Wandering on the shore of the Sandu Bay, looking at the blue ocean and the green mountains, a question comes to mind: How can we meet humans’ energy demand while minimizing its effect on the environment? In other words, how can we ensure a carbon-neutral world in the near future? Many efforts in different dimensions are required to clarify the answer, but one thing is clear: A sustainable and efficient energy-storage system is necessary. The sodium-ion battery (SIB), as a complementary technology to the lithium-ion battery (LIB), is gaining a great deal of attention due to its unique properties, which include a low cost and a green philosophy. Moreover, these exact properties give sodium-ion technology high enough potential to address the issue of carbon neutrality.

The history of sodium (Na) in battery technology can be traced back to the year of 1968, when the Ford group invented a type of high-temperature Na–S cell with Na-β''-Al2O3 as the solid electrolyte [1]. When the so-called ‘‘rocking-chair” LIB was discovered, the SIB, which had the same concept, began to be widely studied at almost the same time. In 1981, Delmas was the first to report the sodiation/re-sodiation behavior of NaCoO2, thereby revealing a layered-oxide material that could be used for the SIB cathode [2]. New materials for SIB cathodes, anodes, and electrolytes have been sufficiently researched during the last 40 years. Scientific research on SIBs is maintaining rapid growth, as an increasing number of researchers commit themselves to this field. Thanks to this research and its rich and outstanding study results, the SIB is finally approaching commercialization.

In recent years, companies and startups from different countries have claimed to be close to achieving SIB commercialization with different technology roadmaps. In the United Kingdom, Faradion published prismatic sodium-ion cells with Ni–Mn–Fe layered oxide as the cathode and hard carbon as the anode [3]. With technology from the Centre National de la Recherche Scientifique (CNRS), the French startup Tiamat published 18 650 cylindrical cells with a Na3V2(PO4)3 cathode and a hard carbon anode, revealing a good rate capability at 10C [4]. In the United States, Novasis worked together with Sharp Lab to focus on a Prussian blue cathode and hard carbon anode technology [5]. Another US startup, Natron Energy, also developed fast-charging sodium-ion technology with symmetric Prussian blue electrodes and a water-based electrolyte [6]. Chinese institutes and companies have participated in SIB progress during the same period as well. HiNa Battery developed an SIB with a Cu–Fe–Mn layered oxide cathode and a soft carbon anode, and successfully applied its product to the first 100 kWh SIB energy storage station [7]. Natrium Energy also focused on a layered-oxide cathode but with elements of Ni–Fe–Mn [8]. Liaoning Starry Sky is working on a Prussian blue cathode [9].

