《1 Introduction》

1 Introduction

The microbial manufacturing industry is a comprehensive industry that uses microbes as the core, cells as the basis, and basic scientific methods to transform theoretical research findings into actual products, production processes, and system services in people’s production and life. Various industries, such as food, have created new production models and economic forms. Over the last 300 years, more than 100 000 microorganisms have been discovered and named. In 1973, scientists used genetic technology to open the door to microbial manufacturing, discovered a variety of model microorganisms, and applied them to scientific research and industrial production [1].

Microbial manufacturing combines genetic engineering, cell engineering, enzyme engineering, and other technological achievements based on fermentation technology. The science and technology of microbial manufacturing has gone through three stages: the early development of metabolic engineering and reverse metabolic engineering; the post-genomic era of high-throughput omics, genome-level metabolic network models, and cell performance modification; and the latest developments promoted by systems metabolic engineering and synthetic biology. With the development of science and technology, synthetic biology and bioreactors have become two important pillars of microbial manufacturing [2]. Because the microbial manufacturing industry has the advantages of environmental friendliness, resource regeneration, and stable production capacity, it has become a sunrise industry for sustainable development and occupies a pivotal position in the development strategy plans of all countries in the world.

With the rapid development of society and the rapid progress of science and technology, the microbial manufacturing industry has covered various fields of human survival, such as pharmaceutical manufacturing, food processing, agricultural production, chemical production, sewage treatment, and innovative energy. The microbial manufacturing industry has a wide range of environmental adaptability, diverse manufacturing strategies, and huge economic development prospects, which provide a sustainable model for social development. This study comprehensively analyzes the development history of the microbial manufacturing industry, the development trend of various fields, and the development opportunities and challenges of China’s microbial manufacturing industry to provide a reference for the development of the manufacturing industry of China.

《2 Industry development trend of microbial manufacturing》

2 Industry development trend of microbial manufacturing

《2.1 The development status of global microbial manufacturing industry》

2.1 The development status of global microbial manufacturing industry

The Organization for Economic Cooperation and Development (OECD) puts forward that microbial manufacturing is one of the most competitive and sustainable industries. It is expected that by 2030, 35% of the world’s chemical products will be replaced by microbial manufacturing products, and the microbial manufacturing industry will gradually establish an economic form with sustainable renewable resource development. As of 2020, there have been 134 industrialized cases of modern microbial manufacturing, and the output value of its main fermentation products is approximately 14 billion USD, with an annual growth rate of approximately 4.7%. The OECD predicts that the microbial manufacturing industry accounts for approximately 40% of the entire bioeconomy, far surpassing biological agriculture (36%) and biomedicine (25%) [3].

In 2020, the United States proposed the ambitious goal of using microbial manufacturing technology to reduce 30% of the energy consumption and pollution emissions of the chemical industry, replacing 25% of organic chemicals and 20% of petroleum fuels by 2030, and establishing a bio-industrial manufacturing and design ecosystem to promote the development of the US bio-manufacturing industry. The European Union’s Roadmap for the European Chemical Industry for Bioeconomy formulated in 2019 pointed out that the annual utilization of biological products will reach 1.2 to 1.5 billion tons by 2030, realizing the production and transformation of largescale microbial manufacturing. Countries in the world, such as the United States, those in the European Union, Japan, and Russia, attach great importance to the development and application of industrial microbial technology, incorporate it into the national bioeconomy exclusive strategy or bioeconomy-related strategic plan, and increase the proportion of their investment in scientific research to quickly promote the industrialization process.

《2.2 The development status of China's microbial manufacturing industry》

2.2 The development status of China's microbial manufacturing industry

China attaches great importance to the research and development (R&D) capabilities of the microbial manufacturing industry and has established a number of national key laboratories, national engineering research centers, and industry-specific technology research centers in conjunction with universities and scientific research institutes. During the 13th Five-Year Plan period, the Ministry of Science and Technology vigorously promoted the development of bio-manufacturing technologies. In major national R&D projects, the strategic needs for the development of biotechnology have been pointed out many times, which vigorously promote the development of China’s microbial manufacturing technology and industry [4].

