《1 Introduction》

1 Introduction

In the context of the active industrial development taking place all over the world, China is striving to develop a theory that suits its situation, which is an inevitable approach to realize the comprehensive revival of economic and social development. A management system is essential for economic development as it comprises a set of important methodologies that are used by production organizations. The construction of such methodologies, which can coordinate with China’s current economic status and have development prospects, will have both theoretical and practical value.

Human beings gradually moved toward the modern industrial system from the previous mode of production that was controlled by workshop workers. In addition to factors such as the means of production and technological revolution, the transformation of production organizations and production methods is also significant [1]. The early production organizations were spontaneous and empirical. Modern human production activities were gradually liberated from traditional empiricism, and a more scientific methodology was introduced. The Principles of Scientific Management (also referred to as “Principles”) of Taylor provided an important theoretical foundation for the establishment of the modern industrial system. Studies on scientific management aim at optimizing resource allocation under resource constraints in order to complete tasks more efficiently and economically [2]. Under the influence of classical management theories represented by the “Taylor system,” numerous countries investigated suitable management systems suited to their national conditions, such as the extension and development of lean manufacturing in Japan with quality management as the core; this type of management practice facilitates economic growth [1].

The essence of scientific management lies in the constant exploration of applications in different fields, improvement of the efficiency and quality of production and service [1], and creation of comprehensive effects aimed at maximizing productivity. From a global perspective, Western countries developed informatization after establishing mature industrial systems [3,4]. Industrialization and informatization present a gradient pattern in time dimension; China developed informatization as the industrial system has not yet been completed. The integration of the two management systems constitutes an informatization development methodology suitable for the actual situation in China. It is a general method for the establishment and application of management systems for enterprise system integration processes [5,6]. This type of a method can also guide the enterprise to achieve its development goals based on the needs proposed by the industry to define the process of integrated development of enterprises and track and monitor its effectiveness, forming new capabilities of enterprise development under the information environment [7,8]. After the preliminary exploration in China, the integration of the two management systems entered the deepening stage of the system. A series of management method standards, such as the integrated management system, have been widely used in China; this supports that new management methods can be established and applied to promote integration.

China also faces challenges in the construction and application of management systems. While focusing on the aspect of “manufacturing + Internet” for the development of manufacturing informatization, a core issue that needs to be addressed is the innovation management system. The Internet Plus management system by 2035 is a systematic summary of development concepts, elements, laws, methods, and paths of a new era of integration of the two aforementioned structures [9] and presents a critical path of realization of sustainable development. This management system uses the cultivation of new capabilities as the output and focus of the Internet Plus strategic transformation work, transforms the technological progress, organizational change, process optimization, data analysis, and utilization into new types of competence, improves core competitiveness, and ultimately promotes the growth of the organization by building new capabilities. The relationships between the employer and enterprise and among enterprises are reformed to create an Internet-based manufacturing development model [10].

Based on the objective foundation of the current development of China’s manufacturing industry and the status of management systems assessment, this paper proposes the construction of a suitable Internet Plus management system outlooking for the 2035 Internet Plus management system.

