《1 Introduction》

1 Introduction

At present, owing to the rapid development of the shipping industry, the energy consumption and environmental pollution associated with petroleum-fueled ships are ongoing problems. In 2020, the CO2 emissions from the shipping industry reached 1.2 × 108 t, accounting for approximately 12.6% of the national emissions caused by transportation. The development and application of environmentally friendly ships has become a technological frontier and trend of the water transportation industry [1]. It is also a decisive measure for achieving the goals of carbon peaking and carbon neutrality for the shipping industry. The development of environmentally friendly ships is also crucial for promoting the transformation and upgrading of China’s shipbuilding industry and the implementation of a strong transportation network in China.

Currently, low-carbon fuels such as natural gas and methanol and battery technology are the main methods used to reduce the CO2 emissions of ships. In the medium and long term, the application of zero-carbon fuel technologies, including hydrogen and ammonia, will be an important way of achieving zero emissions in waterway transportation. Hydrogen, as a clean energy, can achieve a highly efficient power generation through fuel cells without CO2 emissions, and is expected to play a vital role in the process of reducing carbon emissions in waterway transportation. According to the Roadmap for Carbon Neutralization of China’s Energy System issued by the International Energy Agency, the reduction of the shipping industry’s carbon emissions mainly depends on the development and commercialization of novel low-carbon technologies and fuels, such as hydrogen and ammonia. According to target commitments, the application of hydrogen energy based on fuel cells will satisfy approximately 10% of the energy demands of waterway transportation in 2060 [2]. The application of hydrogen energy has shown great potential in the environmentally friendly shipping market as it can satisfy the industry’s requirements of high energy utilization efficiency, zero emissions, and improved comfort of ships [3].

Developed countries have established hydrogen energy strategies and plans for hydrogen-related industries. They have also developed the cutting-edge core technologies of hydrogen energy and fuel cells and launched several demonstration projects including hydrogen-powered ships [4–7]. Novel hydrogen-powered ships have also been the subject of research [6,8,9]. China is working on the application of hydrogen energy in transportation to achieve its carbon peaking and carbon neutralization goals. Hydrogen-powered ships have been developed in several enterprises and institutions based on the progress of domestic hydrogen energy and fuel cell technologies. However, the entire development process is still at an early stage and it is necessary to improve and optimize the top-level design of China’s hydrogen energy strategy to provide scientific guidance for the development of hydrogen-powered ships. Accordingly, considering the development status of hydrogen-powered ships and the situation in related industries, this work focuses on an analysis of the technical and economic feasibility of hydrogen as an energy source and key points in the industrial chain. Consequently, the major objectives, tasks and pathways of the development of hydrogen-powered ship are proposed to provide references to the high-quality development of hydrogen-powered ships in China.

《2 Current development status and industrial arrangement of hydrogen-powered ships》

2 Current development status and industrial arrangement of hydrogen-powered ships

《2.1 Current status of hydrogen-powered ships》

2.1 Current status of hydrogen-powered ships

2.1.1 Hydrogen-powered ships

Hydrogen-based fuel is an effective solution for reducing carbon emissions in the shipping industry, and its application will gradually expand with the development of fuel application technology and the improvement of supporting facilities. Hydrogen-powered ships are usually used in transportation in lakes, inland rivers and offshore, and include passenger ships, ferries, inland cargo ships, and tugboats. The development of large hydrogen-powered ships, such as offshore engineering ships, offshore roll-on/roll-off ships, and super yachts, is a current global trend, and the potential use of hydrogen fuel cell power systems for submarines is also being considered.

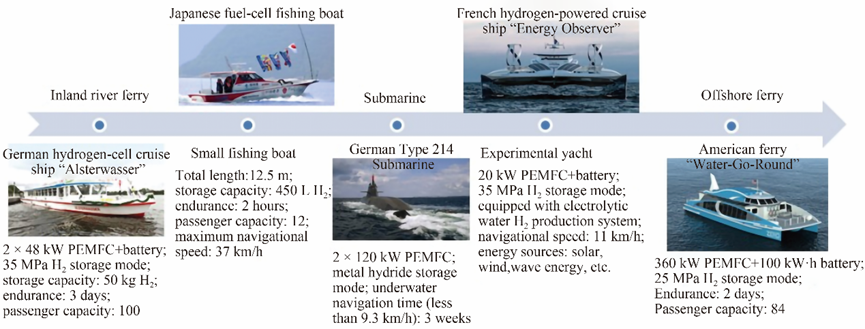

Currently, a hydrogen fuel cell is suitable for many inland river ships, and can be used as both the main propulsion power of small ships and the auxiliary power of large ships. A proton exchange membrane fuel cell (PEMFC) is the major type of hydrogen fuel cell, and its output power level is far less than that of conventional diesel engines. Developed countries have successfully developed and prototyped various types of hydrogen-powered ships, such as the German cruise ship “Alsterwasser” [4], a fuel cell powered Japanese fishing boat, the French cruise ship “Energy Observer” [5], the U.S. ferry “Water-Go-Round” [6], and the Korean hydrogen-powered cruise ship “Gold Green Hygen” [7]. Further research into and applications of hydrogen-powered ships are in progress, such as Norway’s “Ulstein SX190” offshore engineering ship [6], the Topeka roll-on/roll-off ship [8], and Italy’s “ZEUS” testing ship [9] (Fig.1). Besides fuel cells, the hydrogen fueled internal combustion engine (ICE) is also an important method for the application of hydrogen in ships, and has been used in the tugboat “Hydrotug” and the ferry boat “Hydro Bingo” developed by Belgium and Japan, respectively. Japanese enterprises (such as Kawasaki Heavy Industries Co., Ltd. and Yanmar Co., Ltd.) are developing hydrogen ICEs consisting of medium-speed four-stroke engines, medium-high speed four-stroke engines, and low-speed two-stroke engines.

China has also developed hydrogen-powered prototype ships, namely “Fuyuan No.1” and “Tianxiang No.1” (Fig. 1); however, the ships’ size and power output are small. Owing to the vigorous development of a vehicle industry using new types of energy on land, the hydrogen energy and fuel cell technologies are rapidly developing, providing a good opportunity for the development of hydrogen-powered ships in China. The “Lihu” yacht and “Xianhu No.1” cruise ship that launched in 2021 were equipped with a fuel cell power of 70 kW and 30 kW, respectively. Furthermore, the “Green Pearl River” inland cargo ship and the “Three Gorges Hydrogen Boat No.1” official ship, both under development, are powered by fuel cells with an output of 500 kW. However, there is still a gap between domestic types of ships and international advanced products. Moreover, the system integration technology of hydrogen-powered ships in China is not yet fully developed.

