《1. Introduction》

1. Introduction

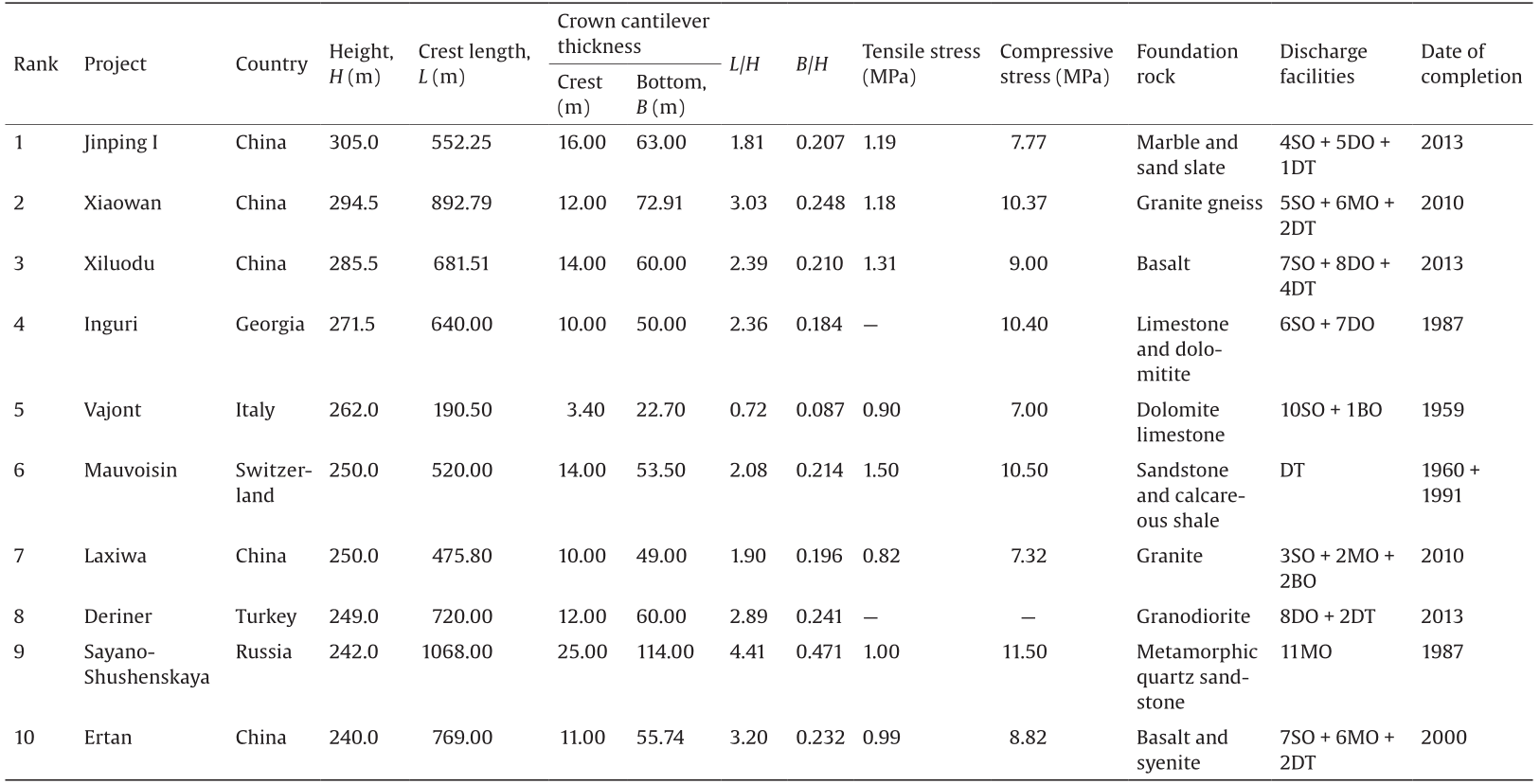

In the last 20 years, China has built seven very high arch dams. With heights exceeding 200 m, these dams are commonly referred to as ultra-high arch dams [1]. The Ertan arch dam (240 m) was completed in 2000 and was China’s first ultra-high arch dam, followed by the Laxiwa (250 m), Goupitan (232.5 m), Xiaowan (294.5 m), Xiluodu (285.5 m), Jinping I (305 m), and Dagangshan (210 m) arch dams. The Jinping I, Xiaowan, and Xiluodu dams are the world’s three highest arch dams (Table 1). More high arch dams are under construction or planned for construction in China, including the Baihetan (289 m) and Wudongde (270 m) dams.

With a greater dam height and higher water pressure, high arch dams have greater demands for strength and stability of the dam foundation and require stricter safety control than lower arch dams. In addition, high arch dams at the 300 m height level (i.e., near or over 300 m) present greater challenges on issues such as crack prevention in mass concrete, seismic safety, and temperature and crack control during construction. It is difficult to control the safety of 300 m high arch dams.

The highest arch dam in the world, the Jinping I Dam, is built in an area with complicated geological conditions. The dam is located in a narrow V-shaped valley with a foundation that is mainly composed of marble and sand slate. The marble has high strength and a blocky structure, while the sand slate is in poor condition. The sand slate is mostly located in the middle and upper part of the left abutment. The sharp river down-cutting led to extensive toppling of the sand slate. The deformation modulus of the sand slate is 1–2 GPa. In addition, the existence of porphyry dikes, interlayer squeeze zones, unloaded and stress-released zones, and other geological defects makes the geological condition of the dam foundation very complicated. The horizontal components of the peak ground acceleration on the rock surface are 269 Gal for the design earthquake (2% probability of exceedance in 100 years) and 317 Gal for the checking earthquake (1% probability of exceedance in 100 years). Foundation treatments and overall stability are the key problems for dam safety control.

Located in a V-shaped valley, the Xiaowan Dam has a maximum height of 294.5 m and a crest length of 892.79 m. The crest length to dam height ratio is 3.03 and the largest water thrust is 1.8 ×108 kN. The dam foundation consists of granite gneiss of overall good geologic condition, except for a number of faults and altered rock bands in the upper parts of the abutments. The horizontal component of the peak ground accelerations on the rock surface of the design and checking earthquakes are 313 Gal and 359 Gal, respectively.

《Table 1》

Table 1

Characteristics of the highest arch dams in the world.

Notes: ① Sayano-Shushenskaya Dam is a gravity arch dam, while the others are all double curvature arch dams. ② Stresses are calculated by the trial load method and by basic load combination. ③ The discharge facilities abbreviations are as follow: SO: spillway orifice; DO: deep orifice; MO: middle orifice; BO: bottom orifice; DT: discharge tunnel. ④ Vajont Dam has not been in use since an accident in 1963. ⑤ Mauvoisin dam was completed with height of 237 m in 1960 and heightened to 250 m tall in 1991.

Located in a U-shaped valley, the Xiluodu Dam has a maximum height of 285.5 m and a crest length of 681.51 m. The crest length to dam height ratio is 2.39 and the water thrust is 1.4 ×108 kN. The dam foundation consists of basalt layers of multiple eruptions with an integral blocky structure. The basalt layers have high strength in general, except for the gently sloped dislocation zones between and within the layers. The horizontal component of the peak ground accelerations on the rock surface of the design and checking earthquakes are 362 Gal and 431 Gal, respectively. Located on the Jinsha River, the main stream of the upper Yangtze River, the maximum design and checking flood discharge flows are 43 800 m3·s–1 and 52 300 m3·s–1, respectively. The dam has seven spillways, eight deep orifices, four temporary discharge orifices at the middle levels, and six temporary discharge orifices at the bottom level. In total, there are 25 openings in four elevations on the arch dam. This is the largest number of flood discharge openings in an arch dam, making the Xiluodu project one of the most complex high arch dam structures in the world.