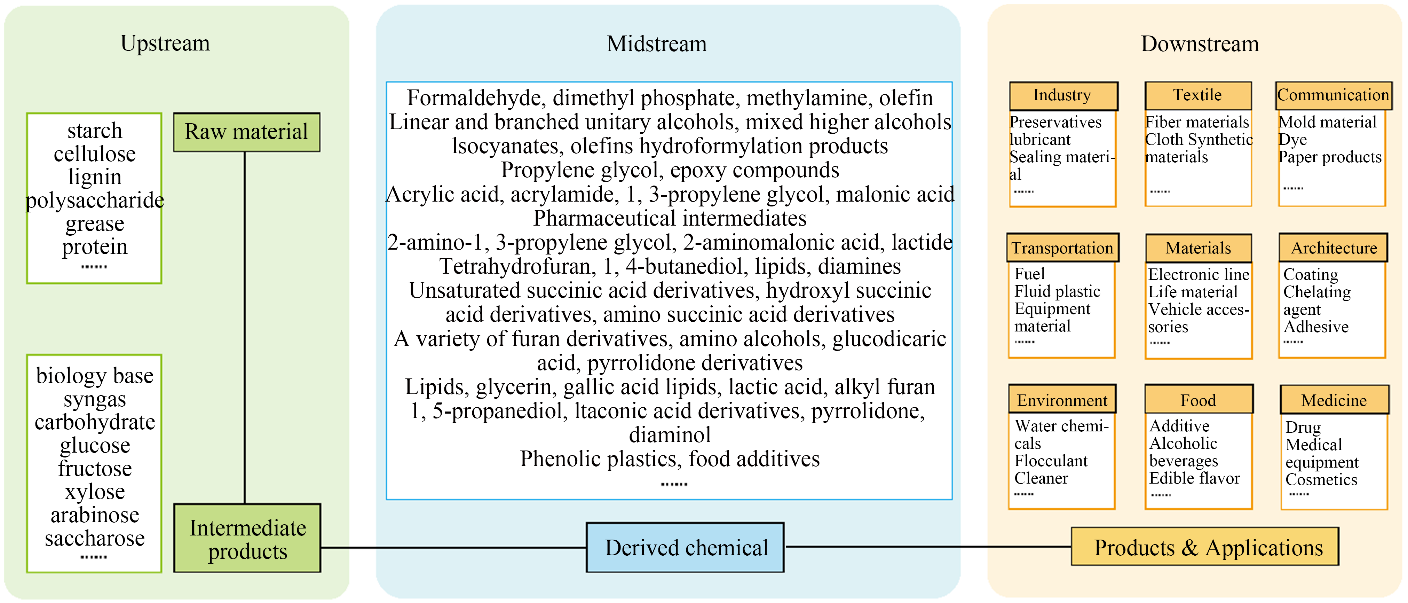

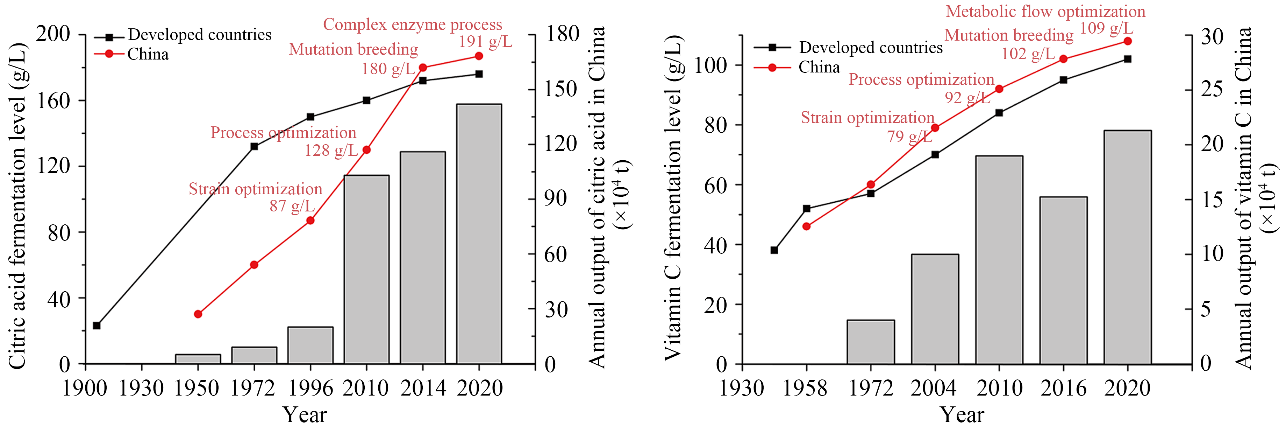

China’s microbial manufacturing industry is transforming into a quality and efficient type. Product output reached 290.16 million tons in 2018, with a total output value of 247.2 billion CNY, and new products continue to increase. During the period 2006–2017, 515 677 patents were applied for in the field of industrial biotechnology worldwide, and 120 586 were Chinese patents, accounting for 23.4% of the total, ranking first in the world [5]. China’s microbial manufacturing industry has formed an industrial chain of starch, cellulose, lignin oil, protein, and other systems and has the world’s largest output in the fields of citric acid, glutamic acid, vitamin B2, and amylase (Fig. 1). Taking citric acid as an example, from 1992 to 2020, Chinese R&D team developed new strains, processes, and compound enzyme technology to achieve a production of 191 g/L, far exceeding that of developed countries, with an annual output of citric acid reaching more than 1.4 million tons. During the period 2004–2020, the production level of vitamin C has increased significantly, with an annual output of 213 thousand tons, reaching a world-class level. In the past two decades, China’s microbial manufacturing industry has progressed from a running companion to a leader in the production technology fields of citric acid and vitamin C (Fig. 2).

《Fig. 1》

Fig. 1. Overview of microbial manufacturing industry chain.

《Fig. 2》

Fig. 2. Development status of the citric acid and vitamin C industry in China.

Although the industrial scale of antibiotics, vitamins, amino acids, and probiotics in China has exceeded 50 billion yuan, the autonomy rate of core strains is less than 20%, and that of amino acids is less than 5%. At the same time, some advanced instruments and core technologies are completely dependent on imports, causing huge capital outflows and forming overseas industrial monopolies. However, with the strong support of national policies, China's microbial manufacturing industry has developed rapidly and surpassed developed countries in many fields. In addition, China's microbial manufacturing has huge room for development in the fields of wastewater and waste gas treatment, material energy development, etc., all of which give China the opportunity to seize future core technology in this field and increase the competitiveness of the industry in the international market.

