《1.Introduction》

1.Introduction

Product digital design involves completing a product design process using advanced digital technologies such as geometry modeling, kinematic and dynamic simulation, multi-disciplinary coupling, virtual assembly, virtual reality (VR), multi-objective optimization (MOO), and human-computer interaction. Although there is no universal definition for customized design, its basic meaning is that a customized product is designed to satisfy the customer’s individual and diversified requirements as quickly and at as low a cost as possible. Many scholars have carried out research into the methodology and key technology of product design [1–3]. Customized design usually involves a strategy in which customer-oriented design is separated from order-oriented design [4]. Customer-oriented design is based on an analysis of customer requirements (CRs), and involves a modular preformed product family that is developed through serialization. Orderoriented design, which is based on an existing product family, rapidly designs a product’s structure in order to satisfy the customized requirements of customers by configuration methods when customer orders arrive. Customer-oriented design influences the cost and time required to market new products. Designing for customer orders affects the delivery of individual customized products. Customized products are designed and manufactured on a per-order basis.

Complex equipment—such as computer numerical control (CNC) machine tools, cryogenic air-separation units (ASUs), plate-fin heat exchangers (PFHEs), and injection-molding equipment—has many characteristics such as demand diversity, fuzzy dynamics, a cumbersome design response, and a complex design process. The question of how to satisfy customers’ individual requirements and achieve rapid design and innovation of complex customized equipment has become an important factor that determines the survival and competitiveness of equipment-manufacturing enterprises.

Therefore, it is urgently necessary to develop an intelligent design platform in order to support the development of manufacturing products. In this way, the digital design or products will develop in the direction of intelligence and customization.

《2. Key technologies》

2. Key technologies

Experts have predicted that more than half (> 50%) of future manufacturing will involve personal customization. Although the studies conducted by the Chinese Mechanical Engineering Society [5] indicate that manufacturing enterprises will generate stronger demands for product development and changes, the harsh reality is that modern enterprises lack advanced design ability. It is worth mentioning that many institutions [6,7] have carried out research into big data and the design technology of customized products. Stanford University’s [8] structured design model combines requirements, technology, and product performance mapping. Yale University [9] has also carried out analysis methods based on big data to support design research.

The key technologies of intelligent design for customized products include: the description and analysis of CRs; product family design (PFD) for a customer base; configuration and modular design for customized products; variant design for customized products; and a knowledge push for product intelligent design.

《2.1. Description and analysis of customer requirements》

2.1. Description and analysis of customer requirements

CRs usually include obvious features such as fuzziness, uncertainty, or dynamism. It is important to describe fuzzy CRs in an accurate way for the realization of customized design.

Designing for customization involves forming customized requirements to meet the CRs by means of analysis, data mining, and prediction. Common design methods include the analytical methods based on the Kano model and quality function deployment (QFD). In the Kano analytical method [10], CRs are divided into basic requirements, expected requirements, and exciting requirements. Customized design should first satisfy the basic requirements, and then satisfy the expected and exciting requirements as much as possible. The QFD method [11] is a multi-level deductive analysis method that translates CRs into design requirements, part characteristics, process requirements, and product requirements. It then builds a product planning matrix called a “house of quality.” At this point, the difficulty of requirements-based design lies in how to analyze, predict, and follow the potential requirements of customers.

Regarding the description and analysis of CRs, Jin et al. [12] investigated information representativeness, information comparativeness, and information diversity and proposed three greedy algorithms to obtain optimal solutions for the optimization problem. Wang and Chin [13] proposed a linear goal programming (LGP) approach to evaluate the relative weight of CRs in QFD. Juang et al. [14] proposed and developed a customer requirement information system (CRIS) in the machine tool industry, by using fuzzy reasoning and expert systems. Haug [15] developed a conceptual framework based on 10 industrial designers’ interviews and studies on reference projects; this framework defined the overall CR emergence models and associated communicative issues, enabled designers to elicit CRs more efficiently, and allowed designers to reduce delay in the emergence of client requirements and avoid wasting effort on design paths. Wang and Tseng [16] proposed a Naïve Bayes-based approach to describe clients’ technical functional requirements and subjective preferences, and to map them according to detailed attributes and design parameters. Raharjo et al. [17] proposed a novel systematic approach to deal with the dynamics of customer demands in QFD. Elfvengren et al. [18] studied the usefulness and usability of group decision support system (GDSS) in the assessment of customers’ needs in industrial companies. Çevik Onar et al. [19] proposed a hesitant fuzzy QFD that could reflect a human’s hesitation more objectively than the classical extensions of other fuzzy sets; they then applied it to computer workstation selection problems. Osorio et al. [20] proposed the extension of a universal product data model (PDM) to mass customization (MC) and sustainability paradigms in order to meet the requirements of supporting a sustainable mass-customized (S-MC) product design process.

Regarding the description of product requirements, research has focused on the following: the description of requirements based on set theory, the broader description of requirements based on ontology, and the description of requirements based on fuzzy clustering.

Requirements-based design faces the following challenges:

(1)Modeling generalized requirements for customization. To rapidly improve the standardization of customized requirements and guarantee the accuracy and consistency of the design process for an understanding of CRs, it is necessary to build a multi-level model of the generalized requirements from the time dimension, space dimension, process dimension, and so on.

(2)Predicting and mining customized requirements. With the development and maturation of big data, it is possible to collect data through the Internet and the Internet of Things. It is important to mine users’ behavior patterns and consumption habits from massive data in order to forecast customized requirements and determine hidden customized requirements.