For the design of the 300 m high arch dams described above, a number of key technologies were studied, and a series of breakthroughs were achieved in the following areas [2]:

•Foundation exploration and dam base design;

•Dam shape optimization;

•Abutment sliding stability and dam overall safety;

•Seismic design and safety control;

•Treatments of complex foundation;

•Anti-cracking technologies of dam concrete and construction temperature control; and

•Application of information technology in design and construction of dams.

The Jinping I, Xiaowan, and Xiluodu arch dams have all been under successful operation since their completion. The reservoirs have each reached the full supply level in three different years. Key technologies for the design and construction of high arch dams at the 300 m level are presented in the subsequent sections.

《2. Foundation exploration and dam base design》

2. Foundation exploration and dam base design

The tremendous water loads carried by 300 m high arch dams require the foundation and abutments to have sufficient bearing capacity, deformation rigidity, sliding stability, and water tightness. Thus, the determination of foundation geology and dam base topography is one of the key issues for 300 m high arch dams. This issue has been addressed through extensive dam site geologic investigation and dam geometry comparison.

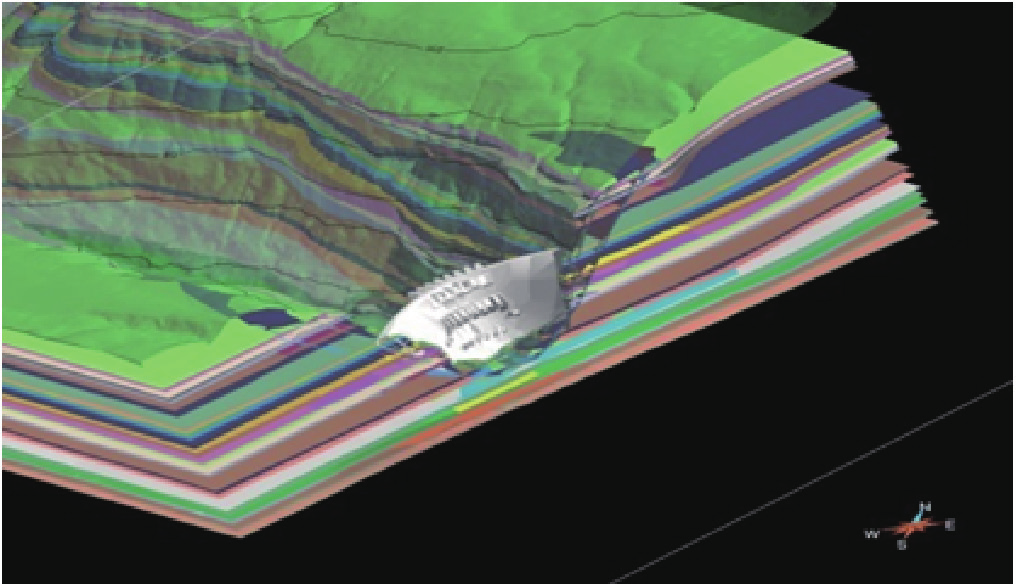

In Xiluodu, geologic explorations provided extensive knowledge of the extent of rock weathering, the distribution of faults and weak discontinuities, the joint set developments, and the mechanical properties of all rock classes and discontinuities. Based on this knowledge, a 3D digital geological model of the dam foundation was developed. The digital model enables straightforward visual observation of the spatial relation between the dam base, the foundation treating pattern, different rock classes, the faults, and the main joint sets. After technical and economical comparisons of three preliminary designs, the dam base was determined as the following [3]:

(1) The upper section rests on a moderately weathered and stress-released rock mass of Class III2 (Chinese hydraulic rock mass classification, referring to rock mass with a mosaic structure and a longitudinal wave velocity, Vp, of 3500–4500 m·s–1), with deformation modulus E0 = 5–7 GPa.

(2) The middle section rests on a moderately weathered rock mass of Class III1 (referring to rock mass with massive to sub-massive block structure, and a Vp of 4000–5200 m·s–1), with deformation modulus E0 = 10–12 GPa.

(3) The lower part rests on a rock mass of Class III1, and on a fresh to slightly weathered rock mass of Class II (referring to rock mass with a massive block structure, and a Vp of 4800–5500 m·s–1), with E0 > 12 GPa. [4,5]

Fig. 1 shows the 3D digital geological model of the Xiluodu arch dam foundation.

The design principle of the dam bases for the Jinping I Dam and the Xiaowan Dam is similar to that of the Xiluodu project. In the Jingping I project, a set of foundation treatments such as a concrete cushion and thrust transfer tunnels were adopted to enhance the rigidity and bearing capacity of the left abutment. In the Xiaowan project, the dam base mostly rests on a fresh to slightly weathered rock mass of Class II, with the upper section on a Class III1 rock mass.

《Fig. 1》

Fig.1 The 3D digital geological model of the Xiluodu arch dam foundation.

《3. Shape optimization of an arch dam》

3. Shape optimization of an arch dam

Arch dam shape is closely related to valley topography, the foundation rock mass condition at the dam site, and the embedment depth of the dam base. Design considerations for any given shape include sliding stability and earthquake resistance. The results depend on the selected optimization method and allowable stress level.

With the development of computer technology, the mathematical optimization method has been mainly employed in high arch dam shape design, e.g., a combination of the criteria method and the modern mathematical programing method. The criteria method seeks to move the dam axis toward the dam pressure center line while maintaining stability against sliding for the abutments. On the other hand, the modern mathematical programing method takes dam volume as the objective function to study all possible arch types including: a linear parabolic arch, elliptical arch, muti-centered arch, unified quadratic curve, mixed-curve arch, and so forth, while simultaneously meeting the stress criteria. The trial load method is typically used for dam stress analysis, as for 300 m dams, the elastic finite element-equivalent stress method is used to further verify the rationality of the dam stress distribution [6].

The allowable stress level of 300 m high arch dams should be determined comprehensively by taking into account the valley topography, geological condition of the dam foundation, dam flood discharge orifice arrangement, overall dam stability, earthquake design, and other factors. The allowable compressive stresses of the three 300 m dams under basic load combination are different, 10 MPa for the Xiaowan Dam, considering its relatively good foundation condition; 8 MPa for the Jinping I Dam, considering its complex foundation condition and asymmetric topographic and geologic conditions; and 9 MPa for the Xiluodu Dam, considering its complicated dam openings and earthquake resistance considerations. The allowable tensile stress is 1.2 MPa for the upstream side and 1.5 MPa for the downstream side for all three projects.

The final suitable dam shapes were determined based on the dam shape optimization procedure and further verified by the analysis of foundation sliding stability, seismic performance, and overall stability. The main parameters of the Jinping I, Xiaowan, and Xiluodu arch dams are shown in Table 1.

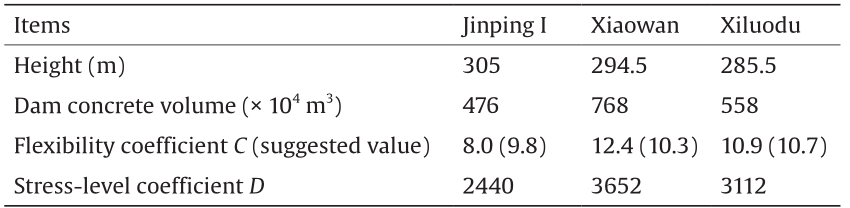

To check their rationality, the shapes of these 300 m high arch dams were checked against the flexibility coefficient index C criterion suggested by Lombardi [7] and further discussed by Ren et al. [8] (Eq. (1)), and against the stress-level coefficient D criterion suggested by Zhu [9] (Eq. (2)).

where, F is the area of the dam mid-face along dam center line (m2); V is the volume of dam concrete (m3); H is the dam height (m); C is the flexibility coefficient; and D is the stress-level coefficient.