《2.3 Market development trend of microbial manufacturing industry》

2.3 Market development trend of microbial manufacturing industry

In modern fermentation industries, such as enzyme preparation and biomedicine, developed countries are in a technology monopoly position. They use cutting-edge technologies, such as gene editing and digital modeling, to promote R&D and application of microbial manufacturing. For example, DuPont of the United States established a high-yield 1,3-Propanediol biomanufacturing technology [6]. Simultaneously, developed countries have made major breakthroughs in the commercialization of microbial fermentation, the development of new degradable products, and the establishment of a global biological data platform. In addition, they are committed to the R&D of related equipment and equipment systems for the microbial manufacturing industry, such as the pipetting robot developed by Opentrons and the cell programming platform developed by Synlogic, to achieve laboratory automation R&D and efficient production in the microbial manufacturing industry.

Japan, China, and South Korea have a long historical background and deep research foundation in the application of microorganisms in the traditional fermentation industry and occupy a large market share in the bulk fermentation industry, such as that of amino acids and yeast. In recent years, China’s GDP has grown at a rate of approximately 10% per year. The coverage and production scale of China’s microbial manufacturing industry have been continuously expanded, and the microbial manufacturing industry has gradually become a new growth point for the national economy. In 2010, antibiotics, vitamins, amino acids, and organic acids were the main export commodities, and the production scale steadily ranked first in the world [6]. The industrial production of ethylene glycol, butanol, ethylene, and other products using microbial methods has been achieved. Meanwhile, the production of new materials, such as bioplastics and biochemical fibers, has reached an industrial scale [7].

《2.4 Technological development trend of microbial manufacturing industry》

2.4 Technological development trend of microbial manufacturing industry

Currently, microbial manufacturing technology is in its initial stages of development worldwide. As per the 13th Five-Year Plan period, the country advocates energy conservation, emission reduction, green production, changes in economic development models, and vigorous development of the microbial manufacturing industry, thus to promote China to transform from a major microbial manufacturing country to a microbial technology powerhouse.

Genome shuffling, system metabolism engineering, cell global perturbation, and other microbial genome breeding technologies, have achieved significant benefits in biosynthesis such as amino acids [8]. The advancement of microbial manufacturing technology has accelerated functional and valuable research on new methods of microbial synthesis based on data analysis and gene editing, the construction of new strains, and the design of complex enzymes. This has greatly improved the biological performance and material conversion efficiency, accelerated the process of China’s microbial manufacturing industry, and promoted the adjustment of China’s industrial structure.

In recent years, the microbial manufacturing industry has applied cloud computing, the Internet of Things, and robotics technologies to develop micro-bioreactors composed of optical sensors and data analysis software. The production goals of multidata online monitoring, high-throughput screening, low unit energy consumption, and a short experimental period were realized. In the future, the microbial manufacturing industry can use big data, artificial intelligence, and other technologies to form a cyber physics system to create an intelligent manufacturing industry chain with self-perception, self-learning, self-decision, selfexecution, and self-adaptive functions, which realize standardized, refined, and intelligent production.

《3 Analysis of the development of microbial manufacturing industry in China》

3 Analysis of the development of microbial manufacturing industry in China

《3.1 Development trend of microbial manufacturing in the field of fermented food》

3.1 Development trend of microbial manufacturing in the field of fermented food

China’s major fermentation industries include the production of amino acids, organic acids, yeast, starch sugars, polyols, and functional fermentation products. Since the 13th Five-Year Plan, the gradually formed industrial pattern of coordinated development of multi-products is based on bulk products such as monosodium glutamate, lysine, citric acid, and crystalline glucose, and supplemented by high value-added products such as amino acids, low Glycans, and microbial polysaccharides. Among them, the production and trade volume of fermented bulk products, such as monosodium glutamate, lysine, and citric acid, rank among the highest in the world. The output of the main products of the fermentation industry increased from 18.4 million tons in 2010 to 30 million tons in 2019, with an average annual growth rate of 7.8%. The output value increased from 199 billion yuan to 329 billion yuan, with an average annual growth rate of 9.3%. The total export volume and value of the main products of the bio-fermentation industry have steadily increased each year. Among these, citric acid, monosodium glutamate, and starch sugar have always been the main export products of the bio-fermentation industry [9].