《Fig. 1》

(a) Hydrogen-powered ships launched abroad

(b) Hydrogen-powered ships planned abroad

(c) Hydrogen-powered ships in China (part)

Fig. 1. Hydrogen-powered ships at home and abroad

2.1.2 Fuel cell systems

At present, the power output of a single fuel cell system for hydrogen-powered ships is in the 100-kW class, while multiple fuel cell systems are in a cascade connection when installed. For example, the “Alsterwasser” cruise ship is equipped with two sets of a 48 kW PEMFC, the type 214 submarine is equipped with two sets of a 120 kW PEMFC, and the “Green Pearl River” inland cargo ship is planned to be equipped with four sets of a 135 kW PEMFC. Megawatt fuel cell systems, regarded as the key development direction of the future, are the foundation for realizing the wide application of fuel cells on ships. The power output of fuel cell systems for the “Topeka” roll-on/roll-off ship and “Ulstein SX190” offshore engineering ship is 3 MW and 2 MW, respectively. Ballard Power Systems Co. Ltd. has developed a 200-kW marine fuel cell module. The module can be simultaneously used by up to six groups to achieve a 1.2 MW power output. Compared with that of foreign products, the power output level of domestic marine fuel cell systems in China is still behind. In 2021, Wuhan Troowin Power System Technology Co., Ltd. obtained an approval certificate for a marine fuel cell product [10], and the corresponding TWZFCSZ-80 fuel cell device has a rated power of 80 kW. They are also developing marine fuel cell systems with a 200-kW power output.

Storage batteries with a certain capacity are usually used in marine fuel cell systems for peak-load shifting. For example, the “Alsterwasser” cruise ship is equipped with a 201.6 kW·h battery [4], the “Water-Go-Round” ferry is equipped with a 100 kW·h battery [6], and the Dutch “AQUA” yacht has a battery storage capacity of 1.5 MW·h. It is possible to establish a matching system model to optimize the battery configuration by combining the power demands of ships and energy supply characteristics of fuel cells and batteries [11].

2.1.3 Hydrogen storage devices

High-pressure gaseous hydrogen storage methods are widely used in existing hydrogen-powered ships such as the “Alsterwasser” cruise ship, “Water-Go-Round” ferry, and “Lihu” yacht. There are also a few ships that use metal hydride for hydrogen storage, such as the Type 214 submarine and “ZEUS” test ship. Owing to the low hydrogen storage density of high-pressure gaseous hydrogen storage models and the maturity of liquid hydrogen technology, the design of large hydrogen-powered ships in developed countries, such as the “Topeka” roll-on/roll-off ship and “AQUA” yacht, mostly uses a low-temperature liquid hydrogen storage model. The cruising range of a hydrogen-powered ship is closely related to its hydrogen storage capacity. Generally, it is considered that hydrogen-powered ships are only suitable for short-distance journeys owing to the on-board hydrogen storage capacity; for example, the calculated cruise time of the “Alsterwasser” cruise ship and “Water-Go-Round” ferry is 3 days and 2 days, respectively.

The hydrogen refueling technology of hydrogen-powered vehicles is rapidly developing, and this lays a solid foundation for solving the problem of refueling hydrogen-powered ships. During the demonstration voyage of the “Alsterwasser” cruise ship, Germany’s Linde Group built a hydrogen refueling station to provide a continuous hydrogen supply for the hydrogen-powered ship. The “Ulstein SX190” offshore engineering ship is equipped with replaceable hydrogen storage modules, which can supply hydrogen energy by changing modules, thereby providing a new method for the fuel supply of hydrogen-powered ships. In China, the marine hydrogen storage technology is mainly based on high-pressure hydrogen storage. However, the development of a hydrogen storage technology with a higher energy density is in progress.

《2.2 Development of the hydrogen ship industry chain》

2.2 Development of the hydrogen ship industry chain

A ship industry chain includes upstream links (e.g., raw materials and supporting facilities), midstream links (e.g., ship assembly and manufacturing), and downstream links (e.g., ship services).

2.2.1 Upstream links

The upstream links of the shipping industry include the supply of raw materials and spare parts. The research and development (R&D) of marine fuel cell technologies in foreign countries have been in progress for some time. Ballard Power System Co., Ltd. and Toyota Motor Co., Ltd. took the lead in launching marine power systems, which have certain advantages in the value chain of the shipping industry, especially in the high-power fuel cell technology of ships, including hydrogen equipment development, hull design and construction, operations management, and hydrogen fuel supply.

The performance of the proton exchange membrane (PEM) produced by Chinese enterprises could satisfy commercial requirements and has the capacity to supply a large amount of energy. China also has the capacity for the research and preparation of catalysts on an industrial scale, which can promote the industrial application of membrane electrode products in vehicles. The marine fuel cell system independently developed by Wuhan Zhongyu Power System Technology Co., Ltd. and the 30 MPa marine hydrogen storage cylinder produced by CIMC Anruike Holdings Co., Ltd. have been exported, all of which indicate that the domestic hydrogen energy and fuel cell industry has a good development status. Nonetheless, there is still a large gap between China's ship-related supporting technology and advanced international level, and the situation where some core supporting equipment depends on imports should be improved.

2.2.2 Midstream links

Various major companies in the shipping industry or working with fuel cell systems in the United States (US), European Union (EU), Japan, and South Korea are participating in the R&D of hydrogen-powered ships, and the applicability of their products is well known.

According to some important indicators, certain ship-building enterprises in China could be ranked amongst the world’s largest shipbuilding companies; however, there is still a gap in the country’s development and design of new and high-end ships compared with those considered to be world-class. China’s hydrogen-powered ships are still in the initial stage of R&D. The launched “Lihu” and “Xianhu No.1” ships are quite small and the output power of their PEMFC systems is only tens of kilowatts. The 500-kW class “Green Pearl River” and “Three Gorges Hydrogen Boat No.1” hydrogen-powered ships are in the development stage and yet to be demonstrated and applied.

2.2.3 Downstream links

In the US and the EU, resource-based or comprehensive ports are actively involved in the transformation toward hydrogen energy ports. For example, the Long Beach Port and Los Angeles Port in the US have tested hydrogen fuel cell trailers and logistics vehicles. Furthermore, the Valencia Port in Spain has demonstrated the applicability of hydrogen-powered reach stackers through its H2Ports pilot project.

Focusing on the carbon peaking and carbon neutralization goals, some of China’s ports are demonstrating the applicability of hydrogen energy to promote their environmentally friendly development. For example, Qingdao Port has applied hydrogen-powered automatic rail cranes with the goal of building China’s hydrogen port. Furthermore, the Chuanshan Port Area of Ningbo-Zhoushan Port is demonstrating the multi-energy integration of wind, light, storage, and hydrogen, providing a stable hydrogen source for the hydrogen load in the port area (including hydrogen power trucks and forklifts), for hydrogen production with electricity generated from the renewable resources of wind and light or from the electrolyzation of water, so as to improve the energy self-consistency rate and reduce carbon dioxide emissions.

