《1 Introduction 》

1 Introduction

Natural gas hydrate (NGH) is a solid cage compound that is formed by natural gas and water at low temperature and high pressure [1]. It corresponds to a high-energy density resource that is present in the Earth’s crust in large amounts [2]. The total amount of CH4 gas contained in global NGH resources is approximately 3×1015 m3 , and it mainly exists in the undersea and terrestrial permafrost regions; marine NGH accounts for more than 95% of the total hydrate reserves [3]. Therefore, NGH, especially marine NGH, is considered a source of new clean unconventional energy that can replace traditional fossil energy sources [4]. NGH can be classified as diagenetic and non-diagenetic based on whether the formation remains intact after hydrate decomposition. The fine grain fissure type and dispersed hydrate, which account for the majority of the total hydrates, are of the non-diagenetic type with the exception of a few sandstone and sandstone fissure hydrates that are of the diagenetic type [5]. Among these types of hydrates, dispersed NGH resources exist in fine sediments at the bottom of the sea and account for approximately 90% of the total hydrate resources with low saturation (<10% of the pore volume), weak cementation, and poor permeability. The exploitation of this type of hydrate involves many issues, including high technical difficulties, poor economy, and high risk. Most NGHs in the South China Sea are dispersed. Hence, breakthroughs in mining technology and equipment are essential for supporting the commercial exploitation of gas hydrates in the South China Sea.

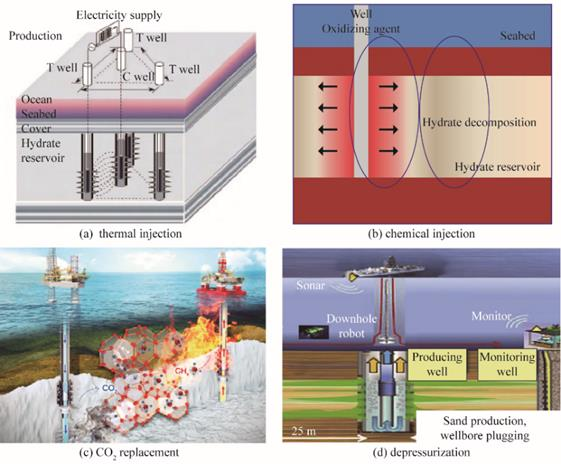

Currently, NGH mining methods include thermal injection, chemical injection, CO2 replacement, depressurization, and solid-state fluidization [6]. The first four are traditional mining methods, which realize the in situ decomposition of natural gas, and their principles are shown in Fig. 1. The heat injection method involves injecting a thermal fluid into the hydrate layer to break the condition of hydrate phase equilibrium and to promote the decomposition of hydrate into natural gas. The chemical injection method changes the natural phase equilibrium of the hydrate by injecting a chemical agent into the underground hydrate layer, and the hydrate is then decomposed under the original temperature and pressure. The CO2 replacement method utilizes the fact that CO2 molecules can easily combine with water; thus, natural gas can be replaced by injecting CO2 into the formation. In the depressurization method, the hydrate phase equilibrium is disturbed by decreasing the hydrate reservoir pressure and promoting hydrate decomposition. Furthermore, solid-state fluidization ensures that the hydrate is solid in situ and promotes hydrate decomposition after it enters the confined space. Thermal injection and chemical injection are economically inefficient [7,8], and relatively few studies focus on them [9]. The CO2 replacement method exhibits advantages of reducing the risk of geological disasters and the probability of the sequestration of CO2 to mitigate the greenhouse effect [10]. However, low replacement rate and efficiency [11] restrict the application of this method. The depressurization method does not require continuous stimulation, and it is considered as an economical method with immense development potential [12]. However, existing issues include secondary generation of hydrates, low production efficiency, and geological engineering disasters such as submarine landslides and borehole wall instability [13]. Compared with other mining methods, the solid-state fluidization method can reduce geological environmental risks due to underground decomposition of hydrates. However, it also exhibits certain problems such as low production and significant challenges in post-mining stratum remediation technology [14]. Currently, depressurization and solid-state fluidization methods are successfully used in marine NGH pilot production projects, thereby leading to significant progress in mining technology. However, the production of hydrates in trial mining is still low. Hence, a significant production gap exists compared with commercial mining. Furthermore, potential geological, equipment, and environmental risks in the mining process have not been fundamentally eliminated. Therefore, it is necessary to analyze the development status of hydrate-mining technology and equipment and evaluate technical bottlenecks that restrict the development of hydrates.