《2 Theoretical model of the Internet Plus management system》

2 Theoretical model of the Internet Plus management system

《2.1 Integrated management system of industrialization and informatization》

2.1 Integrated management system of industrialization and informatization

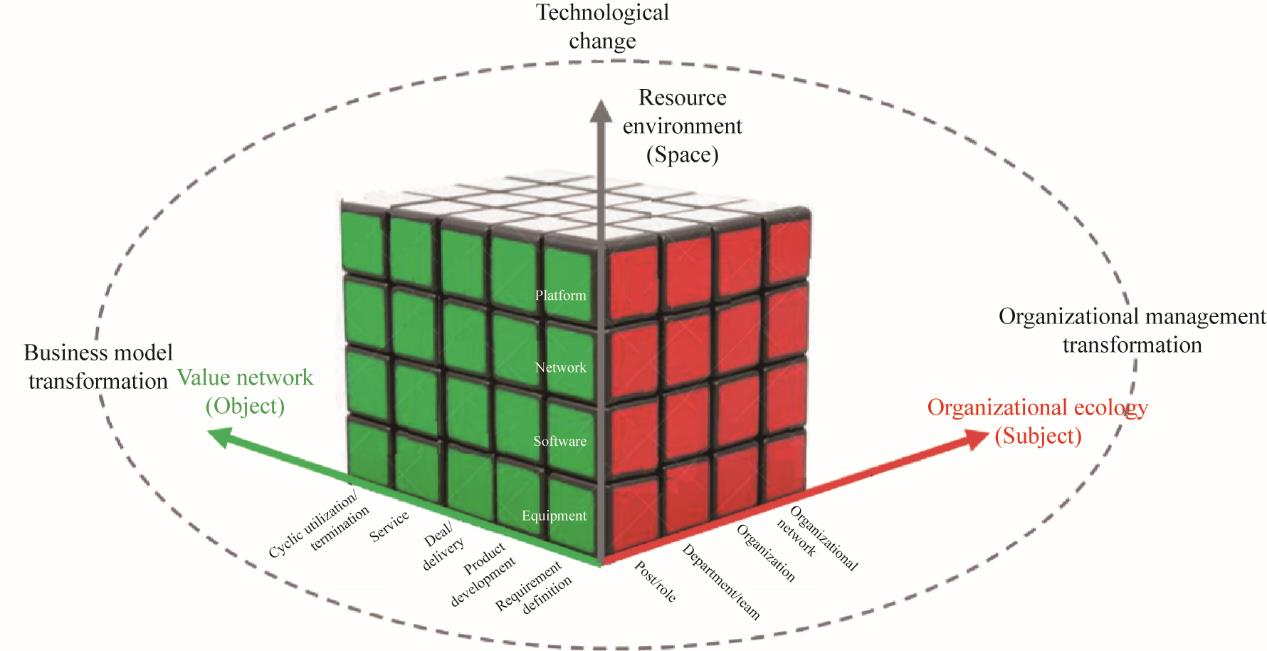

Special Action Plan for Deply Integrating Informatization and Industrialization (2013–2018) was proposed in August 2013 to carry out the standard construction and promotion of the enterprise integration management system. In December 2013, the national standard Management System Requirements for Integration of Informatization and Industrialization was formally approved. In January 2014, Requirements for Integrated Management System of Informatization and Industrialization (Trial) was officially released. The integrated management system of informatization and industrialization is a management methodology suitable for China’s development and is a general method for a clear organization to systematically establish, promote, and improve integration, to standardize the integration process of enterprises, monitor the implementation process, and promote and realize their continuous innovation and improvement of the four elements: data, technology, business process, and organizational structure. This method is aimed at helping organizations continue to build new capabilities in the information-based environment, establish strategic goals for corporate development, establish sustainable competitive advantages, and realize innovative development and intelligent development (Fig. 1).

《Fig. 1》

Fig. 1. Basic framework of the integration management system.

《2.2 Theoretical model of the Internet Plus management system》

2.2 Theoretical model of the Internet Plus management system

Digitization, networking, and intelligence are the different stages of integrated development. Smart manufacturing and Internet Plus are specific tasks in different development periods and are different aspects of integration. Big data, cloud computing, and other new modern information technologies have accelerated the transformation and upgrading of traditional industries. Internet Plus can be used for deeply integrating the innovative achievements of the Internet with the economic society in various fields, to further promote efficiency and technological improvements, enhance productivity and innovation capabilities, and shape a new pattern and model of development based on the Internet of development infrastructure and innovative elements. In the recent round of industrial revolution, the Internet Plus can be said to have impact in nearly all fields and domains, including those of agriculture, manufacturing, service, commerce, finance, and government affairs. The manufacturing industry is the mainstay of China’s economy and the current leading force promoting the recovery of the real economy, maintaining sustained economic growth, and realizing the upgrading of the industrial structure. Therefore, the manufacturing industry can be considered to be the main battlefield of Internet Plus for driving China’s economic transformation and development. “Manufacturing + Internet” focuses on the core issues that need to be resolved for achieving network development in manufacturing informatization. Through the popularization of the Internet and mobile Internet, real-time transmission and sharing of dynamic data can be promoted, and large-scale dynamic sharing and on-demand supply of resources such as labor, technology, equipment and facilities, capital, services, and knowledge can be realized. Dynamic and accurate matching between supply and demand, cost reduction, and transaction efficiency improvement can be realized. The relationships between consumers, enterprises, and enterprises can also be reconstructed. A new model of manufacturing based on the Internet can be developed to further promote the integration and development of the manufacturing industry. The Internet is the only means to promote the intelligent development of the manufacturing industry and a necessary prerequisite to seize the commanding heights of the intelligent manufacturing ecosystem.

Through an in-depth analysis of the basic conditions and development needs of China’s promotion of Internet Plus and reference of the common frame of the integration of the two structures [11], we established a theoretical model of the Internet Plus management system (Fig. 2) from three perspectives: morphology, value of the network, and resources and environment. (1) Organizational ecology (main body): From the perspective of the promotion subject of Internet Plus (“who will do it”), we describe the subject of the activity of Internet Plus from the following four aspects: post/role, department/team, organization, and organization network. (2) Value network (object): Creating value for users when providing products (services) is an important goal of an organization’s operation. This perspective describes the objective (objects) of Internet Plus revolving around the key links and activities of product life cycle and value chain, including demand definition, product development, transaction/delivery, service, and recycling/termination processing. (3) Resources and environment (space): Various physical systems and information systems are the foundation and carrier (space) for the development of Internet Plus. From the perspective of resources and environment, we describe the relevant foundation and carrier (space) involved in Internet Plus, including equipment, software, networks, and platforms. Data, technology, business processes, and organizational structure, which are the main aspects when studying the development impact of the integration of the two structures [12], together constitute the core element of Internet Plus. Internet Plus starts at the operational level embodied in the organizational ecology (subject), value network (object), and resource environment (space) and continues to promote interactive innovation and continuous optimization of data, technology, business processes, and organizational structure.

《Fig. 2》

Fig. 2. Three perspectives of the theoretical model of the Internet Plus management system.

《2.3 Internet Plus management system evaluation framework》

2.3 Internet Plus management system evaluation framework

The three perspectives for the model of the Internet Plus management system provide a theoretical basis for an accurate understanding of the current development situation of this system. Based on the value network, organizational ecology, and resource environment, the connotation and extension under the corresponding perspective should be explored; and the involved objects and content should be summarized, quantified, and evaluated, thereby forming the Internet Plus management system evaluation framework.