(3)Mapping and transforming customized requirements. To ensure consistency, accuracy, and timeliness in the transformation from CRs to technical requirements, it is necessary to build a model that automatically maps and transforms CRs, including dynamic, fuzzy, and hidden CRs, into technical requirements.

(4)Creating value design for the customized requirements of customers. It is difficult to predict and create new CRs based on analyses of existing CRs, and it is also difficult to build customization while considering factors such as cost, feasibility, and urgency.

The description and analysis of CRs form the basis of intelligent design for customized products. The layout scheme design for a lathe-mill cutting center is shown in Fig. 1.

《Fig. 1》

Fig. 1. Layout scheme design for a lathe-mill cutting center.

《2.2. Product family design for a customer base》

2.2. Product family design for a customer base

PFD refers to the extraction of product variant parameters in accordance with CRs for a specific customer base, and the formation of a variable model of dynamic products that includes the main structure, main model, main document, and so forth. According to different variant-driven modes, the PFD method can be module driven or parameter driven [21]. A module-driven product family includes a series of basic, required, and optional modules, and can satisfy different requirements from customers through a combination of different modules. A parameter-driven product family includes a series of products that have the same public variables but different adjustable variables; the structure and performance of products can then be changed by scaling the adjustable variables up or down while maintaining the same public variables, in order to satisfy the individual CRs.

PFD focuses on ensuring product family optimization, data consistency, and traceability in the product life cycle. The challenges of PFD include:

(1)A design program for the product family. Given the preference to and importance of the requirements from customers and the performance characteristics of the products, it is difficult to program the rational variant parameters of the product family and value range so as to achieve integrated optimization of cost and competitiveness for the product family.

(2)Modularization of the product family. The design of the modularized product family focuses on forming a series of functional and structural modules along with a main structure based on the design constraint. It is difficult to form individual products that satisfy different customized requirements using a combination of different modules.

(3)A dynamic model of the product family. Due to market factors, technological innovation, maintenance, recycling, and other reasons, product family data changes during the product life cycle. The construction of a dynamic model for product family technology can ensure the consistency, accuracy, and traceability of life cycle data for the product family.

(4)An evolutionary genetic algorithm model of the product family. It is difficult to build a genetic algorithm model of the product family, which is done through analysis and mining of the evolution history and current situation of the product family. It is also difficult to achieve reuse of the product family and self-organized evolution, which is based on the principle of biological evolution and the corresponding evolutionary algorithm.

(5)A design evaluation of the product family. It is difficult to evaluate PFD and to direct the product family to obtain, for example, the lowest cost and best market competitiveness; these are done by using big data such as the reuse frequency and the maintenance service of products and parts.

《2.3. Configuration and modular design for customized products》

2.3. Configuration and modular design for customized products

Configuration design means conducting a rational variant for a customer-oriented dynamic product model, in order to form an individual product structure that satisfies the CRs for MC [22]. Current research into configuration design focuses on three aspects: the representation of configuration knowledge, the modeling of configuration knowledge, and the solutions to configuration problems [23]. In future, the main problem of configuration design will be how to mine configuration knowledge, in order to improve the automation and intelligence and increase the optimization of configuration design.

Regarding the design of the configuration and modules of customized products, Stone et al. [24] proposed three heuristic methods: dominant flow, branching flow, and conversion-transmission function chains. Fujita [25] discussed design and optimization problems in product variety. Carnduff and Goonetillake [26] proposed a configuration management pattern in which configurations are managed as versions. Jiao et al. [27] proposed a generic genetic algorithm (GGA) for PFD and developed a general encoding scheme to accommodate different PFD scenarios. Tsai and Chiu [28] developed a case-based reasoning (CBR) system to infer the main process parameters of a new printed circuit board (PCB) product, and used the secure nearest neighbor (SNN) search method to objectively retrieve similar design situations. Yadav et al. [29] amalgamated component modularity and function modularity in the product design in order to address design-for-supply-chain (DFSC) issues using a generic bill of materials (GBOM) representation. Schuh et al. [30] proposed a three-stage holistic approach to develop modular product architectures. Pakkanen et al. [31] proposed a method of rationalizing the existing product variety for a modular product line that supports product configuration, which is known as the Brownfield Process (BfP). Chen and Liu [32] constructed a strategic matrix of interface possibilities in modular product innovation using the internal and external aspects of the product and the openness of the interface. Dahmus et al. [33] proposed a method of building a product portfolio to exploit possible commonality by reusing modules throughout the product family on the basis of the functional modeling of products using function structures. Dou et al. [34] proposed an interactive genetic algorithm with interval individual fitness based on hesitancy (IGA-HIIF) in order to achieve a fast and accurate response to users’ requirements for complex product design and customization. Du et al. [35] developed a Stackelberg game theory model for the joint optimization of a product series configuration and a scaling design, in which a two-tier decision-making structure revealed the coupling decision between the module configuration and the parameter scaling. Ostrosi et al. [36] proposed a fuzzyagent-based approach for assisting product configuration. KhaliliAraghi and Kolarevic [37] proposed a conceptual framework for a dimensional customization system that reflects the potential of a constraint-based parametric design in the building industry. Modrak et al. [38] developed a methodological framework for generating all possible product configurations, and proposed a method for determining the so-called product configuration complexity by specifying the classes and sub-classes of product configurations. They also calculated product configuration complexity using Boltzmann entropy theory [39]. Chandrasekaran et al. [40] proposed a structured modular design approach for electro-mechanical consumer products using PFD templates.

The abovementioned research studies thus focused on a module planning method for customized products based on a design structure matrix, the rule-based configuration design method, the instance-based configuration design method, and so forth.