《Fig. 1》

Fig. 1. Schematic of the process principle of the traditional hydrate-mining method.

In the study, we focus on the depressurization and solid-state fluidization of marine NGH and analyze the development status and existing problems from two aspects: special technology and equipment for hydrate exploitation, and general technology and equipment for hydrate-offshore oil and gas-submarine minerals. Finally, in the study, we propose suggestions for research in the field and provide a reference for research on hydrate exploitation technology and equipment development routes.

《2 Marine NGH exploration – analysis of case studies 》

2 Marine NGH exploration – analysis of case studies

《2.1 Exploitation of NGH via the depressurization method in Nankai Trough, Japan》

2.1 Exploitation of NGH via the depressurization method in Nankai Trough, Japan

Recently, five marine NGH trail mining operations were conducted worldwide, and they effectively promoted the development of related mining technologies. The first trial mining operation of marine NGH was conducted in the Nankai Trough, Japan, in March 2013. Hydrate deposits were exploited via fluid extraction. Electric submersible pumps were used to extract fluid in order to decrease formation pressure and hydrate the natural gas. The material was decomposed and recovered. However, the trail mining operation was forcibly stopped owing to sand production at the bottom of the well. After six days of trial mining operations, the cumulative production was 1.2×105 m3 [15]. In 2017, a second trial mining operation was conducted in Japan in the same sea area. The mining operation was forcibly switched to the second mining well because of serious sand production problems at the bottom of the well [16]. The technical feasibility of depressurized exploitation of marine NGH was initially verified via two trial productions in Japan. However, the issue of sand production at the bottom of the well should be urgently solved.

《2.2 Trial mining of NGH via the depressurization method in the Shenhu area of South China Sea》

2.2 Trial mining of NGH via the depressurization method in the Shenhu area of South China Sea

From May to July 2017, China implemented marine NGH trial mining operations in the Shenhu area of the South China Sea via the depressurization method. Hydraulic slitting was adopted, because the trial mining reservoirs had fine-grained sediments and low permeability. The method can reform the reservoir and effectively improve production during trial production [17]. From October 2019 to April 2020, the China Geological Survey conducted the second gas hydrate depressurization test in the Shenhu area at a depth of 1225 m in the South China Sea [18]. In the two trials, a series of technical problems were solved in deep water and shallow soft formations, including drilling wellhead stability, horizontal well directional drilling, reservoir stimulation and sand control, and precise pressure reduction. This led to continuous gas production for 30 d with a total natural gas output of approximately 8.614×105 m3 and average daily natural gas production of 2.87×104 m3 . This indicates that marine NGH-mining technology in China has advanced to an international leading level. However, it should be emphasized that this was only a shortterm trial mining success. The output and mining time have not reached commercial mining levels. The potential geological environmental risks associated with long-term mining are not fundamentally resolved. Further verification is necessary to determine whether the mining technology and equipment used in short-term mining trial can withstand the requirements of long-term commercial mining.

《2.3 Trial mining via the solid-state fluidization method in the South China Sea》

