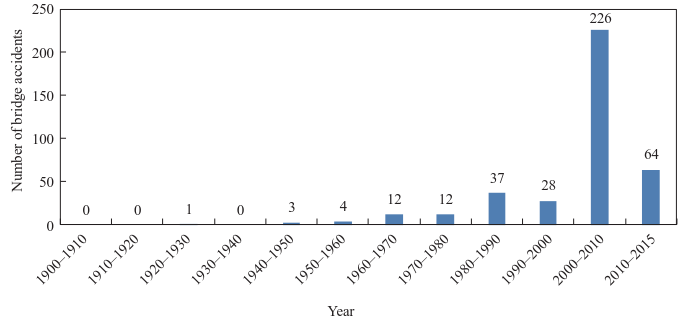

Fig. 4 provides statistics for occurrences of bridge accidents in China since 1900, indicating an extremely low number of accidents prior to the 1960s. With the development of national transportation infrastructure construction, the number of bridge accidents soars. During the years 2000 through 2010, especially, bridge accidents increased dramatically; the increment is much higher than that of the occurrence of bridge accidents abroad in the concurrent period. It is clear that the bridge safety situation in China is exceptionally severe and grim.

《Fig. 4》

Fig. 4. Bridge accident occurrences in China for the period 1900–2015 [3,4].

A statistical analysis of accidents by bridge type in China and abroad (beam bridge, arch bridge, cable-stayed bridge) is shown in Fig. 5.

《Fig. 5》

Fig. 5. Bridge accidents by type in China and abroad for the period 1900–2015 [3,4].

In China, common bridges (with shorter spans) have the most accidents, exceeding 50 %. In China, the number of arch bridge accidents clearly exceeds that of foreign countries, while the number of suspension bridge accidents in foreign countries is far higher than in China. The primary reason for the disparity in arch bridge accidents is that China has many more arch bridges than do foreign countries, while the disparity in suspension bridge accidents is explained by the fact that suspension bridges were developed much earlier in foreign countries than they were in China. Inadequate experience during the early development period, a long service life, and bridge accident risks are responsible for more suspension bridge accidents in foreign countries than in China.

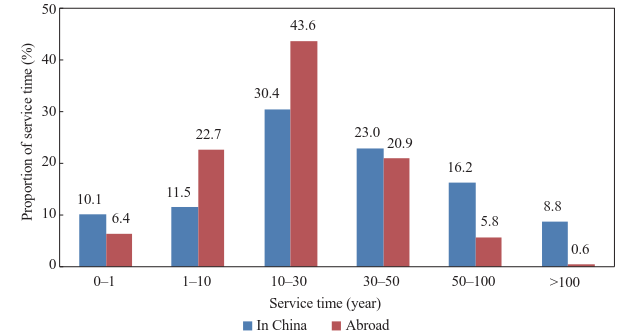

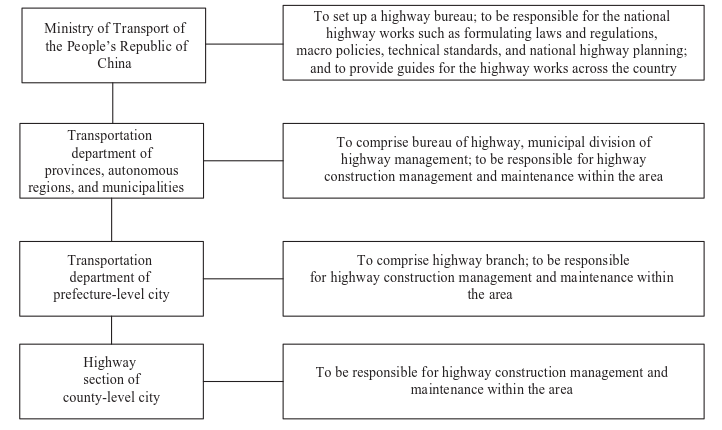

A total of 172 national bridges and 147 foreign bridges with data on the specific year they opened to traffic and the year an accident occurred were selected. The service time of damaged bridges is plotted as shown in Fig. 6.