《2.3 Coordinated development strategy of the hydrogen ship industry chain》

2.3 Coordinated development strategy of the hydrogen ship industry chain

2.3.1 Upstream links

In recent years, the EU, Japan, the US, and Canada have successively established hydrogen energy development strategies or road maps. China’s Medium- and Long-Term Plan for the Development of the Hydrogen Energy Industry (2021–2035) defines the strategic positioning of hydrogen energy development. Therefore, the development of hydrogen energy has become the aim of many countries. The popularization and large-scale application of hydrogen energy should thus be conducted in the field of transportation.

Under policy guidance and support, China’s hydrogen energy and fuel cell industry has developed rapidly. By the end of 2021, the number of hydrogen fuel cell vehicles was about 8938 in China, and it is expected to maintain a rapid growth trend in the future. Since there is no obvious difference between hydrogen-powered vehicles and hydrogen-powered ships in the upstream link, in the early stage, the development of hydrogen-powered ships can adopt a development model that uses the basic research and key components of a vehicle-based fuel cell. However, the differences between the two types of hydrogen-fuel based transportation products should be evaluated during the application process. Meanwhile, according to the power demands of ships, there is a need to focus on the development of high-power-output fuel cell systems. Considering the energy demands of a ship’s cruising range, the focus should be on developing a large-capacity hydrogen storage device.

2.3.2 Midstream links

At present, many places in China have begun to develop new energy ships, including battery-powered ships, liquefied natural gas (LNG) ships, and hydrogen-powered ships. To promote the usefulness and popularization of hydrogen-powered ships, the correct positioning of hydrogen-powered ships and the top-level design of their development need to be clarified.

Conventional design and manufacturing enterprises can cooperate with hydrogen energy companies and integrate their strengths with the operations and application of hydrogen-powered ships. For example, the Guangzhou Shipbuilding and Ocean Engineering Design and Research Institute, China Shipbuilding Power Research Institute Co., Ltd., and Guangzhou Shipyard International Co., Ltd. have jointly developed a 500-kW inland hydrogen fuel cell powered cargo ship. The ship has obtained the Certificate of Approval in Principle issued by the China Classification Society. Meanwhile, the China Classification Society also needs to improve standards and guidelines about hydrogen-powered ships to provide key support for their high-quality development.

2.3.3 Downstream links

The development and application of hydrogen-powered ships will go through a process from a demonstration of their application to expanded deployment and then to commercial application. It is expected that the application of hydrogen-powered ships will still be limited before 2030. At present, the hydrogen energy infrastructure related to waterway transportation in China is fairly basic. From the perspective of developmental efficiency, we should take advantage of the rapid development of hydrogen fuel cell vehicles on land, consider the layout and planning of the hydrogen energy infrastructure for land transportation and waterway transportation as a whole, and promote the layout of hydrogen refueling stations in ports and docks in advance, so as to promote the efficient development of hydrogen-powered ships.

Based on the platform of integrated hydrogen production and refueling stations both on land and offshore, together with the pure hydrogen transportation pipe networks, it is possible to solve three major issues: the large amount of hydrogen refueling; the large usage of land; and the disturbance of a port’s normal operations. The solution to logistical and industrial energy problems by the use of hydrogen energy should solve the issues of port logistics, loading-unloading equipment, and shipping applications. It is important to plan in advance the coordinated development with the internal ports’ shore power, offshore wind power generation, and inland transportation system.

《3 Technical and economic feasibility of hydrogen-powered ships’ development》

3 Technical and economic feasibility of hydrogen-powered ships’ development

《3.1 Hydrogen and ammonia fuels》

3.1 Hydrogen and ammonia fuels

Hydrogen production technologies are divided into hydrogen production using fossil fuels, industrial by-products, and electrolysis of water [12–14]. Although hydrogen production from fossil fuels will finally transit to hydrogen production from renewable energies by the use of water electrolysis, it will still play an important role for a certain period. Using renewable energies to achieve a low-cost and highly efficient hydrogen production is the future development direction of large-scale hydrogen production, and it is also a key aspect supported by various countries in the field of hydrogen energy. At present, the cost of green hydrogen is still high (approximately 32.2 CNY/kg), out of which the cost of renewable energy power and electrolyzing accounts for 90%. Therefore, the key to controlling the cost of green hydrogen is to reduce the price of renewable energies and the cost of electrolyzing. In the future, the cost of green hydrogen in China is expected to be reduced to 14.7 CNY/kg, 10 CNY/kg, and 8 CNY/kg in 2030, 2040, and 2050, respectively, by reducing the power generation cost of renewable energies, improving the technical level of electrolyzers, and promoting cost reduction through large-scale applications [13], which will gradually provide economic feasibility for the large-scale application of hydrogen-powered ships.

Ammonia is another kind of zero-carbon fuel with application prospects, and it can also be used as a hydrogen storage carrier. It has advantages when applied to ships because of its high energy density, low production cost, storage and transportation feasibility, and ideal industrial fundamentals [15]. China’s ammonia synthesis technology and industry are well developed. At present, ammonia is mainly produced by fossil fuels, and the cost is low (approximately 4000 CNY/t) [16]. The Roadmap for Carbon Neutralization of China’s Energy System predicts that China’s ammonia production will increase from 5.4×107 t in 2020 to 8×107 t in 2060. Approximately 2/3 of ammonia fuel will be used in the shipping industry in 2060, satisfying at least 40% of the energy demands of the water transportation industry. The cost of hydrogen production by water electrolysis from renewable sources is high, so it is important to control the cost of green ammonia production by reducing the cost of hydrogen production from renewable sources. It is estimated that the cost of hydrogen production by water electrolysis from renewable sources in China will be reduced by over 70% from 2020 to 2060.

《3.2 Hydrogen fuel cells》

3.2 Hydrogen fuel cells

Since 2010, the cost of hydrogen fuel cells has decreased by approximately 60% [17]. According to the target set in the White Paper on China’s Hydrogen Energy and Fuel Cell Industry (2019 Edition), the cost of a fuel cell system will be reduced from 8000 CNY/kW in 2019 to 4000 CNY/kW in 2025, 800 CNY/kW in 2035, and 300 CNY/kW in 2050 [18]. Furthermore, the cost of a single 500 kW marine fuel cell system could be reduced to about 150 000 CNY in 2050.

With the vigorous development of China’s hydrogen energy industry, the stack power, minimum start-up temperature, life span, and other indicators of domestic fuel cells have been greatly improved, and the degree of autonomy has been continuously improved. The cost of a fuel cell stack accounts for approximately 65% of the fuel cell system. There is still room for further cost reductions, which may reach 85% in the medium and long term [17]. China’s enterprises are working hard on the development of key components of fuel cells such as bipolar plates, membrane electrodes, air compressors, and hydrogen circulating pumps. For example, in the fuel cell stack produced by Shanghai Hydrogen Propulsion Technology Co., Ltd., all 58 first-class core components are manufactured in China. The metal bipolar plates with a new noble metal coating and an optimized structure have further improved the fuel cell efficiency and reduced the manufacturing cost [13]. In 2020, the cost of a fuel cell stack showed a significant downward trend (3000–4000 CNY/kW), and even the quotation for some products dropped to 2000 CNY/kW [13]. Nevertheless, the reliability and durability of hydrogen fuel cell stacks and systems are the key to its commercial application, and therefore still need to be continuously optimized and upgraded [19].