2.3 Trial mining via the solid-state fluidization method in the South China Sea

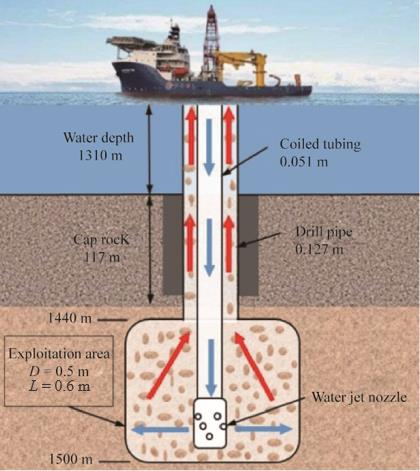

In May 2017, China National Offshore Oil Corporation successfully implemented the world’s first solid-state fluidized trial production of non-diagenetic gas hydrate in shallow oceans by utilizing the Offshore Oil 708 deepwater engineering survey ship at Liwan No. 3 in the northern part of the South China Sea. The trial was conducted using fully self-developed technologies, processes, and equipment at a water depth of 1310 m. The hydrate orebody is buried at a depth of 117–196 m. The trial mining process for the solid-state fluidization method of the South China Sea is shown in Fig. 2. During the mining process, a nozzle jet was used to break the hydrate orebody around the borehole. Approximately 101 m3 of natural gas was produced after approximately 2 h of jet mining. This quantity of natural gas satisfied the trial production target [5]. The operation initially verified the feasibility of the solid-state fluidization method for mining marine NGHs at a technical level. However, the output of the solid-state fluidization method was still low and technical issues (such as drilling fluid loss, high-concentration slurry transportation, formation repair in the mined-out area, and regulation of the orderly release of stress accumulation in hydrate wellbores) were identified.

《Fig. 2》

Fig. 2. Solid-state fluidized trial production process of marine NGH [20].

Note: D denotes the diameter of the mining cavity and L denotes the length of the mining cavity.