The flexibility coefficient C and the stress-level coefficient D of the Jinping I, Xiaowan, and Xiluodu arch dams are listed in Table 2. The C values for these three dams are shown in Fig. 2 along with values for other arch dams around the world. As shown in Fig. 2, the data points for the three Chinese 300 m high arch dams lie close to the control curve proposed by Lombardi [7]. The point for the Xiaowan arch dam is even slightly higher than the Lombardi curve. These 300 m high arch dams are in the uncharted area in terms of dam height and have pushed the boundaries for safe arch dam design.

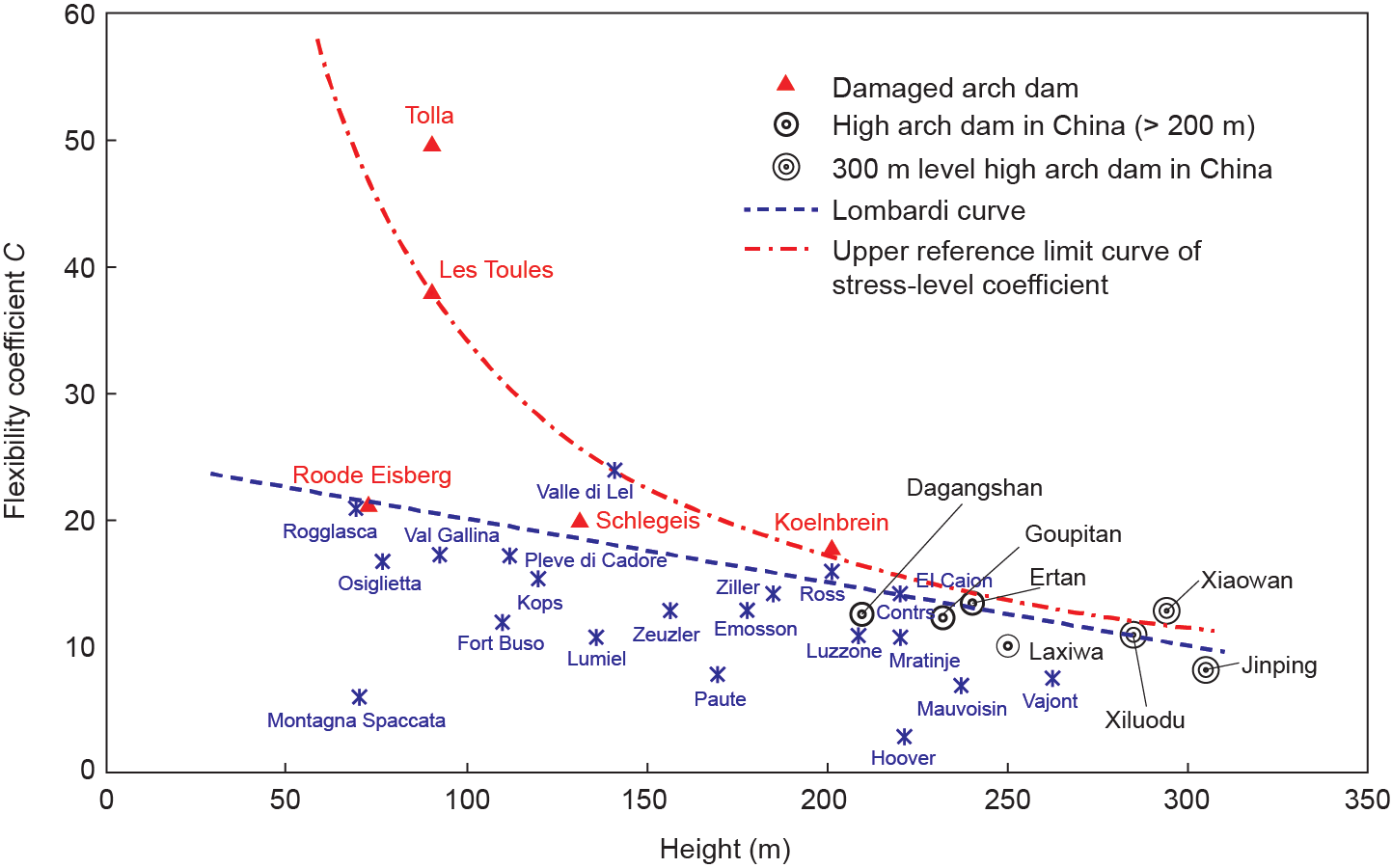

《Table 2》

Table 2

The flexibility coefficient and the stress-level coefficient of the Jinping I, Xiaowan, and Xiluodu arch dams.

《Fig. 2》

Fig.2 Flexibility coefficients C of typical arch dams. Upper reference limit curve of stress-level coefficient takes C = 3500/ H corresponding to that of Koelnbrein Dam.

《4. The analysis and control of dam concrete strength, abutment sliding stability, and dam overall safety》

4. The analysis and control of dam concrete strength, abutment sliding stability, and dam overall safety

For a long time, the safety criteria of dam design have been focused on the safety factor of dam concrete strength and the safety factor for sliding stability of dam abutment. With the development of numerical modeling and physical testing technology, a dam overall stability analysis that considers the interaction of the dam and the foundation has been widely carried out. In addition to the strength safety factor of the dam concrete ( K1) and the sliding safety factor of the dam abutment ( K2), the overall safety factor of the dam and abutment ( K3) provides another critical component for the safety criteria in designs of high arch dams, especially for 300 m high arch dams [10,11].

The dam concrete strength safety factor ( K1) refers to the ratio between the design standard strength and the allowable stress; it should be larger than 4.4 for a high dam. As specified by the Design specification for concrete arch dams (DL/T 5346—2006) [12], the design compressive strength is defined as the 90-day strength of 15 cm3 concrete specimens with an 80% passing rate. Considering the long construction period and the strict requirements for concrete quality, the design standard strengths of the dam concrete for the three 300 m high arch dams were based on a 180-day strength with an 85% passing rate. Specifically, the concrete design compressive strength values are 40 MPa, 45 MPa, and 40 MPa for the Jinping I, Xiaowan, and Xiluodu arch dams, respectively. These concrete strengths are also written as C18040, C18045, and C18040, respectively. The threshold for K1 was increased slightly for the Jinping I Dam, considering its relatively poor foundation conditions.