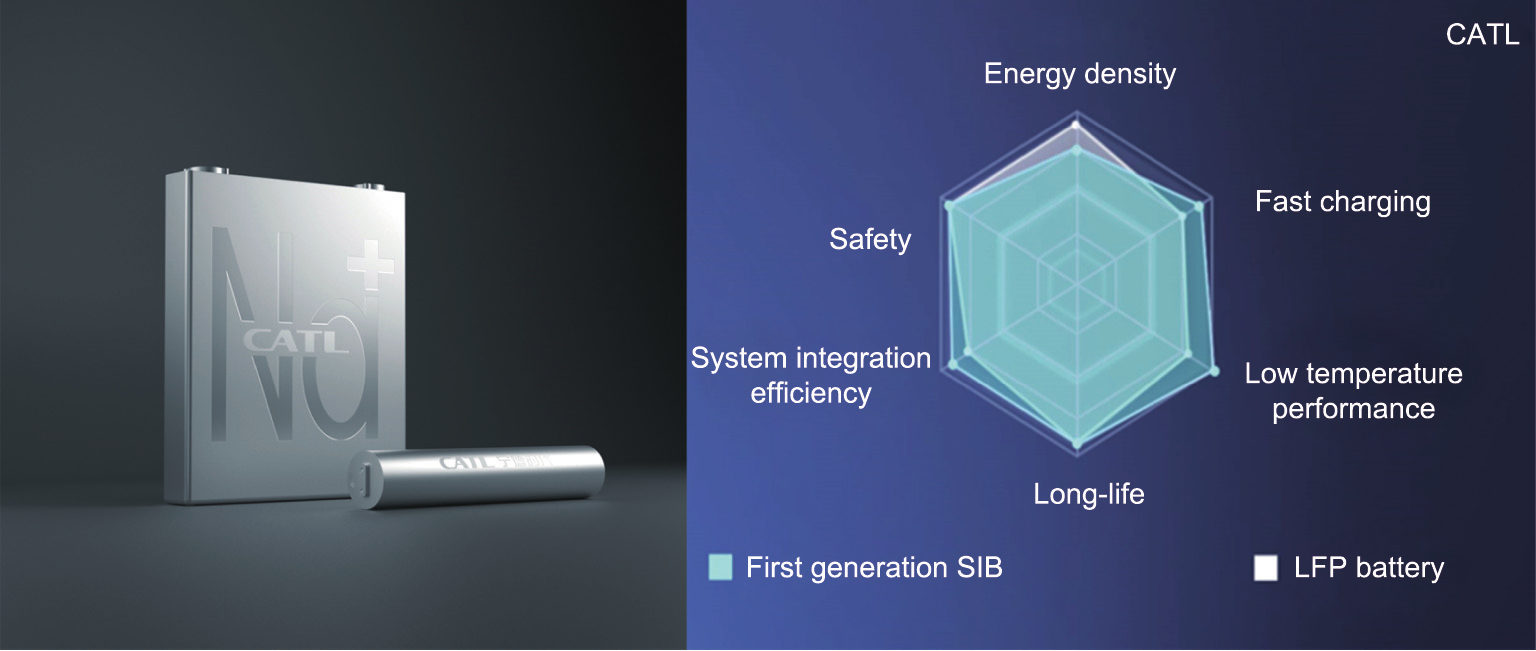

Different categories of cathode material have been chosen by researchers according to their application environments. With a relatively high capacity, a layered-oxide cathode is suitable for electric vehicles, and a Prussian blue cathode fits nicely with the requirements for small energy-storage power stations due to its good power performance. Moreover, a polyanionic cathode is showing attractive capability for long-term energy storage. Contemporary Amperex Technology Limited (CATL) published its first-generation SIB with a Prussian white (Na2Mn[Fe(CN)6]) cathode and a hard carbon anode in July 2021 (Fig. 1); their product has a capacity of 160 W·h·kg–1 and excellent fast-charging and lowtemperature capabilities [10].

《Fig. 1》

Fig. 1. CATL’s first published version of an SIB with a highly competitive performance. LFP: LiFePO4.

After reviewing the exciting scientific and industrial progress in SIBs, a question remains: How can we determine whether the SIB is the technology most appropriate for the carbon-neutrality era? The answer lies within the literature reviewed above. It is noticeable that most of the elements (including sodium) involved in SIB technology are both abundant and low in cost. Moreover, an aluminum (Al) current collector can be used on both the anode and cathode sides to avoid the need for relatively expensive and rare copper (Cu) foil. Hence, it can be said that the key philosophy of SIB technology is low cost and sustainability.

While the importance of low cost is easily understood on a material level, it may be questioned whether sodium-ion technology can maintain its cost advantage at the system level as well. A cost calculation was done by a research team at Karlsruhe Institute of Technology (KIT), Germany in 2018 showing that SIB technology will have a substantial advantage in cost in future, especially in the case of a shortage and associated price increase in lithium [11]. Based on our internal evaluation, when the material cost of lithium carbonate reaches about 100 CNY·kg–1 , the cost advantage of SIB will be non-negligible. Whether fortunately or unfortunately, the price of lithium has recently been increasing at an incredible rate.

Aside from lithium, cobalt is another critical element whose use SIB technology could be used to avoid. The KIT study [11] has shown that, if all internal combustion engine (ICE) vehicles were to be replaced by battery electric vehicles (BEVs), we might have enough lithium, but we would definitely encounter cobalt shortages as long as all electrochemical energy units were based on lithium technology. In fact, the advantage of avoiding lithium and cobalt usage is not only related to their cost; there is strong evidence that SIB has a much safer supply chain than LIB due to this very avoidance. Both lithium and cobalt are centralized in South America and Congo, respectively. A so-called ‘‘lithium Organization of the Petroleum Exporting Countries (OPEC)” is forming among Argentina, Bolivia, and Chile, and nickel has recently exhibited irrational price fluctuation. This recent news clearly reveals that energy safety relies on a safe supply chain.