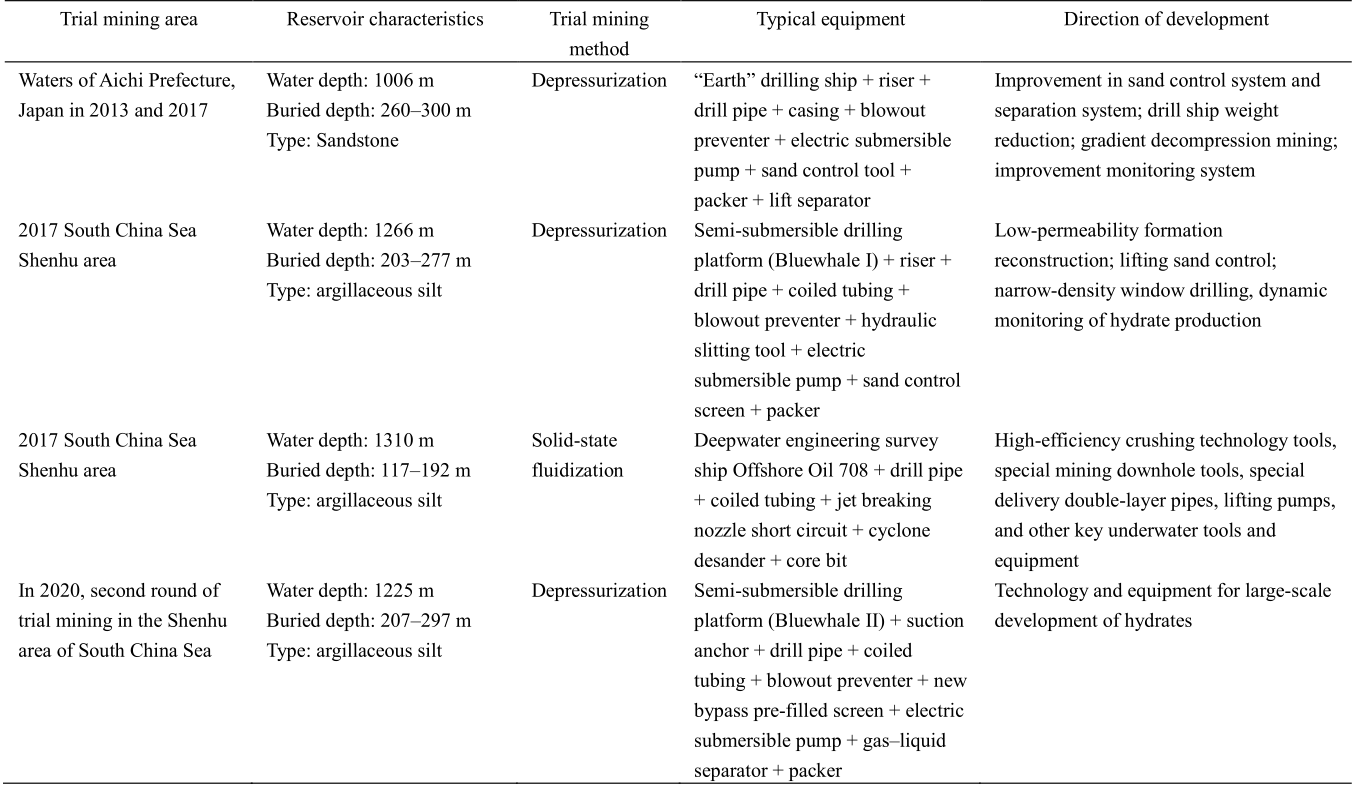

Table 1 lists relevant information on the trial production process and typical technical equipment for the marine NGH trial production cases. In the trial production, traditional technical equipment were adopted, and there was a lack of special technologies and supporting equipment for large-scale hydrate development.

《Table 1》

Table 1. Typical technical equipment for trial production of marine NGH.

《3 Development status of technical equipment for marine NGH mining in China and abroad》

3 Development status of technical equipment for marine NGH mining in China and abroad

Based on the differences in applicability, hydrate-mining technical equipment can be classified into general key technical equipment and special technical equipment. The former refers to technical equipment, which is suitable for marine NGH-mining industry, and it can be applied in other industries such as offshore oil and gas or deep-sea mining. The latter refers to technical equipment that can only be applied to the exploitation of marine NGHs.

《3.1 General technical equipment 》

3.1 General technical equipment

3.1.1 Deep-sea mining vehicle

A seabed mining vehicle is the key equipment in solid-state fluidization technology for seabed surface gas hydrates, as well as the key equipment in seabed mineral resource mining technology. For the Nautilus mining ship project, Specialist Machinery Development (SMD), United Kingdom, developed three large pieces of equipment that can operate at depths as low as 1700 m and can be used for digging, crushing, and collecting. The Changsha Institute of Mining Research developed a mining vehicle with an operating water depth as low as 1000 m. However, the mining vehicle is primarily an experimental equipment and does not exhibit digging and crushing functions. Currently, the two aforementioned pieces of equipment were tested at a water depth of 100 m. However, neither of the equipment were operated at a water depth of 1000 m. They constitute equipment developed for seabed mineral extraction, as opposed that to seabed surface hydrate extraction.

3.1.2 Dual-gradient drilling technology for loose shallow surface

China proposed a new deepwater safety drilling technology for hydrates in deep water with a controllable annulus slurry level, submarine mud pump lift, and double-layer pipe double-gradient [21]. However, it is still not suitable for engineering applications. Foreign dual-gradient drilling technology is relatively mature. It has been commercialized and applied to deepwater oil and gas drilling but has not been used for hydrate mining. However, the technology blockade from other countries has restricted the exploitation of oil, gas, and hydrates in shallow waters.

3.1.3 High-strength lightweight flexible pipe

High-strength lightweight flexible pipes are mainly used in applications involving hydrate and offshore oil and gas exploitation. Baoji Petroleum Machinery Co., Ltd., produces coiled tubing although key parameters, including product diameter and length, are lower than those produced in foreign countries.

3.1.4 Submarine slurry lift pump

Submarine slurry lift pumps can be used to exploit marine hydrates and also to exploit seabed mineral resources. A slurry pump developed in China can realize a slurry lift with a displacement of 120 m3 /h for a water depth of 1000 m and slurry maximum particle size of 20 mm. Furthermore, the water depth, maximum particle size, and efflux displacement of the slurry pump abroad are 3500 m, 50 mm, and 405 m3 /h, respectively. A large difference exists between the domestic and foreign slurry lift pumps.

3.1.5 Subsea/downhole gas–liquid–solid multiphase separator

Currently, downhole separators, including gas–liquid separators for oil and gas and the hydrate gas–liquid–solid multiphase downhole separator in China, are still in the experimental stage. Although other countries have already developed the technology for gas–liquid–solid separation with small treatment capacity, they are yet to satisfy hydrate extraction requirements.

