Manufacturing processes in the process industry comprise a process branch that uses petroleum, natural gas, coal, ore, biomass, and other resources as key raw materials; provides bulk raw materials for national economic construction; and provides high-end electronic chemicals, polymers, and alloy steels for strategic emerging industries, such as the integrated circuit industry and aerospace industry, and for key technologies, such as 5G technology and high-end equipment. These manufacturing processes involve physical and chemical reactions, gas–liquid– solid multiphase coexistence, and continuous complex materialconversion processes. Process industries include the petrochemical, chemical, steel, nonferrous metal, building-material, biomedicine, and other industries, whose industry chain is shown in Fig. 1.

《Fig. 1》

Fig. 1. The industry chain of manufacturing processes in the major process industries. LPG: liquefied petroleum gas; CTL: coal-to-liquids; PTA: terephthalic acid; EE: electronic engineering; IT: information technology.

Below, the process industry in China is taken as an example. The challenges in and strategies for managing current process industry problems are similar in developed countries such as the United States, the United Kingdom, and Germany. The process industry is a pillar of national economic and social development, which is an important supporting force for the sustained economic growth of major manufacturing countries at the same time.

Through decades of development, the production processes, equipment, and automation level of the primary process industries in China have been significantly improved. The scale of these industries and their overall strength have grown rapidly, and their international impact has increased greatly. China’s process industry now ranks as the most complete and largest scale industry of its kind in the world. The production capacities of its steel, nonferrous metals, cement, and other industries rank first in the world; China’s total output of ten nonferrous metals also ranks first; and its petroleum processing capacity and ethylene output rank second worldwide.

Although China maintains the world’s largest process industry, its overall manufacturing efficiency continues to lag behind the advanced international level. International companies in the process industry also face a number of problems, which circumscribe the development of the process industry. Constraints related to resources, energy, and environmental protection, as well as the complexity of the process industry’s system, pose major challenges to optimization and regulation, and thus to the improvement of the operational efficiency of the process industry. Under China’s new development philosophy of achieving the goals of carbon peak and carbon neutrality, it is vital to create a green, low-carbon, and circular economy, improve energy efficiency, increase the proportion of non-fossil energy consumption, reduce carbon emissions, and boost the carbon sink capacity of ecosystems. The primary challenges presented by the process industry can be described as follows:

(1) Frequent changes in and fluctuations of the properties of raw materials cause continuous operation processes to appear multi-modal in the spatiotemporal domain, and it is difficult to characterize multiphase multi-component industrial processes and carry out non-stationary process control.

(2) Upsizing industrial equipment changes the equipment’s reaction and transmission characteristics. Non-uniformity and strong coupling increase the difficulty of system behavior characterization and regulation.

(3) In an open environment and under tight constraints, the multi-objective regulation of manufacturing processes in the process industry for economy, stability, and controllability is challenging.

The rapid development of modern information technologies, such as artificial intelligence, big data, blockchains, the Industrial Internet of Things, and process systems engineering, provides a good opportunity to solve the problems described above. The manufacturing industry is foundational for building a country and is the core of a strong country. To achieve high-quality development, a high-quality manufacturing industry must be ensured and supported. Moreover, the high-quality development of the process industry must be combined with artificial intelligence. Through a deep integration of emerging technologies and process industries, the transformation of new and old energy and manufacturing systems will accelerate, such that the process industry will shift from mechanization and automation to digitalization, networking, and intellectualization, enabling China to realize the historical leap from being a big country to becoming a strong country. China will realize the in-depth integration of a new generation of modern information technology and manufacturing processes, conducting in-depth research on the intelligent optimization and control mechanisms of the manufacturing processes of the process industry. The nation will also carry out cutting-edge and applied basic research in the three aspects of intelligent decision-making for human-in-the-loop systems: namely, the characterization and recognition of the mechanisms of the manufacturing processes in the process industry; the multi-objective autonomous cooperative control of manufacturing processes; and the establishment of cross-layer manufacturing systems. These aims will be accomplished by seizing opportunities, working across disciplines to accelerate key technological smart manufacturing breakthroughs, and forming optimal control software and systems with independent intellectual property rights. Moreover, China will promote industrial upgrading and technological progress, while enabling the process industry to achieve high-quality innovation-driven development. In this way, the goal of manufacturing power will be achieved, while world-leading smart manufacturing technological breakthroughs in the process industry will be accomplished.

