《1 Introduction 》

1 Introduction

The discovery and versatile applications of plastics have significantly changed the lives of human beings. From 1950 to 2015, approximately 7.8×109 tons of plastic waste was generated, around 9% of which was recycled, 12% was incinerated, and 79% was accumulated in landfills or the natural environment as solid waste. If effective measures are not taken, it is estimated that the world’s plastic waste will reach 1.2×1010 tons by the end of 2050 [1]. In the natural environment, plastics take more than decades to gradually disintegrate into microplastic particles because there is no naturally existing biological phenomenon that can completely degrade plastics [2,3]. Waste plastics and their micro- and nano-plastic particles have caused considerable environmental pollution, consequently resulting in serious threats to the health of animals and humans as well as the safety of agricultural produce. Therefore, there is global consensus on the comprehensive control of “white pollution”. Countries around the world are actively promoting the implementation of mandatory laws and regulations for plastic restriction and prohibition, and are striving to develop and use substitutes such as biodegradable plastics.

China is the largest producer and consumer of plastic products worldwide, with an annual consumption of plastic products of approximately 1.3×108 tons [4]. Large amounts of plastic residuals (about 12% of annual consumption) are released into the environment as “white pollution,” which pose a threat to the security of ecology and green sustainable development of the economy. Recently, China has paid close attention to plastic pollution and enforced related policies and regulations. These policies and regulations include taking affirmative actions against plastic pollution; gradually banning or limiting production, sales, and use of plastic; promoting recyclable and degradable alternative products; implementing the comprehensive utilization of straws; recycling agricultural film and pesticide packaging; and promoting the development of degradable agricultural films.

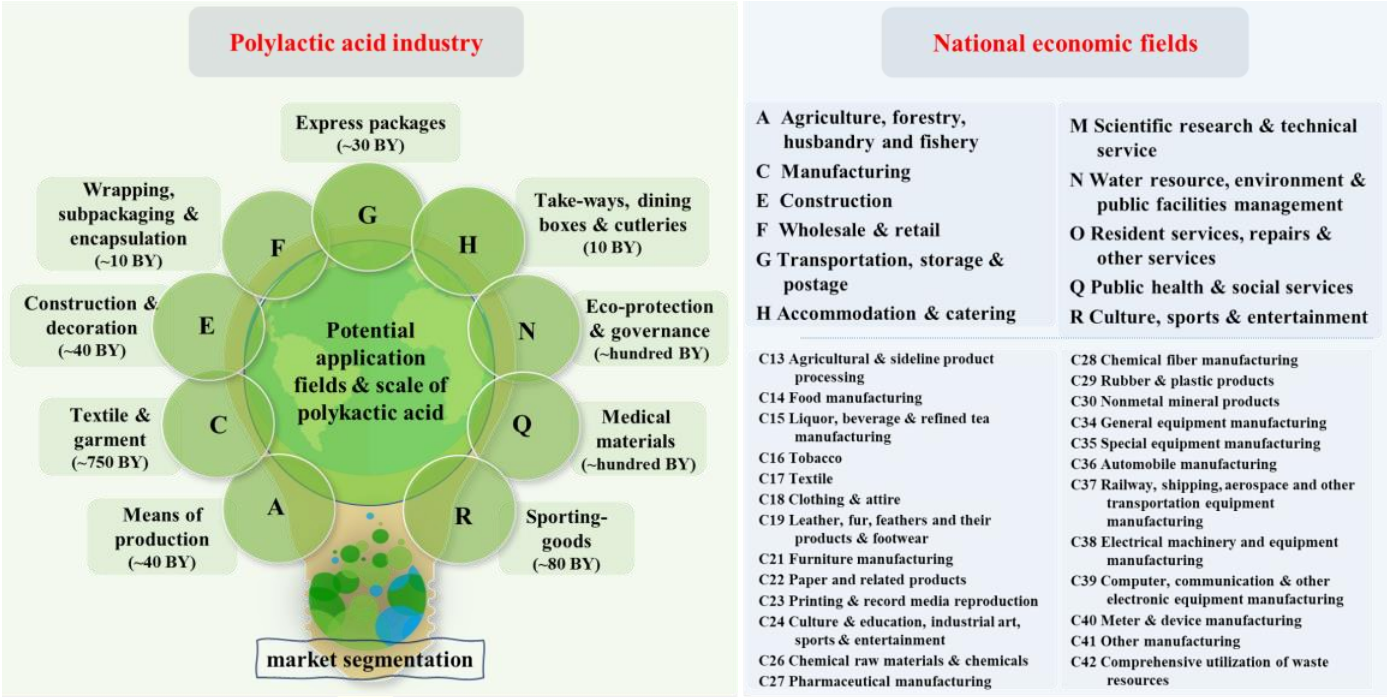

Polylactic acid (PLA) materials are indispensable in the management of “white pollution”. PLA is the core element leading to the development of the biodegradable materials industry and expansion of related application fields. It covers various economic and societal fields in China (Fig. 1). The most prominent applications are in the manufacturing industry, which involves at least 25 categories and their subdivisions, such as delivery, packaging, tableware, personal care, maintenance of urban sanitation and environment, and agricultural and forestry production materials. These fields are priorities for the comprehensive control of “white pollution” in China, with an annual consumption of plastic products exceeding 7×106 tons [5], and comprise the primary objects being replaced by biodegradable PLA materials. Additionally, there is a huge demand for PLA materials in the fields of textiles, sporting goods, children’s toys, daily necessities, health/medical materials, building decoration, scientific research, and teaching. Furthermore, the application of PLA in the fields of sustained-release fertilizers and pesticides, in situ manufacturing of mechanical components, encapsulation of drugs and vaccines, and modern planting and breeding are primary emerging technological revolutions. Therefore, it is of great significance for the high-quality development of China’s PLA industry to fully understand the technical status of the PLA industry chain and related technical barriers, and to reasonably implement the advanced layout of the chain by overcoming them.