《Fig. 6》

Fig. 6. Service time of damaged bridges in China and abroad [3,4].

Fig. 6 indicates that national bridges with a service life in excess of 50 years at the time of an accident account for approximately 5.8 %, while bridges with a service life in excess of 100 years only account for 0.6 %, which is much lower than the proportion of foreign bridges. Meanwhile, the average service life of national bridges is only 23.8 years, which is far shorter than the average life (40 years) of damaged foreign bridges; it is also less than a quarter of its planned life (if it was designed to last 100 years).

Due to the fact that stay cable components are exposed to harsh physical conditions for long periods, in addition to under-estimations in bridge design, short work periods, and weak post-construction maintenance and management, bridges are prone to deterioration in cable-bearing capacity, which leads to the cable’s inability to bear continuous loads. As a result, cables must be replaced ahead of the design reference time. Table 1 provides statistics for cable replacement of cable-stayed bridges, indicating that cable-stayed bridges that had cables replaced had an average life of approximately 13 years, with the shortest being six years—far shorter than a current cable-stayed bridge’s design life (100 years).

《Table 1》

Table 1. Cable replacement of cable-stayed bridges in China.

《3 Current bridge technology in China and global development predictions》

3 Current bridge technology in China and global development predictions

To clarify the technical class of national bridges in service and analyze their risks, road bridges are given as an example to provide statistics for the technical class of national road bridges. Table 2 shows the number of bridges constructed in different years, with different technical classes, i.e., bridges constructed at different times are graded using a limited technical investigation.

《Table 2》

Table 2. Technical condition classification of national highway bridges.

The prediction for the technical deterioration of bridges applies the following major methods: ① Predict bridge deterioration based on technical statistical data of bridge structure in history and through the use of probability statistics and other mathematical methods; ② predict bridge structural deterioration by studying time-dependent change relationships between the factors affecting bridge structure technological conditions and bridge deterioration. This paper mainly applies the inverse of matrix method to compute the state transfer probability matrix and calculation formula, as follows:

in formula (1), Pij is the state transfer probability matrix; A and B are the probability matrix of order 5.

In the Code for Maintenance of Highway Bridges and Culverts (JTG H11–2004), bridge components are classified into five levels according to damage situation, and bridge status is scored by classes of components. Hence, after the original state of bridge structure is obtained and deterioration probability is determined, the structural status at any given moment in time can be calculated. Assuming the prevailing national policy and measures of bridge management and maintenance remain unchanged, the weakening degree and tendency of the technical standard of bridges will generally remain unchanged. According to the above analysis, the technical conditions of current bridges can be taken as starting points to predict the technical conditions of national bridges in years to come. The specific calculation formula is shown as follows:

![]()

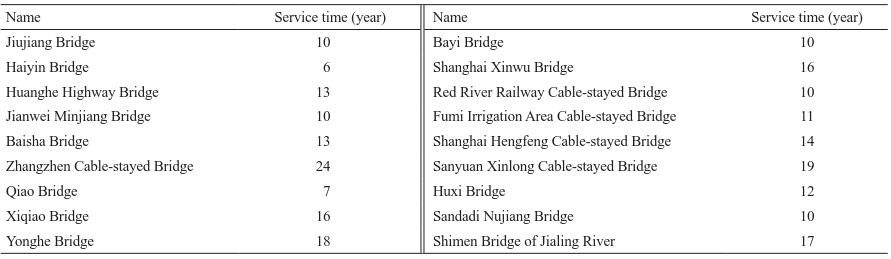

in formula (2), P(ti ) is the forecast result, P(t0) is the current bridge technological condition, [π] is the transfer matrix, and the calculation results are shown in Fig. 7.

《Fig. 7》

Fig. 7. Forecast of bridge technical conditions.

Fig. 7 indicates that if current bridge construction speed, technical methods, measures, and investment in bridge maintenance and management are maintained, with the passage of time, the overall technical conditions of current bridges in service will considerably deteriorate, and the technical condition class will dramatically decline. After 30 years, the proportion of first-level bridges will decrease from 52.0 % at present to 26.8 %, a reduction of approximately 1/2, while the proportion of third-level bridges will rapidly increase from 3.0 % to 13.3 %. The total number of third-, fourth-, and fifth-level bridges accounts for 20% of total highway bridges in China, which means that approximately 1/4 of bridges are subject to damage and hazards related to inadequate bearing capacity across the entire country. Hence, assuring bridge safety is a big challenge for the government.