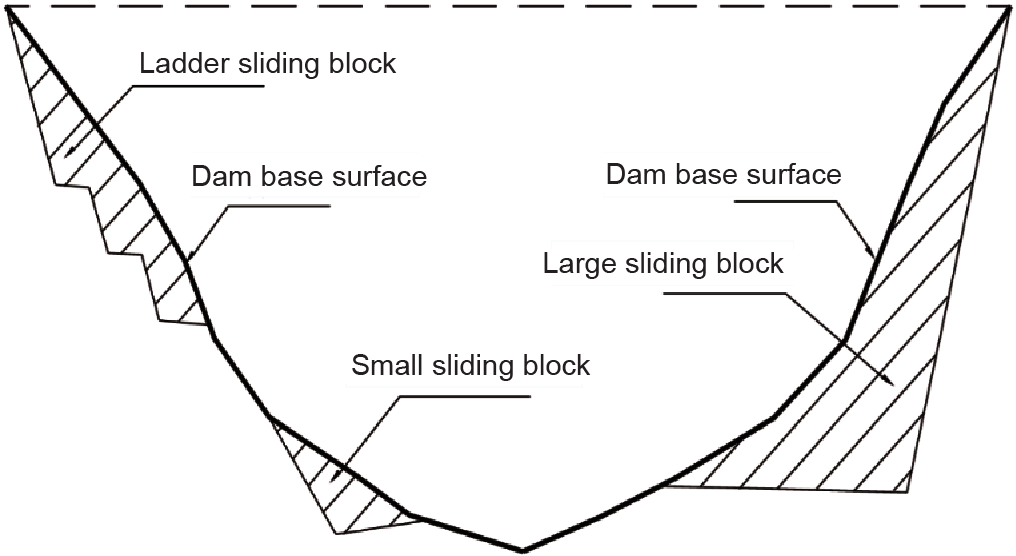

The sliding safety factor of the dam abutment ( K2) is calculated based on the rigid limit equilibrium method. The Design specification for concrete arch dams (DL/T 5346—2006) specified the formula and parameters of the sliding safety factor and its design safety control index [12]. For 300 m high arch dams, the sliding safety analysis involves calculating the safety factor for each potential sliding block, such as the large sliding block, small sliding block, and ladder sliding block shown in Fig. 3.

《Fig. 3》

Fig.3 Possible sliding mode in arch dam abutment.

The arch dam overall stability safety factor ( K3) refers to the ability of the dam and foundation to resist overload as an integral structure against water thrust on the top of the other basic load combination. Note that overload is only applied by multiplying the unit weight of the reservoir water, without increasing the other loads in the basic combination. The safety factor can be regarded as the load multiplying factor on the water unit weight that leads to structural failure in the dam. The main method for finding the safety factor is by using the 3D nonlinear finite element method (FEM) and/or a geomechanical model test.

Nonlinear FEM can account for the nonlinear characteristics of the dam concrete, the foundation rock of different regions, and the replacement concrete in the foundation. It provides the response of the dam under the basic load case, including displacement, stress, and yielding area distribution. In addition, the overload capacity of a dam structure can be investigated by gradually increasing the upstream water pressure and updating the dam response.

On the basis of similitude theory, an overall physical geo-mechanical model of an arch dam can accurately simulate a dam structure and its foundation rocks, faults, weak zones, and well-developed joint sets. The model can be loaded using the basic load case and followed by overload cases. The displacement, strain, crack initiation, and propagation pattern, as well as the failure mechanism of the dam, can all be automatically recorded to provide valuable data for the evaluation of the overload capability of an arch dam [13].

Prof. Zhou from Tsinghua University is one of China’s leading researchers in the study of the overall stability of arch dams. Based on the perfect elasto-plasticity theory with the Drucker-Prager yield criterion, Zhou’s group [14] has developed a 3D nonlinear FEM program called TFINE. His group has also been conducting geomechanical model tests for arch dams for years. By combining numerical simulation with physical modeling, his group has studied more than 20 high arch dams, and has established a method for evaluating the overload capacity of arch dams.

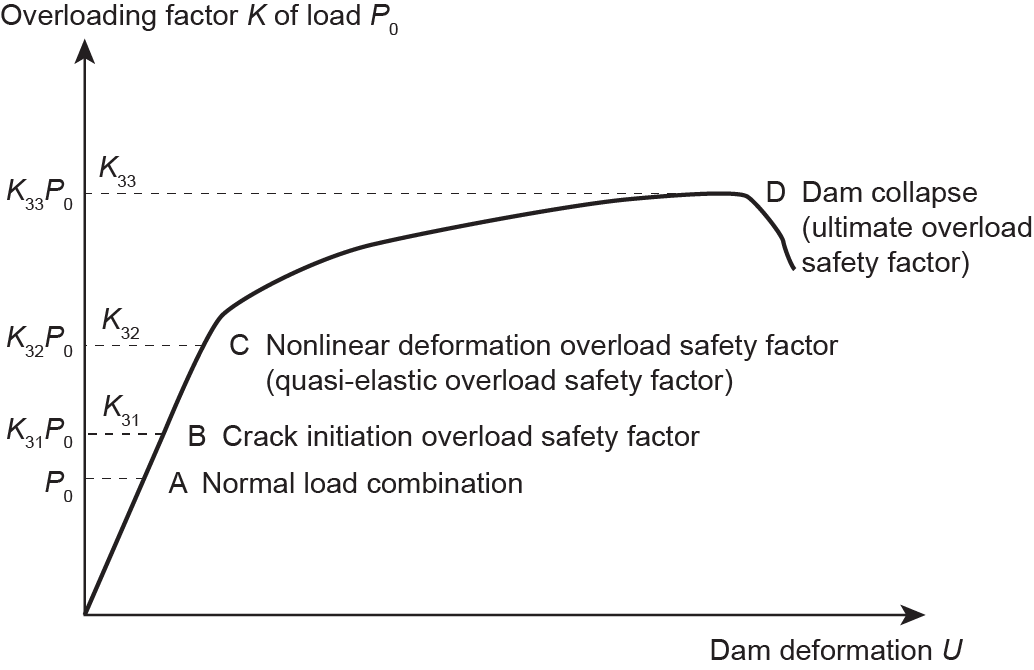

Through numerical analysis or model tests, the load-displacement behaviors of an arch dam under both normal and various overload cases can be established. Fig. 4 shows a typical result.

The overload of K31 times P0 corresponds to the emergence of the first crack in a physical model test or to the moment when the range of yielding zones reaches 1/6 of the arch dam thickness in the nonlinear FEM analysis. Accordingly, K31 is called the crack initiation overload safety factor.

As the overload increases further, the crack starts to propagate in the physical model test, while the yield zones continue to expand in the nonlinear FEM simulation. The structure is stable overall, and the dam displacements remain in linear correlation with the load until the overload exceeds K32 P0. An overload of K32 P0 corresponds to the end of the quasi-elastic state for the dam structure. Therefore, K32 is called the quasi-elastic overload safety factor.

The overload of K33 P0 corresponds to the occurrence of a large number of cracks throughout most of the dam or foundation, and the dam becomes instable overall in the physical model test. In the nonlinear FEM calculation, K33 P0 coincides with the time when the nonlinear solution does not converge. The overload factor K33 is called the ultimate overload safety factor.

