《1. Introduction》

1. Introduction

The Middle-Line South-to-North Water-Transfer Project (also referred to herein as the Middle-Line Project) is a major strategic infrastructure and ecological rehabilitation project intended to alleviate the serious shortage of water resources in China’s Huang–Huai–Hai Plain, optimize the allocation of water resources, and improve the water ecology and water environment in the Beijing, Tianjin, and Hebei areas. The project is being constructed in two stages. In the first stage, the project diverts water from the Danjiangkou Reservoir of the Han River (a tributary of the Yangtze River); in the second stage, the project will be extended to the main stream of the Yangtze River for water transfer. The total length of the main canal of the first stage of the project is about 1432 km, with an average annual water-transfer volume of 9.5 billion cubic meter. The main canal crosses the four major basins (Yangtze River, Huai River, Yellow River, and Hai River) and more than 700 rivers, making the Middle-Line Project the longest large-scale inter-basin water-transfer project in the world. The first stage of the project includes the heightening of the Danjiangkou Dam, along with the construction of the head works of the Taocha canal, the main water-transfer canal, and 2387 different constructions involved in the project (tunnels, aqueducts, concealed culverts, inverted siphons, etc.). The general layout of the project is shown in Fig. 1.

《Fig. 1》

Fig. 1. General layout of the first stage of the Middle-Line Project.

The first stage of the Middle-Line Project started on 30 December 2003, and its operation officially began on 12 December 2014. Since the project was put into operation, it has been generally safe and stable. By the end of 2021, the cumulative volume of transferred water had reached 44.70 billion cubic meter (including 9.05 billion cubic meter in 2021), benefiting 191 rural and urban areas with 21 large and medium-sized cities along the project, and thereby directly benefiting about 79 million people. The cumulative ecological water replenishment to more than 50 rivers in north China exceeds 7.6 billion cubic meter, which effectively ensures the water safety of national construction strategies area such as the integration of Beijing, Tianjin, and Hebei; the Xiong’an new district; and the Mid-China urban agglomeration. It also creates favorable conditions for underground water-pressure mining and promotes the restoration and protection of the ecological environment in the water-receiving areas, with remarkable social, economic, and ecological benefits.

The first stage of the Middle-Line Project had a huge scale and complex technology, and faced with many important technical difficulties [1]:

(1) The project has a long line, spanning four major basins to deliver water to four provinces and many cities. The general layout of the project was affected by various factors, such as the temporal and spatial distribution of water resources in the water-supply and -receiving areas, the economy and ecological environment, flood control, water supply, water quality, and investment. Thus, it was very difficult to determine a scientific and reasonable general layout of the project.

(2) The Danjiangkou Reservoir, a water-source sub-project, needed to be raised and reinforced under the normal operation conditions of the dam because of its irreplaceable flood-control position in the middle–lower reaches of the Han River.

(3) An expansive-soil section 387 km in length was distributed along the main canal, so it was difficult to control the stability of the wading expansive soil canal slope.

(4) It was difficult to design and construct a shield tunnel for high-pressure water transfer through the wandering Yellow River section in the multistage complex soft soil layer.

(5) The structural design and construction of the large-span prestressed aqueduct with a design flow of 420 m3 ·s–1 was very difficult.

By focusing on these technical difficulties, the first stage of the Middle-Line Project has achieved a number of theoretical and technological innovations and has overcome these technical problems through the National Science and Technology Support Project and specific scientific research on the major sub-projects.