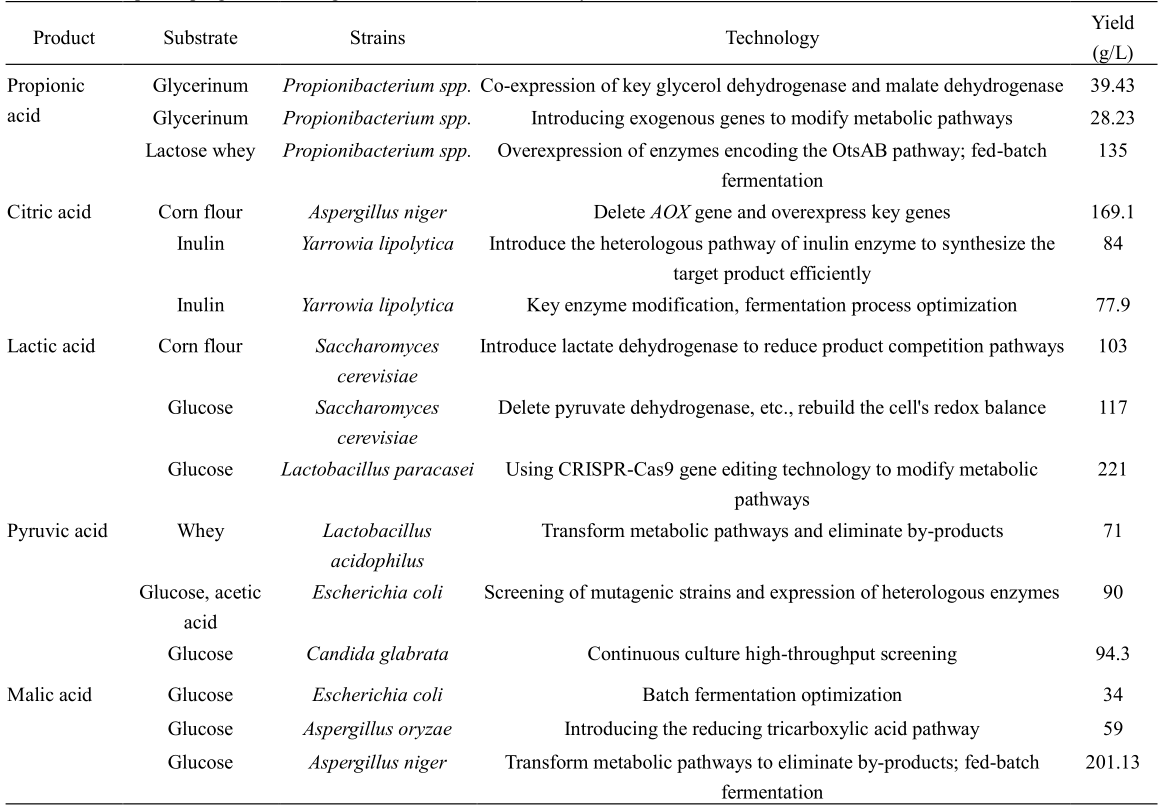

China’s microbial manufacturing industry combines a variety of synthetic biology technologies, such as metabolic engineering, multi-omics analysis, metabolic network model calculation, regulatory gene circuit design, and gene element design, and is widely used in the production of organic acids, amino acids, antibiotics, and other products (Table 1). For example, the direct conversion of glucose into malic acid can increase the output by more than 180 g/L by modifying the metabolic pathway; the transformation of the arginine synthesis pathway, reducing the overflow pathway, and other operations to synthesize new strains, so that the output of L-arginine can reach 92.5 g/L; the use of model design, overexpression of key genes, and other technologies, effectively improved the production level of erythromycin, adriamycin, and tylosin [6].

《Table 1》

Table 1. Development progress of the organic acid fermentation industry in China

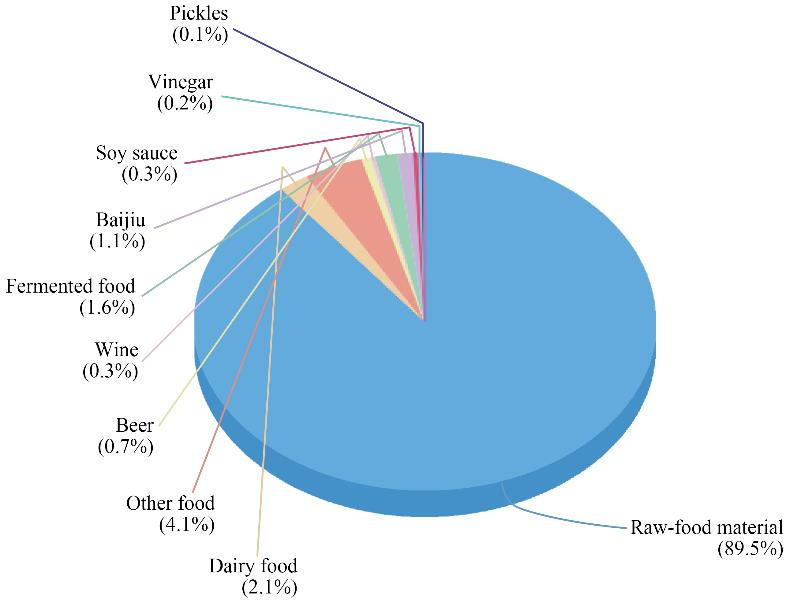

At present, the liquor industry is developing at the same speed as other food industries such as dairy products, and has shown a good development trend. The sales of the entire liquor industry will increase from 450 billion yuan in 2012 to 583.639 billion yuan in 2020, a cumulative increase of 4.61%, and a total profit of 158.541 billion CNY, a cumulative increase of 13.35% by 2020 [10]. Soy sauce, vinegar, pickles, and other industries have also used techniques such as microbiological analysis, brewing process optimization, and functional component analysis to upgrade from traditional natural fermentation to precision-controlled industrialized CNC fermentation, and have developed from handcrafted workshops to small- and medium-sized enterprises and leading enterprises (Fig. 3). In general, since the 13th Five-Year Plan period, the output and scale of China’s fermentation industry have greatly increased through the use of advanced microbial synthesis technology and advanced production equipment, and a stable development trend has been maintained.