《Fig. 1》

Fig. 1. PLA industry and the national economic fields involved.

Note: Market size data are estimated or predicted according to previous publications, professional industry reports, and academic presentations. The national economic fields involved are sorted according to the classification of national economic industries (GB/T 4754–2017). BY: Billion yuan (RMB).

《2 Development status of PLA material industry》

2 Development status of PLA material industry

The PLA industrial chain integrates technological achievements in biological fermentation, chemistry, chemical engineering, and polymer materials. It is monopolized by a high technological threshold, high technological integration, and deep interdisciplinary integration in the early stages of development. PLA industrial chain incorporates the following sections: (1) Bio-production of lactic acid monomers using agricultural output as feedstock. These include fermentation, purification, and comprehensive treatment of by-products and wastes. (2) Chemical preparation of lactide and PLA. This process includes a one-step process (lactic acid monomers are directly polymerized into PLA by a chemical process) and two-step processes (lactides are prepared from lactic acid monomers through a condensation reaction, and PLA is then prepared from lactides with ring-opening polymerization). (3) Development and application of PLA. This includes making terminal products and expanding applications of PLA, modified PLA, or PLA composite materials.

The PLA industry has taken a long time for technological maturation. In 1913, French scientists initially synthesized PLA through polycondensation; however, the resulting PLA could not be directly used as a structural material because of its low degree of polymerization. In 1932, Wallace Carothers, well-known as the father of polymer chemistry, invented the technology of synthesis in organic solvents under vacuum conditions. In 1954, DuPont from the United States introduced a two-step method to prepare PLA with a high molecular weight. In 1966, Kulkani et al. synthesized a biodegradable surgical suture from poly L-lactic acid (PLLA) and demonstrated that PLA possesses advanced biocompatibility and biodegradability. In 1976, Yoles et al. reported that PLA can be widely used as a carrier for sustained-release drug delivery. In 1987, Rensselager et al. used tetraphenyltin as a catalyst to prepare higher-molecular-weight PLLA with desirable mechanical properties. They also demonstrated the broad application of PLA in internal fixation of bone fractures. In 1987, the Cargill Company from the United States began to invest in the research and development of new PLA manufacturing technology and developed a series of new PLA synthesis technologies, which greatly promoted the industrialization process of PLA. In 2005, NatureWorks from the United States announced the launch of lactic acid and PLA. Currently, its products are subcategorized and serialized, and its production capacity is the world’s largest, with an annual output exceeding 1.5×105 tons.

The research and development of PLA material technology and large-scale industrial applications in China began around the year 2000. Currently, over ten Chinese enterprises are constructing or expanding production facilities for polymer-grade lactic acid and PLA. Representative enterprises include Anhui BBCA Biological Technology Co., Ltd., Shanghai Tongjieliang Biological Materials Co., Ltd., Zhejiang Hisun Biomaterials Co., Ltd., Wanhua Chemical Group Co., Ltd., Jilin Cofco Biomaterial Co., Ltd., Shandong Tongbang New Material Technology Co., Ltd., Henan Jindan Lactic Acid Technology Co., Ltd., Shenzhen Esun Industrial Co., Ltd., and China Hengtian Group Co., Ltd. Several other megacompanies are planning to enter this field. According to the correlative plan, China’s PLA annual production capacity will increase from 1.6×105 tons to 2.5×106 tons in coming five years.

《3 Key technologies for PLA material industry》

3 Key technologies for PLA material industry

《3.1 Manufacturing technology of lactic acid monomers》

3.1 Manufacturing technology of lactic acid monomers

Lactic acid monomers with high optical purity (≥ 99.5%) and high chemical purity (≥ 98.0%) are key for the development of the PLA industry. Currently, the main method for large-scale manufacturing of lactic acid monomers is fermentation. A microbial strain with the ability to efficiently synthesize lactic acid monomers is the core of this process, which also determines the process route and equipment requirement.