In conclusion, overall, the level of general key technologies and equipment in China trails behind that of foreign countries, and only a few technology applications are slightly ahead. Furthermore, existing equipment and technology level of foreign countries still lag behind that used in commercial mining of hydrates or seabed metal mines.

《3.2 Dedicated key technical equipment 》

3.2 Dedicated key technical equipment

3.2.1 Sand control technology and equipment

Hydrate reservoirs are non-cemented fine-grained sediments, and the problem of downhole sand production occurs during hydrate mining. Sand control screens and a new type of bypass pre-filled screen sand control technology were used in the test production of hydrates in the South China Sea to ensure the smooth progress of the test production. Japan adopted Baker Hughes GeoFORM sand control tools, which confirmed the effectiveness of downhole expansion and sand control in trial production. However, trial production was interrupted due to sand plugging. Overall, the current domestic sand control technology is in a leading position, although further evaluation is required to determine whether it can ensure the long-term commercial exploitation of hydrates.

3.2.2 Prefabricated directional drilling technology for shallow hydrate mining

In contrast to the basic theory of traditional deflection steering, loose shallow surface deflection steering focuses on higher requirements including strength, flexibility, turning radius, and reservoir adaptability of the steering tool. Specialized pre-inclined steering drilling for hydrate-mining technology and tools are urgently required. The progress in domestic development is as follows. The Honghua Group developed the coiled tube ultra-short radius directional drilling technology, which can realize 8–9°/30 m deflection. Orito Energy Technology Co., Ltd., proposed that it can adapt to soft bent-screw deflection technology and equipment (2–4° / 9.6 m) for the formation. Moreover, the China Geological Survey adopted the suction anchor pre-deflection directional drilling technology to successfully implement the horizontal well exploitation of marine NGH. The development progress in foreign countries is as follows. NeoDrill Technology Company proposed a suction anchor-based prefabricated directional drilling technology (90°/100–250 m). The American Schlumberger Company proposed a new type of bit directional drilling technology and tool (16.7°/ 30 m). Thus, a certain gap exists in the level of domestic deflecting technology compared with foreign countries. The gap is particularly evident in pre-inclined directional drilling technology suitable for soft formations.

This technology corresponds to a specific implementation technology based on the solid-state fluidization mining method of marine NGH. However, relevant supporting technologies and equipment are not developed worldwide. Domestic jet breaking nozzle tools and process charts have been successfully used to hydrate fluidized trial production, and the supporting downhole recovery device for improving hydrate production efficiency is still in the indoor integrated joint debugging/land well experimental test stage. Given the issues of low efficiency of jet crushing and fluidization, serious leakage, and post-harvest stratum repair, it is critical to expand research on integrated drilling and mining technology and on equipment for hydrate crushing and recovery.

3.2.4 Experimental simulation platform for hydrate mining

Relevant experimental testing devices for hydrate synthesis, decomposition kinetics, and physical properties have been developed in China. Furthermore, a pipe string experimental simulation system for a solid fluidized hydrate mining tool and a sliding experiment simulation device for goaf were preliminarily established. Hydrate experimental devices are used for synthesis, decomposition, and basic physical property research of the simulation test platform. Overall, there is a shortage of technical experimental equipment required for research on hydrate depressurization, solid-state fluidization, and combined mining technology. Furthermore, the evaluation of the suitability of the tool string and the simulation analysis of reservoir risk assessment are required.

3.2.5 Commingled production technical equipment for hydrate, free gas, and natural gas

Given the issues of low hydrate production and poor economic benefits, commingled production technology of hydrate, free gas, and conventional natural gas (hereafter, three-gas commingled production) has been proposed in China to fully utilize the mining equipment and decrease the economic cost of mining. However, the mechanism and core technical equipment for the integrated development of seabed surface, mid-deep gas hydrates, and deep oil and gas resources for the three-gas commingled production have not been established to date. Further, there is a lack of supporting technical equipment for the implementation of the three-gas commingled production.

In summary, China is at a leading level in terms of special technical equipment for hydrate mining. Sand control technology and equipment based on the depressurization method ensure the smooth progress of the two trial mining methods. Integrated drilling and production technology and equipment for hydrate crushing, recovery, and separation and the experimental simulation platform for hydrate mining have been pioneered. Hence, they are leading in terms of replacing pre-developed directional horizontal drilling technology for loose shallow surface hydrate drilling. Additionally, the technical idea of three-gas commingled production proposed by China is expected to be an important technical direction for increasing hydrate production and realizing commercial hydrate mining.