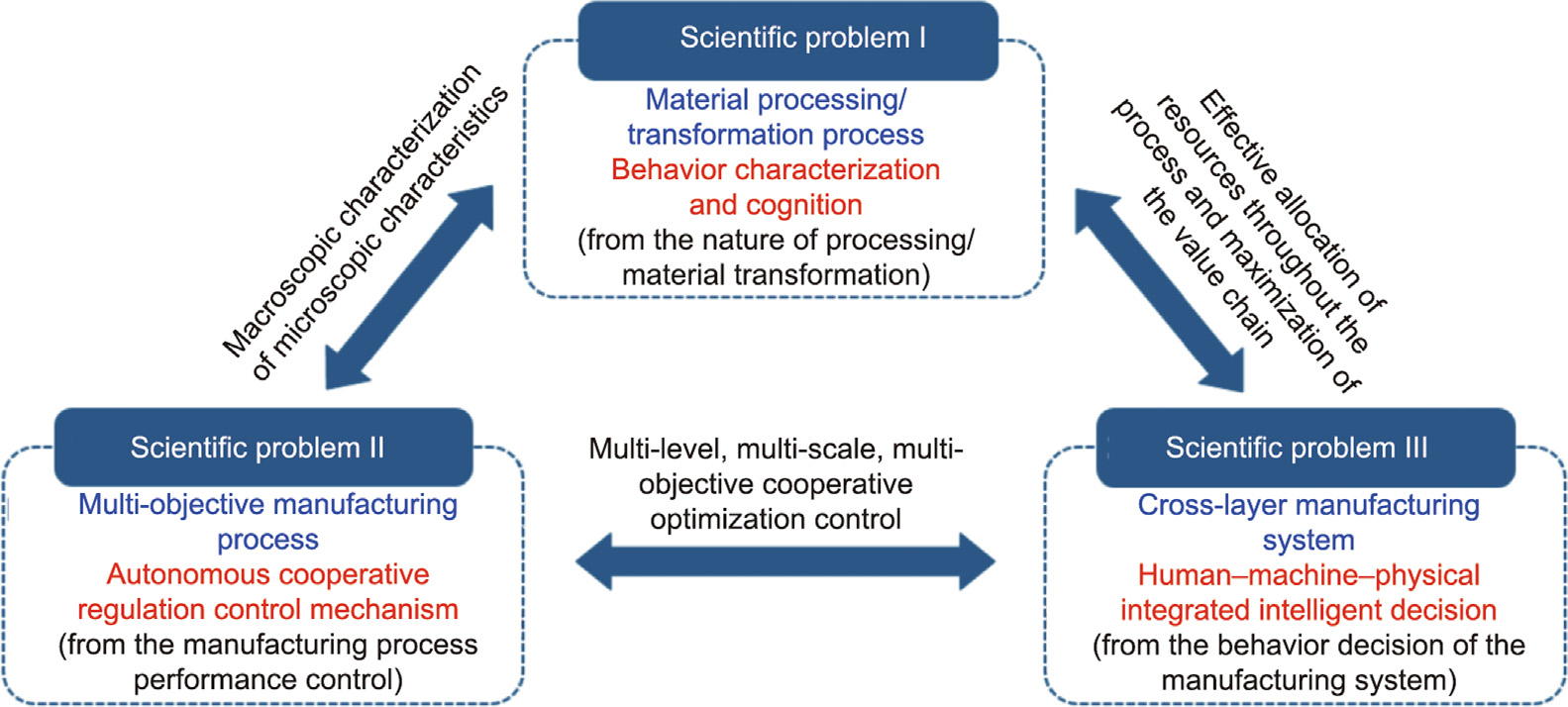

With the aim of understanding the thought patterns and decision-making related to regulation mechanisms in the manufacturing processes within the process industry, our research team will investigate three cutting-edge scientific issues: the characterization and recognition of the key characteristics of processes in the process industry; multi-objective autonomous cooperative control mechanisms for manufacturing processes; and intelligent decision-making within cross-layer human–machine–physical manufacturing system integration (Fig. 2).

《Fig. 2》

Fig. 2. Three scientific problems in the process industry.

(1) We will investigate the structure–effect relationship between the microscale processes of industrial mechanisms and the macroscale system operating characteristics to realize the causal interpretation of massive data/models and carbon emission models based on the mechanisms of the process industry.

(2) We will study how to describe the dynamic coupling characteristics of the process industry on a multi-spatiotemporal scale in order to achieve the active coordination of multiple control systems with the multiple objectives of safety, reduced carbon emissions, environmental protection, quality, and economic benefits.

(3) We will enhance the robustness of decision-making in manufacturing processes in open environments through the ternary integration of human–machine–physical parts, consider human behaviors as they affect automated systems, and promote the integration of planning, scheduling, and optimization operations in large-scale manufacturing systems.

Through research on cutting-edge basic theories and methods in the three aspects listed above, our research team aims to reach the international frontier of disciplinary development, while closely focusing on the major strategic needs of smart, green, and high-end manufacturing in national, regional, and industrial economic development. We will also systematically solve major scientific problems in basic and applied basic research, strengthen the function of original innovation in science and technology, promote high-end industrial chains for the manufacturing industry, modernize supply chains, maximize value chains, and help maintain the security and stability of industrial and supply chains. In this way, we will ignite a new high-quality economic development engine and start a social development accelerator.

《Acknowledgment》

Acknowledgment

The work was supported by National Natural Science Foundation of China Basic Science Center Program (61988101), Fundamental Research Funds for the Central Universities (222202317006), the Programme of Introducing Talents of Discipline to Universities (the 111 Project) (B17017) and Shanghai AI Lab.

京公网安备 11010502051620号

京公网安备 11010502051620号