《1 Introduction》

1 Introduction

Urban mines refer to the resources embedded in consumer products, buildings, and infrastructure. Urban mines are an energyloaded and recyclable strategic resource that saves significant resources and is environment friendly [1]. Urban mining is an important approach for realizing the sustainable use of resources through the repeated recycling of renewable resources. In this way, the multiplier effect of renewable resources can be achieved. The definition of urban mines in China refers to materials such as recyclable iron and steel, non-ferrous metals, rare and precious metals, plastics, and rubber, which are by-products of industrialization and urbanization, and those embedded in all kinds of carriers, including waste electromechanical devices, wires and cables, communications tools, automobiles, home appliances, electronic products, metal and plastic packing materials and other scrap. The available amount and value of urban mines is considered equivalent to that of natural mineral resources.

Through recycling renewable resources, urban mining generates significant environmental benefits including the reduction of natural resource exploitation, greenhouse gas emissions, and waste generation. This also provides strong support for China to tackle climate change, promote sustainable development, actively assume international responsibility and obligations, and fulfill emission reduction commitments. Urban mining can also effectively assist the development of manufacturing technical equipment, logistics, and other related fields and create new social employment opportunities.

《2 Current status of urban mining in China》

2 Current status of urban mining in China

The Chinese government’s issuing of the “Notice for Establishing Urban Mining Demonstration Bases” in 2010 marks its emphasis on urban mining and indicates the transformation of the national concept and strategy of resource use. The government directly planned the layout of the urban mining demonstration bases. By 2016, 49 national demonstration bases had been constructed.

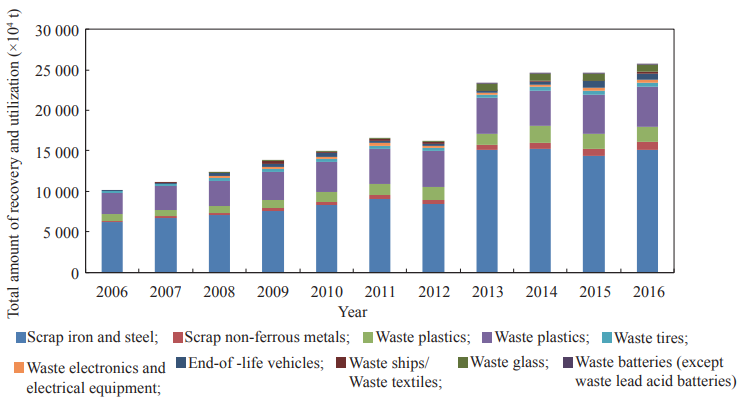

From 2006 to 2016, the quantity of collected secondary resources through urban mining has been on an upward trend (Fig. 1). In 2016, China collected 2.56×108 t of ten main kinds of materials from urban mines, including scrap iron and steel, scrap non-ferrous metals (copper, aluminum, lead, zinc), waste plastics, tires, paper, electronics and electrical equipment, end-oflife vehicles, ships (or waste textiles), glass, and batteries. The combined production value amounts to 590.28 billion yuan [2]. However, there are still some factors restricting the development of urban mining, such as imperfect policy and regulations, lack of a long-term and stable fiscal and taxation policy, and absence of business models for renewable resource collection channels.

《Fig. 1》

Fig. 1. Status of recovery and utilization of major urban mines in China from 2006 to 2016† .(† Data is from Report on the Renewable Resources Recovery Industry in China from the Ministry of Commerce of China.)

《3 Use potential analysis of typical urban mines in China》

3 Use potential analysis of typical urban mines in China

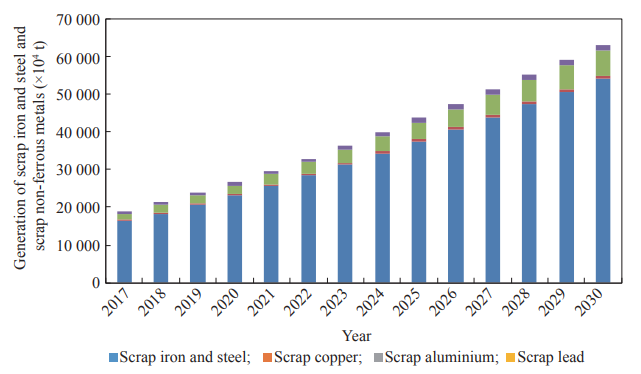

The generation quantity of scrap iron and steel, scrap nonferrous metal, waste electronics and electrical equipment, end-oflife vehicles, construction and demolition waste, and municipal solid waste was predicted as shown in Fig. 2 to Fig. 4, taking the year 2010 as the baseline. The result shows that there is huge potential for urban mining in China before 2030.

《Fig. 2》

Fig. 2. Prediction of the generation of scrap iron and steel and scrap non-ferrous metals from 2017 to 2030.