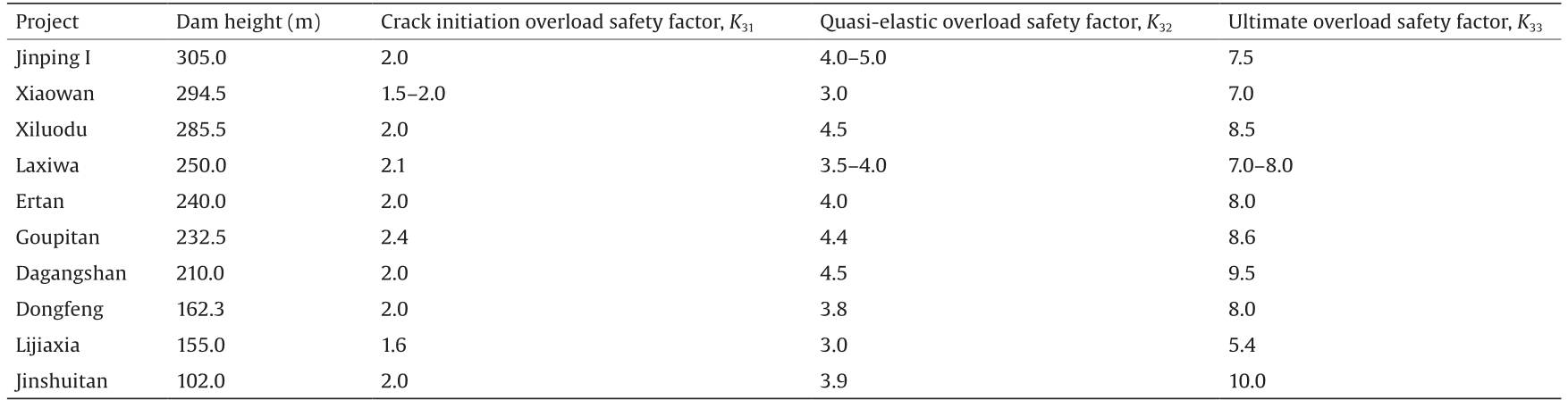

Using the above definitions, the overall overload safety factors of the Jinping I, Xiaowan, and Xiluodu arch dams are listed in Table 3 [15], along with values for other high arch dams. As indicated in Table 3, the three 300 m high arch dams have high overload safety factors that are consistent with those of other high arch dams.

《Fig. 4》

Fig.4 Load-displacement behaviors of an arch dam under both normal and various overload cases.

《Table 3》

Table 3

Overload safety factors of high arch dams.

《5. Seismic design and safety control》

5. Seismic design and safety control

《5.1. Seismic design standards and principles》

5.1. Seismic design standards and principles

The Wenchuan earthquake happened on May 12, 2008 in Sichuan Province in Western China. The dams located in the earthquake zone include the Shapai roller-compacted concrete (RCC) arch dam (132 m high), the Zipingpu concrete-face rockfill dam (156 m high), the Baozhusi gravity dam (132 m high), and the Bikou earth core rockfill dam (101.8 m high). These four dams all survived the earthquake safely, even though the earthquake intensity at each dam site exceeded the corresponding design standard. This outcome suggests that these reservoirs and dams were designed with a large seismic safety cushion, and that the current seismic design theory and method can ensure the seismic safety of dams.

Due to their greater dimensions, 300 m high arch dams have higher seismic responses than lower arch dams and thus require stricter control of seismic safety. Specialized researches are also required including seismic safety evaluations of engineering sites and seismic safety design of the dam.

In China, based on dam site area geological and historical earthquake research and comprehensive evaluation of seismic probability, the seismic design of dams has been carried out using two levels of ground motions, one for design and the other for checking. The design earthquake corresponds to a 2% probability of exceedance in 100 years, while the checking earthquake corresponds to a 1% probability of exceedance in 100 years. The checking earthquake can be either an extreme earthquake or the maximum credible earthquake. The peak ground acceleration used for each level is determined based on the seismic geology and earthquake history in the surrounding area, through a seismic hazard evaluation using comprehensive probabilistic analysis.

Dam seismic design in China follows the rules of “intact in the design earthquake, and no collapse in the checking earthquake.” The “intact in the design earthquake” rule means that the structure remains intact after being hit by the design earthquake [16], although a few contraction joints may open or be partly damaged in the surface of the dam. After being repaired by grouting and other measures, the dam still works well. The “no collapse in the checking earthquake” rule means that the dam needs to withstand the checking earthquake and retain water without collapse, even if parts of the contraction joints or dam structure are cracked.

《5.2. The dynamic analysis method of arch dams》

5.2. The dynamic analysis method of arch dams

The Code for seismic design of hydraulic structures of hydropower projects (NB 35047—2015) [16] stipulates evaluating methods for dam seismic performance and stress control indexes, e.g., the use of the trial load method, dynamic elastic FEM, and modal response spectrum analysis of arch dams. The code also specifies the need to conduct a dynamic sliding stability analysis and the corresponding safety criterion, and also emphasizes the necessity of nonlinear FEM analysis for first class dams. As for 300 m dams, beside the code required methods, nonlinear FEM and dynamic model test are also required to perform comprehensive seismic safety study and evaluation.

In the last 30 years, based on experiences from a dozen high arch dams in Western China, researchers from the China Institute of Water Resources and Hydropower Research (IWHR) [17], Tsinghua University [18], and Dalian University of Technology, among others, have made substantive progress in the subjects of dam-foundation-reservoir dynamic interaction, non-uniform seismic input and reservoir compressibility effects, the dissipation of seismic energy at the infinite foundation, and the nonlinear response of dam contraction joints opening and closing. Furthermore, many dynamic analysis theories, methods, and software have been developed to take into account the individual or coupled effects of the factors mentioned above.

The shake table model test of arch dams conducted by the IWHR [17] can simulate the dynamic interaction between the dam, transverse joints, dam foundation with major geological structures, and reservoir water. It can also simulate the impact of seismic radiation damping of model boundaries, as well as non-uniform seismic input, and more. Through incremental loading, dynamic responses of arch dams under the design and checking earthquakes can be studied, including the change in natural vibration characteristics, the opening and closing of contraction joints, and the potential of cracking. The seismic capability of the dam can also be evaluated by progressively increasing the intensity of the earthquake.

《5.3. Findings from dynamic response research on 300m ultra-high arch dams》

5.3. Findings from dynamic response research on 300m ultra-high arch dams

As indicated by the dynamic analyses of the Xiaowan, Xiluodu, and Jinping I arch dams using the trial load method and FEM analysis, the combined stress due to static and dynamic loads is mostly compressive, with the maximum stresses occurring around the dam toes. There are also some areas of tensile stress in the upper area of the upstream surface and in the bottom area of the downstream surface. The maximum stresses of the three dams are shown in Table 4. According to the Code for seismic design of hydraulic structures of hydropower projects, the allowable concrete dynamic compressive/tensile stresses (c/t) for the Xiao-wan, Xiluodu, and Jinping I arch dams are 18.8 MPa (c)/3.5 MPa (t), 17.7 MPa (c)/3.3 MPa (t), and 19.0 MPa (c)/3.5 MPa (t), respectively, using the trial load method. The maximum dynamic compressive stresses of these three dams are lower than the allowable values, while the maximum tensile stresses are higher than the allowable values in certain regions.

《Table 4》

Table 4

Maximum dynamic principal stresses of 300 m high arch dams (MPa).

Notes: ① In nonlinear finite element method (FEM) analysis, the foundation radiation damping effects and the nonlinear effects of transverse joints were simulated, assuming the dam concrete to be elastic. ② Overloading is based on the acceleration of the design earthquakes.

Taking into account the foundation radiation damping effect and the nonlinearity of dam transverse joints, the nonlinear dynamic FEM analysis revealed that, in general, the dam dynamic stresses meet the requirements, with the exception of localized areas, mainly due to tensile stress release in the axial direction. Further study on the material nonlinearity indicated that there would be some yielding areas in the upstream and downstream dam surface. Under the checking earthquake, the yielding areas expand but do not penetrate the dam in the thickness direction. Fig. 5 and Fig. 6 show the dynamic stress and yielding/damaged area after an earthquake.