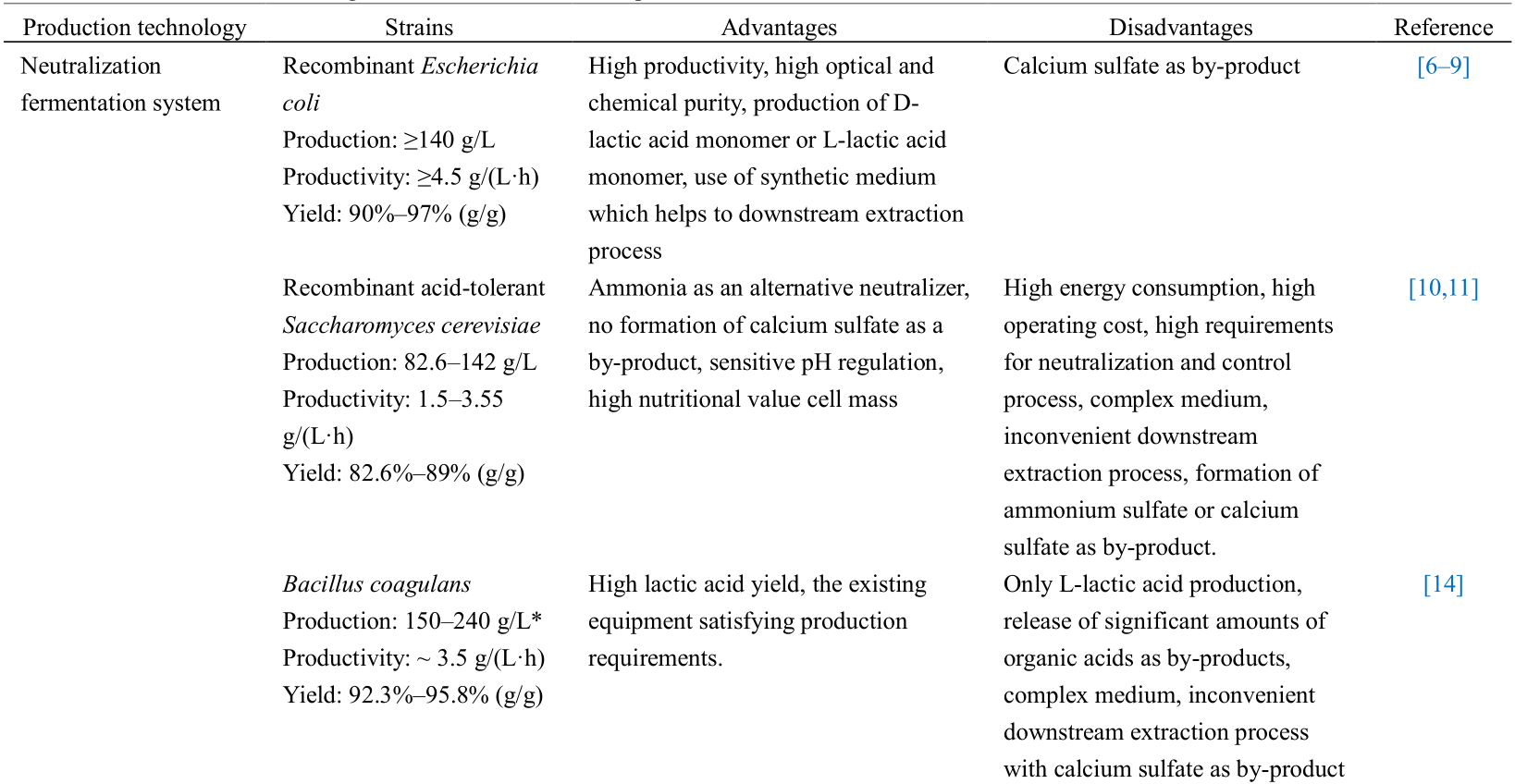

Different from the existing food-grade L-lactic acid production, the excellent microbial strains (metabolically modified Escherichia coli (E. coli) [6–9] and yeast [10–13]) with industrial application value for lactic acid monomer production have been obtained through modern microbial breeding, especially molecular breeding (Table 1). The screening and breeding process of lactic acid monomer-producing strains include: (1) Isolation of parent strains with specific properties from natural samples. Their metabolic properties over a broad range of substrates, tolerance to high concentrations of substrates and lactic acid, high metabolic rates, simple nutritional requirements, rapid proliferation, and metabolism in synthetic media are highly desirable. These properties of strains enable lactic acid monomer production using various raw materials, simplify the fermentation process, and provide the convenience of further genetic improvement [6,8,9]. (2) Use of genetic modification technology to strengthen the productivity and yield of the lactic acid monomer synthesis process, eliminate by-product pathways, and expand substrate utilization capacity; thereby maximizing the optical and chemical purity of lactic acid monomer in the fermentation, and simplifying the processes of fermentation, separation, and purification units [5–8]. (3) Application of molecular switches to control growth and lactic acid synthesis of strains (mainly E. coli) and resolve the natural contradiction between the growth and lactic acid monomer synthesis, thereby creating a temperature-shifting process technology for lactic acid monomer production and maximizing production capacity [6,8,9]. (4) Development of a new nonneutralizing process by employing acid-tolerant strains (mainly yeast) developed using molecular breeding technology, thereby greatly reducing by-product (especially gypsum) formation [12,13].

《Table 1》

Table 1. Main technologies for lactic acid monomer production.

Note: *Owing to the limitation of calcium lactate solubility, the lactic acid yield in actual industrial production generally does not exceed 160 g/L.

There are two completely different systems for lactic acid monomer fermentation (Table 1). (1) Neutralization using either Ca(OH)2 or NH4OH as neutralizers. The former possesses high yield and productivity, with the formation of CaSO4 as a by-product. The latter possesses lower productivity and higher running costs, with (NH4)2SO4 as a by-product. Most of the existing industrial processes of lactic acid monomer production in domestic and foreign enterprises use Ca(OH)2 as the neutralizer [6–11,14]. (2) Non-neutralization process using acid-tolerant yeast to produce lactic acid monomers with the advantage of no by-products. However, the disadvantages are lower productivity and yield, higher consumption of energy and raw materials, and the requirement for special fermentation equipment. Only one or two international companies have adopted this technology for L-lactic acid monomer production [15]. Additionally, the use of special production processes, such as in situ extraction processes, can eliminate the formation of by-products, such as gypsum or ammonium sulfate [16], but their production efficiencies and economic benefits need to be further improved.