The evaluation dimension from the perspective of organizational ecology and the definition and management of the position roles are the foundation for building a good organizational ecology. The hierarchy of full-time management system leadership is important for the implementation and promotion of the management system. There are three clear measures of the degree of job-tier-defined roles: no full-time supervisor, middle managers, and senior manager. The department team is the main work promotion organization. The information department is categorized into three types: no information department exists, the information department belongs to other business departments, and the information department is a full-time first-level department organization; the third type integrates informatization, management reform, model transformation, business process optimization, and other functions, and represents the Internet Plus management system, whose settings match with those of the department. The innovative development of the management system forces the traditional organizational structure to move toward the organizational structure network. Organization-networked enterprises are capable of realizing internal and undifferentiated information exchange and high resource sharing. They can quickly replicate and promote knowledge and experience in technology, management, application, etc. and significantly improve the company’s dynamic co-ordinational and dynamic market response capabilities. The organizational model of an enterprise can be divided into bureaucratic, matrix, process-oriented, and networking; this demonstrates the maturity of the networked organization model level by level.

The evaluation dimension from the perspective of the value network focuses on research and development (R&D), manufacturing, user service, recycling, recycling, etc., to evaluate the product lifecycle integrated management and control level. The R&D level is closely related to the independent innovation capability of an enterprise. The introduction of digital tools in all aspects of production can characterize the level of R&D in terms of hardware configuration. The manufacturing process has a core link to corporate value creation for enterprises. The application of digital tools in the underlying equipment, process control, manufacturing execution, and production management layers can more comprehensively characterize the digital level of the entire production process. User service links are a key component of the in-depth interaction between products and end users. Digital methods are used to evaluate the status of a company’s user base management system, which supports advanced interactive enterprise applications such as online interaction and precision marketing. Under the control of the product lifecycle, the level of product remanufacturing at the end represents the company’s ability to recycle and rebuild.

Regarding the evaluation dimension from the environmental perspective, the equipment, software, network, and platform are important carriers of the development of the Internet Plus management system. The digital level of equipment is the basis for the interconnection of product data among all links of production and becomes an important breakthrough in the implementation of the Internet Plus management system. The digitization rate of production equipment and the equipment networking rate of digital production are used as quantitative indicators of the equipment digitalization level. The underlying software is a key resource and environmental foundation used for supporting enterprises to form networked and distributed collaborative R&D, production environments, and management systems. Therefore, the application rate of industrial software in management, product development, and production control is used to quantify the software application level of resources and the environment. An efficient industrial cloud platform forms the core of innovation of industrial Internet development and has become a necessary path to promote industrial transformation and upgrading. The application rate of the enterprise cloud platform is used to characterize the resource configuration level of the network and platform.

《3 Application status of the Internet Plus management system》

3 Application status of the Internet Plus management system

The Internet Plus management system presents a comprehensive summary of the development laws of enterprises, industries, economy, and society in the information age that collectively form the theoretical framework of the governance system, “If you cannot measure, you cannot manage.” Based on the evaluation framework of the Internet Plus management system, industry evaluation data from more than 160 000 enterprises are collected by the integration of the two service platforms to quantitatively evaluate the current Internet innovation achievements in China and the current status of deep integration of economic and social fields and innovative development trends. Currently, China’s Internet Plus integration has achieved remarkable results. The new capability system was gradually established under the background of enterprise Internet development. The path direction of industrial transformation and upgrading gradually became clear. However, some problems, including a low level of integration and coordination, lags in the upstream and downstream connections of the industry chain, locked low end of the industry value chain, and lags in the development of information infrastructure, still exist.

《3.1 Organizational ecological innovation in the context of Internet Plus》

3.1 Organizational ecological innovation in the context of Internet Plus

Owing to the integration and penetration of network technologies such as the Internet and Internet of Things and business management, profound changes have taken place in the organization, management, and cooperation methods of different companies. Focusing on strategic closed-loop control, refined financial control, and comprehensive decision-making to promote management reform and innovation is a typical approach for leading companies. To promote management activities such as standardization, precision, process, and networking, enterprises rely on unified information platforms to monitor resources, businesses, and funds in order to realize unified management and dynamic real-time monitoring. Enterprises optimize related business processes and organizational structures and apply intelligent analysis models to perform intelligent decision-making based on big data analysis to realize the unified and balanced scheduling of human, financial, and material resources, as well as for collaborative sharing and optimized configuration. The management refinement level and efficiency should be continuously improved through the closed-loop management and control, which include activities ranging from strategies to business management.

3.1.1 Diversified job responsibilities

In the era of Internet Plus, information technology promotes an organization’s job/role changes and largely extends the scope of personal activities. The role of individuals in with regard to organizational and operating practices has become increasingly prominent. Individuals may be assigned multiple job responsibilities and roles in production activities, or one job or role may be shared by multiple individuals. This requires individuals to shift from the traditional model in which the responsibilities in the organization are fixed, toward one in which these responsibilities are flexible and diverse. In addition, cooperation between the producers must be made more dynamic and flexible. Based on the principle of “process-oriented,” multiple dynamic work groups should be quickly built according to requirements of the process reengineering team. Therefore, organizations in the Internet Plus era should focus on strengthening the management of employee empowerment, inspiring employee innovation potential, and achieving precise empowerment and flexible empowerment through tracking evaluation and continuous optimization.