《4 Development ideas and suggestions for China’s marine NGH mining》

4 Development ideas and suggestions for China’s marine NGH mining

Based on the development status of marine NGH trial production, current challenges in hydrate development include difficulty in continuous production, low output, lack of special equipment for hydrate mining, short trial production cycle time, and safety risks that have not yet emerged. Given the focus on the strategic goal of safe and large-scale development of marine NGHs, it is important to urgently address global problems, such as environmental, lack of equipment, and geological risks, for the development of non-diagenetic hydrates. Hence, the future development direction of marine NGH mining technology and equipment corresponds to the key technology and equipment that is urgently required for the development of deepwater oil and gas, hydrates, and seabed mineral resources, along with special key technologies and equipment that are essential for hydrate mining.

《4.1 Strategic goals for the development of marine NGH technology and equipment》

4.1 Strategic goals for the development of marine NGH technology and equipment

A comparison of the development of key technologies and equipment for marine NGH development in China and other countries indicates that China’s jet crushing recovery technology and equipment, simulation experimental platform for hydrate production, and innovative method of three-gas commingled production are in the leading position on an international level. However, core equipment including pre-oblique guidance, safe drilling, underwater wellhead, efficient sand control, and multiphase flow pumping and lifting are monopolized by other countries. The domestication rate of the equipment is low; it is 5–8 years behind that of the advancement at the international level.

Table 2 lists China’s strategic objectives for the development of marine NGH technology and equipment. The objectives are as follows: complete the R&D of key technologies and equipment for safe drilling and production of hydrate trials by 2025; realize stable, large-scale hydrate production by 2030; and establish a complete set of engineering and equipment systems for large-scale hydrate development by 2035.

《Table 2》

Table 2. Strategic planning for the development of marine NGH technology and equipment.

《4.2 Development directions of general key technologies and equipment 》

4.2 Development directions of general key technologies and equipment

4.2.1 Intelligent mining vehicles suitable for collaborative development of deep seabed mineral resources and hydrates

An intelligent mining vehicle for intelligent walking, path planning, and efficient mining on the seabed surface is the core equipment that is required for deep-sea mining and deep-sea surface non-diagenetic hydrate mining. The development and application of this equipment is critical for aiding the development of deep-ocean mineral resources (metallic and hydrate minerals), occupying strategic commanding heights of deep-sea energy development, and promoting China’s marine power. Our recommendations include setting up a key R&D program for the development and application of intelligent mining equipment for the collaborative development of deep-sea mineral resources and hydrates. This will also address the technical bottleneck of deep-sea resource development, general core technology, and equipment restricted by foreign technology.

4.2.2 Dual-gradient drilling technology and equipment for collaborative development of deepwater oil, gas, and hydrate in China

In a manner similar to deepwater oil and gas exploitation, the exploitation of marine NGH faces challenges involving narrow safety drilling pressure window for loose shallow surface layers, poor wellbore stability, high drilling risks, and high costs. Thus, it is essential to urgently develop dual-gradient drilling technology and equipment, which can be used for the coordinated development and safe drilling of deepwater oil, gas, and hydrate. Furthermore, independent intellectual property rights should be protected to address foreign technology blockades and monopolies and to ensure China’s energy strategic security. A major scientific and technological project to demonstrate the application of safe drilling dual-gradient drilling technology and equipment engineering for the collaborative development of deepwater oil, gas, and hydrate is also recommended.

4.2.3 Development and application of multiphase flow pumping and high-efficiency separation devices for deepwater hydrate, submarine mineral resource exploitation, and deepwater oil and gas development

A multiphase flow pumping and lifting device for deep sea resource development is directly related to the productivity of deepwater marine NGH and submarine mineral resource extraction pumping, as well as to the dualgradient drilling effect of the subsea pump lifting in deepwater oil and gas development. An efficient separation device for multiphase flow transportation is directly related to the energy consumption on the recovery of hydrate slurry and pipeline transportation of seabed mineral resources. In order to achieve safe, efficient, and low-cost development, general key devices should be developed and applied for multiphase flow pumping, lifting, and efficient separation to realize the collaborative development of deepwater oil and gas, marine NGHs, and submarine mineral resources, and to provide general equipment support.