The following challenges are encountered during configuration and modular design:

(1)Achieving a configuration design for MOO. When meeting the requirements of customer orders, configuration design needs to comprehensively consider the manufacturing cost, service mode, low-carbon and green characteristics, and many other product goals, in order to achieve MOO.

(2)Mining configuration knowledge. Using big data technology, it is difficult to mine the existing historical data of enterprises and translate the findings into configuration knowledge that can provide a basis for the product configuration design.

(3)Using inference and decision technology for configuration design. With the increase of individual-level configurationknowledge complexity, inference and decision technology has influenced the efficiency of configuration design and the effectiveness, economy, and feasibility of the configuration results.

(4)Achieving a configuration design based on VR. Given progress in VR, augmented reality, and mixed reality technologies, configuration design will provide online awareness and an experience function that is matched and received, thereby greatly improving customer satisfaction.

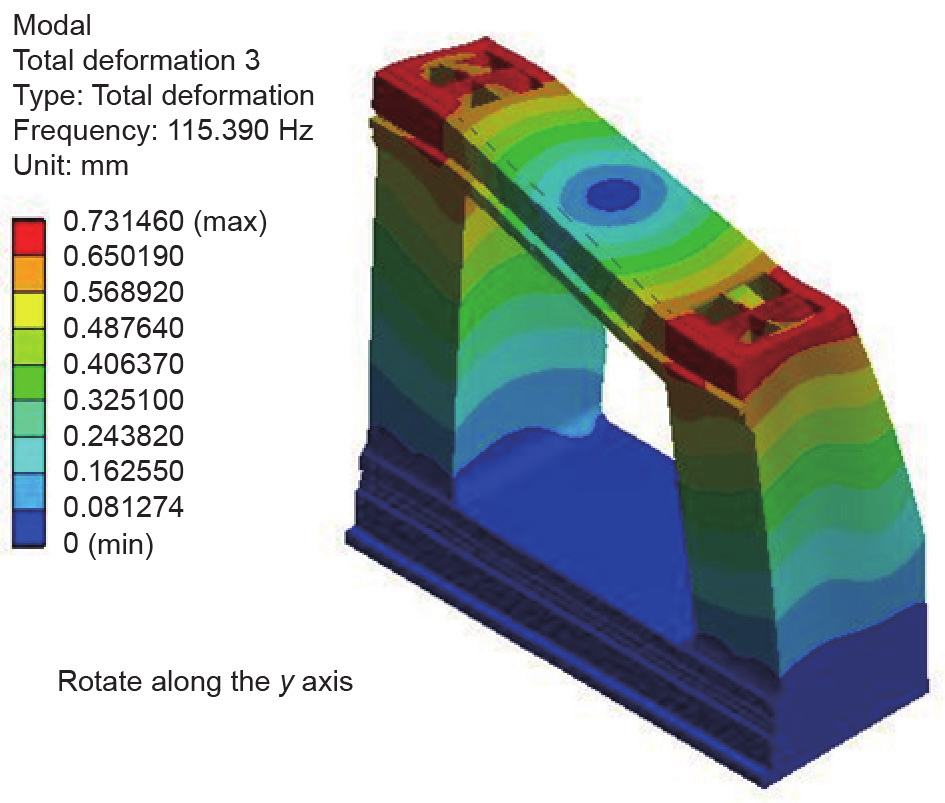

The total structural deformation of the third and fourth order modal of a gantry is shown in Fig. 2 and Fig. 3, respectively. Modal analyses of the base frame and the vertical column were carried out in order to investigate dynamic characteristics. The frequencies of the first, second, third, fourth, and fifth order modal are 72.042 Hz, 78.921 Hz, 115.390 Hz, 162.860 Hz, and 163.680 Hz, respectively.

《Fig. 2》

Fig. 2. Structural deformation of the third order modal of a gantry.

《Fig. 3》

Fig. 3. Structural deformation of the fourth order modal of a gantry.

《2.4. Variant design for customized products》

2.4. Variant design for customized products

Variant design refers to the completion of a design of either a geometric structure or a product module in order to produce more design schemes corresponding to CRs.

Nidamarthi et al. [41] proposed a systematic approach to identify the basic design elements of a profitable product line. Snavely and Papalambros [42] proposed a method to reduce the size of configuration problems by abstracting components to higher levels of abstraction. Yu et al. [43] proposed a joint optimization model for complex product variant design according to changes in customer demand for maximized customer satisfaction and minimized cost. Gero [44] presented a number of computational models for creative designing. Hong et al. [45] proposed a two-step similarity comparison method for boundary representation (B-rep) files in order to compare similarities between mechanical components in the design process. Fowler [46] noted that variant design is a technique for accommodating existing design specifications in order to meet new design goals and constraints, and proposed barriers of variant design in current systems in order to improve current systems in their support of variant design. Chen et al. [47] proposed a property-based, object-oriented approach for effectively and comprehensively implementing change impact analysis (CIA) tasks in variant design. Lo et al. [48] proposed a holistic methodology, based on threedimensional (3D) morphological diagrams of QFD, to support the variant design of serialization products and to simplify the traditional cascading QFD process in order to meet the special needs of technically mature and highly modularized products. Modrak et al. [49] investigated and presented a novel methodology for creating all possible product configurations and variations, based on a given number of base components and an optional number of complementary components. Wang et al. [50] presented an assembly variant design system architecture and a complementary assembly method. Ketan et al. [51] introduced three different types of variant feature models based on the concept of engineering description for variant features. Prebil et al. [52] studied the possibilities of design process methods related to the capabilities of a computer-aided design (CAD) system used for the manufacture of rotational connections and the design of workshop documentation. Nayak et al. [53] proposed the variationbased platform design method (VBPDM) for PFD, which uses the smallest variation of the product designs in the family to enable a range of performance requirements. Jiang and Gao [54] proposed a class of drawing tool: the conicoid. The scope of a 3D diagram that can be drawn with a conicoid is larger than what can be drawn using only planes and spheres. After adding a conicoid, the designers can draw a figure that can be described by a sequence of equations of a degree that is less than nine. Lee [55] proposed a degree-of-freedom (DOF)-based graph reduction approach to geometric constraint solving for maximizing the efficiency, robustness, and extensibility of a geometric constraint solver.