《Fig. 3》

Fig. 3. Proportion of green factories in the field of fermented foods in China.

《3.2 Development trend of microbial manufacturing in the field of biological fertilizers》

3.2 Development trend of microbial manufacturing in the field of biological fertilizers

Beginning in 2015, the State Council issued the Action Plan for the Zero Growth of Fertilizer Use by 2020 to control the use of chemical fertilizers, and is committed to solving the problems of soil and water pollution and overcapacity of chemical fertilizers, which promotes the development of microbial fertilizers. At present, China’s 200 million mu (1 mu equals to ~666.67 m2 ) of microbial fertilizer feed production base mainly produces biological fertilizers, organic fertilizers, and microbial inoculants. There are nine microbial fertilizer products registered by the Ministry of Agriculture, including rhizobia, nitrogen-fixing bacteria, and phosphate-dissolving bacteria. From traditional strain screening to strain modification design, multi-efficient compound strain manufacturing, fertilizer strain function mining, and other technological applications, microbial manufacturing has realized the diversity, regulation, and accuracy of fertilizer strain R&D. Currently, there are many products, such as nitrogen-fixing green algae fertilizer, antibiotic fertilizer, vesicular arbuscular mycorrhiza, and combined nitrogen-fixing bacteria as seed dressing agents [11]. In 2020, the Quality Supervision, Inspection and Testing Center for Microbial Fertilizers and Edible Fungi of the Ministry of Agriculture showed that the number of microbial inoculum products was 3315, accounting for 45.75%; the number of bio-organic fertilizer products was 2205, accounting for 30.43%; and the number of compound microbial fertilizer products was 1399, accounting for 19.31%. There are more than 2000 microbial fertilizer manufacturers in China with a production capacity of 30 million tons and an output value of 40 billion, which has formed a certain industrial scale. After 2017, the number of new enterprises increased significantly, and the development momentum was rapid. As of the end of 2020, 7604 products have been registered by relevant departments. The top four registered products are microbial inoculants, biological organic fertilizers, compound microbial fertilizers, and organic fertilizer decomposing agents [12].

In December 2020, the Microbial Fertilizer Technology Research and Promotion Center of the National Key Promotion Program for Scientific and Technological Achievements launched the Fourth China Microbial Fertilizer Technology Research and Industry Development Conference. It is proposed to actively promote the long-term development of China’s microbial fertilizer industry in the direction of microbial technology and innovative industrialization. In the future, the primary goal of the development of China’s microbial fertilizer industry is to be demand-oriented, to build a scientific and technological innovation platform that integrates production, education, and research, to select new strains, develop new products, and expand new functions to realize the sustainable and innovative long-term development of the microbial fertilizer industry

《3.3 Development trend of microbial manufacturing in the field of enzyme preparations》

3.3 Development trend of microbial manufacturing in the field of enzyme preparations

Enzyme preparations are a class of substances with enzymatic characteristics extracted from organisms. They can replace chemical reactions requiring special conditions such as high temperature and strong acids in production, and have advantages that cannot be ignored, such as simplifying processes, reducing costs, increasing yields, saving energy, and reducing pollution. At present, enzyme preparations are used in food processing, medicine, environmental protection, agriculture, and chemical industries. According to statistics from the Competitive Strategy and Investment Feasibility Study Report on China’s Enzyme Preparation Market from 2020 to 2026, the annual output of enzyme preparations reached 1.2 million tons in 2016, with an annual growth rate of approximately 10%. There are more than 3000 varieties of enzyme preparations, but only over 60 types of enzyme preparations have achieved large-scale industrial production. There is still huge room for the development of the industry.

In 2005, the annual output of enzyme preparation products was only 480 000 (standard) tons, and by 2010 it had increased to 775 000 tons, reaching a compound growth rate of 10.1% [13]. Although Chinese companies have achieved major breakthroughs in the field of feed enzyme preparations, accounting for 14% of the global market, core industrial enzyme preparations in the entire bioeconomy field still lag behind leading international companies. With the accumulation of knowledge in genetic engineering, protein engineering, and other disciplines, as well as breakthroughs in high-throughput sequencing technology, gene editing, and other technologies, the microbial manufacturing of industrial enzyme preparations has also ushered in new development opportunities. The discovery of microbial enzymes, transformation of microbial cell factories, and de novo synthesis of specific enzymes will provide new solutions for industries such as biomedicine, environmental energy, and biomaterials, thereby promoting a new wave of technological revolution. Therefore, grasping opportunities in the new wave of the technological revolution, quickly mastering core technologies, improving the technical level of the industry, and improving international competitiveness are strategic priorities for the development of China’s enzyme preparation industry.