Both the SIB’s low cost and its supply-chain safety are rooted in the abundance of its raw materials. Moreover, the SIB’s relatively good environmental impact is another key advantage that defines it as a technology for the carbon-neutrality era. Recent scientific study has been done to assess different aspects of SIB technology [12], such as an energy requirement estimation for key materials, a life-cycle analysis (LCA) at the cell level, and production procedure compatibility. In particular, the carbon footprint, which is usually generated according to the global warming potential (GWP) according to the LCA method, has come into high focus. To meet the requirements of carbon neutrality, it is necessary to research and understand the amount of CO2 equivalent (eq.) emitted in the life-cycle of key components or aspects of the whole SIB supply chain.

A more realistic and economy-related motivation is that more correlated standards or policies are being published or are under formulation, and the environmental impact of a technology will influence its carbon tax or carbon trading. The 26th Conference of the Parties to the United Nations Framework Convention on Climate Change (COP26) published the Glasgow Climate Pact, which ‘‘keeps the 1.5 °C target alive” [13]. This major success in our aim to curb global warming places more responsibility on the whole world and thereby provides significant motivation to the battery industry. The European Parliament proposed a new regulation draft for batteries in 2020, requiring labels stating the carbon footprint of batteries with over 2 kW·h capacity by 2024. In the year of this article’s publication (2022), the European Parliament published another draft of its Proposal for a Directive on Corporate Sustainability Due Diligence to check the records of employee right and environmental influence [14]. China also published the second version of its Roadmap for New Energy Vehicles in 2020. In comparison with the first version of the roadmap, the concept of ‘‘low-carbon emission” has been emphasized in the new version [15]. To support carbon neutrality, or even just to consider the minimum requirements to obey upcoming policies and regulations, it is very necessary to promptly conduct battery value-chain carbon-footprint verification and a methodology study for such verification.