《Fig. 3》

Fig. 3. Prediction of typical E-waste generation in China.

《Fig. 4》

Fig. 4. Prediction of end-of-life vehicles generation in China.

Scrap iron and steel: By 2030, 5.3991×108 t of scrap iron and steel will be produced in construction, transportation, machinery, durable consumer goods, and other industries [3].

Scrap non-ferrous metals: By 2030, 7.79×106 t of scrap copper resources will be produced in the electricity, household appliances, communications, electronic equipment, construction, and other industries. The packaging industry has always been the largest user and waste generator of aluminum. By 2030, this industry will produce 6.701×107 t of scrap aluminum. For scrap lead, the battery industry is the largest user and waste generator, and will produce 1.444 ×107 t by 2030.

E-waste: Based on household appliances ownership for every hundred households, as well as the penetration of mobile phones, as shown in the China statistical yearbooks, the generation of waste electronics and electrical equipment and waste mobile phones were predicted by using the apparent consumption and life cycle method [4] (Fig. 3). The result shows that the generation of waste home appliances increases rapidly and will amount to 1.5162×107 t in 2030, including 82.785 million televisions, 87.713 million refrigerators, 72.397 million washing machines, 134.35 million air conditioners, 86.667 million personal computers, and 481.774 million mobile phones. Regarding end-of-life vehicles: Taking the average lifetime of automobiles as being 12 years, the number of end-of-life vehicles will rise rapidly, and will amount to 30 million in 2030 (Fig. 4).

《4 The reduction effect and environmental benefit assessment for using secondary resources》

4 The reduction effect and environmental benefit assessment for using secondary resources

Based on the prediction of the use potential of typical urban mines, this study selected several kinds of typical metal resources with high recycling value, assessed the resource reduction and recycling potential, and quantitatively evaluated the energy and environmental benefits for the replacement by secondary resources [5–12]. Based on the current policy and management measures, this study assumes three different reduction measures, including a baseline scenario, a low resources consumption scenario, and an enhanced recovery scenario. The prediction shows that the demand for iron and steel, copper, aluminum, and lead will decrease, which will generate significant supplemental benefits of secondary resources and environmental benefits under the condition of the fundamental adjustment in the resource consumption structure, improvement of the use rate of resources, and compulsory recycling (Fig. 5).

《Fig. 5》

Fig. 5. Energy saving effect and environmental benefits of reduction measures.

Under the reduction measures, the energy saving benefits of recycling scrap steel are remarkable. Energy equal to 2.459 million tons of standard coal will be saved in 2020, and 5.4 million tons of standard coal in 2030. Among the four kinds of metal resources, the water saving and solid waste reduction benefits of secondary lead are better than other secondary metal resources. Although the energy saving, water saving, and solid waste reduction benefits of secondary aluminum are not obvious, it is expected to make a significant contribution regarding SO2 emission reduction.

《5 Comprehensive analysis of the substitution effects of typical secondary metal resources in China》

5 Comprehensive analysis of the substitution effects of typical secondary metal resources in China

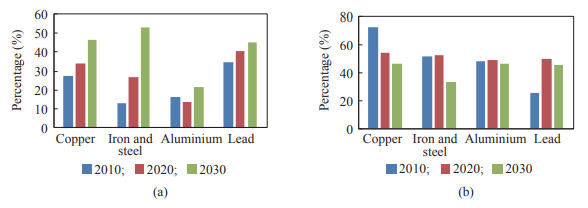

The foreign-trade dependence of metal resources in China is relatively high at the present stage [4]. The substitution ratio of four kinds of metal resources was predicted in the baseline scenario by using material flow analysis. It shows that the substitution ratio will be improved significantly, especially for iron, steel, and copper (Fig. 6 (a)). The external dependency of these four kinds of metal resources presents a downward trend, among them, the trend for iron, steel, and copper are more apparent (Fig. 6 (b)).

《Fig. 6》

Fig. 6. Substitution ratio (a) and external dependency (b) of four kinds of mineral resources under baseline scenarios.

As the metal scraps produced during the process of industrial production are mainly used to substitute natural mineral resources, which have limited impact on the resource import, secondary metal resources in the urban mines have a substitution effect on resource imports. For the secondary metal resources, the influence on the substitution effect of secondary metal resources was analyzed under different reduction measures. Under the low resource consumption scenario, the overall resource demand decreased sharply which triggered a fall in demand for imports. Compared with the baseline scenario, although the substitution ratio of secondary metal resources was promoted, the external dependency was decreased under both scenarios. The enhanced recycling scenario, however, fundamentally changed the metabolic characteristics of resources, which can promote the substitution effect significantly and can produce profound influence for decreasing the external dependency of metal resources in the long term (Fig. 7).

《Fig. 7》

Fig. 7. Substitution ratio (a) and external dependency (b) of four kinds of mineral resources under a low resource consumption scenario and an enhanced recycling scenario.