《3.3 Hydrogen ICE》

3.3 Hydrogen ICE

The effective thermal efficiency of the existing hydrogen ICE is 35%–45% [20], while the efficiency of the PEMFC system is 50%–60%. Although the efficiency of the hydrogen ICE is low, its power output can reach a very high value (currently in the MW class) and be used in tugboats and ferries [6]. The cost of a hydrogen ICE is obviously lower than the PEMFC system. Taking a 100-kW power plant as an example, the cost of the hydrogen ICE based on the current technology is only 50% of the PEMFC system [21]. It can be predicted that with the development of the ship’s hydrogen storage technology and the improvement of the hydrogen energy infrastructure, hydrogen ICEs will be widely used in ships.

《3.4 Infrastructure of hydrogen energy》

3.4 Infrastructure of hydrogen energy

In China, the existing hydrogen refueling technologies and infrastructures are mainly used in vehicles, and there is almost no application in ships. The major hydrogen refueling stations are on the scale of 500 kg/d and 1000 kg/d, and the corresponding construction costs are 12–15 million CNY and 20–25 million CNY, respectively (without land costs), of which the equipment and civil construction costs account for over 70% [16]. The compressor, hydrogen storage tank (divided into a high-pressure hydrogen storage tank and liquid hydrogen storage tank), and hydrogen refueling machine are the main pieces of equipment of a hydrogen refueling station [17]. In terms of hydrogen compressors, diaphragm compressors and liquid-driven compressors could be manufactured in China, and they are expected to dominate the domestic market gradually in the future. However, the ionic compressors need to be further developed. Hydrogen storage devices in hydrogen refueling stations already have a certain domestic foundation. For example, the 45 MPa large-volume seamless steel hydrogen storage cylinder produced by CIMC Enric Holdings Co., Ltd. could be exported [16]. Moreover, the design scheme and small-scale production of a 300 m3 large liquid hydrogen storage tank has been completed [17]. The 35 MPa hydrogen refueling machine could be made in China; however, its core components such as the hydrogen refueling gun, flowmeters, and valves still rely on imports. Domestic enterprises have mastered the technologies of 70 MPa hydrogen refueling, but the application still lags behind that of foreign countries [16].

In the early stage of hydrogen-powered ship development, it is advisable to accumulate infrastructure-related technologies with the help of hydrogen-powered vehicles. It is sensible to gradually develop the application of hydrogen energy in the shipping industry and match the exclusive application requirements of hydrogen-powered ships with improvements in technology and equipment.

《3.5 Total cost of ownership of ships》

3.5 Total cost of ownership of ships

The total cost of ownership (TCO) of ships includes construction and operational costs. The construction costs include the cost of the main propulsion power system, auxiliary propulsion power system, fuel storage tank, the hull, and other parts. The operational costs consist of fuel, maintenance, loss of space, staff salaries, and warranty costs. Since hydrogen-powered ships are still in the stage of development and small-scale application, the relevant TCO analysis is still insufficient. The TCO analysis of a 15 000 Twenty-Foot Equipment Unit ammonia- and hydrogen-powered container ship shows that if one 51 MW ammonia-fueled engine is used as the main propulsion power, while two 4 MW and 2 MW hydrogen fuel cell systems are used as the auxiliary power, the TCO is about twice that of a conventional fuel ship under the same conditions. Fuel costs are an important parameter that affects the economic performance of ammonia- and hydrogen-powered ships [22].

《4 Analysis of the key links in the hydrogen ship industry chain》

4 Analysis of the key links in the hydrogen ship industry chain

《4.1 Efficient and low-carbon hydrogen production technology》

4.1 Efficient and low-carbon hydrogen production technology

At present, hydrogen is mainly generated from fossil fuels, which accounts for about 95% of the world’s hydrogen production; however, the production process emits CO2. Hydrogen production by water electrolysis at the grid scale using electricity from renewable energy causes zero carbon emissions, but it accounts for only about 4%-5% of the world’s hydrogen production. Additionally, the carbon capture, utilization and storage (CCUS) technology can be applied to the conventional process of hydrogen production from fossil fuels to reduce carbon emissions. However, having considered the state of existing technologies and infrastructures, it is expected that there will be no significant breakthrough in hydrogen production technologies from fossil fuels based on CCUS technology before 2030 [2]. Therefore, hydrogen production by water electrolysis based on renewable energy is the future development trend of hydrogen production.

The hydrogen production technologies from water electrolysis can be divided into alkaline water electrolysis, PEM water electrolysis, and solid oxide water electrolysis. Both alkaline water electrolysis and PEM water electrolysis are currently practical technologies [23]. The former has been industrialized in China, and the productivity of domestic equipment has reached 1000 Nm3/h [24], while the latter is in the early stages of moving from R&D to industrial application. In recent years, the installed capacity of water-electrolysis based hydrogen production equipment in China has increased significantly. In 2020, the installed capacity was 18 MW, accounting for about 1/4 of the world’s increment. To achieve the carbon peaking and carbon neutralization goals, with the improvements in technology and the supporting manufacturing industry, the installed capacity of China’s water-electrolysis-based hydrogen production equipment will reach 25 GW and 750 GW, respectively in 2030 and 2060, accounting for 15% and 40% of the world’s total capacity [2].

《4.2 Large-scale low-cost hydrogen transportation technology》

4.2 Large-scale low-cost hydrogen transportation technology

The ways to realize large-scale hydrogen transportation mainly include the high-pressure long-tube gas hydrogen trailer, low-temperature liquid hydrogen tanker, and hydrogen pipeline. The technology of the high-pressure long-tube gas hydrogen trailer is mature, and it is suitable for users travelling a short distance, with a low transportation capacity and a ton-class daily hydrogen consumption. The method is comparable with the current developmental scale of the hydrogen energy industry. The working pressure of hydrogen cylinders on a domestic long-tube trailer is mostly 20 MPa, and the TT11-2140-H2-20-I type container bundle can be filled with about 347 kg of hydrogen each time. A high-pressure long-tube gas hydrogen trailer is suitable for transportation within 200 km, and the transportation cost for this distance is about 7.72–8.82 yuan/kg [16].

A low-temperature liquid hydrogen tanker has a large hydrogen transportation capacity (over 10 times that of a high-pressure long-tube gas hydrogen trailer), and the transportation cost for a journey of over 200 km is only 1/5–1/8 of that of a high-pressure long-tube gas hydrogen trailer [16]. However, the energy consumption of hydrogen liquefaction is high, e.g., the compression cost of a 20 MPa high-pressure gas hydrogen is about 2 CNY/kg, while the liquefaction cost of a large-scale hydrogen liquefaction device is about 12.5 CNY/kg [17]. In addition, the initial investment cost of hydrogen liquefaction equipment cannot be ignored. After solving the issues of cost and efficiency, a liquid hydrogen tanker will have good application prospects in the field of medium- and long-distance hydrogen transportation. More recently, liquid hydrogen transportation ships, such as the Japanese “Suiso Frontier” ship, have received widespread attention and may become a new mode of transport.