The challenges in variant design include: establishing the variant design of a structure based on multi-domain mutual-use models; customizing a design based on evolution; and developing a performance-enhancement design for complex equipment.

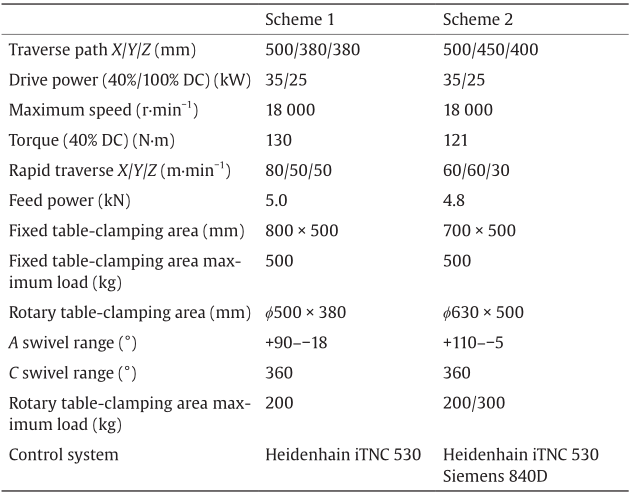

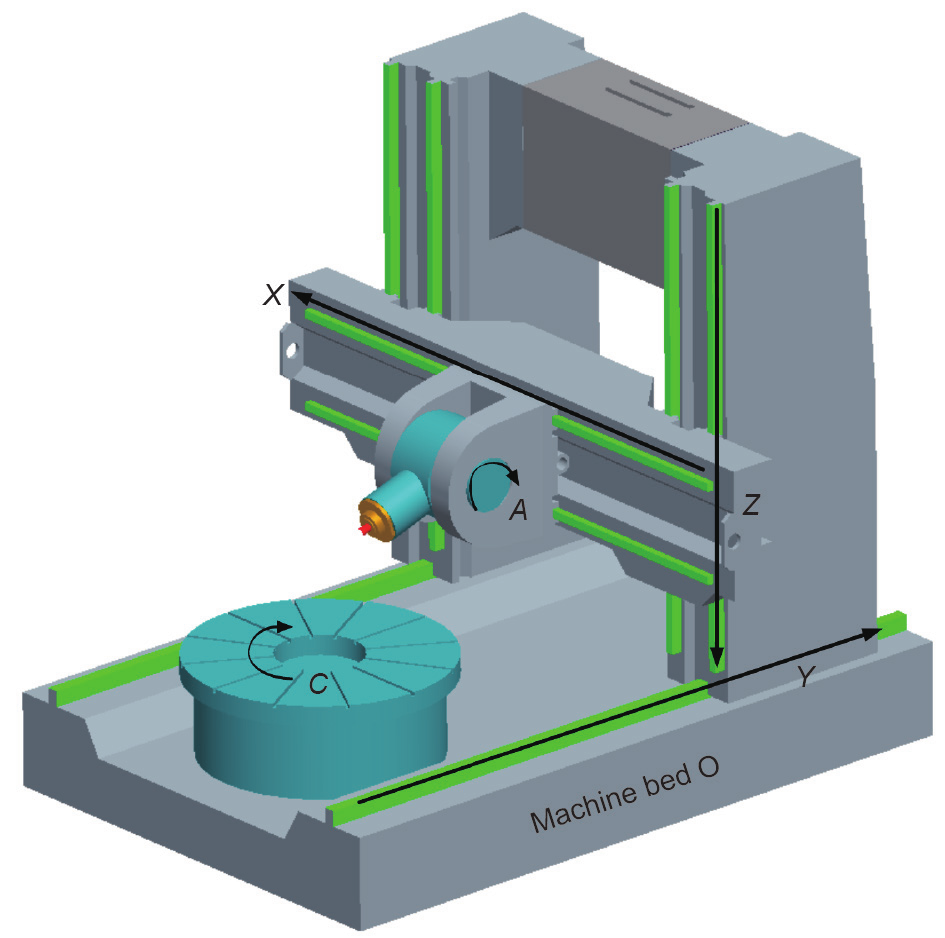

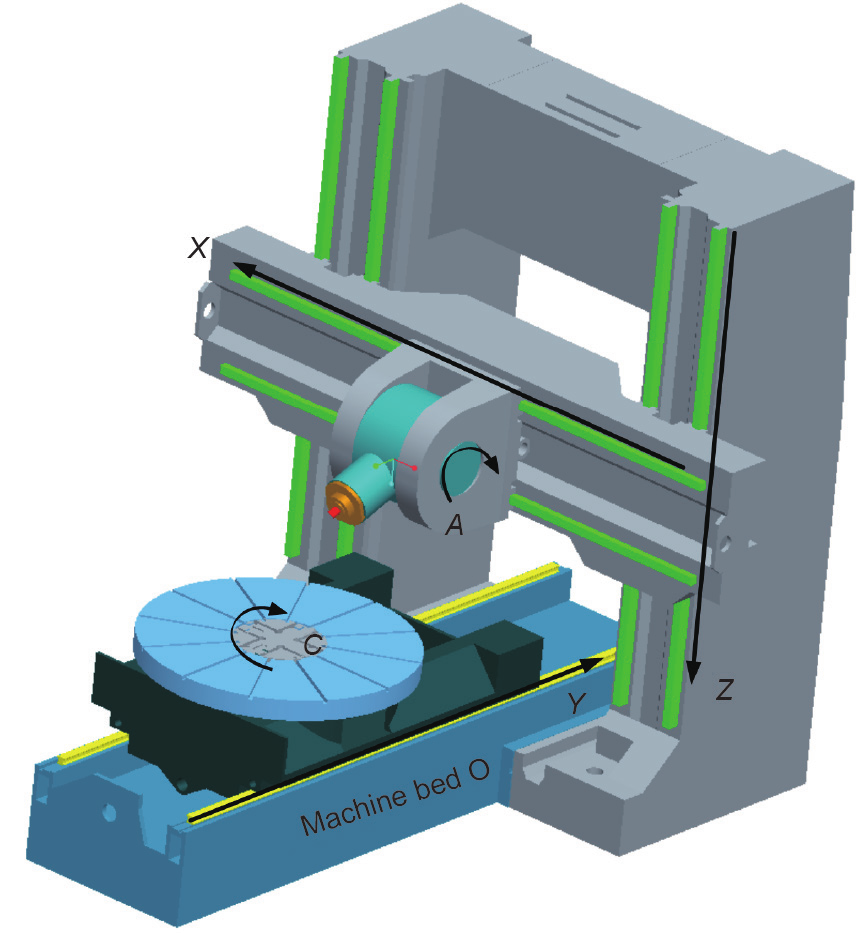

To complete the design of either a geometric structure or a product module in order to produce more design schemes corresponding to CRs, Table 1 shows a comparison of two design schemes for multi-axis machine tools. Scheme 1 and Scheme 2 of a lathe-mill cutting center are respectively shown in Fig. 4 and Fig. 5. The kinematic chain of Scheme 1 is WCOYZXAD, and the kinematic chain of Scheme 2 is WCYOZXAD, where W represents the workpiece, O represents the machine bed, D represents the machining tool, and X, Y, Z, A, C represent the coordinate axes of the machine tools.

《Table 1》

Table 1 A comparison of two design schemes for multi-axis machine tools.

DC: direct current.

《Fig. 4》

Fig. 4. Scheme 1 of a lathe-mill cutting center.

《Fig. 5》

Fig. 5. Scheme 2 of a lathe-mill cutting center.

《2.5. Knowledge push for product intelligent design》

2.5. Knowledge push for product intelligent design

Regarding product support from intelligent design, Younesi and Roghanian [56] proposed a comprehensive quality function deployment for environment (QFDE), a fuzzy decision-making trialand-evaluation laboratory (DEMATEL), and a fuzzy analytic network process (FANP) for sustainable product design in order to determine the best design standards for a specific product. Pitiot et al. [57] studied a preliminary product design method based on a primitive evolutionary algorithm called evolutionary algorithm oriented by knowledge (EAOK). Costa et al. [58] presented the product range model (PRM), which combines rule-based systems with CBR to provide product design decision support. Winkelman [59] proposed an intelligent design directory that consists of a virtual design environment associated with standard