《4 Existing safety assurance system for bridges in service in China》

4 Existing safety assurance system for bridges in service in China

To ensure normal operation of bridges during their service period in China, corresponding specifications and technical solutions are published that target all phases from design through construction, operation, and maintenance management [3,4].

《4.1 Relevant policies, laws and rules, and measures》

4.1 Relevant policies, laws and rules, and measures

To enhance the management and maintenance of highway bridges, maintain bridges in normal service states, and ensure safe vehicular travel, a series of Chinese laws and bridge safety assurance measures in connection with bridge maintenance and management are prepared and published.

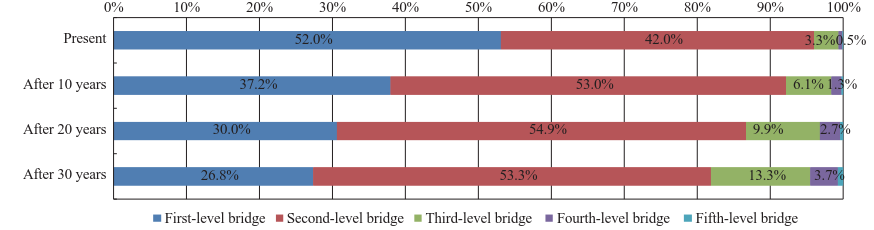

4.1.1 Policy and laws and rules of bridge safety assurance

The highway management system in China is established based on the principle of unified leadership and management at all levels. The highway construction, maintenance, and management authority is controlled mainly by a competent, local agency. Bridge management and maintenance following completion is key to ensuring operational security. According to the Highway Law of PRC and the rules and regulations governing bridge management and promulgated by various ministries, the Chinese bridge management system is mainly comprised of four levels:Ministry of Transport; transport department at the provincial, autonomous region, and municipal levels; transport bureau of local city; and highway section at the county level, as shown in Fig. 8.

《Fig. 8》

Fig. 8. Bridge management system in China.

The study of bridge rehabilitation technology began in the 1970s in China. The Criteria for Evaluation of Technical Conditions of Highway Bridges was implemented in September 2011 and provides a comprehensive technical statement in connection with highway bridge maintenance inspection, evaluation, and strengthening. Fig. 9 indicates the specifications (code) for the current inspection, evaluation, and strengthening of bridges.

《Fig. 9》

Fig. 9. Specification system for inspection, evaluation of load-bearing capacity, and strengthening of highway bridges in China.

Regular inspection and monitoring of bridges are important measures to ensure bridge safety; bridge monitoring has become a supplementary measure that is extensively accepted by the industry.

In terms of emergency indemnity in compliance with the Highway Law of PRC, Safe Production Law of PRC, Law on Road Traffic Safety of PRC, and Highway Bridge Maintenance and Management Work System by the Ministry of Transport of PRC, in order to apply emergency control of possible major accidents, local governments and management in all regions have prepared corresponding emergency procedures and supporting measures as appropriate.

4.1.2 Technological measures of bridge safety assurance

Methods of bridge structural safety assurance mainly comprise inspection; bridge condition assessment; bridge inspection and bearing capacity evaluation; bridge maintenance and reinforcement; and structural health monitoring, among others.

(1) Bridge inspection and condition assessment

The purpose of bridge inspection and condition assessment is to evaluate the technological condition of a bridge following its completion. By checking for bridge defects and damage, the main causes of such damage and defects are analyzed, and their impacts on bridge quality and bearing capacity are evaluated. Bridge inspection primarily consists of frequent inspection, regular inspection, and special inspection.

(2) Bridge inspection and bearing capacity evaluation

Bridge inspection and bearing capacity evaluation represent an important means and basis for the determination of bridge safety, as well as the core content of bridge evaluation. The procedure mainly involves inspection and testing, loading tests, evaluation methods, testing instruments and apparatus, bridge bearing evaluation, and so forth.