《2. Technological achievements》

2. Technological achievements

《2.1. General layout》

2.1. General layout

2.1.1. General scheme of the Middle-Line Project

The Middle-Line Project crosses the Yangtze River, Yellow River, Huai River, and Hai River basins, and the situation, temporal distribution, and spatial distribution of the water resources in each basin are obviously different. The general layout of the project shall comprehensively consider the temporal and spatial distribution of the water resources in the water-supply and -receiving areas and its impact on the middle–lower reaches of the Han River, covering a wide range of fields such as waterresource utilization, flood control, disaster reduction, water environment, and water ecological protection. In order to scientifically realize the multi-objective optimal allocation of water resources, a cross-basin water-resource allocation theory based on the carrying capacity of water resources and the water environment was proposed. Moreover, a multi-source, multi-objective, multibasin, and super-large-scale optimal allocation model of water resources was constructed to establish the general scheme of the project. This general scheme considered the water use and ecological-environment protection in the water-supply and -receiving areas, and along the water transfer line was put forward for the construction of Middle-Line Project, which required heightening the Danjiangkou Dam in the near future. It was also necessary to increase the capacity of the water-resource dispatching, storage, and utilization of the Han River in order to meet the requirement of transferring an annual average of 9.5 billion cubic meter of water. At the same time, it was necessary to raise the water level of the Danjiangkou Reservoir in order to realize artesian water transfer to Beijing and to improve the flood-control and disaster-reduction capacity in the middle–lower reaches of the Han River. In the long term, the transferred water volume will be greatly increased due to water-source supplementation from the main stream of the Yangtze River in order to realize the water resources complementarity between the south (abundant) and the north (dry), and the joint allocation of multiple water sources, so as to ensure water safety in the water-receiving areas.

2.1.2. General layout of the main canal of the project

As mentioned earlier, the total length of the main watertransfer canal is about 1432 km, crossing more than 700 rivers and involving many other constructions. Here, the key problem was how to distribute the water head of each canal section in order to realize free flow in the whole canal, under conditions in which the available water head is less than 100 m. The engineering design proposed a discrete differential dynamic programming method to solve the optimal distribution of the longitudinal slope and water head of the canal, tunnel, and culvert [2]; it also established a dynamic planning model for the longitudinal slope of the main canal. A general layout scheme of the main canal, which involved an all-line artesian flow and overpass, was put forward; this scheme was conducive to ensuring the water quality and protecting the ecological environment while successfully solving the problems of the all-line artesian water transfer and overpass crossing the rivers along the project. The scheme avoided the impact rivers along the project could have on the transferred water quality and the sediment deposition caused by the flat crossing of transferred water, so as to ensure the long-term safety and stable operation of the project. It also considered the flexibility of the large-scale, long-distance, and multi-objective water-transfer and distribution-system scheduling.