《3.4 Development trend of microbial manufacturing in the field of bio-based chemicals》

3.4 Development trend of microbial manufacturing in the field of bio-based chemicals

Bio-based products mainly refer to the use of straw and other lignocellulosic agricultural and forestry wastes as raw materials to produce environment-friendly chemical products and green energy. Among them, bio-based chemicals are one of the hotspots in the world today, and can effectively solve the disadvantages of the traditional chemical industry, which consumes large amounts of energy and pollutes the environment. The world produces more than four trillion dollars in chemical products every year. According to OECD estimates, over the next 10 years, at least 20% of petrochemical products (approximately 800 billion) can be replaced by bio-based chemicals. Among the bio-based economic development goals proposed by the European Union by 2030, bio-based chemicals will account for 30% of the European Union’s total chemical production. According to a research report of the United States Department of Agriculture, by 2025, bio-based chemicals will occupy 22% of the global chemical market, and its output value will exceed 500 billion dollars per year. Meanwhile, bio-based chemicals are also one of the materials to be developed in China’s 13th Five-Year Plan. China’s bio-based economy has maintained an average annual growth rate of approximately 20% in recent years, and its total output has reached 6 million tons per year [14].

Among the bio-based products manufactured by microorganisms in China, bio-based fine chemicals account for most of the market share. At present, there are more than 5000 biological manufacturing enterprises in China, reaching a total output value of 1.5 trillion yuan, of which more than 400 billion CNY are in the modern biological manufacturing industry. With the continuous development of core theoretical technologies, such as metabolic engineering, synthetic biology, and enzyme engineering, and through the use of metabolic modification, protein de novo design, and other technical means, China uses a one-step biosynthesis method to efficiently produce L-alanine, shortening the production time while saving costs, with obvious advantages in competition with traditional international giants such as BASF and Japan Ajinomoto, which occupy more than 60% of the international market. Furthermore, in the production of bulk chemical products, such as succinic acid and d-lactic acid, technical methods such as de novo synthesis of new enzymes by modifying the metabolic pathways of strains have reached the leading international technical level. However, the domestic bio-based chemical industry still has the status quo of limited key raw materials, a lack of core technologies, high product costs, and insufficient market competitiveness, and there is still a gap between the overall scale and level of developed countries.

《3.5 Development trend of microbial manufacturing in the field of bio-based materials》

3.5 Development trend of microbial manufacturing in the field of bio-based materials

China is the world’s fourth largest producer of plastic products. The annual demand for plastic products is 7 million tons and the amount of discarded plastic products is approximately 2 million tons. In the global “plastic ban” environment, bio-based materials known as “green, environmentally friendly, renewable, and easily degradable” appear to be particularly important, ushering in the golden age of development. According to a report by the German Nova Research Institute, the market share of bio-based materials for polymers and plastics is approximately 1%. By 2024, the compound annual growth rate is expected to reach approximately 3%–4%. The growth rate was the same as that of the traditional petroleum-based polymer materials. The annual demand for bio-based plasticizers in the domestic market is approximately 3.1 million tons, and with the continuous expansion of application fields, it is increasing at an annual rate of 8% to 12%, but the production capacity is still less than 10 000 tons, which is far from meeting the market demand.

Currently, the production and application of bio-based materials have become more specialized and universal. It has become a research hotspot to transform the proteins of microorganisms through synthetic biology, genomics, and other technologies and to construct new bio-based materials with special properties. New biological materials, such as polylactic acid, polybutylene succinate, and polyhydroxyalkanoates (PHAs), have been used in the production of bio-based plasticizers. By introducing exogenous genes, weakening inhibitory genes, and strengthening promoters, a one-step method using glucose to synthesize PHA in Escherichia coli was achieved. The molar percentage of the lactic acid component was 1.6%, and the polymer content was 83.9 wt.%. This provides a basis for the manufacture of bio-based materials [15]. Using microorganisms to prepare bio-based materials can greatly reduce pollution problems in chemical synthesis, and the relatively low production costs can greatly enhance the market competitiveness of bio-based materials. The bio-based materials industry has broad room for development to enhance technological innovation capabilities and accelerate the process of industrialization. Microbial manufacturing is expected to become the core technology for the production of bio-based materials in the future.

《3.6 Development trend of microbial manufacturing in the field of biomass energy》

3.6 Development trend of microbial manufacturing in the field of biomass energy

Biomass energy is the use of microbial fermentation of plant materials such as straw to produce energy in the form of biogas, biological hydrogen, biodiesel, and fuel ethanol. In 2019, the United Kingdom’s BP World Energy Statistical Yearbook indicated that the world’s biofuel production has been increasing annually, and the market share of biofuels has gradually increased. By 2018, the global production of fuel ethanol had reached 60.4 million tons of oil equivalent. In China, biomass energy includes biomass power generation, biodiesel, and biogas production. For example, the use of emulsification and biosynthesis technologies to efficiently synthesize lignin into liquid fuel has the advantages of low environmental pollution, high combustion efficiency, and abundant reserves [16]. According to data on the development prospects of the biomass energy industry, as of 2019, China’s biomass power generation investment exceeded 150.2 billion CNY, a year-on-year increase of 12.3%. In 2020, China’s biomass energy industry will invest approximately 196 billion CNY in new investments, among which biomass power generation, bio-natural gas, biomass-based fuel heating, and bio-liquid fuel have become key investment projects [17]. In March 2021, the State Grid issued the Announcement of the List of the Sixth Batch of Renewable Energy Power Generation Subsidy Projects in 2021. It points out six biomass power generation projects, including five waste incineration power generation projects and one agricultural and forestry biomass power generation project, with an approved/registered capacity of 139 MW. In addition, it has changed a centralized biomass power generation project to the list of renewable energy power generation subsidies, with an approved/filed capacity of 30 MW. This indicates that biomass energy has become a key strategic goal for energy development.