(3) Bridge maintenance and reinforcement

In recent years, bridge technological condition evaluation, structural testing, and bearing capacity evaluation have become progressively quantified and scientific. With the rapid development of technology, calculation methods for the maintenance and reinforcement of older bridges have been established.

(4) Bridge structural health monitoring

An effective method for assuring structural safe operation of bridges is to establish a long-term bridge structural health monitoring system. The structural health monitoring system can acquire information on bridge structural workings’ surroundings, and identify real-time variations in the ambient temperature, wind loads, and vehicular load, and also obtain information on bridge structural response characteristics and real-time working and health conditions of bridge structures.

Recently, bridge structural health monitoring has been a hot topic in civil engineering research, while bridge monitoring technology has been widely applied in China. The majority of bridges included are large river and marine crossings that are either completed or under construction and have been equipped with bridge health monitoring systems.

《4.2 Existing problems in current bridge safety assurance》

4.2 Existing problems in current bridge safety assurance

Generally, national policies, laws and rules, and technology on bridge safety assurance have played positive roles. However, some distance still exists between China and foreign developed countries. Specific differences lie in the following aspects: ① Currently, there are multiple practices regarding apparent external bridge defects; however inspection and evaluation of internal bridge defects are inadequate; ② there are abundant manual inspections and checks of bridge conditions but inadequate systematic, information- and network-based support;③ there are many inspections and checks of individual bridges but inadequate overall safety checks and service life predictions on a macro level for all bridges within a regional range; ④ there are many specific reinforcement solutions and studies aimed at individual bridges but inadequate national strategic planning of rapid overall improvement with regard to bridge bearing equipment capacity. Furthermore, there is an insufficient supply of technicians engaged in highway bridge safety assurance and enforcement of laws. All of the above makes it difficult to implement regulations and systems associated with safety assurance and supervision.

《5 Learning from bridge safety assurance plans of foreign countries》

5 Learning from bridge safety assurance plans of foreign countries

This paper investigates and studies bridge safety assurance practices in the US and Japan and other developed countries, studies the merits of foreign countries with respect to bridge safety assurance plans, and conducts an analysis based on a comparison with the Chinese reality.

《5.1 Bridge safety assurance in the US》

5.1 Bridge safety assurance in the US

In 2008, the Office of Infrastructure Research and Development of the Federal Highway Administration, along with state transport authorities in the US and other federal institutes launched the “Long-Term Bridge Performance Program” (LTBP) with a plan to establish a detailed bridge health database over a period of 20 years and carry out a theoretical and technological application study on bridge structural performance to improve the safety, longevity, and reliability of US highway transport property. In December 2015, American President Barack Obama signed the Fixing America’s Surface Transportation (FAST), providing funding in the amount of 305 billion USD to rehabilitate transportation infrastructure during the fiscal years 2016 to 2020. Through this law, support for LTBP was greatly enhanced [5].

The plan was mainly intended to fund the study of bridge performance deterioration mechanisms; promote the development of bridge deterioration and prediction models; promote the development of non-destructive inspection, testing, and evaluation technologies; quantify bridge maintenance, repair, and reinforcement efficiency; optimize bridge maintenance operations; develop next-generation bridge maintenance management systems; and provide a basis for the government’s stipulation of relevant policies.