component catalogues. Hahm et al. [60] proposed a framework to search engineering documents that has fewer semantic ambiguities and a greater focus on individualized information needs. Akmal et al. [61] proposed an ontology-based approach that can use feature-based similarity measures to determine the similarity between two classes. Morariu et al. [62] proposed a classification of intelligent products from the perspective of integration, and introduced formalized data structures for intelligent products. Li et al. [63] proposed a knowledge training method based on information systems, data mining, and extension theory (extenics), and designed a knowledge-management platform to improve the quality of decision-making. Diego-Mas and Alcaide-Marzal [64] proposed a neural-network-based approach to simulate the consumers’ emotional responses for the form design of products, and developed a theoretical framework for the perceptions of individual users. Tran and Park [65] proposed eight groups of 29 scoring criteria that can help designers and practitioners compare and select an appropriate methodology for designing a product service system (PSS). Kuo et al. [66] used a depth-first search to create a predictive eco-design process. Andriankaja et al. [67] proposed a complete PSS design framework to support integrated products and services design in the PSS context. Muto et al. [68] proposed a task-management framework that enables manufacturers to develop various PSS options for their product-selling business. Ostrosi et al. [69] proposed a proxy-based approach to assist with the configuration of products in conceptual design. Chan et al. [70] proposed an intelligent fuzzy regression method to generate a model that represents the nonlinear and fuzzy relationship between emotional responses and design variables.

Challenges affecting knowledge push design include: establishing an instance-based product design method; utilizing the intelligent design method based on knowledge-based engineering (KBE); and developing a knowledge push using task-oriented requirements.