In addition, it has changed a centralized biomass power generation project to the list of renewable energy power generation subsidies.

The 13th Five-Year Plan for Biomass Energy Development pointed out that the biomass energy industry has reached commercialization, standardization, and large scale, and its annual utilization is about 58 million tons of standard coal, achieving green production, energy conservation, and emission reduction. According to statistics from relevant agencies, China’s urban waste generation is estimated to exceed 360 million tons by 2021. At present, in the face of such huge garbage resources, China mainly remains in a treatment mode of centralized incineration. However, developed Western countries have employed domestic waste recycling to produce agricultural fertilizers, industrial materials, etc. Looking forward to the future, the biomass energy industry can conduct R&D in the field of waste remanufacturing and finely classify and use waste materials, turning wastes into treasures.

《4 SWOT analysis of the development of China’s microbial manufacturing industry》

4 SWOT analysis of the development of China’s microbial manufacturing industry

《4.1 Strengths》

4.1 Strengths

With strong support from relevant national policies, the microbial manufacturing industry has developed steadily, the scale of the industry has grown rapidly, and social benefits have been significant. Among them, the output and output value has steadily increased, exports have grown steadily, and international competitiveness has greatly improved. Simultaneously, China has huge market space and potential. Taking the bioenergy field of microbial manufacturing as an example, by 2035, China’s crude oil demand is expected to exceed 700 million tons and the natural gas demand is expected to exceed 600 billion cubic meters, of which 70% of crude oil and 30% of natural gas need to be imported. Survey data show that the exploitable potential of bioethanol and bio-natural gas in China is 150 million tons and 250 billion cubic meters respectively [18]. This shows that microbial manufacturing in China has a very large market potential and development space in the field of bioenergy.

《4.2 Weaknesses》

4.2 Weaknesses

4.2.1 Weaknesses of raw materials

The existing technologies in the microbial industry are in high demand for non-grain biomass raw materials such as lignocellulose (straw) and C1 (methanol), bottlenecks exist in the R&D technology of core raw materials for microbial production, and import dependence is severe. This has led to a series of problems, such as low product quality and added value, insufficient atomic economy, high production costs, and low market competitiveness compared with petrochemical refined products.

4.2.2 Weaknesses of technology

China’s innovation ability in basic technology fields, such as the creation of biocatalysts, is relatively weak, and is constrained by the intellectual property rights of core bacteria and key enzymes. There are problems such as large initial investment, scattered resources, lack of expertise, and low achievement conversion rate, which cause the domestic microbial manufacturing industry to lack competitiveness in the international market. In addition, China’s microbial manufacturing industry has insufficient forward-looking technological reserves. Compared with developed countries, such as those in Europe and the United States, China still has gaps in its strategic structure and underlying core technologies. In particular, the interdisciplinary layout of frontier disciplines in the new era, represented by dynamic control, digital models, and sensor technology, is insufficient.

4.2.3 Weaknesses of facility

At this stage, the core equipment support system of microbial manufacturing in China still has a huge gap when compared to that of advanced countries, and there is a lack of equipment support systems based on big data, artificial intelligence, and other technologies such as microbial reactors and process sensing and detection equipment. As China has an insufficient accumulation in the high-end equipment manufacturing industry chain and is relatively backward in many subdivisions of the technical fields, such as raw materials, standardized processing, auxiliary accessories, and online testing. The monopoly of high-end equipment R&D technology, high cost, and long R&D time make the investment risk of manufacturing companies very high and ultimately form a vicious circle in the industry.

《4.3 Opportunities》

4.3 Opportunities

The 14th Five-Year Plan for National Economic and Social Development of the People’s Republic of China and the Outline of Long-Term Goals for 2035 pointed out that the integration and innovation of bio-information technology should be vigorously promoted, accelerating the development of biomedicine, biomaterials, bioenergy, and other industries for a bigger and stronger bioeconomy. Additionally, in the Outline of National Science and Technology Medium- and Long-term Development Plan, industrial biotechnology is listed as the frontier technology of science and technology, and the biotechnology industry is identified as one of the seven strategic emerging industries. In addition to macro-industrial policies, China has also actively promoted the Belt and Road strategy to promote talent exchanges and efficiently utilize global innovation resources.

In addition to strong policy support, China’s investment in the microbial manufacturing industry has also increased year by year, and the industry infrastructure has been improved, which has greatly promoted the development of the biotechnology industry. The industrial bio-industry clusters with Beijing–Tianjin–Hebei region, Yangtze River Delta, and Pearl River Delta as the core are all internationally competitive. It can be said that China’s emphasis on microbial technology has been raised to an unprecedented strategic height. Encouraging high-tech innovation, entrepreneurship, guiding interdisciplinarity, and integrating big data and artificial intelligence measures will form a favorable guarantee for further development of the field.