Pipelines for gaseous hydrogen transportation can be categorized into pipelines for pure hydrogen transportation and pipelines for a mixture of natural gas and hydrogen. Pipeline transportation is suitable for large-scale and long-distance hydrogen transportation, but the initial investment is quite large. When the hydrogen storage and transportation facilities are not well prepared, the transportation of hydrogen and natural gas mixtures using natural gas pipelines is a techno-economic effective method for large-scale hydrogen transportation. When the hydrogen content in the mixture is about 15%, only minor modifications of the original natural gas pipeline are needed [25], mainly involving the compatibility of natural gas transportation pipelines with hydrogen, hydrogen leakage and detection, and hydrogen separation in terminal sites. With the expansion of the hydrogen energy industry’s scale and the increase in application demand, hydrogen transportation via pipelines will become a preferred way for hydrogen transportation owing to its scale advantages.

《4.3 Large-capacity hydrogen storage technology for ships》

4.3 Large-capacity hydrogen storage technology for ships

The development of hydrogen storage technology shows a trend from low to high hydrogen storage density. The high-density hydrogen storage technology is still developing, and the technical route is still under investigation, including ultra-high-pressure gaseous hydrogen storage [7], liquefied hydrogen storage [26], metal hydride hydrogen storage [9,27], and liquid organic hydrogen storage [28].

High-pressure hydrogen storage is currently a suitable method for ships. There are two kinds of hydrogen storage cylinders, 35 MPa and 70 MPa, with the corresponding volumetric hydrogen storage densities being 25 g/L and 41 g/L, respectively [16]. The 70 MPa high-pressure hydrogen storage technology is basically mature and has been commercialized in foreign countries. For example, the hydrogen fuel cell vehicle from Toyota Mirai is equipped with a 70 MPa hydrogen storage cylinder. The technical standard of a 35 MPa high-pressure hydrogen storage cylinder in China has been established, and the cylinder is widely used in domestic hydrogen fuel cell vehicles. China is also working on the development of a 70 MPa high-pressure gas cylinder, and its progress is approaching the stage of commercial application. Therefore, China’s hydrogen-powered ships, such as the “Green Pearl River” inland cargo ship, have adopted the hydrogen storage mode of 35 MPa high-pressure gas cylinders. The hydrogen storage will be switched to higher specifications with any technical upgrade.

The density of liquid hydrogen is 70.8 g/L, which has apparent advantages over high-pressure hydrogen storage in terms of storage density. With the rapid development of the hydrogen energy industry, low-temperature liquid hydrogen storage will gradually expand to the field of civil application and is expected to become the major hydrogen storage method in the future. Considering that the storage density of the existing high-pressure hydrogen storage technology was too low to meet the future requirements of a ship’s cruising distance, on-board hydrogen storage will develop toward the direction of a higher energy density. For example, the “Topeka” roll-on/roll-off ship and the “AQUA” concept yacht plan to use low-temperature liquid hydrogen storage technology. Metal-hydride-based hydrogen storage has the advantages of a high bulk density, low pressure, and high safety, thereby demonstrating good application prospects in submarines. Nonetheless, the promotion and application processes need to focus on solving the issues of high cost, dehydrogenation temperature, and reaction rate.

Theoretically, the hydrogen storage density of ammonia is about 17.6%, and the volumetric hydrogen storage density of liquid ammonia is 1.5 times that of liquid hydrogen. The mature technologies of ammonia liquefaction, storage, and transportation make ammonia (as a hydrogen carrier) the ideal hydrogen storage method, showing great potential for large-capacity hydrogen storage. The cracking and decomposition of ammonia are key issues to be solved in a hydrogen storage system that uses ammonia as a hydrogen carrier. The development of high-activity and low-cost catalysts which could be operated at a low pressure and temperature should be the focus of future research [16]. Methanol also has a high hydrogen storage density, and its hydrogen content can reach 12.5%. It can be used as a carrier of green hydrogen to achieve efficient storage and transportation requirements. When the transportation distance is greater than 200 km, it has cost advantages over direct hydrogen transportation [16]. Considering that hydrogen production from methanol will produce a byproduct of CO, a hydrogen purification device should be used to avoid the poisoning of the PEMFC catalyst.

《4.4 Rapid and safe hydrogen refueling technology》

4.4 Rapid and safe hydrogen refueling technology

The existing hydrogen-powered ships have various hydrogen storage methods, and the corresponding hydrogen refueling methods and time taken are quite different. In the demonstration project of the “Alsterwasser” cruise ship, Linde Group established a hydrogen refueling station at the wharf to provide a persistent hydrogen source for the ship. The ship can store up to 50 kg hydrogen on board, and it takes about 12 minutes for a single hydrogen refueling process. Germany’s 212A submarine uses the metal hydride-based hydrogen storage method, and it takes 10 hours and 25 hours to complete 80% and 100% of hydrogen refueling, respectively. Since the technologies of high-pressure gaseous hydrogen storage and hydrogen refueling for land vehicles are well developed, it is feasible to adopt the vehicles’ method in the early stage of the development of hydrogen-powered ships.

Compared with vehicle hydrogen refueling, ship hydrogen refueling has the characteristics of a large refueling amount and long duration time. The refueling equipment should adopt a more reliable refueling connection mode and have the function of an emergency cut-off between the ship and on shore equipment in case of an accidental disconnection. Generally, a power failure when refueling at the wharf is not allowed. Therefore, it is of great importance to guarantee the normal operation (power supply) of the fuel cell system during hydrogen refueling and the requirements of synchronous operations such as loading and unloading, as well as the safety of the hydrogen refueling operation.

《4.5 Marine high-power fuel cell technology》

4.5 Marine high-power fuel cell technology

Marine fuel cell technology displays a development trend from low to high power output. Fuel cells are mainly divided into low-temperature fuel cells represented by PEMFC and high-temperature fuel cells represented by molten carbonate fuel cells and solid oxide fuel cells (SOFCs). The former technology is undergoing industrialization and large-scale development, with the aim of lower costs, a longer service lifetime, and higher power. The latter technology is more suitable for application in ships because of its technical advantages of high power, high efficiency, and low requirements for hydrogen purity. It is also the future development direction of large ships.

The power output demand of ships is related to the ship’s type and operating conditions. The power demands of different ship types are shown in Table 1 [29]. PEMFC systems can be used as the main propulsion power of small ships or the auxiliary power of large ships. In the current hydrogen-powered ship demonstration projects, the output power of the PEMFC system is basically in the 100-kW class. To expand the application scenarios of hydrogen-powered ships, the output power of the PEMFC system should be increased to the megawatt class in the future. This is a key technology that urgently needs to be developed for marine fuel cells.