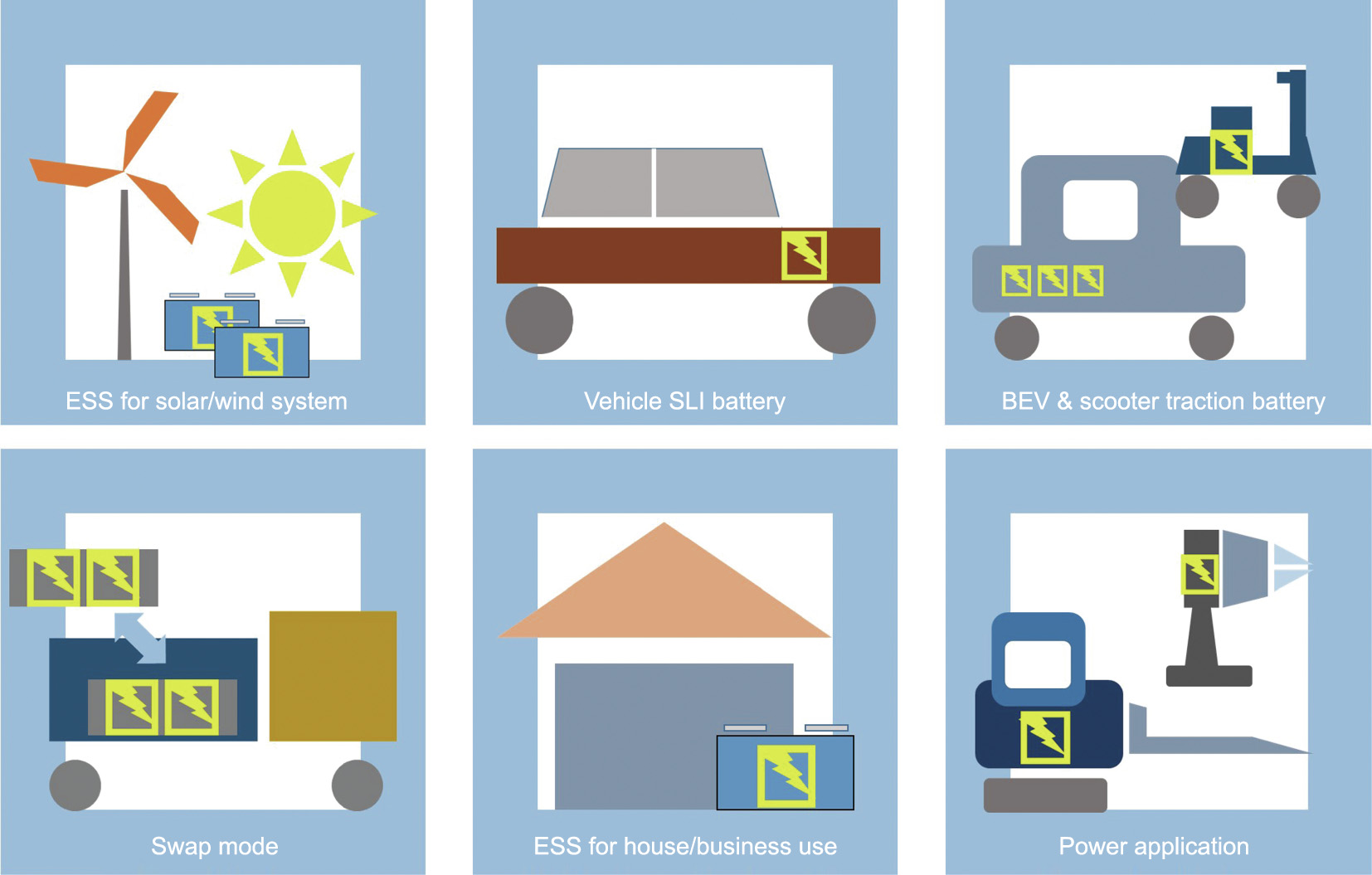

With its advantages of low cost and sustainability, the SIB is considered to be a very promising technology for energy storage, especially for wind and photovoltaic power. Considering its safe supply chain, the SIB is showing high compatibility for A-class BEVs; in particular, with the maturity of battery swap solution (replace discharged modular battery with charged ones) such as in CATL’s EVOGO battery-swap solution, the SIB could work as Choco-SEB (swapping electric block), allowing flexible combinations of different functional units (Fig. 2).

《Fig. 2》

Fig. 2. Possible applications for the SIB include energy storage systems (ESSs) for wind/solar power stations and house/business use, starting, lighting, and ignition (SLI) batteries for vehicles, traction batteries for A-class BEVs and scooters, swap modes, and power applications such as forklifts and electric tools.

The sodium-ion also inherently exhibits a higher desolvation capability in regular electrolyte than the lithium-ion [16]; thus, together with the unique structure of a hard carbon anode and a Prussian white cathode, the SIB demonstrates excellent power capability at the cell level. As a result, SIBs are considered to be ideal candidates for power applications such as forklifts, electric tools, and 12 V/48 V starting, lighting, and ignition (SLI) batteries for vehicles. Compared with the lead-acid battery, which is the traditional technology for power applications, the SIB exhibits a much longer use span (more than eight years vs two years) and higher energy density (160 W·h·kg–1 vs 40 W·h·kg–1 ). As vehicles become increasingly intelligent, the power battery will cover an increasing share of vehicle function; thus, more energy will be required for power batteries. In this way, SIBs provide more room for future concepts of vehicle intelligence.

The commercialization process of sodium-ion technology will never be a solo act by an individual company; rather, it will require full coordination of the whole value chain. At a cautious estimation, there will be a demand for at least 50 GW·h of SIBs by 2025. To achieve this target, a mature and economic supply chain of raw materials will have to be established in the very near future. This presents a major opportunity for all participants in the market, along with a correspondingly high risk. Thus, we look forward to a more tolerant and rational market view on this new technology. No battery technology exists that can fulfill all the demands of different applications, so every technology can have its own place in a specific niche market. With effort from all of society, we believe that sodium-ion technology will soon contribute to accelerating the world’s carbon neutrality.

《Acknowledgments》

Acknowledgments

This work was supported by the National Natural Science Foundation of China (12174162 and 51962010).

京公网安备 11010502051620号

京公网安备 11010502051620号