《4.4 Threats》

4.4 Threats

Under the current severe international situation and fierce industry competition, the United States, European Union countries, Japan, and other countries have strengthened their forward-looking layout in the field of microbial manufacturing, trying to divide the international market and set up technical barriers in multiple microbial manufacturing industries. All of these factors have brought many challenges to the development of the microbial manufacturing industry in China. As the core strains and advanced equipment are constrained by others, market development has been restricted. After the Dacheng Group, Yipin Company, Longda Biotechnology, and other companies have expanded their scale or entered the international market, they have been subject to patent lawsuits by leading international companies, which have seriously hindered their development, and some have even reached bankruptcy and reorganization. These incidents indicate that the current advanced technology in the field of microbial manufacturing is heavily dependent on foreign countries, and the protection of intellectual property rights is weak. This indicates that there are still many problems in the current technology, industrial, and intellectual property systems of the microbial manufacturing industry.

Despite facing many threats and challenges in the international environment, we should also clearly realize that the microbial manufacturing industry is still an emerging industry, and the overall development level of China is basically parallel to that of foreign countries. Under the continuous breakthroughs of domestic R&D institutions and enterprises, we have the opportunity to seize future core technology in this field and form continuous R&D capabilities and independent product systems, technical systems, industrial systems, and intellectual property systems to ensure the healthy development of China’s microbial manufacturing industry.

《5 Suggestions for the development of China’s microbial manufacturing industry》

5 Suggestions for the development of China’s microbial manufacturing industry

《5.1 Process and equipment》

5.1 Process and equipment

The report of the 19th National Congress of the Communist Party of China pointed out that it is necessary to accelerate the construction of manufacturing power, accelerate the development of advanced manufacturing, and promote the deep integration of the Internet, big data, artificial intelligence, and the real economy, and cultivating new growth points and forming new kinetic energy in the fields of high-end consumption, innovation leadership, green and low-carbon development, sharing economy, modern supply chain, human capital services, etc. [19]. This urgently requires China’s manufacturing industry to move toward green, high-end, and intelligent directions.

Therefore, in the process and equipment of microbial manufacturing, the focus should be on the high-end, green, and intelligent requirements of biological manufacturing, and take the key core equipment-intelligent bioreactor, intelligent process sensing, and detection as the direction, combining the intelligent analysis of biological processes and decision-making software development to realize intelligent biological manufacturing driven together by big data and knowledge.

《5.2 Cross-cutting frontiers and disruptive innovation》

5.2 Cross-cutting frontiers and disruptive innovation

According to the 13th Five-Year Plan for Biotechnology Innovation, the development of biotechnology highlights the development trend of global scientific and technological innovation with increasingly close interdisciplinarity, and expands the space for scientific discoveries and technological breakthroughs. The United States has always attached great importance to the cutting-edge exploration of biomaterial cross technology. World-renowned thinktank research predicts that biomaterial cross-technology may achieve disruptive breakthroughs in the next 10 years. Therefore, China should promote the deep integration and cross-cooperation of cross-discipline and cross-industry, give full play to the leading role of biotechnology, strengthen original and integrated innovation, promote the transformation of biotechnology achievements and the development of industrialization, and seize the strategic commanding heights of international competition.

The cutting-edge crossover and application of bio-manufacturing will help China eliminate the lack of original innovation ability and improve the quality of scientific and technological innovation; it will contribute to the leapfrog development of China’s scientific and technological innovation and provide a new material basis, which will help narrow the technological innovation gap with developed countries and provide new strategic opportunities for China to build global technological power.

《5.3 Advance deployment》

5.3 Advance deployment

In the process of developing the microbial manufacturing industry, we should insist on integrated deployment, from basic research and key technologies to industrial application demonstrations. This will accelerate the development of the biotechnology industry and strengthen the technical and manufacturing power of China [20].

China should give full play to the supporting and leading role of microbial technology in economic construction and social development, aiming at the frontiers of microbial basics, major key technologies, and industrial applications, and adhere to the policy of “independent innovation, key leapfrogging, supporting development, and leading the future.” In addition, China should also concentrate resources on a systematic layout, strengthen original innovation and integrated innovation, and regard independent innovation as the strategic basis for the development of China’s microbial manufacturing industry.

《6 Conclusions》

6 Conclusions

The microbial manufacturing industry has shown great economic benefits and social value in the fields of food, chemicals, agriculture, and medicine, and is developing rapidly in the materials, environment, and energy industries. With continuous basic biological research and R&D of technical equipment, the microbial manufacturing industry is possible to enter mining, metallurgy, and other fields in the future to realize the all-round, multi-field, and highprecision long-term development of microbial manufacturing. However, China’s microbial manufacturing industry has a long way to go in terms of scientific research and technological innovations. It is believed that with China’s policy support and the joint efforts of relevant scientific research institutes, China’s microbial manufacturing industry can enhance industrial efficiency, expand the scope of application, and improve international competitiveness to strengthen China’s microbial manufacturing.

京公网安备 11010502051620号

京公网安备 11010502051620号