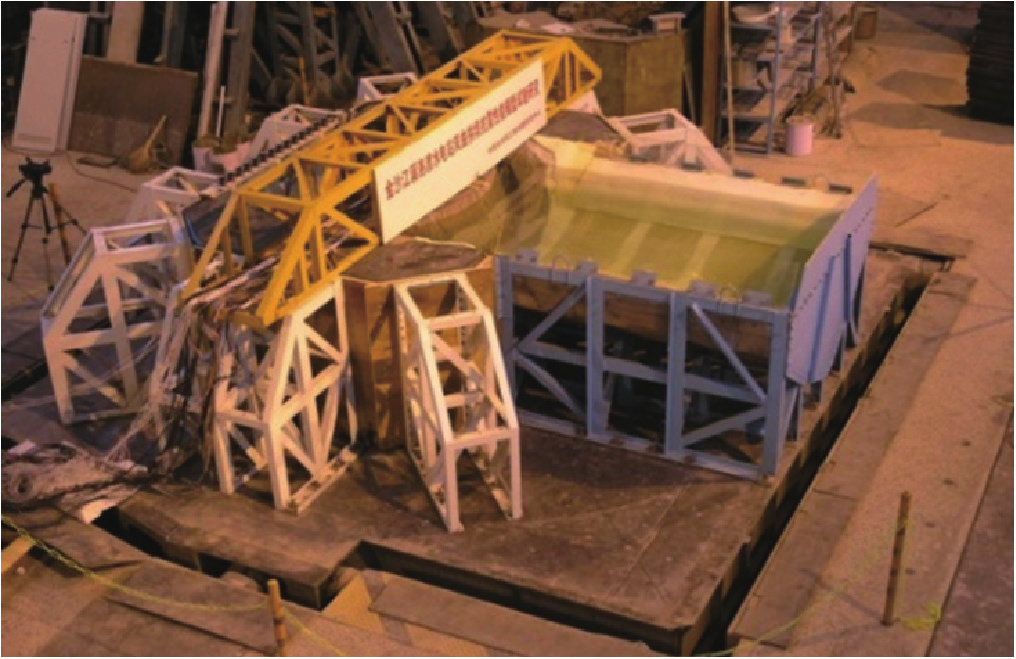

The effects of different input ground motion waves have been studied by running shake table dynamic model tests under progressively increasing loads. The dam models exhibited good overall stability when overloaded to the checking earthquake levels using the most unfavorable wave inputs. Further overloading suggested that the three dams remained stable under 6–7 times the ground motion corresponding to the design earthquake. Fig. 7 shows the shake table dynamic test model for the Xiluodu Dam.

Compared with the Xiluodu and Jinping I arch dams, the Xiao-wan arch dam has a greater seismic response in terms of the range and level of tensile stress exceeding design criteria, and the size of the yielding area. This difference is believed to be due to the wider dam geometry and stronger seismic action for the Xiao-wan project.

《5.4. Anti-seismic measures》

5.4. Anti-seismic measures

In Xiluodu and Jinping I, a C18040 high-strength concrete was adopted in the areas with high calculated stresses near the dam foundation and around the orifices. Steel reinforcement was used in areas with calculated stress higher than 1.5 MPa, mostly at the upper area of the dam surface. The steel reinforcements were not allowed to cross the contraction joints. Finally, dam foot filets were installed near the dam toe to enhance the anti-seismic capability.

《Fig. 5》

Fig.5 Maximum principal dynamic stress of the Xiluodu Dam upstream face.

《Fig. 6》

Fig.6 Yielding area of the Dagangshan Dam downstream face.

《Fig. 7》

Fig.7 The Xiluodu Dam shake table dynamic test model.

Seismic safety is an important factor in the geometric design of the Xiaowan arch dam. Concrete with C18045 strength was adopted in the area with strong seismic response. To deal with the potential large opening of transverse joints in the middle and upper portion and the high tensile stress at the heel, bi-directional seismic steel reinforcements were installed in these areas, combined with viscous joint dampers installed around the arch top. Pits for the joint dampers were reserved near the transverse joints when necessary to help the installation. The steel reinforcements in the arch direction span cross the transverse joints in order to limit their aperture in an earthquake and to ensure the safety of water retention structures. The steel reinforcements were deployed mainly in the top 50 m section, with two layers on the upstream side and one layer on the downstream side. The portion of the steel reinforcements within 4 m of the joints was coated with asphalt and enclosed with polyvinyl chloride (PVC) casing to allowing free sliding. The remaining parts of the steel bars were designed to be long enough to ensure sufficient anchorage. Steel reinforcements were also laid in the area with tensile stress higher than the 1.5 MPa limit along the cantilever-beam direction in order to limit the extent of potential cracking. These reinforcements are mostly located near the dam surfaces about 135 m from the crest. The reinforcement varies from one to three layers, depending on the magnitude of tensile stress.

《6. Typical treatments of complex foundation》

6. Typical treatments of complex foundation

Arch dams in the 300 m height level have higher demands for foundation integrity and uniformity. Foundation treatments depend on the rock quality and discontinuity properties specific to each project. The basic treatments for high arch dams include effective consolidation grouting, concrete replacement for weak rock, anchoring and reinforcement of fractured rock near the dam toe, and seepage curtain grouting. The foundation treatment for the upper left bank of the Jinping I Dam is the most difficult and most complicated of the three 300 m high arch dams.

The upper left bank of the Jinping I Dam is composed of sand slate that has been severely weathered and subjected to significant stress release. The rock mass shows extensive toppling deformation. As these conditions are combined with a steeply dipping fault and the existence of lamprophyre dikes, the condition of the foundation is extremely poor and is one of the key problems of dam safety control. After a tremendous amount of analysis, the final implemented treatments include: ① an abutment concrete cushion with a vertical height of 155 m, an average axial thickness of 40 m, and a trapezoidal profile to expand the effective supporting range to the abutment; ② five force-transferring adits in three elevations with a length of 80 m each behind the concrete cushion and going through the faults and lamprophyre dikes; ③ the replacement of faults and lamprophyre dike with a concrete grid; ④ consolidation grouting to the stress-released rock mass; and ⑤ anchorage reinforcement to the downstream side of the cushion and dam abutment, to ensure overall stability. Schematics of these treatments are shown in Fig. 8.

《Fig. 8》

Fig.8 Foundation treatments layout in the upper part of the Jinping I Dam left abutment.

《7. Anti-cracking technologies of dam concrete and construction temperature control》

7. Anti-cracking technologies of dam concrete and construction temperature control

《7.1. Use of aggregate combinations in dam concrete》

7.1. Use of aggregate combinations in dam concrete

Limited by the aggregate sources available near the dam sites, aggregate combinations were adopted for both the concretes for the Xiluodu and Jinping I arch dams. Specifically, the Xiluodu project used basalt for coarse aggregates and limestone for fine aggregates, and the basalt was excavated for the construction of the underground powerhouse. The Jinping I concrete used sandstone for coarse aggregates and marble for fine aggregates. By using aggregate combinations, the concrete had the advantage of both the high strength and good wear resistance of coarse aggregate, and the good deformation ability and thermal performance of fine aggregate. These advantages led to improved durability and crack resistance of the dam concrete.

Considering the high strength, high elastic modulus, and low ultimate tension of the concrete used in the Xiluodu project, it was decided to study and implement the use of a high percentage of fly ash in the concrete in order to increase the ultimate strength, as well as the use of slightly modified polyvinyl alcohol (PVA) fiber in order to increase the crack resistance. Specifically, by using 35% fly ash in the concrete, the 180-day strength of the C18040 concrete became more than 10% higher than its 90-day strength, while its adiabatic temperature rise was simultaneously reduced by 3–4 °C. A small dosage of 0.9 kg·m–3 of modified PVA fiber led to about 15% improvement in the concrete ultimate tension.