《6 Strategic goals and suggestions for urban mining in China》

6 Strategic goals and suggestions for urban mining in China

The use potential of urban mines in China is tremendous for the future. It will show obvious substitution effects on natural resources and environmental benefits if recycled properly. Considering scrap iron and steel, the quantity will amount to 5.3991×108 t in 2030. If jointly implemented with low resource consumption measures and enhanced recovery measures, the external dependency rate for scrap iron and steel will decrease by 8.7 %; the substitution rate will increase by 7.3 %, which will save 5.4 million tons of standard coal and 2.66×107 t of water, reduce 3.76×107 t of solid waste, and reduce 3.8×104 t of SO2 in 2030. Thus, during the 13th Five-Year Plan period, urban mining should be supported as a strategic new emerging industry.

《6.1 The strategic goal of urban mining in China》

6.1 The strategic goal of urban mining in China

During the 13th Five-Year Plan period, the strategic goal of urban mining in China is to realize a leap-forward in development, which means the following objectives need to be achieved step-by-step.

The Plan intends that, by 2020, China will realize a standard separate collection rate of 25 % on municipal solid waste, and a recycling rate of 35 % on renewable resources in municipal solid waste from cities, in which compulsory classification of the solid waste is implemented. China will establish and promote the extended producer responsibility system and the supervision system, improve the management system for waste importation and management measures, the classification system, and standards of municipal solid waste. China will establish the coordination mechanism of urban mining across different departments. China will build a properly managed recycling system with diversified collection channels for main kinds of renewable resources and municipal solid waste in main cities of China where the collection sites are reasonably distributed. China will promote the experience of urban mining demonstration bases in the country and build one large-scale urban mining comprehensive utilization base in each prefecture-level city. China will popularize the technology of the Internet and cloud platform in urban mining to raise public awareness on environmental protection and resource recycling.

By 2030, China intends to realize a coverage rate of 90 % for conducting separately collecting municipal solid waste from prefecture-level cities, and a recycling rate of 60 % for municipal solid waste in these cities. China will put extended producer responsibility into practice, and focus on the establishment of producers’ reverse logistics systems to promote manufacturers and distributors to separately collect major durable consumer goods from cities and towns. China will form a resource-flexible allocated industry market of urban mines to promote the scaleup of valuable resources extraction in urban mining industry. The scale of urban mining will be continuously enlarged to an advanced international level, promoting the urban mining industry as a pillar among emerging strategic industries.

《6.2 Policy suggestion for urban mining in China》

6.2 Policy suggestion for urban mining in China

Urban mining covers recycling, processing, and using secondary materials to manufacture a new product, which involves different stakeholders including residents, industries, and different government departments. Society and government departments need to plan, coordinate, and manage the development of urban mining. In the process of developing the comprehensive use of resources, the prevention and control of environmental pollution must be monitored. The resources should be gathered in large parks and enterprises where pollution is controllable and preventable, and pollutant discharge is under a certain level. Urban mining will make comprehensive use of centralization, scale, and industrialization to finally realize the synergistic facilitation of the prevention and control of environmental pollution and the increase in economic benefits. Specific measures are suggested as follows:

(1) Promote the strategic position of urban mining. Determine the role of the circular economy and urban mining in the development of the national economy, consider urban mines as an important part of strategic resources, and establish a new resource concept comprising urban mines, natural resources, and imported resources. Determine the order of resource use of urban mines, natural resources, and imported resources.

(2) Improve the extended producer responsibility system. Complete the hierarchy design of policy, improve the recycling system, and promote the innovation of ways of recycling. Establish a capital mechanism, encourage industry to invest in recycling and in conducting comprehensive resource use activities, and promote the establishment of demonstration enterprises.

(3) Support the development of urban mining demonstration bases. Establish political and economic incentives for assisting the development of urban mining demonstration bases, including setting tax incentives, broadening financing channels, and coordinating industry policies. Reflect the value of the resource in the price mechanism, and strengthen the popularization of the development experience of urban mining demonstration bases.

(4) Innovate urban mining technology. Strengthen the organization and coordination mechanism among different departments/regions, diversify the funding guarantee mechanism, and organize forces of different stakeholders to carry out joint research among industries, universities, and research institutions. Establish a commercial model for the transformation of scientific technology achievements and applications, and promote the international science and technology cooperation on solid waste use.

(5) Strengthen public education on urban mining. Schools, media, and public organizations should take responsibility for public education on urban mining to promote green consumption, reduce the waste of resources and the generation of waste. Stakeholders, including producers, distributors, consumers, recyclers, and managers should be fully aware of their responsibilities. Producers should have ecological designs to save resources and reduce waste generation. Consumers should positively cooperate and participate in the separate collection of waste. Managers should push forward initiatives and design related policies and regulations for the separate collection of waste.

京公网安备 11010502051620号

京公网安备 11010502051620号