3.1.2 Integration of business units

The main aim of an organization is to promote its production, operation, management, and service, in addition to other activities such as process integration and interconnection. The main function of the organization is “processoriented” in the sense that it involves the realization the overall optimization of the original work method and mode across various business fields or links. The barriers between business links have been broken down and the optimal allocation and unification of resources has been realized based on comprehensive coverage and integration in digital technology and single business. The focus of integrated development work is shifting from “deepening local applications” to “breaking through comprehensive integration”. With the promotion and penetration of information technologies in offices, finance, R&D, production, procurement, sales, and other individual business links, key business system integration, resource optimization, and integrated management models are now being explored. For example, financial integration management and control, strategic integration management and control, and intelligent development of business decisions are based on business units to enable the integration of interconnections. The opening of “departmental walls” and “information islands” between links can therefore facilitate performance improvement in business management.

3.1.3 Flexible organizational structure

To adapt to the ever-changing market needs, the internal organizational structure of the enterprise is changing from one that is traditional, unidirectional, hierarchical, and multi-departmental, and has a decentralized coexistence toward one that is flat and involves integrated collaboration. Through emphasis on and transformation of data management, the data throughout the lifecycle of the product are monitored and circulated in real time. Owing to unclear rights, responsibilities, and unsmooth information, management constraints are avoided. With the optimization of business processes, the industrial collaboration, organizational reorganization, process reengineering, and redistribution of rights and benefits will become deeper, and the requirements for standardization, precision, flexibility, and openness of the management model will be further improved. When the internal links are integrated and interconnected in the enterprise, there will be significant process-oriented and network-based changes in organizational modes and flexibility. Approximately 60% of enterprises have formed a process-oriented or networked organization pattern, and the performance management patterns have also changed from traditional empirical management to accurate management based on comprehensive business data and value-network-based value performance management.

3.1.4 Blurred organizational boundaries

Organizational boundaries have blurred in the current era of Internet Plus, leading to the creation of virtualized organizational functional units, scattered organizational elements, and flexible organizations. The platform economy connects the ecosystem of all relevant parties in the company with the same interest orientation, realizing efficient division of labor, collaboration, cross-enterprise resource integration, and overall planning. The innovation vitality of enterprises is mobilized and stimulated to the greatest extent, and competitiveness has been effectively improved. For example, the community, based on the agreement of the industrial Internet platform, promotes the coordinated development of the industrial chain, and realizes coordination of production planning, R&D design, procurement, sales, logistics, financial settlement, and other links through the relevant parties, which has provided the foundation for the formation of the industrial structure of the full traceability of orders and full control of quality among enterprises, and effectively improves the company’s ability to control the supply chain. In China, 10% of enterprises have conditions for coordinated development of the current industrial chain.

《3.2 Value network innovation in the context of Internet Plus》

3.2 Value network innovation in the context of Internet Plus

In the context of Internet Plus, driven by the information technology and data core, the organization actively develops the coverage and application of digital tools throughout the product lifecycle and conducts related management and maintenance of product-related data. It also continues to optimize product design, enhance R&D and innovation capabilities, carry out interactive collaborative R&D, promote R&D integration of art and manufacturing, and enrich user-oriented value-added services. Companies focus on various aspects of the product lifecycle to actively carry out related explorations on integrated management and control of the entire product lifecycle.