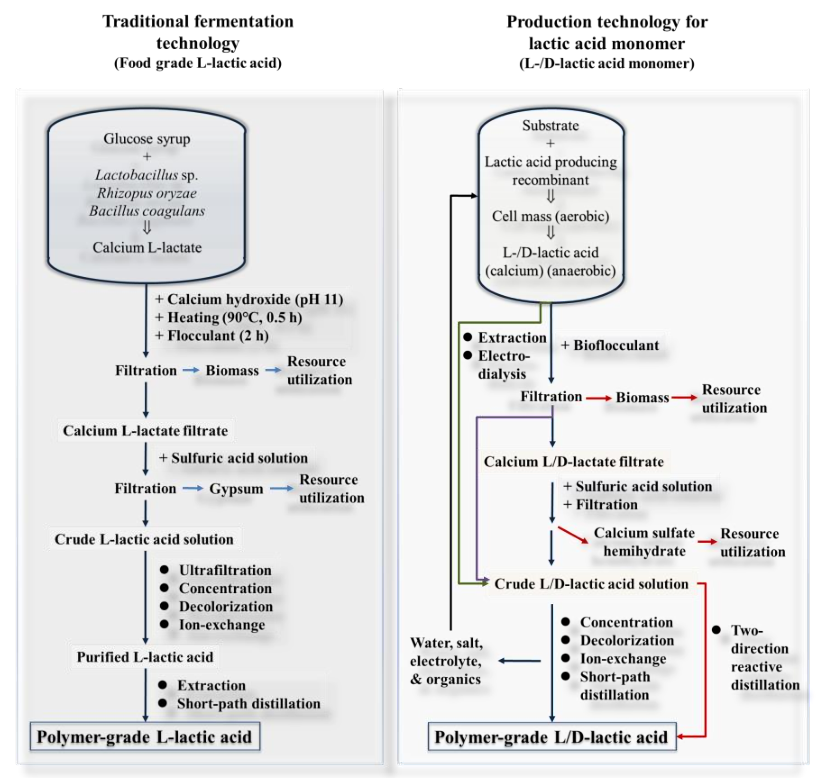

Extraction and purification of lactic acid monomers include the following processes: separation of biomass, release of lactic acid monomers, separation of by-products, refining and purification of lactic acid monomers, and recycling of by-products and wastes. The refining and purification of polymer-grade lactic acid monomers through coupling distillation is an important direction for future development because it generates a relatively high yield and high quality of lactic acid monomers, although the technology and required equipment are complex. The traditional polymer-grade lactic acid monomer production process includes calcium lactate crystallization, solvent extraction, decolorization with ion-exchange resin, and molecular distillation. This process has been adopted by most domestic and international enterprises because of its high yield and acceptable product quality. However, this process is timeconsuming and yields several by-products.

《3.2 Lactide and PLA manufacturing technology》

3.2 Lactide and PLA manufacturing technology

Production of PLA is mainly divided into: one-step synthesis, two-step synthesis, enzymatic synthesis, and de novo biosynthesis of PLA directly from glucose [17–20]. The two-step method is the main technology used for industrial production. The technology and industrial devices for lactide polymerization have been well developed. But lactide synthesis with high purity is crucial for a relevant technical system, which is still under development[17–19].

The current two-step processes with industrial feasibility for lactide preparation [17,18] are summarized as follows: (1) Condensation polymerization–depolymerization method involves the polymerization of lactic acid monomer into oligomeric lactic acid at low temperatures (approximately 130 °C) and under high vacuum conditions, and depolymerization of the resulting oligomeric lactic acid into lactide at higher temperatures (150–180 °C). This method is commonly used for lactide production. However, isomerization of lactide at high temperatures also occurs in the process, which causes a decrease in the purity and recovery of lactide and generates a relatively high proportion of racemic by-products. (2) Gas-phase synthesis can convert vaporized lactic acid monomer to lactide under the protection of inert gas and normal pressure in one step, with a conversion rate of approximately 70%–90%. However, its productivity is too low for it to be economically feasible. (3) One-step liquid-phase synthesis is an important method for the industrial preparation of lactides. In this method, lactide is formed through the dehydration polycondensation reactions of lactic acids catalyzed by zeolite. The lactide conversion rate reaches 80% and the optical configuration is maintained above 99%. For the industrial implementation of the above technologies, the assistance of related technologies, especially for lactide purification, is required, in addition to the need for further device design and catalyst selection.

China has indigenously established a considerable number of PLA production lines. The technical route applied was ring-open polymerization of lactide (two-step process). Recently, technologies and devices for polymer-grade lactic acid preparation and lactide purification have made significant progress in China, which has promoted breakthroughs in technology for high-purity lactide preparation. Zinc, tin, lead, rare earth metals, zeolite, and organic guanidine have been applied as catalysts for lactide and PLA synthesis [17,18,21]. Technologies and devices such as polycondensation reactions coupled with distillation and melting crystallization for lactide preparation, have also been advanced by Chinese scholars.

Notably, the international company representatives have well-established PLA material production lines and product segmentation for different application purposes. Currently, the PLA products in China are limited to PLLA. Because of the polymerization degree, uniformity, and purity of domestic PLA products, most are only applicable in injection molding, film-forming products, and other primary applications. With the advancement of the commercial preparation of polymer-grade lactic acid monomers (L-lactic acid monomer and D-lactic acid monomer) and high-quality lactide intermediates (L-lactide and D-lactide), the research and development of a series of domestic PLA products on commercial scales will be significantly accelerated.

《3.3 PLA modification and processing technology》

3.3 PLA modification and processing technology

Modification and processing of PLA materials are downstream applications in the PLA industry chain. Most of the technology and equipment have been mastered by domestic enterprises, which are a relatively mature and large part of China’s PLA industry. With the emergence of new PLA products and application segments, inventions and breakthroughs in related fields are continually being made. The progress in PLA material modification and processing technology has been reviewed in recent publications [22–25].