《4.3 Development directions of special key technologies and equipment 》

4.3 Development directions of special key technologies and equipment

4.3.1 High-efficiency sand control technology and equipment for continuous deepwater hydrate mining

Sand control technology and equipment are directly related to long-term, continuous, and large-scale development as well as the stable production and efficiency of hydrates. Hence, an R&D project is recommended in the field.

4.3.2 Integrated drilling and production technology and equipment for efficient crushing, recovery, separation, and pumping of deepwater marine non-diagenetic hydrates

Issues including low mining efficiency, serious leakage, and high pumping energy consumption persist. There is a lack of integrated drilling and production technology and equipment for efficient breaking, recovery, and separation of marine non-diagenetic hydrates and pumping. Hence, it is extremely important to realize a breakthrough in integrated drilling, production technology, and equipment for fluidized hydrate mining. Furthermore, a breakthrough in the integrated mining model of the South China Sea marine NGH jet fragmentation recovery, pumping, and separation backfill, is urgently needed. Our recommendations include setting up key R&D projects for integrated drilling and production technology. Furthermore, equipment for the efficient crushing, recovery and separation of marine non-diagenetic gas hydrates; pumping; and transportation should be developed for providing support to demonstrate the applications of core technology and equipment for the large-scale development of marine NGHs.

4.3.3 Large-scale scientific experimental devices

The R&D of large-scale scientific experimental devices provide experimental environments and test guarantees for hydrate depressurization, solid-state fluidization, combined mining process equipment, and reservoir risk monitoring and evaluation simulation during mining. Our recommendations include establishing a major scientific research instrument and equipment development project to provide a scientific basis and experimental platform support for the process design of commercial hydrate mining implementation, R&D of supporting equipment, and mining risk assessment.

4.3.4 Core technologies and equipment supporting implementation of three-gas commingled production in a threedimensional development project

With respect to the three-gas commingled production and three-dimensional development project implementation, it is necessary to set up major national scientific and technological engineering projects to ensure the stable trial production of marine NGHs. Major technical bottlenecks in chemical gas production, research, and development of major equipment, which can support the three-dimensional development and implementation of three-gas commingled production, should be overcome to promote the transition from stable test production to pilot demonstration.

《5 Conclusion》

5 Conclusion

Marine NGH is a clean alternative energy source with large reserves. Current and future goals of hydrate mining include safe, efficient, and economic development. The exploitation of this resource is still in the stage of trial mining technology verification, exploratory trial mining, and experimental trial mining. Thus, a large gap exists between the development of the relevant technology and the realization of commercial hydrate mining. In the future, the development of marine NGHs should focus on addressing global risk problems related to the environment, equipment, and geology, while developing marine non-diagenetic hydrates on a large scale.

The main problem in the exploitation of marine NGH is the lack of a long-term economic and safe exploitation methods. Therefore, it is important to develop a method and related technology that can satisfy commercial exploitation of hydrates in follow-up research. Mining volume and economical aspects should be considered while ensuring that the long-term mining process does not cause geological environmental disasters. Specific technology and equipment should be developed based on an in-depth demonstration of the feasibility of the new mining method.

To fully utilize marine NGH resources, it is recommended to formulate a R&D plan for the marine NGH development technology and equipment at the national level to promote the commercial development of hydrates. Specifically, it is necessary to implement the R&D and application of special and general technical equipment for marine non-diagenetic hydrate mining, drive the advancement of marine hydrate trial mining technology, promote stable trial mining of marine NGH and pilot demonstration of core equipment in sea trials, upgrade hydrate trial mining plans and core technology and equipment to the advanced international level, lay a solid foundation for commercializing the development of marine NGHs, and form a complete system for the scaled and commercial mining of hydrates.

京公网安备 11010502051620号

京公网安备 11010502051620号