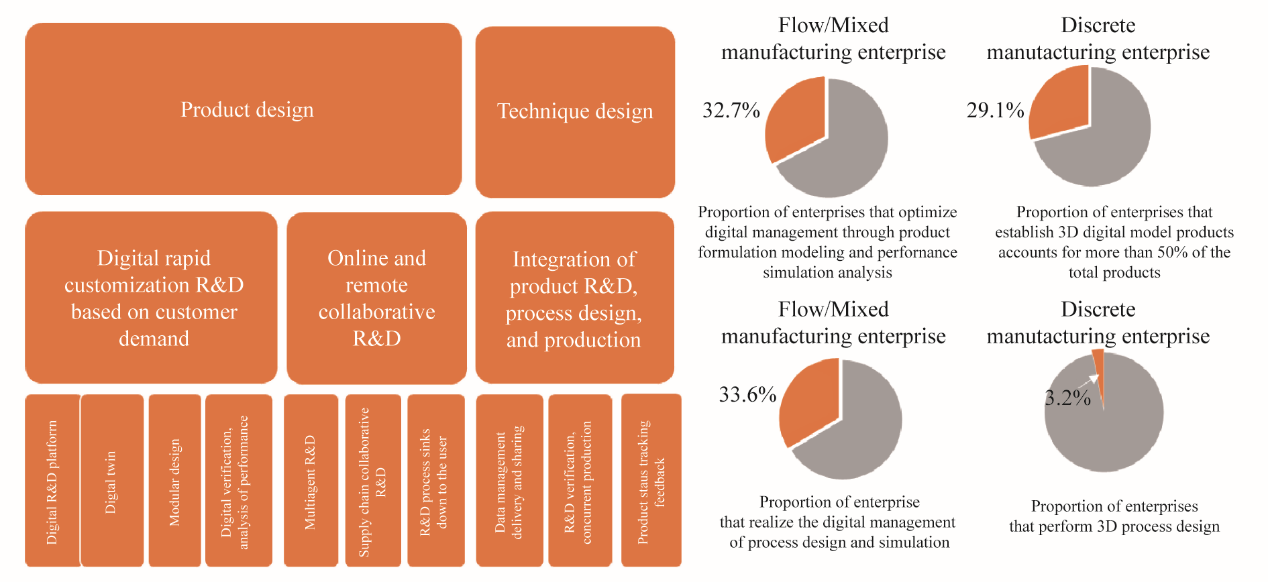

3.2.1 Agile and precise responses to market demand in R&D design

The R&D design link is at the forefront of the product lifecycle and largely determines product performance, quality, quantity, and cost [13]. During product design, 32.7% of the process/hybrid manufacturing companies achieve optimal digital management of product formulation and performance simulation analysis, whereas 29.1% of the discrete manufacturing companies establish three-dimensional (3D) digital model products that account for more than 50% of the total number of products. In the process design link, 33.6% of the process/mixture manufacturing companies realize digital management of process design and process simulation, whereas only 3.2% of the companies simultaneously realize 3D product design and process design (Fig. 3).

《Fig. 3》

Fig. 3. Innovation direction and status quo of product design and process design of Chinese enterprises in 2019.

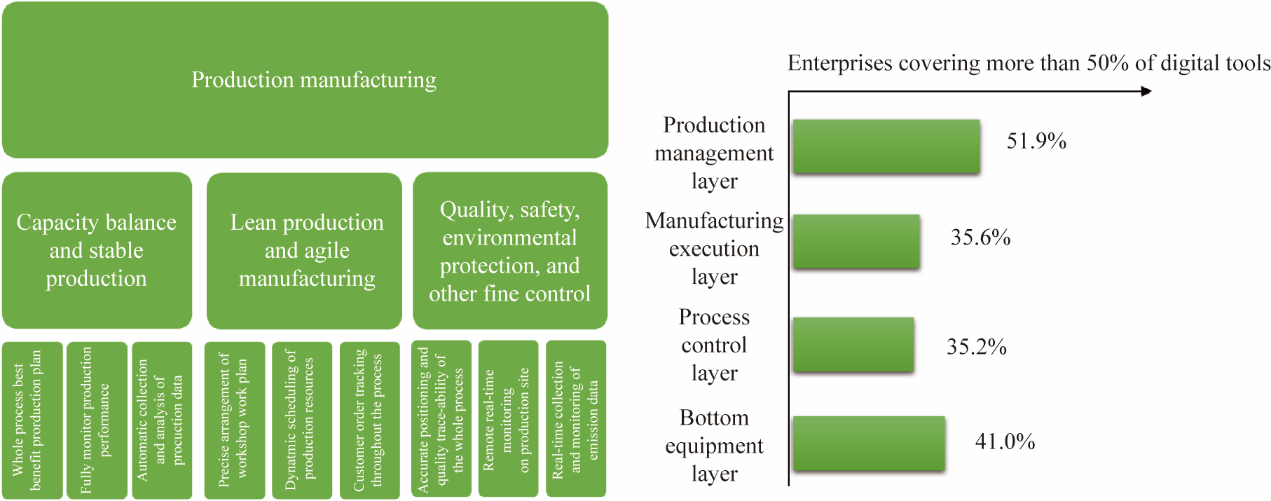

3.2.2 Flexibility in production and manufacturing and lean expression in R&D design

The manufacturing process is the core of corporate value creation and has high complexity and large industry differences. It involves numerous aspects such as production equipment, industrial control software, and underlying network facilities. Companies are required to improve the digitization level of the entire production process, strengthen information exchange, promote closed-loop production control, improve capacity utilization, and optimize the allocation of various production resources. Companies conduct exploration focusing on various aspects of production capacity balance and stable production, lean production and agile manufacturing, quality, fine control of quality, safety, and environmental protection. The proportions of enterprises whose manufacturing processes in the bottom equipment, process control, manufacturing execution, and production management layers realize digital tools covering more than 50% are 41.0%, 35.2%, 35.6%, and 51.9%, respectively (Fig. 4).

《Fig. 4》

Fig. 4. Innovation pathway and status quo of Chinese enterprises’ production and manufacturing services in 2019.