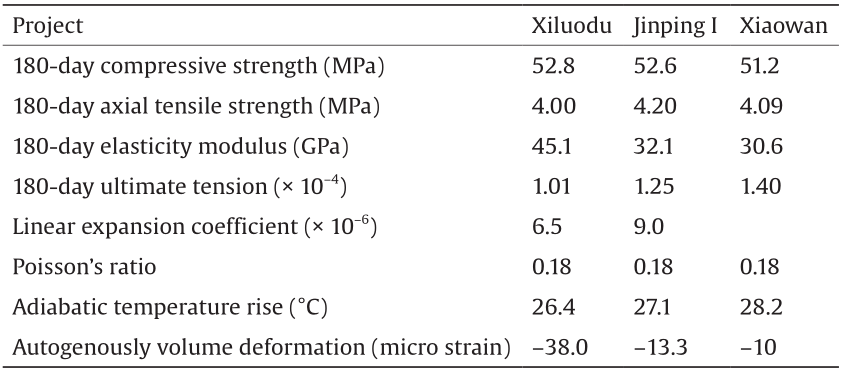

The mechanical and thermal parameters of the C18040 dam concrete used in the Xiluodu, Jinping I, and Xiaowan projects are shown in Table 5.

《Table 5》

Table 5

Mechanical and thermal parameters of the C18040 dam concrete used in the Xiluodu, Jinping I, and Xiaowan projects.

《7.2. Concrete temperature control and crack prevention》

7.2. Concrete temperature control and crack prevention

Due to the low crack resistance of the dam concrete, large concrete placement spacing, poor weather conditions, and other factors, the problems of temperature control and crack prevention during construction were a significant challenge for the three 300 m high arch dams. In particular, due to restrictions in the Xiluodu Dam’s layout of the discharge spillway and orifices, and also because of the special contraction joints of the steep dam blocks, the Xiluodu Dam concrete pouring spaces were usually 1000–1800 m2, with a maximum at 2400 m2. A majority of the pouring areas had aspect ratios of 2.5 to 3.5. As the dam site is located in the northern part of the Yunnan–Guizhou Plateau, the perennial average temperature is about 20 °C, with large daily temperature variations. There are frequent sudden temperature drops in autumn and winter, with a maximum drop of more than 10 °C. Given that these factors were combined with the strong constraints of the foundation and the disturbance from consolidation grouting, it was difficult to achieve good concrete tempera-ture control and crack prevention.

《7.3. Thermal stress analysis of a concrete arch dam》

7.3. Thermal stress analysis of a concrete arch dam

The thermal stress of dam concrete under construction can mainly be calculated by FEM simulation. The simulation can track the placement of each concrete layer of each dam section and can take into account factors such as concrete strength, hydration heat, hardening process, creep, autogenously volume deformation with age change, and temperature change by pipe water cooling and surface insulation. The simulation can provide the temperature field, stress field, and their changes throughout the dam over time.

The thermal stress of an arch dam in operation is mainly influenced by the arch-closure temperature, reservoir water temperature, and ambient air temperature, and can usually be analyzed by the trial load method and FEM analysis.

《7.4. Temperature control during concrete placement》

7.4. Temperature control during concrete placement

During the long construction period of a 300 m high arch dam, different design and measures are required for concrete placement and crack prevention that correspond to different seasons and different locations. Construction seasons are typically divided into summer and winter, while construction locations are divided into riverbed dam section, steep slope dam base section, discharge confinement region, and other regions. FEM analysis can be used to determine the allowable values of temperature difference between the inside and outside, upper layers and lower layers, and dam body and foundation, and can also determine the target temperature profile when the pipe water-cooling systems are running.

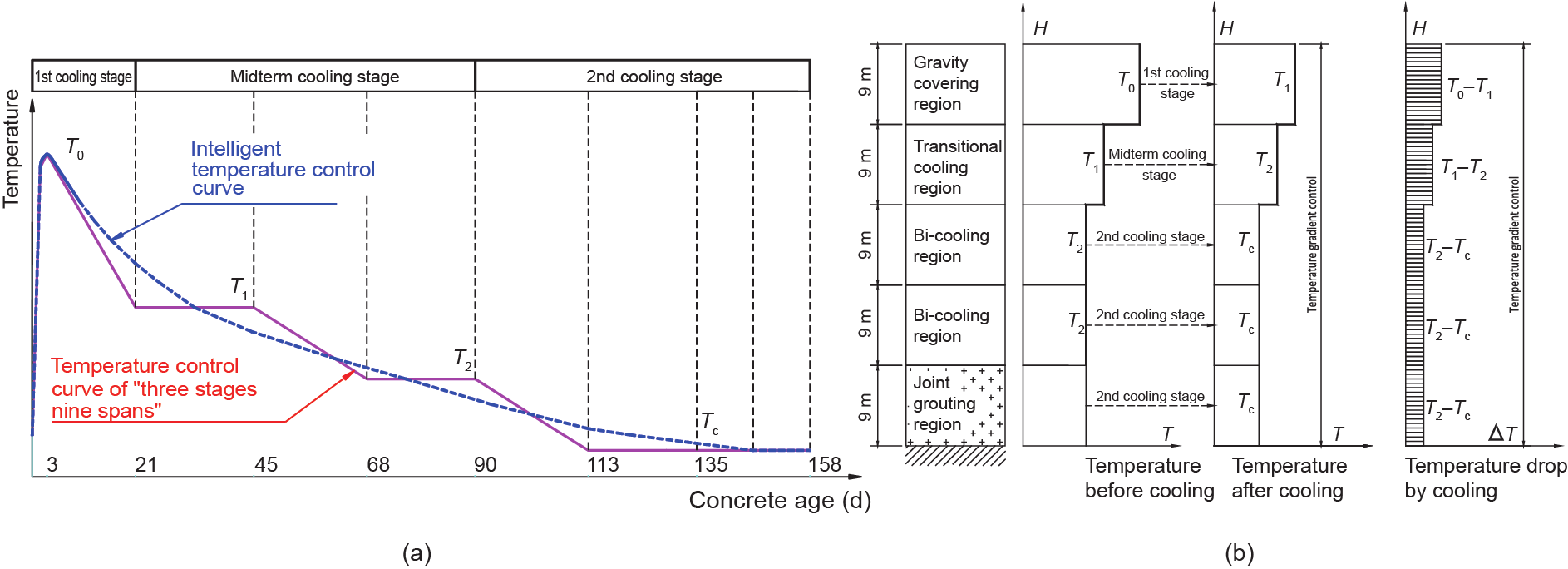

Following the guideline of “early cooling, slow cooling, smooth temperature drops in cooling” suggested by Zhu et al. [19], a series of temperature measures were adopted during concrete construction that included pipe water cooling, mist spraying in hot seasons, and surface insulation with a quilt on new surfaces in general and with polystyrene boards on the upstream and downstream dam surfaces in winter. After placement, temperature control followed the “three stages and nine segments” temperature control curve in the time dimension and the “five vertical zones coordination” vertical profile in the spatial dimension. These concepts are illustrated in Fig. 9. In the Xiaowan project, the principal of keeping the height of the bi-cooling region over the seal grouting region below 0.2B (where B stands for dam thickness) was proposed based on the experience.

《Fig. 9》

Fig.9 Schematic diagram of (a) “three stages nine spans” and (b) “five vertical zones coordination.” T: temperature; T0: maximum temperature limits; T1: target temperature of 1st cooling stage; T2: target temperature of 2nd cooling stage; Tc: arch sealing temperature; ΔT: temperature drop.

The combination of good quality control and the use of an automatic pipe water-cooling system eliminated the occurrence of hazardous cracking during concrete construction in all three 300 m high arch dams.