《5.2 Japanese bridge safety assurance plan》

5.2 Japanese bridge safety assurance plan

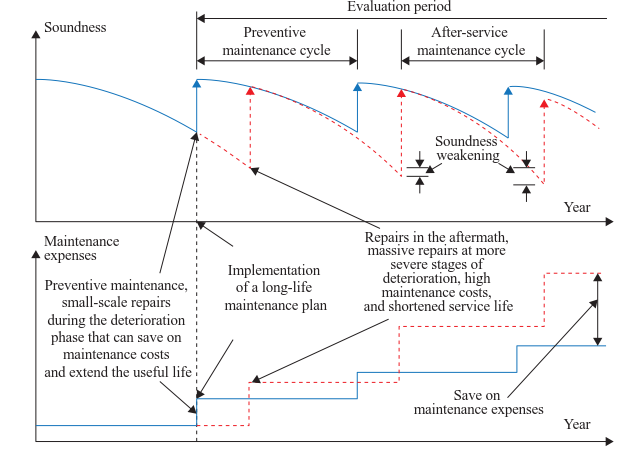

In November 2013, with the aim of addressing such public utilities as bridges, dams, embankments, and schools, the Japanese government stipulated its “Primary Plan for Long Life of Infrastructure Facilities” to protect infrastructure facilities as shown in Fig. 10. This plan requires all provincial authorities and autonomous organizations in Japan to prepare an overall maintenance management system and medium- to long-term action plan to ensure safety through checks and repairs on the one hand, and determinations to abandon or dismantle unnecessary infrastructure facilities due to a reduced population, on the other hand. In particular, the plan points to the application of sensors, robots, and non-destructive check techniques to improve inspection and repair levels and ensure zero occurrence of performance deterioration-inducing major incidents at infrastructure facilities by 2030 [6].

《Fig. 10》

Fig. 10. Preventive maintenance method for bridges in Japan.

《5.3 Lessons learned》

5.3 Lessons learned

By gathering information on bridges at different times, the technological conditions of American bridges before and after the implementation of LTBP can be analyzed as shown in Fig. 11.

《Fig. 11》

Fig. 11. Ratio of bridge defects in the US National Bridge Inventory.

Fig. 11 indicates that the outlook for American bridges in the 1990s was not optimistic. There were 8 % of bridges with structural damage on average and 20 % with performance defects, while more than 1/4 of bridges had defects or damage to varying degrees. In recent years, the proportion of bridges with structural defects has been reduced steadily in the US, especially after the implementation of LTBP. The defective and damaged bridges incorporated into the National Highway System (NHS) database management system are limited to a range of 3 % to 4 %. This proves that as long as sufficient attention is paid to bridge safety assurance and practical and feasible solutions are proposed, bridge safety can be assured.

It is clear that developed countries have proposed their respective schemes and plans for bridge safety assurance and longevity by investigating and analyzing the conditions of bridges and other infrastructure facilities, focusing on economic selfdevelopment characteristics and construction technology, valuing bridge safety assurance, fully utilizing the bearing potential of old bridges, proactively applying advanced technology and methods, and mastering as much as possible the current safety conditions of bridges; these practices have thus far proved successful.

Much experience related to bridge inspection, monitoring, and reinforcement has been accumulated in China. The safety of bridges in service and new buildings in China is assured by further implementation of strategies of bridge safety assurance, enhanced national investment with respect to systems, laws and regulations, specifications, maintenance management, inspection, evaluation, talent pool, and in-depth scientific research and study.

《6 Challenges to national bridge safety assurance》

6 Challenges to national bridge safety assurance

Bridges are important links to economic development. In recent years, with the rapid development of the national economy, traffic volume and the quantity of high tonnage vehicles has increased accordingly. Thus, bridges must bear an ever-increasing load and traffic volume. Therefore, even higher safe travel capacity of bridges is demanded by traffic.

《6.1 “Aging trap” of infrastructure facilities》

6.1 “Aging trap” of infrastructure facilities

Foreign statistics show that in the US and Europe bridge accidents began to increase as of the 1960s and that most bridge collapses occurred during service periods of 50 to 100 years; many infrastructure facilities progressively reached the end of their design life, and aging and signs of deterioration steadily appeared. Calculations show that by complying with current concepts of maintenance management and technology, due to the sharp increase in costs after 2020, Japan will be short on funds for new buildings. Bridges in America are suffering even more serious deterioration, while bridge maintenance, rehabilitation, and renewal costs have dramatically increased; America is also facing the problem of how to sustain the maintenance management of highway bridge properties worth a trillion dollars.