《Table 1》

Table 1. Power demands of different ships (unit: kW)

| Ship types | Electricity source | Propeller type | |

| Slow | Fast | ||

| Small yachts and ships | – | 1–100 | – |

| Civil ships | 100–2000 | 500–1000 | 50 000 |

| Submarine and naval ships | 500–2000 | 1000–2000 | 50 000 |

《4.6 Marine hydrogen ICE technology》

4.6 Marine hydrogen ICE technology

The flame from hydrogen combustion spreads rapidly and releases intense heat. Thus, compared with conventional ICEs, the hydrogen ICE has a higher thermal efficiency. The thermal efficiency of conventional ICEs is about 30%–40%, while the efficiency of hydrogen ICEs developed by German enterprises could be up to 42%. The thermal efficiency of hydrogen ICEs being developed in China is expected to reach 44% [16]. It is worth noting that although hydrogen ICEs have the advantages of a high output power, high thermal efficiency, high energy conservation, and being environmentally friendly, there are drawbacks such as deflagration, early combustion, and tempering. The use of hydrogen ICEs will also generate NOx. Therefore, improving the performance of the propulsion system and reducing NOx emissions are key points for the future research of hydrogen ICEs to consider.

Compared with a PEMFC system, a hydrogen ICE has the advantage of output power. After overcoming the relevant technical drawbacks, it will be widely used in the shipping industry. In 2017, the Belgium Maritime Group launched the world’s first diesel-hydrogen dual-fuel passenger ship equipped with a Behydro engine. The Behydro engine has a power output of 1000–2670 kW [6]. At present, China’s hydrogen ICE technology is mainly used in the automotive field but little research into its marine application has been carried out. Thus, there are still large gaps between China and developed countries with regard to the hydrogen ICE.

《4.7 Collaborative control technology of multi-energy sources for ships》

4.7 Collaborative control technology of multi-energy sources for ships

Conventional ships mainly use marine diesel engines with light/heavy diesel, while some use diesel generators for their electric propulsion systems. The energy structure is relatively simple. The diversification of a ship’s energy supply sources is a future development trend. For example, the “Energy Observer” yacht is equipped with a solar photovoltaic power generation system, wind power generation system, lithium battery system, seawater desalination system, PEM water electrolysis system for hydrogen production, and PEMFC system. In the design scheme of the Japanese cruise “NYK Super Eco Ship,” the power system will use LNG fuel cells, solar cells, and wind power [29].

With the diversification of a ship’s energy supply sources, the collaborative control technology between various energy supply systems is becoming increasingly important. In the future, the power system of hydrogen-powered ships will include fuel cells, batteries (or super capacitors), converters, and propulsion motors. It is necessary to employ multi energy collaborative control technology to optimize the matching and collaborative control between various power systems to ensure the safety, reliability, and economic efficiency of the power system [30].

《4.8 Safety technology for hydrogen application in ships》

4.8 Safety technology for hydrogen application in ships

The navigation environment of ships is complex and could be significantly affected by meteorological and hydrological factors, waterways and other aspects. A ship’s system is relatively isolated. Thus, in case of an accident, people are unlikely to escape in time and need to wait to be rescued. Therefore, a high level of safety is required in ships. In the promotion and application of hydrogen energy and fuel cells, it is necessary to limit the possibilities of fire, explosions, and other risks related to fuel to a very low level to ensure that relevant devices have the same safety level as conventional main/auxiliary engines based on fossil fuels. Accordingly, the existing safety regulations and emergency measures related to hydrogen-powered ships need to be further improved [3]. Safety technology in hydrogen applications is the basis for the safe operation of hydrogen-powered ships, as it is an effective way to establish measures for relevant risks based on the numerical simulation results of the leakage and diffusion of hydrogen [31].

《4.9 Standards and specifications for hydrogen-powered ships》

4.9 Standards and specifications for hydrogen-powered ships

The technical standards of hydrogen energy and fuel cell onshore transportation are basically mature, and China has issued 91 relevant technical standards. However, there are very few standards and specifications for hydrogen-powered ships. The relevant fuel cell systems and hydrogen storage and refueling systems for hydrogen-powered ships mainly follow the onshore standards. The International Maritime Organization is preparing the technical specification for the International Safety Code for Ships Using Gas or Other Low Flash Point Fuels to include the fuel cell system for ship applications, but the fuel storage and supply system are currently not considered. The problems in the technical standards of hydrogen-powered ships lie in the lack of specifications, regulations, operating procedures, and safety research. For example, the marine hydrogen refueling standards (including the liquid hydrogen refueling and metal hydride refueling technology for ships), the on-board standards of 70 MPa hydrogen storage cylinders, and the standards of hydrogen production by reforming on ships are all missing.

Owing to the rapidly increasing demand for hydrogen-powered ships, the relevant standards and specifications need to be improved as soon as possible. (1) The specified research and verification of marine fuel cell power systems. The power requirements of ships are large, and the demand for the consistency of fuel cell units, battery management systems, and heat dissipation are higher than that of vehicle systems. (2) The risk assessment of the design scheme of hydrogen fuel cell powered ships and the verification of the specified research on the safeguarding of marine fuel cells and their location. An environment with a high salt spray, high humidity, and strong ship vibration may reduce the reliability and durability of the system. (3) Research on the refueling method, safety operation regulations, and supervision of hydrogen refueling for ships. There are no marine hydrogen refueling facilities in ports or anchorages in China, and the relevant technologies and specifications need to be further studied. (4) Specified research and verification of the marine hydrogen storage and supply systems. It is also important to quickly establish and improve the technical standards of hydrogen fuel cell powered ships.

《5 Goals and pathways of the development of hydrogen-powered ships in China》

5 Goals and pathways of the development of hydrogen-powered ships in China

《5.1 Development goals of hydrogen-powered ships in China》

5.1 Development goals of hydrogen-powered ships in China

China and the rest of the world are working hard on reducing carbon emissions in the shipping industry to fulfill the goal of carbon peaking and carbon neutralization. China will try to develop hydrogen-powered ships and fully promote the construction of the infrastructure for terminal applications of hydrogen energy in waterway transportation. The energy structure of waterway transportation equipment will be improved to support the transformation to clean energy. To strengthen China’s transportation and manufacturing sectors, China will promote the upgrading of the conventional shipbuilding industry and set up a series of new ship design and research institutes and enterprises, all of which will lead to the high-quality development of the shipbuilding industry. China will also prioritize the R&D of key core technologies such as high-power fuel cells, high-capacity hydrogen storage, rapid hydrogen refueling, collaborative control of multi-energy systems, and the safe use of hydrogen. The establishment of standards and specifications for hydrogen-powered ships, the improvement of hydrogen energy supporting facilities, and the prototyping and application of various types of hydrogen-powered ships will also be carried out.