The modification of PLA materials includes physical methods (such as blending, compounding, or isotactic/stereoisomeric) and chemical methods (such as copolymerization, crosslinking, grafting, and modification). The degradability, barrier properties, toughness, conductivity, thermoplasticity, bio-loading properties, and antibacterial properties of PLA materials can be further improved according to the target products. For processing, various methods related to polymer materials are widely used, such as extrusion, injection molding, calendaring, blow molding, thermoforming, stretch blow molding, transfer molding, melt spinning/microspheres, solution spinning/microspheres, electrospinning, melt spraying, spray drying, supercritical foaming, and additive manufacturing. Additionally, specific enzymes or microbial cells can be immobilized on the surface of or inside PLA materials through immobilization technology, which results in new materials with specific biological activities or functions.

《4 High-quality development strategies for China’s PLA material industry》

4 High-quality development strategies for China’s PLA material industry

In China, the development of the PLA material industry is initiated in the downstream segment and gradually extends upstream. The PLA industry’s application layout is vast and dynamic. In the preparation of PLA from lactide, while introducing–digesting–absorbing foreign advanced technology, China has gradually realized technical improvement and proprietary equipment development. However, the international dependence of the entire industry chain is still high owing to the lag in the development and industrialization of polymer-grade lactic acid monomer and lactide manufacturing technology. Through unremitting efforts, Chinese scholars have made breakthroughs in the large-scale manufacturing technology of polymer-grade lactic acid monomers (L-lactic acid and D-lactic acid) and have made great progress in the preparation and purification of high-purity lactide. The integration of technology and equipment in the PLA chain and efficient green production of PLA are expected. In view of the high-quality development of China’s PLA material industry, this study proposes strategic suggestions on the core issues of the industrial chain, such as raw material supply, technology and equipment for lactic acid monomer production, products of industrial chains, key development directions, quality management systems and industrial coordinated development, and policy guidance and support.

《4.1 Attention to the diversity and safety balance of raw material supply》

4.1 Attention to the diversity and safety balance of raw material supply

Similar to other fermentation industries, lactic acid monomer production mainly uses agricultural output as feedstock. Currently, starch from various sources is the most important feedstock. The PLA industry, with an annual production of less than one million tons, does not significantly impact the balance of food supply security. Considering that the PLA industry will continue to expand, the principle of “not competing for grain with people and not competing for land with grain” is also instructive for the future development of the PLA industry. Planning ahead for the supply diversity and safety balance of raw materials before the large-scale development of the PLA industry and endowing production strains with the ability to utilize various raw materials are the core keys to solving such problems (Fig. 2).

《Fig. 2》

Fig. 2. Raw materials for PLA industry.

Note: E: Enzyme; TCA: Tricarboxylic acid cycle.

Glycerol is a by-product of the oil-processing industry and accounts for approximately 10% of the total output. Glycerol is considered a valuable raw material for large-scale production of lactic acid monomers in the future. The technology for manufacturing lactic acid monomers from glycerol is well developed, which also reflects the important academic contributions of Chinese scholars [6,8,9,26]. Currently, glycerol is the main raw material for the chemical industry in China, and its supply relies on imports. Using glycerol for lactic acid monomer production in China does not have cost advantages; it can be set as the key direction for future international market layout.

Sucrose is another high-quality bulk raw material used for the production of lactic acid monomers. The conversion of sucrose into value-added lactic acid monomers also endows China’s sugar industry with developmental opportunities. With the global restructuring of sugar consumption, sucrose consumption has significantly declined year by year, resulting in sugar production costs being higher than the sales prices. It can be predicted that sucrose and molasses from sugarcane and beets will inevitably become bulk raw materials for lactic acid monomer production. In China, technologies for lactic acid monomer production from sucrose are well developed and can be directly applied in industrialization. China is one of the largest producers of sugarcane and beet, and there are a huge number of practitioners in related fields, but with low income. It is necessary to allocate resources reasonably, thereby further releasing the driving potential of the PLA industry to the sugarcane and beet industries and significantly increasing farmers’ income.

The production of lactic acid monomers from straw and other agroforestry biomasses exhibits strong prospects. Currently, the relevant technology is feasible, but not economically feasible because of the high cost of straw transportation, pretreatment, saccharification, and comprehensive utilization. Therefore, technological research in the following aspects is necessary to achieve application breakthroughs. (1) Development of efficient and inexpensive enzyme cocktails is crucial. Existing commercial cellulase and hemicellulase can be used for the saccharification of specific straws. However, the efficiency of saccharification is insufficient, the loading dose of the enzyme is too high, and the cost of the enzyme is too high. Therefore, increasing the hydrolysis efficiency of the enzyme, reducing its manufacturing cost, and reformulating enzyme cocktails specific to a type of biomass are indispensable. (2) The study and optimization of high-efficiency fermentation technology and related equipment is required for high-efficiency conversion of raw straw materials. Special emphasis should be placed on the further development of the fermentation process based on production strains, simultaneous saccharification and fermentation processes, supporting equipment, lactic acid monomer purification and refining equipment, and water recycling devices. (3) New technological breakthroughs in the comprehensive development and utilization of straws are required, which will result in the full utilization and increase in economic value of straws. An example of such breakthrough can be the exploitation of high value-added products from lignin and the simultaneous recovery of high value-added sugars such as xylose and arabinose.

There are other potential raw materials for the production of lactic acid monomers. Currently, modifications and fine-tuning of a specific gene and/or the whole genome of selected strains have become a reality after the invention of molecular cloning technology 50 years ago and the implementation of the Human Genome Project 30 years ago. These developments will endow microorganism strains with better production, productivity, and yield of lactic acid monomers, and with more efficient utilization of raw materials. Therefore, synthetic biology techniques offer new possibilities for future PLA production. Construction of chassis microorganisms and optimal rearrangement of the genetic modules (such as the growth module, special metabolic module, lactic acid monomer synthesis module, and PLA synthesis module) provides the production strains with the ability to convert unusual raw materials (such as waste biomass, biogas, natural gas, syngas, and CO2) into lactic acid monomers or PLA directly by de novo biosynthesis (Fig. 2).