China has the largest scale of transport infrastructure in the world, and its infrastructure construction investment accounts for a much higher proportion of the GDP compared to developed countries; thus, the country is facing the more serious problem of the “aging trap of infrastructure.” According to the 13th Five-Year Plan for Modern Comprehensive Transportation and Transportation System Development, by 2020 it is predicted that around 200 000 large, medium, and small bridges will be built in China, with a total bridge length in excess of 1×104 km and hundreds of long-span bridges. Due to differences in design criteria, bridge aging, and the rapid increase in traffic volume, a large number of bridges completed in the 1960s will face a higher risk of collapse as they age.

《6.2 Different building criteria and construction quality of bridges》

6.2 Different building criteria and construction quality of bridges

Bridge design specifications in foreign countries are relatively uniform. In China, from the implementation of the Code for Design of Road Engineering started in the 1950s to the implementation of the General Specifications for Design of Highway Bridges and Culverts (JTG D60–2015), six versions of specifications have been applied. Bridges built according to older criteria before the 1980s are still in service but have especially poor technical conditions due to the application of lower technical norms, more attention placed on construction versus maintenance, and a lack of capital for technological improvements.

The newly published specifications adjust load standards and improve the safety level of highway bridges in China. However, design loads of some bridges do not reflect the loading characteristics of vehicles in reality, which makes bridge maintenance management inconvenient and also poses potential safety hazards. According to the General Specifications for Design of Highway Bridges and Culverts (JTG D60–2015), national road bridges mainly apply design norms that are higher than vehicle-20 and class I load highways. However, there are over 4355 bridges with norms lower than vehicle-20, accounting for 3.8 %. Bridges at the provincial level have relatively uniform load distribution. Nevertheless, there are still 9629 bridges of design norm lower than class vehicle-20, accounting for 10.8 %. Bridges at the county level mainly apply load class of vehicle-20 and highway loads of class II, yet 9062 bridges apply levels lower than vehicle-15 class, accounting for 8.0% [7].

In addition, bridges completed in earlier periods (concrete structures with less reinforcement, etc.) such as shell bridges, composite bridges with less reinforcements and slightly bent plates, two-hinge plate arches, and double curvature arch bridges, etc. have structural shortcomings that pose potential hazards to safety.

《6.3 Challenges of serious overloading, large regional differences, laws of deterioration》

6.3 Challenges of serious overloading, large regional differences, laws of deterioration

Overloading of highways in China is common, but overloading may increase the burden on bridge structures and cause serial problems of fatigue and durability, damage and injury, premature damage, and even collapse.

China is a vast and broad territory. In coastal regions, durability problems such as reinforcement corrosion, uncoating, or scaling develop. In Northwestern and Northern China, where seasonable rivers are abundant, and there is a wide temperature range, problems of worn and corroded bridge substructures exist. In northeastern and other cold regions, there are problems of structural bridge damage associated with the freezing-thawing effect, while in southern regions the problems concern erosion and water damage to bridge foundations. Bridges serving and located in different environments suffer demonstrably different deterioration tendencies that are difficult to predict, making bridge safety assurance even harder in China.

《6.4 Low degree of documentation and incomplete bridge database material》

6.4 Low degree of documentation and incomplete bridge database material

In spite of great achievements in bridge documentation building, China still lacks a unified information-based management system for bridge information, design norms, specifications for uniformed monitoring systems, and theories of structural health evaluation. Since bridge safety assurance is based on a clear understanding of the current conditions of bridges, the low level of documentation in China contributes to making bridge safety assurance difficult.

To summarize the above, it is clear that China is still experiencing a period of rapid economic development with lots of newly-built transport infrastructure using more and more complex spatial systems. Furthermore, with the ever-increasing service periods of infrastructure, damage from defects, disasters, and human events has steadily increased. Disaster-induced damage, along with damage-causing behavior and its consequences, are even more changeable. There are many influences on bridge safety and the situation is challenging. In conclusion, safety assurance for the longevity of highway bridges in China is a significant issue in urgent need of a solution.

《7 Contemplating strategy for safety assurance and longevity of bridges by 2035 in China》

7 Contemplating strategy for safety assurance and longevity of bridges by 2035 in China

Based on the results of the investigation and analysis in this paper and in consideration of the reality of bridges in China, the following ideas are proposed regarding safety assurance and longevity of highway bridges in China.