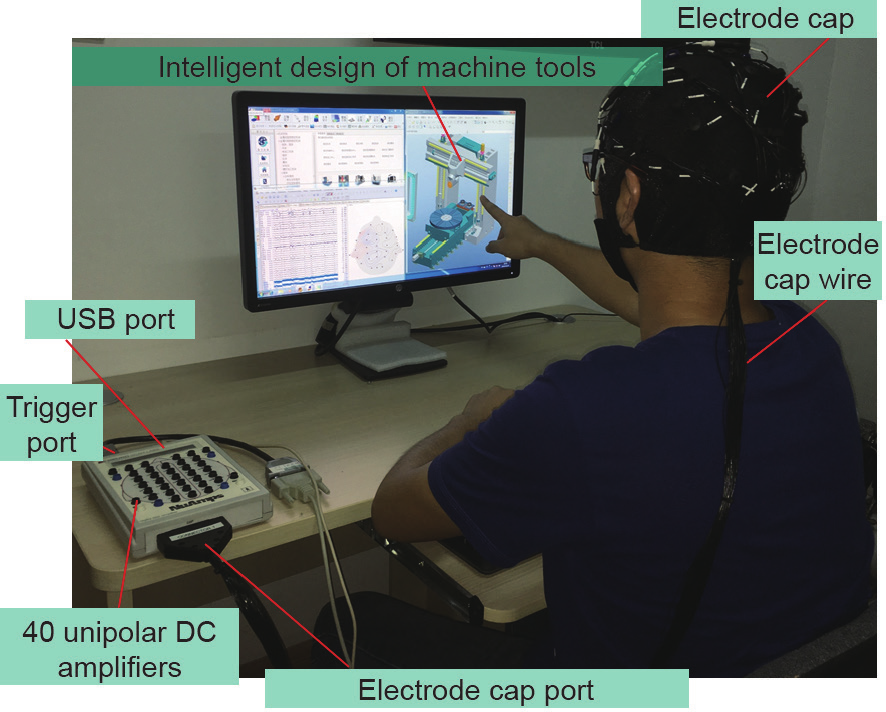

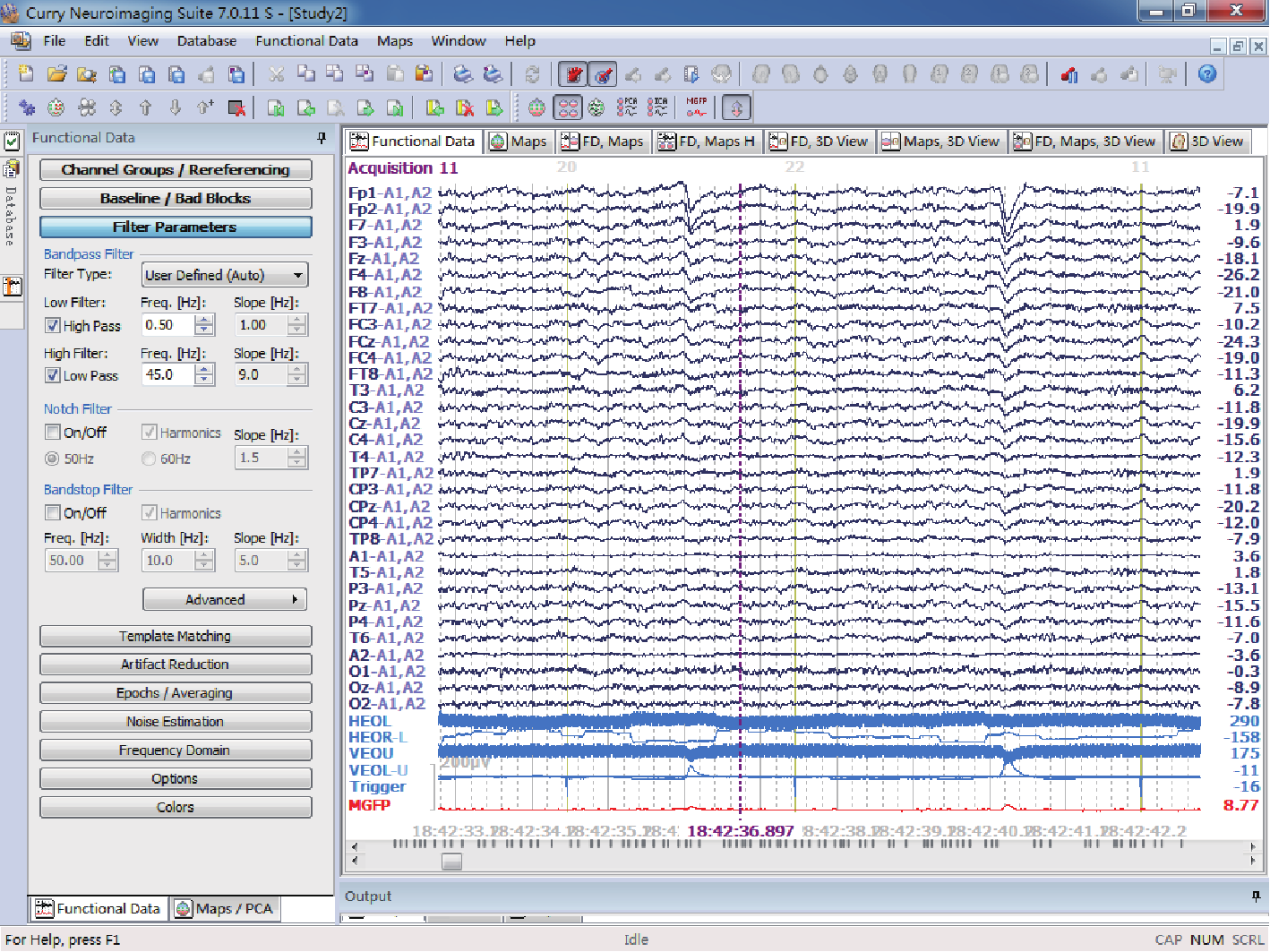

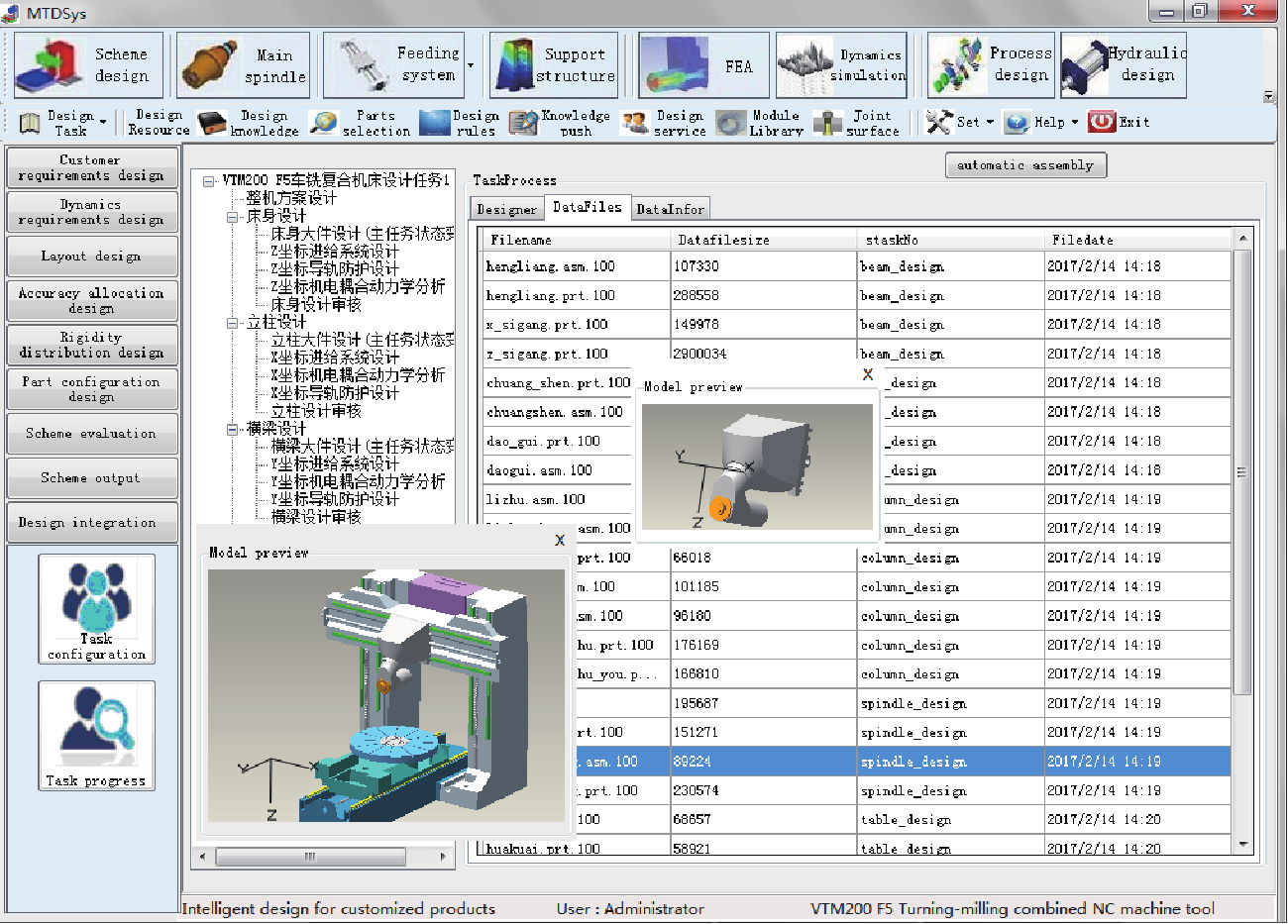

An electroencephalogram (EEG) measures and records the electrical activity of the brain, using biofeedback and the biological effects of an electromagnetic field. Special sensors called electrodes are attached to the head. Changes in the normal pattern of electrical activity can show certain conditions, such as an epiphany, imagination, and reasoning. Fig. 6 shows the intelligent design of machine tools utilizing an EEG for the purpose of intelligent design. Fig. 7 shows the graphical user interface (GUI) for measuring EEGs, and Fig. 8 shows the relative voltage of the EEG along with spectral analysis for a knowledge push.

《Fig. 6》

Fig. 6. An intelligent design for machine tools. DC: direct current.

《Fig. 7》

Fig. 7. The GUI for measuring EEGs.

《Fig. 8》

Fig. 8. (a) The relative voltage of the EEG and (b) spectral analysis for knowledge push.

《3. Difficulties and our previous work》

3. Difficulties and our previous work

Existing intelligent design methods for customized products usually require the establishment of design rules and design templates in advance, and the use of knowledge matching to provide a design knowledge push and to enhance design intelligence.

It is still difficult to complete a design for customized products with individual requirements. The following technical difficulties still hinder the achievement of rapid and innovative design for complex customized equipment:

(1)It is difficult to adapt the excavation of requirements based on big data. In a big data environment, the data source of individual requirements is mainly information from pictures, video, motion, and unstructured data in the form of radio frequency identification (RFID), which is not limited to structured data. It is difficult to establish a matching and coordinated relation of individual requirements between heterogeneous and unstructured multi-source data, so the accuracy of the requirements data analysis is affected.

