《1 Introduction》

1 Introduction

Industrial solid waste is produced in industrial activities that enrich many types of toxic and hazardous substances and have un-used metallic, non-metallic, and other resources. The intensity of industrial activity in China is the highest in the world, and the annual amount of new industrial solid waste generated is more than 3×109 t, but the comprehensive utilization rate is only about 60 %. The current situation results in a large number of industrial solid waste storage sites in some areas and leads to prominent atmospheric dust, soil pollution, and groundwater pollution, which affects the status of regional environmental quality and produces long-term environmental risks. However, a portion of industrial solid waste is also a valuable resource that can be recycled to reduce storage and disposal under certain technical and economic conditions to achieve environmental, resource, and economic benefits.

Since the 18th National Congress of the Communist Party of China, China has regarded resource conservation and recycling, improvement of environmental quality, and environmental risks control as some of the key tasks of ecological civilization construction and has also considered the establishment of resource recycling systems as a comprehensive goal toward building a well-off society by 2020. Compared with other solid wastes, industrial solid waste is the largest produced and stored waste in China, and it is the main source of resource recycling. However, the stage objectives, development paths, key tasks, and other management strategies for China’s industrial solid waste resource utilization have not yet been clarified. This study analyzed the growth trend and resource demand and potential of industrial solid waste in China and proposes suggestions pertaining to the overall goal, development path, and specific strategy for industrial solid waste resource utilization for ecological civilization construction in China.

《2 Overall situation of industrial solid waste in China》

2 Overall situation of industrial solid waste in China

《2.1 Industrial solid waste production is related to industrial economic development》

2.1 Industrial solid waste production is related to industrial economic development

China’s industrial solid waste production is huge and obviously concentrated. In recent years, the efficiency of resource recycling has increased with China’s efforts to promote industrial pollution control and industrial restructuring. Meanwhile, the three major industries, the coal, steel, and nonferrous metals industries, are sluggish, and the industrial solid waste production per unit of industrial added value has decreased slightly (Fig. 1). However, the total amount of industrial solid waste generated in China is still very high. Environmental protection statistics show that in 2014, 155 000 key industrial enterprises under investigation generated 3.3×109 t of solid waste [1] and that industrial solid waste production per industrial added value was 1.4 t/ten thousand yuan. The industrial solid waste production per person and the total amount were 3 times and 30 times those of Japan, respectively, and the industrial solid waste production per industrial added value was inversely proportional to regional economic development. For example, the industrial solid waste production per industrial added value in the eastern region is about half the national average, and the industrial solid waste production per industrial added value of the western region is about 1.5 times the national average, which is three times that of the eastern region.

《Fig. 1》

Fig. 1. China’s industrial solid waste production and industrial added value.

China’s industrial solid waste production has shown distinct features of concentration. Firstly, the production concentrates on several major categories of industrial solid waste. Productions of tailings, coal gangue, fly ash, smelting slag, slag, and desulfurization gypsum accounted for 83.7 % of the total industrial solid waste production. Secondly, the production concentrates on several major industries. The total contribution rate of industrial solid wastes from iron and steel, coal, nonferrous metals, and related industrial activities is more than 70 %. Thirdly, the production concentrates on several major areas with high resource occurrence. Nine of the top 10 cities with the largest industrial solid waste productions in 2014 are resource-based cities [1]. However, about 40 % to 50 % of the new solid waste generated each year cannot be utilized fully. In the enterprises under environmental investigation, the industrial solid waste annual utilization rate is about 60 %, and there are more than 1.3×109 –1.6×109 t of industrial solid waste that require storage and disposal each year (Fig. 2). Since 2012, influenced by the demand decline of the comprehensive utilization product market, the growth of annual total comprehensive utilization has become negative.

《Fig. 2》

Fig. 2. Overall situation of comprehensive utilization of China’s industrial solid waste in recent years [2].

China will basically complete industrialization in 2020 [4] and basically complete urbanization in 2030 [5]. Under the existing development pattern, the average annual growth rate of industrial solid waste production will remain at around 5 %. Industrial solid waste production will exceed 4×109 t and 5×109 t in 2020 and 2030, respectively, will stabilize by around 2035– 2040, and may exceed 5.5×109 t in 2050. This will further exacerbate the environmental stress caused by industrial solid waste storage and disposal.

《2.2 Achievements of industrial solid waste resourceutilization management》

2.2 Achievements of industrial solid waste resourceutilization management

Under the three special legal frameworks of the Solid Waste Pollution Prevention and Control Law of the People’s Republic of China, Cleaner Production Promotion Law of the People’s Republic of China, and Circular Economy Promotion Law of the People’s Republic of China, China has built legal principles and a supporting system of solid waste reduction, resource utilization, and hazard-free treatment. Within their respective functions, each department introduced relevant management regulations, and a multi-department coordination mechanism was initially established. With the development of China’s circular economy strategy, waste recycling has become an important part of the national macro-strategy and has specific work arrangements.