《7.5. Intelligent pipe water temperature control in a concrete dam》

7.5. Intelligent pipe water temperature control in a concrete dam

Through the use of distributed fiber-optic temperature sensors, dam temperatures were automatically collected. This allowed automatic temperature control using a pipe water circulation system. Specifically, a proportional integral derivative (PID) control algorithm was used to calculate the desired water temperature and flow rate to be injected into the pipe in order to achieve the target temperature control curve corresponding to the concrete age. A specialized set of equipment was used to perform the intelligent water temperature control of each concrete dam.

《7.6. Computer simulation and optimization of the dam concrete construction sequence》

7.6. Computer simulation and optimization of the dam concrete construction sequence

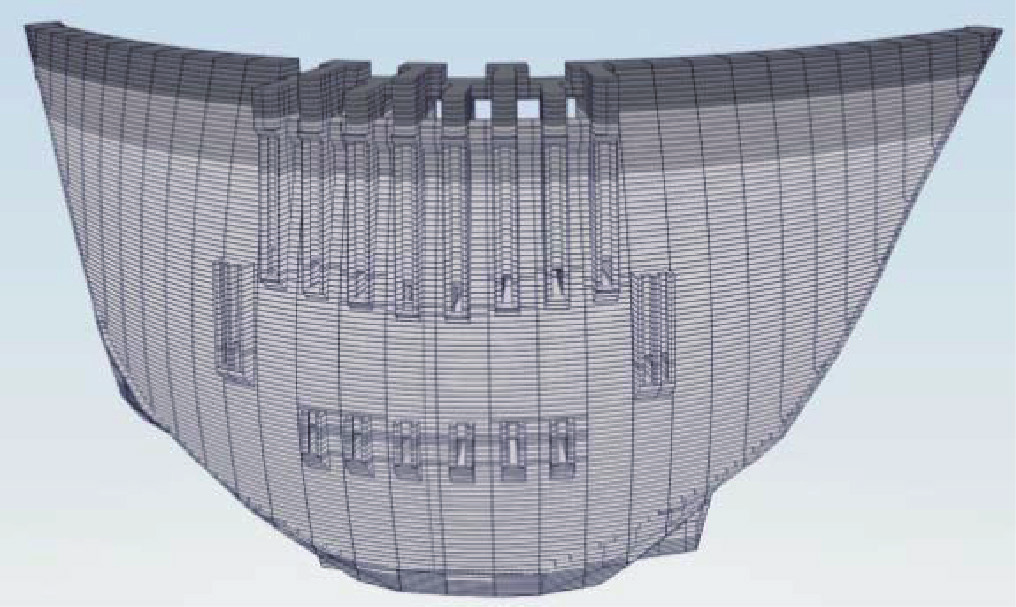

By incorporating computer simulation technology, virtual reality (VR), and modern construction practices, the effect of almost all kinds of construction factors on the schedule can be automatically analyzed. Examples include the intermittent time of different layers, preparation time, equipment disturbance, cast intensity, height difference of adjacent blocks, foundation block construction, and discharge orifice section. The objective is to minimize the duration of the construction by optimizing the concrete casting sequence of different dam sections, the concrete temperature control, and the arch-sealing grouting scheme. The ultimate goal is to achieve fast and efficient concrete arch dam construction. Fig. 10 is a simulation diagram of the Xiluodu Dam concrete casting while reaching the crest level.

《Fig. 10》

Fig.10 Simulation diagram of the Xiluodu Dam concrete casting while reaching the crest level.

《7.7. Real-time monitoring technology of concrete placement quality and the Internet of Things》

7.7. Real-time monitoring technology of concrete placement quality and the Internet of Things

Based on the Internet of Things (IoT) and on global positioning system (GPS) technologies, a system has been developed to allow the real-time online monitoring, early warning, and feedback control of dam concrete production, transportation, casting, and vibration (including vibration location, depth, velocity, and span). This system enables the digital control of the concrete construction process and quality.

《8. Dam operation and monitoring》

8. Dam operation and monitoring

The Xiaowan Dam was completed in 2010. After two years of initial slow rise, the water level rose to the design water level for the first time by the end of 2013. The Xiluodu and Jinping I arch dams were both completed early in 2013, and the reservoirs were impounded to the normal water levels in October 2013. To date, each dam has undergone the test of normal water level three times.

According to the monitored results of stress, strain, seepage flow, seepage pressure, temperature, joint gauges, and other data, all three 300 m high arch dams are working well and the foundation seepage is well under control.

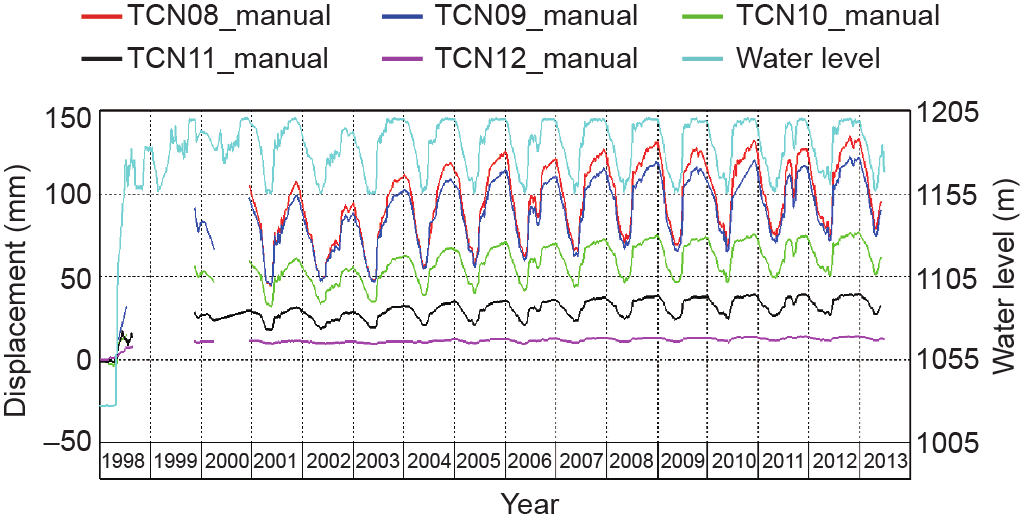

Compared to high arch dams, the ultra-high arch dam showed a delayed displacement increment during the initial water impounding. However, during the normal operation period, the dam has shown normal characteristics, including during the rise and fall of the water level. These characteristics include: ① a positive correlation of structure displacement and reservoir water level; ② the clear convergence of deformation at certain water levels; ③ a close correlation between the measured and calculated incremental structural deformation; and ④ the dam displacement changing cyclically in pace with the reservoir water level changes, showing the clear characteristics of quasi-elastic behavior.

Fig. 11 shows the recorded radial displacements of the crown cantilevers of the Jinping I arch dams, Fig. 12 shows the moni tored radial displacements of the crown cantilevers of the Ertan arch dam in first fifteen years since water impounding.

《Fig. 11》

Fig.11 The radial displacements of the Jinping I Dam crown cantilever.

《Fig. 12》

Fig.12 The radial displacements of the Ertan Dam crown cantilever.

《9. Conclusions》

9. Conclusions

The successful completion of the Jinping I, Xiaowan, Xiluodu, and Ertan arch dams has provided valuable experience in the design and construction of modern ultra-high arch dams. This experience will be applied and further enriched in the construction of future ultra-high arch dams such as the Baihetan, Wudongde, Yebatan, and Mengdigou dams. With further applications of networking technologies, sensors, cloud computing, and other technologies, intelligent arch dam construction practices will continue to improve.

京公网安备 11010502051620号

京公网安备 11010502051620号