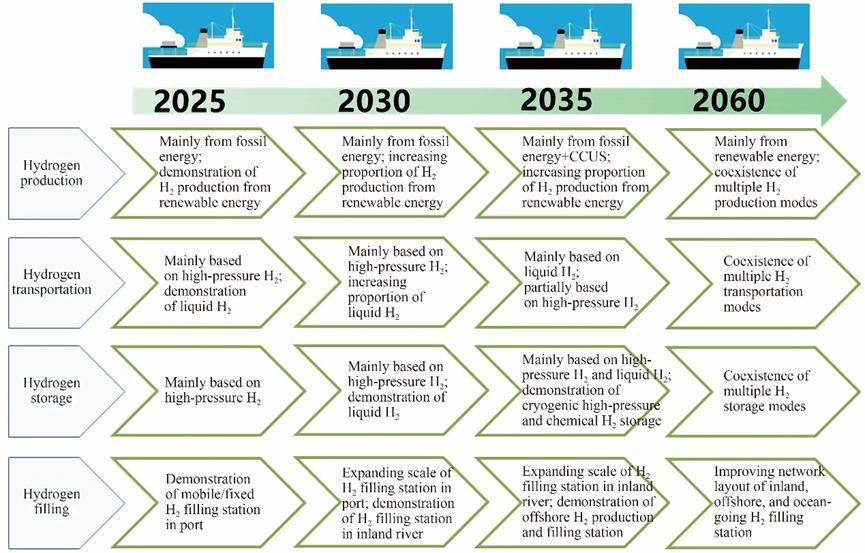

The period from now to 2025 will be the technology development stage. Guided by the technical progress of fuel cell vehicles, China will focus on key technologies, such as marine hydrogen fuel cells, and establish the standards and specifications of hydrogen-powered ships. China will also complete the R&D of hydrogen-powered ships’ equipment and realize the applicability of hydrogen-powered ships in inland rivers/lakes and other areas.

The period from 2025 to 2030 will be the industry improvement stage. China will create a system consisting of the design of hydrogen-powered ships, manufacturing, commissioning, testing, functional verification, and performance evaluation. The infrastructure for the production, storage, and transportation of hydrogen will also be established. The scale of the applicability of hydrogen-powered ships in inland rivers/lakes and other areas will be expanded, and the infrastructure related to waterway transportation will be further improved.

The period from 2030 to 2035 will be the quality improvement stage. China will aim to reduce the cost of fuel cells and hydrogen, and improve the service lifetime, conversion efficiency, and hydrogen storage capacity of the marine hydrogen fuel cell system. High-temperature fuel cell and waste heat utilization technology will be developed. A complete technology and industrial system of waterway transportation equipment will be created, and demonstrations of hydrogen-powered ships in offshore areas will be carried out.

The period from 2035 to 2060 will be the promotion and application stage. China will optimize the comprehensive performance of hydrogen-powered ships and promote their local commercial applications. By cooperating with ships with green ammonia, carbon neutralized LNG/methanol, and other power forms, China will achieve the goal of carbon neutrality in the field of waterway transportation equipment. The applicability of hydrogen-powered ships on international routes will be conducted to enhance the international competitiveness of China’s hydrogen-powered ship industry.

《5.2 Pathways of hydrogen-powered ships in China》

5.2 Pathways of hydrogen-powered ships in China

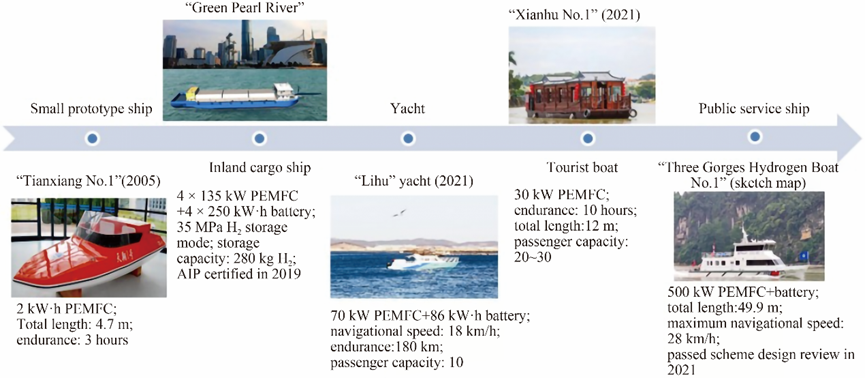

5.2.1 The general roadmap of hydrogen-powered ships for carbon neutralization

LNG ships have a good potential and will be the main form of clean energy utilization for ships in the near future. Battery technology is currently the solution to achieve zero emissions from inland and offshore ships. However, the energy density of storage batteries is limited, and they are mainly used in short-range and small ships, while their application in the field of medium- and short-distance transportation is limited. Hydrogen fuel is the main direction of development to achieve zero emissions from ships, which will be soon studied and applied on inland-river and offshore ships. In terms of hydrogen production, at present, this is mainly generated from fossil fuels, but the proportion from this source will gradually decrease in the future. After the further development of CCUS technology, the carbon emissions from the fossil fuels used in hydrogen generation will become more limited. Thus, hydrogen production from renewable energy will be the main method in the future. In terms of hydrogen storage, to meet the endurance requirements of international transportation, it is necessary to further develop highly efficient hydrogen storage technologies including liquid hydrogen storage, methanol reforming hydrogen production, ammonia decomposition hydrogen production, and other on-site hydrogen production technologies.

The best carrier of hydrogen in applications is a fuel cell. However, owing to the limitations of a low power level and the requirement for a high hydrogen purity, a PEMFC will be mainly used in inland-river and offshore ships. Meanwhile, a high-temperature PEMFC will be further developed. High-temperature fuel cells (such as SOFCs) can utilize hydrogen-rich liquid fuel instead of pure hydrogen. The use of waste heat utilization technology can further improve the system’s thermal efficiency, and the power level may reach the megawatt class. In the long term, this will be a promising method for ocean going ships. A hydrogen ICE is another hydrogen power system. With the development of on-board hydrogen storage technology, this system shows good prospects and will play an important role in achieving the carbon peaking and neutralization goal of waterway transportation.

The development pathways of hydrogen-powered ships are closely related to hydrogen fuel cells, hydrogen ICEs, hydrogen storage, and other technologies, as well as the hydrogen energy infrastructure. The pathway is implemented step by step according to the route from the inland river/lake to the offshore area, and finally to use on an ocean (Table 2). The hydrogen fuel cell powered systems can be firstly used for cruise ships/ferries in lakes and small ships (less than 8000 tons) on inland river trunk lines. The ICE system based on hydrogen, ammonia, methanol, and other fuels can be used for large ships (more than 8000 tons) on inland river trunk lines. Finally, the hybrid power systems can be used for offshore and ocean-going ships.