《4.2 Improvement of the modern fermentation process, technology, and equipment》

4.2 Improvement of the modern fermentation process, technology, and equipment

To meet the requirements of purity and production cost of lactic acid monomers, the invention and application of new strains, new technologies, processes, and equipment are constantly required, thereby driving revolutions in lactic acid monomer fermentation technology and its downstream engineering technology (Fig. 3). For high-quality development of China’s PLA industry, technological optimization, engineering implementation technology, and equipment development should be emphasized.

《Fig. 3》

Fig. 3. Technology systems for lactic acid monomer production.

The first step toward the required technological improvement is the simplification of the fermentation medium used for lactic acid monomer production. The medium composition should be optimized using a chemically defined medium, and the medium consumption should be further minimized using a modern fed-batch process. Inorganic salts should be the main component of the medium to drag fewer impurities into the fermentation system, thereby facilitating downstream recovery and purification of lactic acid.

Second is the establishment of an efficient and intelligent fermentation system. Through the development of new strains, rapid cell mass propagation under aerobic conditions and efficient anaerobic accumulation of lactic acid monomers controlled by a temperature shift strategy can be achieved, thereby decoupling growth with lactic acid synthesis in the fermentation process and significantly improving the production and productivity of the monomers. By developing new fermentation equipment, adopting and optimizing Industry 4.0 solutions, and applying artificial intelligence technology, thereby realizing real-time (online and off-site) automatic monitoring, automatic control, and machine learning, the capability of the fermentation process in a larger fermenter can be maximized, the production cost (energy, raw materials, and laborers) and the by-products can be significantly reduced, and full automation plants (unmanned factory) for lactic acid monomer production can be gradually realized. Additionally, exploring the feasibility of industrial applications and the value of new lactic acid monomer production technologies, such as in situ extraction fermentation, in situ esterification separation, and the technical feasibility of the continuous production process, are also beneficial.

Third is the development of new technologies and equipment for downstream engineering. Advancements in strain development and fermentation technologies can simplify the implementation of lactic acid monomer purification and refining and provide a good platform for the exploration and application of new technologies. The innovation of a continuous process of sulfuric acid acidification, which releases lactic acid monomer and synchronously forms calcium sulfate hemihydrate as a by-product, can replace the existing process that forms gypsum as a by-product, thereby further initiating new potential applications of calcium sulfate. The development of a two-direction reactive distillation coupling technology (esterification–distillation–hydrolysis) will efficiently improve the preparation of polymer-grade lactic acid monomers. Innovation in internal circulation technology that recycles and reuses process-produced water, salt, electrolytes, and organics for fermentation medium formulation can also be simultaneously targeted.

The fourth category includes other innovations in technologies. The utilization of cell biomass, especially as new materials, and the application of acid-tolerant lactic acid-producing strains require further examination and optimization for different applications. The technologies and equipment used in reactive distillation for producing lactide, melting crystallization for purification of high-purity lactide, synthesis and classification of PLA, optical configuration transformation control in the preparation of lactide, and depolymerization and racemization of tailings will require interdisciplinary development and combinatorial innovation.

《4.3 Key directions in PLA industry chain: strengthening the diversity of products and innovation of production technology》

4.3 Key directions in PLA industry chain: strengthening the diversity of products and innovation of production technology

The main products of the PLA industry chain include lactic acid monomers and direct derivatives, intermediate lactides, and PLA and its derivatives. The related products in the production chain include manufacturing devices, chemical catalysts, modified materials, and quality control and analysis accessories (instruments, kits, standards, and standard substances) (Fig. 4).

《Fig. 4》

Fig. 4. Main products of the PLA industry chain.

4.3.1 Product diversity and balanced development of the PLA industry chain

Polymer-grade lactic acid monomers (L-lactic acid and D-lactic acid) are fundamental for ensuring the healthy development of the PLA industrial chain. The L-lactic acid and D-lactic acid monomers must be industrialized simultaneously and developed in a coordinated manner. Lactic acid has important applications in food (L-lactic acid), animal feed additives (L-lactic acid), environmental protection and treatment (L-lactic acid and D-lactic acid), drug or herbicide synthesis (L-lactic acid and D-lactic acid), soil improvement (L-lactic acid and D-lactic acid), electroplating, and electrodialysis. It is necessary to improve the relevant production technologies and maintain a balanced product layout.

Lactic acid salts and esters are direct derivatives of lactic acid. These materials have numerous applications. Currently, there are numerous types of derivative products of lactic acid, and new products can be developed for wider applications. Sodium L-lactate, calcium L-lactate, zinc L-lactate, magnesium L-lactate, methyl L-lactate, ethyl L-lactate, methyl D-lactate, and ethyl D-lactate are widely used in food, feed, cultivation, breeding, medicine (especially in hemodialysis, peritoneal dialysis, and other dialysis), perfumes, spices, and special cooling agents. The rational integration of lactate derivatives with the PLA production system is also a solution for non-polymergrade lactic acid and by-products concurrently generated in the preparation of lactic acid monomers, lactides, and PLA. This will be conducive to the comprehensive improvement of the economic benefits of the entire PLA industry chain, and hence, proceeds and upgrades the current technology and equipment system or accumulates to create new production systems.