In recent years, China has promoted the development of resource-utilization industrial markets by fiscal and taxation subsidies, industrial policy, green procurement, and other activities. Comprehensive utilization of resources enterprises has resulted in a discount on the comprehensive utilization of product valueadded tax and resource tax, as well as other tax incentives [6]. The central government has arranged special funds to support the comprehensive utilization of solid waste. On the other hand, the environmental protection departments carry out various types of environmental protection renovations to promote and purify the resource-utilization industry market.

The innovation of resource-utilization technology has improved the efficiency of resource utilization. In recent years, China has made a number of breakthroughs in the extraction of mineral resources and has turned low-quality, combined, and difficult-to-use resources into economically recoverable resources. During the 12th Five-Year Plan period, the application technology of using tailings and waste rock in concrete has reached a leading level internationally, and the comprehensive utilization technologies of desulfurization gypsum, steel slag, and other solid wastes have achieved large-scale promotion [7].

《2.3 Industrial solid waste restricts the healthy development of China’s economic environment》

2.3 Industrial solid waste restricts the healthy development of China’s economic environment

Industrial solid waste is a bottleneck problem restricting China’s environmental management. From the viewpoint of total production, in 2014, China produced 343 t of industrial solid waste per unit land area, which is 57 times the total emissions of the main air pollutants (sulfur dioxide, nitrogen oxides, and smoke dust). From the viewpoint of impacts of environmental pollution and environmental risks, long-term accumulation of industrial solid waste prominently polluted atmospheric dust, soil, and groundwater, which led to long-term environmental risks. Based on the incomplete statistics by the Ministry of Environmental Protection, in 2010, there were 343 sites and 7.35×107 t of historical storage of dangerous wastes, of which more than 100 sites were close to rivers, farmland, residential areas, and other environmentally sensitive locations.

The lack of comprehensive utilization of industrial solid waste affects the healthy development of China’s economy and society to a certain extent. Ministry of Land and Resources survey data show that the cumulative storage of national tailings, waste rock, and other industrial solid wastes had reached about 6×1010 t by 2015 [8]. According to industry associations and related experts, it is estimated that the cumulative storage might be as high as 70×1010–8×1010 t and that the total coverage area could be about 2.5×106 –3×106 hm2 . In recent years, the costs of industrial solid waste storage and disposal have continued to increase, accounting for 8 %–40 % of the total cost of business operations. The lack of comprehensive utilization has led to structural deficiencies of terminal disposal capacity, and some enterprises have had to take measures to cut production in order to avoid long-term storage of hazardous waste.

《3 Prominent problems of China’s industrial solid waste management》

3 Prominent problems of China’s industrial solid waste management

《3.1 One-way development pattern led to excessive consumption of resources and industrial solid waste production》

3.1 One-way development pattern led to excessive consumption of resources and industrial solid waste production

China has special resource occurrences, which are low-grade and have multi-elements associated with the main resources, so industrial solid waste production intensity is higher. For example, the current average grade of China’s domestic iron ore is about 25 %–30 % [9], and about 3 t of tailings are produced with the average production of 1 t of iron ore (iron content of 65 %). The resource-utilization rate is low during resource development, and the comprehensive recovery of mineral resources does not exceed 50 %. By the end of 2014, among 11 359 tailings in the country, only 3.4 % of these had been utilized comprehensively.

《3.2 Legal system design paying more attention to the end, despising the source, and weakening recycling》

3.2 Legal system design paying more attention to the end, despising the source, and weakening recycling

In the aspect of the legal basis, the reduction of solid waste in China is based mainly on the Cleaner Production Promotion Law of the People’s Republic of China, and the resource utilization is based mainly on the Circular Economy Promotion Law of the People’s Republic of China, but these two laws are not compulsory. The Solid Waste Pollution Prevention and Control Law of the People’s Republic of China only includes principle regulations on reduction and resource utilization.

In the aspect of system design, there is a lack of top-level design of a producer responsibility system and there are blind spots and blocking points in resource-utilization environmental management. Access of industry sources lacks regulation, industries with large solid waste production are concentrated, and local resource-utilization capacities are not adequate. The recycling sector is a regulatory blind spot, and a situation of “small, scattered, and chaos” is common in this sector. Resource utilization industry development lacks technical specifications, consumers have doubts about the safety of comprehensively utilized products, and the market’s acceptance of relevant products is low, resulting in a large amount of hazardous waste with comprehensiveutilization potential or comprehensive-utilization products being forced into disposal facilities.