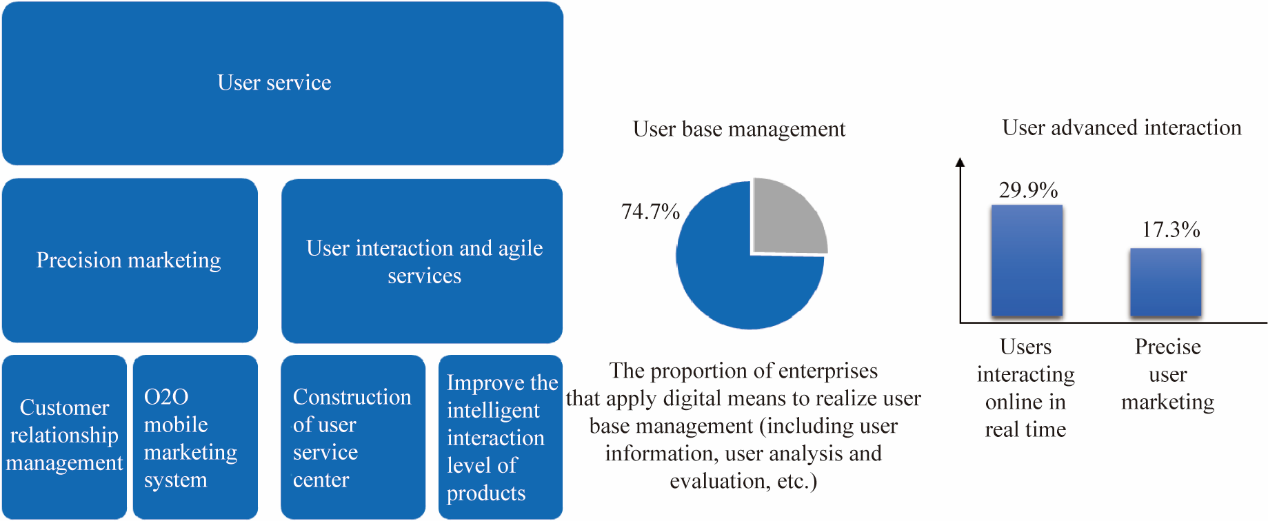

3.2.3 Unlimited user service links and immersive realization of user interaction

User service links are a vital component of the deep interaction between products and end users. The quality and level of user services directly affect the market acceptance of the product. The proportion of enterprises that are increasingly dedicated to user management and apply information technologies to realize user-based management, including basic information management, user-based analysis, and user evaluation, reaches 74.7%. However, the proportion of enterprises that achieve advanced interactions, such as real-time online interaction and precision marketing, is lower than 30% (Fig. 5).

《Fig. 5》

Fig. 5. Innovation direction and status quo of Chinese enterprises’ user services in 2019.

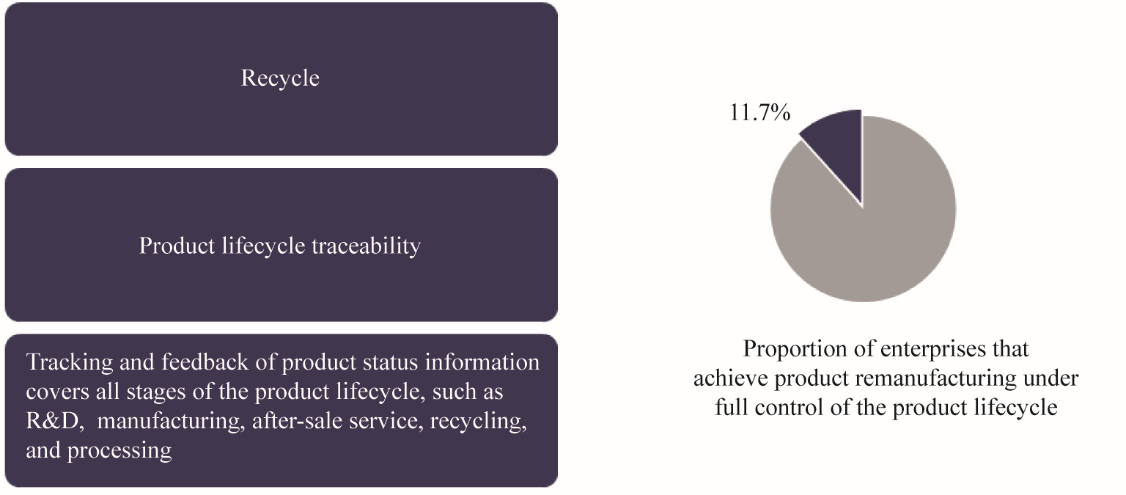

3.2.4 Recycling green link and the systematic extension of the value chain

Recycling marks the end of a product’s life cycle. In recent years, China’s manufacturing companies have gradually begun to promote recycling aiming at digital transformation and green development. The extension of information tracking of product status as well as feedback coverage from research, development, design, production, and after-sales service to recycling, transaction/delivery, service, recycling/termination processing, and other product lifecycles and back-end links of the value chain highlight the role of recycling in value creation. The proportion of enterprises that realize product remanufacturing under the conditions of product lifecycle control is 11.7% (Fig. 6).

《Fig. 6》

Fig. 6. Innovation pathway and status quo of recycling processes of Chinese enterprises in 2019.

《3.3 Resource and environmental innovation in the context of Internet Plus》

3.3 Resource and environmental innovation in the context of Internet Plus

In the context of Internet Plus, various physical systems and information systems constitute the basis and carrier of integrated development. In recent years, particularly during the “13th Five-Year Plan” period, China’s key technologies of major equipment, core industrial software, fifth-generation mobile communications (5G), and network and cloud computing continue to deepen, and the integrated development infrastructure is constantly being consolidated.

3.3.1 Equipment precision and intelligence

The networking of industrial equipment and facilities is the foundation for the sound development of advanced manufacturing ecology. During the “13th Five-Year Plan” period, owing to projects such as manufacturing of innovation centers, smart manufacturing, and green manufacturing, 5G chips were introduced for commercial use, new breakthroughs were achieved in the mass production of storage devices and flexible display screens, and design and manufacture of multi-axis precision computer numerical control machine tools and industrial robots garnered significant attention. However, owing to the impact of the traditional industrial closed technology system and value barriers, unclear business models, insufficient online service capabilities, high equipment access costs, and insufficient value return expectations, the level of networking of industrial equipment and facilities in China is generally not high. In 2019, the rate of production equipment digitization of China’s enterprises was only 47.1%, whereas the rate of digital production equipment networking was only 41.0%. The digital transformation of enterprises must be break through the bottleneck of the terminal’s full connection.