(2)It is difficult to achieve many individual design requirements, and to rapidly respond to and support the design innovation schemes of customized products for individual requirements. It is difficult to complete intelligent design that comes from different specialties and different subject backgrounds through swarm intelligence in order to develop the intelligence of public groups.

(3)It is difficult to master the inherent knowledge and experience of designers. Existing intelligent design needs push knowledge based on learning specialties, owned skills, and existing design experience.

We have researched intelligent design theory and the method and application of customized equipment for precise numerical control (NC) machine tools, a super-large cryogenic ASU, a PFHE, injection molding equipment, and low-voltage circuit breakers (CBs) [71–81].

《4. Development tendencies》

4. Development tendencies

《4.1. Big-data-driven intelligent design for customized products》

4.1. Big-data-driven intelligent design for customized products

In recent years, humankind has entered the big data era, with the development and application of technologies such as the Internet, cyber-physical systems (CPSs), and more. Based on an Internet platform, China’s Internet Plus initiative, which began in 2015, crossed borders and connected with all industries by using information and communication technology to create new products, new businesses, and new patterns.

Big data has changed the product design and manufacturing environment. These changes strongly influence the analysis of personalized requirements and methods of customized equipment design. The specific product performance is as follows.

4.1.1. The influence of big data on the analysis of individual requirements

Designing customized equipment is different from designing general products, as it usually reflects particular requirements from customers by order. This CR information usually shows non-regularity. The relationship among different orders is not strong, which leads to situations in which the type of product demand information is extremely mixed up and the amount of information is very great. With the development of e-commerce concepts, such as online-to-offline (O2O), business-to-customer (B2C), business-to-business (B2B), and so forth, a large amount of information on effective individual needs becomes hidden in big data. An essential question in product design is how to mine and transform individual requirements in order to design customized equipment with high efficiency and low cost.

4.1.2. The influence of swarm intelligence design on design modes

Customized equipment design is usually based on mass production, which is further developed in order to satisfy the customers’ individual requirements. Modular recombination design and variant design are carried out for the base product and its composition modules, in accordance with the customers’ special requirements, and a new evolutionary design scheme that is furnished to provide options and evolve existing design schemes is adopted. An individual customized product is provided for the customers, and the organic combination of a mass product with a traditional customized design is achieved. In the Internet age, the design of customized equipment stems from the knowledge and experience of available integrated public groups, and is not limited to a single designer. In this way, the innovation of customized equipment is enhanced via swarm intelligence design. As a result, the Internet Plus environment has transformed the original technical authorization from a manufacturing enterprise interior or one-to-one design into a design mode that fuses variant design with swarm intelligence design.

《4.2. Customized design tools and applications》

4.2. Customized design tools and applications

Intelligent design using intelligent CAD systems and KBE is a new trend in the development of product design. This is a gradually deepening process of data processing and application, which moves from the database to the data warehouse, and then to the knowledge base.

Fig. 9 shows the GUI of an accuracy allocation design for NC machine tools. Fig. 10 shows the GUI of a design integration for NC machine tools. Fig. 11 shows surface machining using a five-axis NC machine center with a 45° tilt head.

《Fig. 9》

Fig. 9. The GUI of an accuracy allocation design among hierarchy kinematic chains.

《Fig. 10》

Fig. 10. The GUI of the intelligent design of a component and the complete machine of a lathe-mill cutting center.

《Fig. 11》

Fig. 11. Surface machining using a five-axis NC machine center with a 45° tilt head.

《5. Conclusions》

5. Conclusions

《5.1. Intelligent design corresponding to individual requirements》

5.1. Intelligent design corresponding to individual requirements

The process of intelligent design corresponding to individual requirements includes achieving individual mutual fusion of the requirements and parameters, and providing a foundation to solve the dynamic response and intelligent transformation of individual requirements.

The basic features of future customized equipment design are numerous, incomplete, noisy, and random. Unstructured design requirement information is equally mapped between individual requirements. A mutual fusion-mapping model of the different requirements and design parameters from the big data environment is urgently needed.

《5.2. Customized design using swarm intelligence rather than a single designer》

5.2. Customized design using swarm intelligence rather than a single designer

The process of customized design using swarm intelligence includes achieving the drive and feedback of a swarm intelligence platform design, and providing technological support for a further structural innovation design platform for Internet Plus customized equipment.

The future design of customized products lies in the process of cooperation between multiple members of the public community and in swarm intelligence design, which is not limited to a single designer. Swarm intelligence design can be integrated into the intelligence of public groups.

《5.3. Intelligent design for customized products using a knowledge push》

5.3. Intelligent design for customized products using a knowledge push

The process of intelligent design for customized products with a knowledge push includes achieving the active push of a design resource based on feedback features, and enhancing the design intelligence of complex customized equipment. In future, intelligent design for customized products can be achieved by design status feedback and scene triggers based on a knowledge push. With the development of advanced technology such as cloud databases and event-condition-action (ECA) rules [71], future intelligent design for customized products will be more requirement-centered and knowledge-diversified, with appreciable specialty and higher design efficiency.

《Acknowledgements》

Acknowledgements

The work presented in this article is funded by the National Natural Science Foundation of China (51375012 and 51675478), the Science and Technology Plan Project of Zhejiang Province (2017C31002), and the Fundamental Research Funds for the Central Universities (2017FZA4003).

《Compliance with ethics guidelines》

Compliance with ethics guidelines

Shuyou Zhang, Jinghua Xu, Huawei Gou, and Jianrong Tan declare that they have no conflict of interest or financial conflicts to disclose.

京公网安备 11010502051620号

京公网安备 11010502051620号