《3.3 Inadequate measures of economic adjustments》

3.3 Inadequate measures of economic adjustments

Solid waste generation and disposal lacks restrictive fiscal and taxation policies. In the implementation of the environmental tax system in 2018, in accordance with the current smooth convergence with sewage charges design ideas and facing the problems of low charge and small scope of industrial solid waste, it has almost no effect on the containment of solid waste production or the promotion of resource utilization.

Current fiscal incentives for comprehensive utilization lack stimulation effect, and the coverage of preferential policies is narrow. In the current policies, the applicable fiscal and taxation preferential policies for the comprehensive utilization of industrial solid wastes are only the VAT Preferential Directory Products and Services for Comprehensive Utilization of Resources (2015). These are only applied to 12 types of industrial solid waste and 36 kinds of comprehensive utilization products and provide 50 % and 70 % tax rebates. The coverage is very limited, and preferential efforts are weak. Enterprises lack motivation to carry out the resource utilization.

《3.4 Insufficient resource-utilization technology and slow development of industrial market》

3.4 Insufficient resource-utilization technology and slow development of industrial market

In terms of the technological level of the resource-utilization industry, the gap between China and the developed countries in Europe and America is about 5 to 10 years, which does not give full consideration to the role of supplementary metal resources and alternative building material resources. Additionally, the problems of efficient dissociation and safe recovery of hazardous contents and valuable elements in non-ferrous metal smelting slag and other high-risk industrial solid wastes have not yet been resolved. In the area of industrial comprehensive-utilization technology, the proportions of utilization for building materials and other low-end utilization are high.

In 2014, the proportion of high-value utilization of extracted valuable resources was less than 11 % of China’s comprehensive utilization of industrial solid waste [9]. Blind utilization by those who currently do not have the optimal technical conditions for extraction leads to irretrievable waste. From the viewpoint of industrial development, the average output value of China’s current comprehensive utilization of solid waste enterprises is less than 20 million yuan each, and the number of employees is less than 170. More than 80% of the scale consists of small industrial enterprises, which shows that the industrial market is not mature.

《4 Recommendations for China’s industrial solid waste resource utilization development strategy》

4 Recommendations for China’s industrial solid waste resource utilization development strategy

《4.1 China’s industrial solid waste resource utilization has very impressive potential》

4.1 China’s industrial solid waste resource utilization has very impressive potential

In the near future, China’s industrial development will continue to depend on the overall trend of resources and energy investment, which is difficult to change fundamentally, and the rigid growth trend of resource demand will continue for a long period of time. Under the condition that economic structure and technology do not improve significantly, maintaining high operation of industrial solid waste is an objective reality.

However, if we can effectively improve the utilization of industrial solid waste resources in China, it will provide considerable support to the capability of resource support for China’s economic and social development. Using the tailings as an example, if the proportion of extracted valuable resources were to increase to 2 %, it would increase the valuable resources supply by 3.5×107 t. Additionally, for alternative non-metallic resources, under the existing industrial conditions, industrial solid waste utilization could be an alternative for 60 %–70 % of building materials and reduce mineral resources mining. From the viewpoint of economic benefits, under the existing technical conditions in China, the average utilization of 1 t of industrial solid waste can produce 370 yuan of output value. By 2020 and 2030, the comprehensive utilization of industrial solid waste could reach about 2.6×109 t and 2.9×109 t, respectively, and the output values could reach 1000 billion–1600 billion yuan.