3.3.2 Platformization and microservice of software

With the active development of technologies such as cloud computing and the industrial Internet, industrial applications (apps) have now become increasingly common in the development of industrial software. The layout and development of such apps are important for the collaborative evolution of the Internet platform application ecology. Countries have accelerated the advancement of industrial technology along with the development of industry APP. China’s industrial development of APP is still in its infancy and there is a large technological gap between China and developed countries in this regard. In 2019, China’s industrial APP application rate was 19.1%. Some leading companies have already explored layouts focusing on industrial apps. In particular, in some large and medium-sized enterprises, industrial applications have become an important auxiliary means for product development and for the operation of large-scale manufacturing systems.

3.3.3 High network speed and low consumption

The enthusiasm associated with “5G + industrial Internet” industrial application is continuously increasing, along with the successive emergence of “5G + ultra-clear video,” “5G + augmented reality,” “5G + virtual reality,” “5G + drone,” “5G + cloud robot,” “5G + machine vision,” “5G + cloud-based automatic guided transport vehicles,” and other application scenarios. Among them, “5G + ultrahigh-definition video” is the first batch of 5G application scenarios in the industrial Internet field for face recognition, behavior analysis, object recognition, and other intelligent developments. “5G + industrial Internet” comprehensively breaks through time and space constraints of the value creation of production activities, opens the black box of production links, realizes the explicitness of tacit knowledge, and greatly increases the efficiency, quality, and value of production activities.

3.3.4 Open and ecological platform

The industrial cloud platform has effectively reduced the threshold of enterprise informatization application and promoted innovations regarding enterprise production mode and industrial organization. In 2019, the application rate of the national industrial cloud platform reached 44.4%. Recently, an increasing number of large-scale enterprises in China established Internet-based “mass entrepreneurship and innovation” platforms to efficiently gather, open, and distribute various entrepreneurial and innovative resources. They eventually created a new “mass entrepreneurship and innovation” ecology with the aid of rich resources, active innovation, and efficient collaboration. In 2019, 81% of the critical enterprises in key industries in China built and applied the “mass entrepreneurship and innovation” platform.

《4 Prospects of the Internet Plus management system toward 2035》

4 Prospects of the Internet Plus management system toward 2035

《4.1 Evolution of the perspectives of the Internet Plus management system》

4.1 Evolution of the perspectives of the Internet Plus management system

Organizational ecology (subject), value network (object), and resource environment (space) are the three basic perspectives of the Internet Plus management system. The promotion subjects (“who will do it”), activity object (“what to do”), and basic resource conditions (“based on what to do”) are three basic issues in the integrated development of Internet Plus. Predictably, these three perspectives are expected to further evolve in 2035 [14].

4.1.1 Organizational ecology becoming increasingly diverse

Organizational ecology focuses on the basic question of “who will do it,” which forms the main body of organizational integration and innovation developmental activities. In the future information age, closed-loop strategic management, refined financial management and control, and intelligent management and decision-making will have greater practical value. The organizational form of product (service) manufacture has gradually shifted from bureaucracy to a flat, process, and networked mode; organizational management virtualization and blurring of boundaries become important trends in organizational reform and development. The relationship between employees and organizations is gradually transforming from close contact to loose coupling, and this trend of employee creation is becoming increasingly common.

4.1.2 Value network gradually correlating and overlapping

The value network starts from the basic question of “what to do” and revolves around the sections and activities of the product lifecycle and key links of the value chain that describes the objective activity objects. In the future that will be driven by data, the development model of the industrial economy based on material production and material quality services will shift to a sharing and digital economy based on information production and information services. As is evident, flexible production, personalized design, service experience, and product ecology have gradually deepened over the years. The roles of transaction delivery, service, recycling, termination processing, other product lifecycles, and the back end of value chain links in value creation will continue to appear.

4.1.3 Continuous optimization and upgrading of resources and environment

Starting from the basic question of “what to do” based on resources and environment lay the foundation involved in the development of integrated innovation, which includes equipment, software, networks, and platforms. With the current stage of development, intelligent and precise equipment, platformed and microservice software, high-speed and low-consumption networks, and open and ecological platforms are expected to become increasingly significant. Further, in the coming era of information, the integration of physical systems and information systems will deepen. The new generation of information technology will accelerate the penetration and integration of such systems with the real economy. Cross-domain, collaborative, and networked innovation platforms will reorganize the traditional economic systems.

《4.2 Upgrade of the elements of the Internet Plus management system》

4.2 Upgrade of the elements of the Internet Plus management system

The fundamental factors that affect the organization’s innovation and development and capacity building may change. However, analysis based on core elements is always an effective approach for future research on the Internet Plus management system. From the perspective of the four elements of data, technology, business process, and organizational structure, a discussion of the direction of change and development trend of future enterprise management systems will still be meaningful.