5.2.2 Construction pathways of the hydrogen fuel supply system

In the near future, hydrogen production from fossil fuels will still play a major role, including hydrogen production from coal, natural gas, and chemical byproducts. Hydrogen production from coal has the advantages of technical maturity, reliability, and a low production cost, which can fully satisfy the needs of hydrogen energy development in terms of production potential. Against the background of clean and low carbon production, the application of CCUS technology will have a more important effect on the hydrogen production route from coal. In the medium term, the proportion of hydrogen production from renewable energy will gradually increase. The production of “blue hydrogen” combined with carbon capture technology will also have a certain role to play. In the long term, hydrogen production through water electrolysis using electricity generated from renewable energy will be an important method (Fig. 2).

《Table 2》

Table 2. Development progress of hydrogen-powered ships.

| Categories | Stages | ||||

| Short term | Medium term | Long term | |||

| Fuel | Hydrogen | Gray hydrogen | Blue hydrogen and green hydrogen | Green hydrogen | |

| Ammonia | Gray ammonia | Blue ammonia and green ammonia | Green ammonia | ||

| Methanol | Methanol | Methanol | Methanol (carbon neutral) | ||

| Power unit | Fuel cell | PEMFC | High-temperature PEMFC/SOFC | High-temperature PEMFC/SOFC | |

| ICE | High thermal efficiency and low NOx emission | High thermal efficiency and low NOx emission | High thermal efficiency and low NOx emission | ||

| Route evolution of hydrogen-powered ships | Inland river/lake | Offshore | Ocean-going | ||

《Fig. 2》

Fig. 2. Construction path of hydrogen fuel supply system for hydrogen-powered ships in China.

Hydrogen transportation methods suitable for large-scale industrial applications mainly include high-pressure long-tube gas hydrogen trailers and low-temperature liquid hydrogen tankers. At present, the storage and transportation of high-pressure gas hydrogen is the main method. This will gradually transit to a low-temperature liquid hydrogen storage and transportation, supplemented by a high-pressure gas hydrogen storage and transportation. In the future, with the wide application and large-scale production of hydrogen, the construction (or transformation) of the hydrogen transportation pipeline network, including pipelines for pure hydrogen transportation and pipelines for the mixture of natural gas and hydrogen, will be the focus of the construction of energy infrastructure.

In the field of inland cruises, the focus is to increase the scope and scale of hydrogen energy utilization. It is important to form a shipping industrial ecosystem for hydrogen energy centered at ports and focused on ships. The ecosystem would support the environmentally friendly development of waterway transportation. It is also important to expand the application of hydrogen energy in ports and explore the mode of supplying hydrogen fuel in transit, which could benefit the promotion of hydrogen-powered ships and improve the hydrogen energy ecological chain of waterway transportation.

Chemical industry parks are concentrated along the rivers in China. Most of the chemical industry would generate byproducts of hydrogen, indicating abundant sources of hydrogen energy. In addition, most of the hydrogen production capacity is close to ports. A port near hydrogen sources can utilize hydrogen energy locally. Meanwhile, long-distance hydrogen energy transportation can be conducted between ports by shipping while reducing the cost of hydrogen transportation by exploiting economies of scale. Hydrogen refueling stations can be built near the existing oil and gas refueling stations. The abundant industrial land and locations far away from cities and towns also mean the construction of the hydrogen refueling stations is likely to be approved. The building of mobile hydrogen refueling stations can also be considered.

Hydrogen production from offshore wind power refers to converting offshore wind power into hydrogen directly through water electrolysis-based hydrogen production equipment. Hydrogen could be then used as an energy carrier to realize the long-term storage of clean energy, which provides the possibility of supplementing hydrogen fuel for hydrogen-powered ships at sea. Developed countries are intensively planning offshore wind power hydrogen production projects. In their roadmaps, the future hub facilities will be composed of hydrogen fuel centers set around offshore wind farms. China’s energy system plan also encourages the construction of offshore wind power bases and promotes the creation of offshore wind farms in deep-water and far away shore areas. There is a certain trend toward carrying out offshore wind power hydrogen production projects, and the offshore green hydrogen production base is expected to become an important part of the hydrogen fuel supply system.

《6 Suggestions for promoting the development of hydrogen-powered ships in China》

6 Suggestions for promoting the development of hydrogen-powered ships in China

《6.1 Clarification of the application scenarios of hydrogen power》

6.1 Clarification of the application scenarios of hydrogen power

In view of the development status and future trend of hydrogen fuel cell power systems, China should learn from the operational experience of hydrogen-powered ships in developed countries. By combining its hydrogen energy strategy and industrial layout, China should clarify the application scenarios of hydrogen-powered ships that adapt to national conditions. The national industrial plan can be established according to the order of development of firstly inland-river/lake ships, then offshore ships, and finally ocean-going ships to promote technology research, the development of equipment, demonstrations, and the construction of infrastructure step by step.

《6.2 Breakthroughs in key technologies》

6.2 Breakthroughs in key technologies

China should pay full attention to the guiding role of its national strategy and integrate both independent innovation and foreign cooperation. It is important to consider the advantages of certain enterprises, research institutions, and universities, and implement innovation plans for hydrogen-powered ships’ equipment with enterprises as the main body. China should also focus on breakthroughs in key technologies in the R&D, demonstration, and promotion of hydrogen-powered ships, such as high-efficiency and low-carbon-emission hydrogen production technology, high-capacity on-board hydrogen storage technology, and high-power-output fuel cell technology. With breakthroughs in key technologies, China would be able to promote the application of hydrogen energy in waterway transportation and reach a world class level as soon as possible. This would also lay a solid foundation for a larger scale demonstration of the application of hydrogen-powered ships.

《6.3 Improvement in related supporting facilities》

6.3 Improvement in related supporting facilities

It is suggested that China heed the trend of increasing energy demands in the transportation sector at the national level to coordinate the comprehensive application of hydrogen energy in land, water, and air transportation. China should also propose specific plans for the fuel supply system and the construction of infrastructure. All regions in China are encouraged to combine their own energy and technological advantages to develop low-cost, less polluting, and highly reliable hydrogen production projects and conduct demonstrations of hydrogen application to accumulate engineering experience. It is important to provide support for the subsequent large-scale construction of hydrogen energy infrastructure.

《6.4 Innovations in system operation》

6.4 Innovations in system operation

As there is a large initial investment and long return cycle in the industrialization and application of hydrogen-powered ships, China should propose supporting policies and funds for any related enterprises. In addition, all kinds of enterprises are encouraged to plan, in advance, for the hydrogen-powered ship market using their own strengths. The development of new operational modes should also be studied through demonstrations. Meanwhile, the downstream links of conventional shipping industries are encouraged to develop, in advance, the detection, maintenance, training, and other practices for hydrogen-powered transportation equipment. Finally, China’s innovative operational system for hydrogen-powered ships must be explored and established within a coordination model along the whole industrial chain.

《Compliance with ethics guidelines》

Compliance with ethics guidelines

The authors declare that they have no conflict of interest or financial conflicts to disclose.

京公网安备 11010502051620号

京公网安备 11010502051620号