《4.2 Road map of development and suggestions for stage objectives》

4.2 Road map of development and suggestions for stage objectives

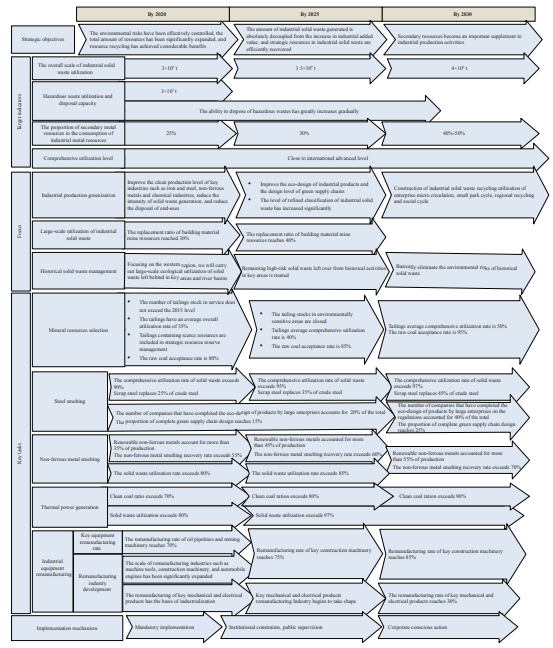

To promote resource conservation and utilization effectively and to eliminate gradually the sustainable effects of industrial solid waste on the quality of the ecological environment and human health, it is proposed that reducing the environmental impacts of industrial solid wastes and controlling the environmental risks should be the main control objectives. With the construction of a closed management system of “resource–waste– resource”, comprehensive utilization of resources needs to be fully improved in order to disconnect the relationship between industrial solid waste generation and economic development and to achieve an industrial solid waste limited growth pattern. By 2030, China’s industrial solid waste production will be controlled to less than 3×109 t, then the total amount will be reduced gradually to about 2.5×109 t in 2050. According to the development path of “general scale of resource utilization expanded in 2020, development of resources and quality achieved by 2025, and waste and resources management improved in 2030”, when the development of the industrial economy in China is basically realized, resources and energy consumption and social and economic development will attain a balance. At that time, industrial solid waste will become a “new mine”, the stockpile will begin to diminish, and the historical environmental risk will be basically eliminated (Fig. 3).

《Fig. 3》

Fig. 3. Road map for industrial solid waste resource development in China.

《4.3 Recommendations for key missions》

4.3 Recommendations for key missions

4.3.1 The establishment of a legal system for resources and environment coordination management

Establish a legal system coordinating resource conservation, intensive recycling, and solid waste pollution prevention and control. Establish a producer-responsibility extension system. Clearly define the legal responsibilities of life cycle design, source classification, forced recycling, reuse, and so on. Promote the development of product life cycle eco-design and green supply chain design to accelerate resources recycling and utilization.

Improve economic adjustment measures. Optimize the collection of resource taxes and promote the comprehensive utilization of mineral resources. Strengthen the adjustment function of environmental taxes by offering environmental tax reduction incentives and other incentives to utilization enterprises. Expand the comprehensive utilization of tax preferential policies for resources to support the development of industries.

Construct a forcing mechanism of resource circulation. Implement the “waste production” strategy for iron and steel, copper, aluminum, and other important strategic resources using the actual economic and social development of domestic demand and the similar production capacity of renewable resources to determine the overall production scale. For resource-based industrial solid waste, implement the “restricted disposal” policy to limit alternative mineral resources or energy extraction and consumption.

Strengthen the development of utilization technical standards. Based on the environmental risk control of toxic and hazardous substances, improve the technical standards system for pollution control of industrial solid waste recycling processes. Establish an environmental standards system conducive to alternative resources and comprehensive utilization and national standard system of by-products. Regulate solid waste resource-utilization disposal activities.

4.3.2 Implementation of resources and environment coordination strategy

Guided by the ecological red line, coordinate the district planning of mineral resources mining and environmental functional protection. In principle, strictly control, entirely protect, and prohibit from development the mineral resources located within the ecological red line; for those already being exploited, stop the development and gradually reclaim. For the mineral resources located outside of the ecological red line, promote the backfilling of tailings and the recovery of the mine geological environment to reduce operating pressures of tailings industries. Limit open mining of mineral resources and strictly control underground mining.

Coordinate a green manufacturing strategy and use full implementation of the clean energy strategy. Promote the ecodesign and green supply chain design of major industrial products and major consumer durables, and improve the clean production level across the entire industry chain and the solid waste classification level to reduce the production intensity of industrial solid waste. Vigorously improve the wash rate of coal, improve energy efficiency, and promote the comprehensive utilization of industrial waste heat and pressure to reduce the overall social intensity of coal consumption.

4.3.3 Optimization of the layout of resource industries

According to the law of material movement in economic activities, construct resources development and utilization and solid waste utilization recycling industry chains; promote the construction of eco-industrial parks and the recycling and ecological transformation of existing parks; create solid waste utilization of the enterprise microcirculation, small park circulation, regional circulation, and national cycle; promote inter-enterprises, industry, industry symbiotic coupling, and establish a circular related industrial network; promote proximal comprehensive utilization of solid waste, and encourage agglomerative industrial development.

4.3.4 Strengthening the technological support for high-value comprehensive utilization

Establish national science and technology projects on industrial solid waste resource utilization. Support key technology research on China’s industrial solid waste utilization and development, key technology introduction and integration, major equipment research and development, and industrial application demonstration. Promote technology research and industrialization for deep resource utilization as a priority. Accelerate the speed of key industrial equipment remanufacturing technology research and industrial applications.

京公网安备 11010502051620号

京公网安备 11010502051620号