4.2.1 Data becoming a key driver

Data is now considered the new oil of the digital economy and is a key factor driving economic development. In the future, the focus of enterprise production, processing, and manufacturing will be extended from data product services of traditional materials to those of data resource elements. The sustainable competitive advantages of future enterprises will be established on the basis of data production and processing, development and utilization, and value creation. Data-drive-based accurate and dynamic management will become the basic capabilities of future enterprises. The organizational structure, management model, and decision-making methods of the enterprise will depend more on the internal mechanisms, relationships, and interaction rules among the data.

4.2.2 Technological changes lead innovation and development

The new generation of information technologies, such as big data, the Internet, and artificial intelligence, are rapidly developing. Such developments continuously promote the cross integration, interrelated penetration, and mutual driving of various technologies, leading to accelerated innovation and continuous technological breakthroughs. Innovative applications and integrated innovations in technologies will trigger reforms in the optimization of resource allocation within the organization. Further, the industrial chains all over the globe will drive the creation and implementation of new ideas and methods in R&D innovation, operation management, market services, business decision-making, etc., and effectively accelerate the digital, networked, and intelligent development of the industry for the creation of a series of new business models and industrial forms.

4.2.3 Business processes for an extended sharing

As the degree of integration of such technological innovations continues to deepen, the objects, responsibilities, content, and combination methods involved in the business process will undergo continuous refactorization and optimization. Through the introduction and traction of strategic information and system thinking, the rate of efficiency of the enterprise will increase significantly at the global level. Business process optimization and reengineering under the Internet environment emphasize user participation and continuous improvement. Participants will be required to realize real-time online interorganizations by jointly building and sharing more efficient, transparent, and dynamic business processes. Modularization of the business process and reliance on the “plug and play” function to enrich the relationship between different entity connections are expected to be the future development trends.

4.2.4 Breaking of the organizational structure boundary

The traditional organizational structure represented by bureaucracy has clear barriers and is unable to meet the key requirements of continuous iteration, rapid response, and precise decision-making. In the coming age of information, increasingly blurred boundaries between the producers and users, individualized business needs, and decentralized production resources will inevitably promote a flat, flexible, and networked organizational structure. The decentralization trend of an organizational structure will become increasingly obvious. The characteristics of organizational function virtualization, diversification of composition, decentralization of resources, flexibility of response, and networking of associations will also become increasingly clear.

《4.3 Operational model of the Internet Plus management system》

4.3 Operational model of the Internet Plus management system

The operation mode of the management system involves a combination of relevant elements of the system and is a key component affecting the efficiency of the system’s operation. A scientific, reasonable, and coordinated operation mode guarantees the continuous and effective implementation of the management system. The effective operation of the future management system will involve relevant subjects, including implementation personnel, information systems, and artificial intelligence. Characteristic attributes, behavioral habits, and interactive relationships between these subjects will lead to a fundamental difference in the management system.

4.3.1 Transition from economic man to self-realization

In the future, the “economic man” who currently only pursues the maximization of personal interests will aim at accomplishing more complex self-realization goals that will not be purely based on money and material. In other words, more attention will be given to psychological needs with regard to the society, including the pursuit of friendship, loyalty, care, understanding, love, security, belonging, and respect between people. Therefore, the implementation culture of the management system is expected shift from command and control to open and transparent sharing and responsibility.

4.3.2 Continuous improvement of human–computer interaction experience

With the deepening of the application of information technology, the coordination and interaction modes between humans and information systems will undergo a significant change. Many such interpersonal interactions and information transmissions are realized through online systems based on information technology. To ensure that the information system can consider factors such as behavior and emotion, the authenticity of the algorithm should be enhanced, and the coordination and integration of human–computer interaction should be improved. In addition, interactive design should be considered to achieve an interactive experience; this will make user experience more pleasurable while conforming to user logic and also effectively enrich the dimensions of management.

4.3.3 Realization of intelligent decision based on data

Decision making is the core of management and scientific decision making is the core of modern management. As data converge and accumulate, it is possible to use computers to help or replace the human brain to make intelligent decisions with best judgments. With the aid of system science, management science, and computer science, the decision making abilities of management systems will enable them to achieve status awareness and perform realtime analysis, autonomy decision-making, precise execution, learning improvement, real-time optimization, and effective coordination, while making scientific, planned, refined, and personalized managerial decisions.

《5 Countermeasures and suggestions》

5 Countermeasures and suggestions

Driven by the combined forces of the new round of technological revolution and industrial transformation, the evolution and upgrading of management systems and models are the general trend and only approach. In the future, first, we must inherit the innovation, embrace the change, strengthen the top designs, expand ideas, employ a longterm view and create overall plans, and continue to build and improve the future-oriented “interconnection Network +” management system. Second, we must make breakthroughs, test first, focus on the future digital era and core features of the new generation of information technology, tackle the issues from the core, make targeted efforts, create a management innovation “experimental field,” and release force of examples. Third, to popularize science, we should actively guide and promote the role of publicity training and model demonstration, enhance public understanding and awareness, and cultivate compound talents of theory, management, general industry, application, and technology. Fourth, we must employ a step-by-step approach and transform from quantity to quality, because management reforms as a result of multi-party integration of thinking, technology, and data cannot be accomplished overnight. Instead, we must aim at leading the innovation and upgrading of real economy management in an orderly manner, from a shallower level to one that is deeper.

京公网安备 11010502051620号

京公网安备 11010502051620号