According to the optical configuration of lactic acid or lactide as well as the participation of other monomers, the PLA product types are divided into poly L-lactic acid, poly D-lactic acid, co-polymeric stereotactic PLA (poly L/Dlactic acid), and co-PLA (such as polylactic-co-glycolic acid). According to the polymerization degree and purity, PLA products are subdivided into injection molding grade, film-forming grade, spinning grade, industrial grade, food grade, medical grade, and in vivo injection grade. Based on their functional and application characteristics, PLA and its derivatives are divided into transparent, antibacterial, anti-ultraviolet, flame retardant, solvent-resistant, and thermally stable types. Therefore, on the basis of the application and the quality and purity of lactic acid monomers and lactide, the studies on the technology and equipment for lactic acid polymerization, PLA product fractionalization, and PLA modification and processing are required to meet the market demand for PLA products. While preparing all kinds of PLA on a large scale and at low cost, the market demand should be scientifically evaluated, products urgently needed in the market should be steadily industrialized, and technological innovation and product diversity creation should be directionally implemented.

4.3.2 PLA products and their development priorities

Single-use plastic (SUPs) products are widely applied in various fields, including packaging, daily life, medical care, planting and breeding, express catering, and family living. Highly dispersible application scenarios and difficult recycling or low-value recycling are the emphasis and nodus of “white pollution” governance. The replacement of SUPs with biodegradable products based on PLA is the key step to efficiently control “white pollution”. The quality requirements for the type and degree of polymerization of PLA are relatively low. It can be made by blending with other biodegradable materials (such as starch, polyadipate/butylene terephthalate, and plant fiber) or through surface spraying. Additionally, ultra-lightweight PLA foam materials prepared by advanced processing technologies (such as supercritical fluid foaming) have exhibited the properties of sound absorption, heat insulation, and buffering. This is a desirable alternative for replacing petroleum polymers [27].

Agricultural films and modern planting are inseparable from each other. For example, the application of agricultural film-covering planting technology has increased the output of agricultural produce by about 30%, which plays an important role in ensuring the safe supply of agricultural produce. However, agricultural films are not easily recycled and degraded, and there is a shortage of recycling technology. “White pollution” caused by plastic mulch and environmental accumulation of plastic films for decades (the usage of agricultural films in the whole country exceeded 2.5×106 tons in 2020 alone) has become a major problem for sustainable development. Degradable photolytic film and plastic film blended with starch or straw developed and used in past years are essentially unbiodegradable. They naturally collapse into plastic fragments or micro- and nano-plastic particles, causing even more serious potential pollution. Biodegradable plastic film based on PLA is a direct and effective alternative to replace the traditional plastic film and solve the residual pollution of plastic films. Therefore, PLA should be vigorously investigated in this field. Furthermore, seed paper, coated seeds, sustained-release fertilizers, sustained-release nutrients, etc. made from biodegradable PLA materials are expected to play a positive role in the fully automated and accurate development of the planting industry.

PLA fiber is an advanced fabric used in textiles and clothing. Fibers from PLA with high polymerization degrees can be prepared by solution spinning, melt spinning, or other technologies and subsequently used to prepare long filaments, short filaments, monofilaments, woven fabrics, cloths, and non-woven fabrics. The resulting fabrics exhibit good hand feel, drapability, resilience, water diffusion, UV resistance, pollution resistance, low flammability, processing performance, crimping stability, and shrinkage control. Relevant fabrics are also suitable for all kinds of fashion, casual wear, personal care products, sporting goods, and sanitary products and have considerable market demands [28].

PLA exhibits excellent biocompatibility and is widely used in the medical field. It can be used to prepare medical masks, gloves, sheets, pads, medicine boxes, and utensils. It can also be used as in vivo medical material, for instance, absorbable screws and surgical lines, fabrics or membrane materials for human tissue repair, fracture internal fixation materials, ophthalmic injection materials, and tissue engineering scaffold materials. Medical-grade PLA can also be used as a controlled drug release material, which has special application value in the upgradation of modern drugs and dosage formulations, such as in drug molecular encapsulation, vaccine encapsulation, and sustained/controlled release preparations for targeted implantation of drugs [17,29]. Additionally, the biological grade of PLA, directly synthesized by enzymes or de novo synthesis by whole cells, exhibits prospects in future medical PLA material manufacturing, although the existing technical level and its polymerization degree and purity must be further improved [30,31].

In the field of mechanical manufacturing, numerous parts or components (such as automobile body, door, rim, seat, ceiling, spare tire box cover, and footpad) can be quickly manufactured with PLA using injection molding, extrusion and forging, or additive manufacturing. This can realize lightweight overall production, convenient installation, individual disassembly, recycling, and reprocessing. The use of PLA material parts is also valuable for small-batch, short life cycle, personalized, and flexible production of products; in situ maintenance, renovation, and upgradation of second-hand products. Its application in national defense, military, aerospace, and other industries is valuable for further exploration.

PLA exhibits important application value in the field of electronic products, such as computer/mobile phone parts, infrared receiving accessories, electronic product casings, CDs and discs, and chips/large-scale integrated circuit packaging tapes. PLA and its composite/modified materials (such as PLA alloys) can be used to realize the processing and preparation of foldable, twisted, malleable, and extensible electronic materials, and can promote the innovative development of electronic skin, prosthetics, robots, health monitoring, and biomedical instruments [32].

In the field of children’s toys/products, to respond to the rapidly rising market demand for relevant consumption (annual consumption exceeds 300 CNY per child) and to match the technical needs of products such as safety, diversity, intelligence, creativity, novelty, and functionality, PLA materials can not only replace almost all materials of the existing children’s toys, but also expand new product ecology and high biosafety application scenarios. Moreover, design and manufacturing methods that match this new material system, rapid style renewal, and the recycling and reprocessing of old models can also be developed. This is one of the most important fields in the development of the PLA industry.