《7.1 General goal》

7.1 General goal

Establish a complete bridge safety assurance system featuring scientific management, efficient emergency response, intelligence, documentation, and all other dimensions by 2035, so as to provide overall improvement of comprehensive safety assurance and risk resistance capacity of major bridge structures. Realize the general goal through “three stages.”

Stage 1: Clarify current bridge conditions (duration 2018– 2022). Establish bridges with design lives of 100 years (120 years for important bridges) as targets and discover differences between current bridges in service and bridges at 100 years by conducting comparisons by region, bridge type, and building year. Define the needs for bridge performance improvement and extension of bridge life.

Stage 2: Improve bridge performance (duration 2023–2027). Establish bridges with design lives of 100 years as targets. Building on Stage 1, implement the overall plan for bridge performance improvement, achieve significant breakthroughs in key technical fields, and considerably improve the overall standards of bridge safety assurance.

Stage 3 (duration 2028–2035): Establish a complete safety assurance system featuring intelligence, documentation, all other dimensions, and comprehensive power with respect to bridge safety assurance. Assume a leading position among world powers.

《7.2 Specific measures》

7.2 Specific measures

7.2.1 Improve bridge maintenance concepts by shifting from a sole emphasis on building to an equal emphasis on management and maintenance

Modify the concept of bridge maintenance to meet the technical needs of a service bridge’s maintenance and management; preserve assets and increase efficiency; develop technology for preventive maintenance of bridges; develop a complete bridge information management system; implement a system of maintenance engineers; improve mechanical maintenance capacity; and establish maintenance technology and equipment systems suited to the national reality, so as to achieve bridge technology transformation that places “equal emphasis on bridge building and maintenance.”

7.2.2 Establish an integrated bridge maintenance system integrating information-based and multi-dimensional bridge inspection and monitoring, evaluation, and reinforcement

Develop and establish highly accurate and non-destructive detection technology and equipment systems to meet the needs of bridge inspection, with testing in China. Study and develop high-performance intelligent sensors to meet the technical requirements of bridge long-term performance study and operation management of major long bridges in China. Complete and develop methods of bridge technical condition assessment, determination of bearing capacity, disaster prevention, and mitigation capacity; complete bridge reinforcement theory and methods to meet practical needs for handling damage to service bridges and improving service load grade; develop fast and reliable reinforcement technology; develop technologies of large-scale reinforcement and monolithic replacement, so as to improve safety reliability of reinforced bridges.

7.2.3 Improve emergency response capacity and level of bridges in China

Enhance the alert system for extreme and accidental risks of bridges; establish an alert intelligence, evaluation, and handling system for bridges under extreme conditions such as seismic events; improve crossing and bearing capacity of bridge emergency equipment to meet requirements for emergency obstruction removal and assurance of free traffic; expand bridge emergency equipment types to improve emergency supply capacity and levels for highway bridges in China.

7.2.4 Complete Chinese bridge management system

Enhance bridge maintenance, monitor super-large bridges, and ensure real-time controllability of key bridge operations; complete bridge operation safety management system; complete full bridge management system and enhance enforcement concerning illegal behaviors such as overloading; eliminate human risk to safety to a large extent; introduce third party evaluation mechanism for bridge accidents; establish a database for complete bridge accident analysis and handling.

《8 Conclusions》

8 Conclusions

Technical conditions and bridge accident cases in China and abroad are analyzed in this paper. Problems and challenges in the field of bridge safety assurance in China are presented, along with the disadvantages that exist in bridge safety assurance technology and measures. Thoughts on strategies for bridge safety assurance in China are also analyzed.

With the passage of time, large numbers of bridges are progressively demonstrating structural aging and performance deterioration, and some important structures are approaching the end of their design life sooner rather than later. It is therefore suggested that a national “Structural Safety Assurance Plan for Bridges and Other Infrastructure” be implemented. The establishment of a technical system and standard for bridge safety assurance is of significance to ensure the security of bridge structures, as well as human life and property in China.

京公网安备 11010502051620号

京公网安备 11010502051620号