In terms of sporting goods, PLA materials have good application prospects on a large industrial scale. They can be used in sports clothing, sports protective equipment, outdoor sports leisure products, fitness equipment, gymnastic equipment, sports competition supplies, stadiums, gymnasiums, and other sports-related products. With the promotion and implementation of the national fitness plan (2021–2025), the healthy, green, and environmentally friendly sporting goods market is expected to develop rapidly, which will promote the development scale and quality of the PLA material industry.

In terms of academic research, education, and school supplies, PLA materials can be applied to pens, paper, stationery, schoolbags, teaching aids, school uniforms, decorations, scenery, sports devices, disposable scientific research and teaching consumables (e.g., gloves, test tubes, cylinder, measuring cup, centrifugal tube, pipette tips, tags, binding wire, paper/film, etc.), molds and models, field fabrication, research chemicals, reagents, and standards. It is necessary to form a serialized and panoramic product system as soon as possible to meet the requirements of students and practitioners (approximately 300 million people). By innovating the application mode of PLA materials and enhancing residents’ awareness of environmental protection, a long-term additional effect on the PLA industry can be obtained.

《4.4 Establishment and improvement of products quality control and environmental management systems》

4.4 Establishment and improvement of products quality control and environmental management systems

Quality control and environmental management systems are the premises of the high-quality and sustainable development of the PLA industry. The Degradable Plastics Committee of the China Plastics Processing Industry Association, Chinese Association of Environmental Protection Biodegradable Plastic Professional Committee, and Biobased Degradable Materials and Products in China are the main specialized agencies and organizations in the PLA field. Furthermore, joint industrial research institutes, collaborative innovation centers, and industry alliances established by universities, research institutes, and competitive enterprises are also unignorable. Owing to the short development time of China’s PLA industry, the relevant factors still need to be gradually improved for better standardization and guidance of the development of the PLA industry.

As a systematic project, the quality control and environmental release management system of the PLA industry should be set up in high standards by referring to the operational experience of relevant industries in developed countries and some advantageous industries in China. This should be based on national conditions, forward-looking needs, and integration with international norms. It should include all key quality control nodes of the industrial chain and build an authoritative quality evaluation organization and data-sharing platform for all products of the industrial chain. Based on the environmental release of PLA products, basic research covering the product lifecycle needs to be performed, such as breeding high-efficiency microbial strains for efficient degradation of PLA and creation, preparation, and application of high-efficiency enzyme cocktails for the efficient treatment of PLA. This will ensure medium- and long-term development of manufacturing technology and expansion of application technology.

《4.5 Implementation of active policies for PLA industry development》

4.5 Implementation of active policies for PLA industry development

The PLA industry in China is still in its infancy, and unbalanced development of the industrial chain is obvious. To promote rapid development of the PLA industry, active industrial policies that highlight the scientific and forward-looking industrial chain layout are suggested to guide and support its development. The front-end layout of the PLA industry chain should match the supply of raw materials and subsequently drive upgradation of bulk agricultural processing from aspects of accuracy, depth, and comprehensive level, thereby promoting the transformation, upgradation, and industrialization of farming (such as sugarcane, sugar beet, cassava, corn, and sweet potato). The mid-end layout of the PLA industry chain should rely on the advantages of technology, talent, capital, and market in high-tech equipment manufacturing developed areas to digest the existing PLA manufacturing capacities and devices and to quickly establish new professional industrial clusters. The terminal layout should carry out rational integration and gathering based on product categories, application diversity, and distribution of existing enterprises, thereby driving industrial upgradation.

It is suggested that national scientific and technological research and development channels can give special support to PLA industry chain development by promoting the collaboration of domestically advantageous technical strengths and deep cooperation of “industry–university–research–practice”. The following aspects should be addressed and focused on: (1) key technology innovation and prototype development of key equipment in the PLA industry chain, such as automatic and intelligent oversize fermenters; (2) new equipment for separation and purification; (3) new devices for lactide purification; (4) new devices for PLA polymerization and fractionation; and (5) new devices for modification and processing of PLA. Simultaneously, in response to the urgent need to develop the PLA industry, the training of interdisciplinary talents should be strengthened, and universities, scientific research institutes, and qualified enterprises should be encouraged to jointly establish research institutions and industrial colleges, thereby accomplishing the demand for first-class professional talents.

《5 Conclusion》

5 Conclusion

PLA, a typical carbon-neutral, renewable, and biodegradable polymer material, is a revolutionary alternative to petrochemical polymers. It will gradually become the basic bulk raw material for national economic and social development in China, and will strongly promote the development of other biodegradable materials, related industries, and their peripheral industries. With 20 years of technical research and application practice, China has established a solid foundation for large-scale development of the PLA industry. In the future, through full cooperation at the level of government–industry–university–research–practice, multi-disciplinary cross-border combination innovation, and the consideration of technology and equipment in the whole industrial chain, the strangle-hold technologies that restrict the development of the PLA industry and the level of autonomy will be effectively and completely resolved. It is expected and predictable to quickly realize the rational layout and coordinated operation of PLA innovation chains, industry chains, talent chains, and supply chains, and to drive the high-quality development of the PLA industry.

《Acknowledgement》

Acknowledgement

The author appreciates the constructive guidance provided by Fuping Lu, Hongxing Wang, Jinyu Han, and Bowen Cheng from Tianjin University of Science and Technology, Tianjin, China, in terms of industrial fermentation and industrial strains, lactic acid monomer purification and lactide preparation, chemical engineering, and textile engineering. I would also like to thank the graduate students in the author’s laboratory for helping to sort out some professional data. The English version was assisted by Dr. Meng Zhang from Tianjin University of Science and Technology.

京公网安备 11010502051620号

京公网安备 11010502051620号