《2.2. The Danjiangkou Dam heightening sub-project》

2.2. The Danjiangkou Dam heightening sub-project

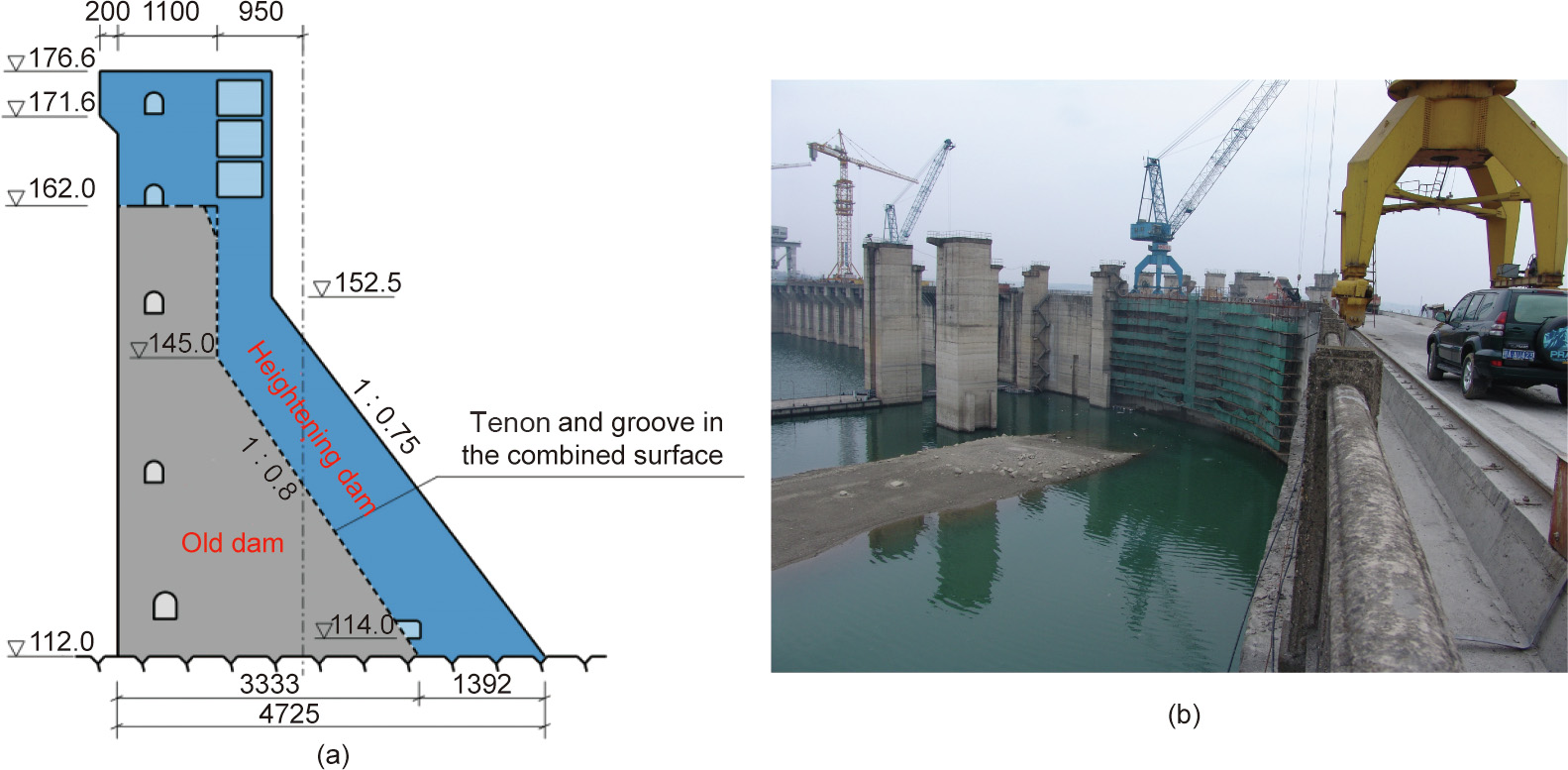

The Danjiangkou Dam is located on the main stream of the Han River in Danjiangkou City, Hubei Province. It has comprehensive utilization benefits such as flood control, water supply, power generation, and shipping, and was the main water-source sub-project of the Middle-Line Project. The dam was built in the 1950s and completed in early 1974. Due to the great differences that occur in the annual water flow amount coming from the Han River, the multi-year dispatching capacity of the Danjiangkou Reservoir needed to be increased in order to ensure an annual average water supply from the Danjiangkou Reservoir to the north about 9.5 billion cubic meter and to increase the water-resource dispatching, storage, and flood-control capacity of the Han River. Therefore, the elevation of the dam top had to be increased from 162.0 m in the initial stage to 176.6 m, and the total storage capacity had to be increased by 11.06 billion cubic meter. The Danjiangkou Dam after completion of the heightening sub-project is shown in Fig. 2.

《Fig. 2》

Fig. 2. The Danjiangkou Dam after completion of the heightening sub-project.

For the Danjiangkou Dam, a slope-sticking heightening method with back assistance was adopted, as shown in Fig. 3(a), which depicts the heightening scheme of the right-bank dam section. In general, the heightening of such a dam requires the emptying or significant reduction of the water level in front of the dam. During the heightening period of the Danjiangkou Dam, the dam still needed to undertake tasks such as flood control, power generation, and irrigation, meanwhile blocking floods and cutting the peak of the flood season (Fig. 3(b)). Therefore, the heightening of the dam had to be implemented under normal operation conditions, which presented problems such as the combination and joint load bearing of the old and new dam body. These structural design and construction problems were extremely complex, and no standards were available to refer to; in fact, there was no precedent in the history of engineering construction in China.

《Fig. 3》

Fig. 3. (a) The heightening scheme for the right-bank dam section and (b) the heightening of the Danjiangkou Dam during the normal operation period.

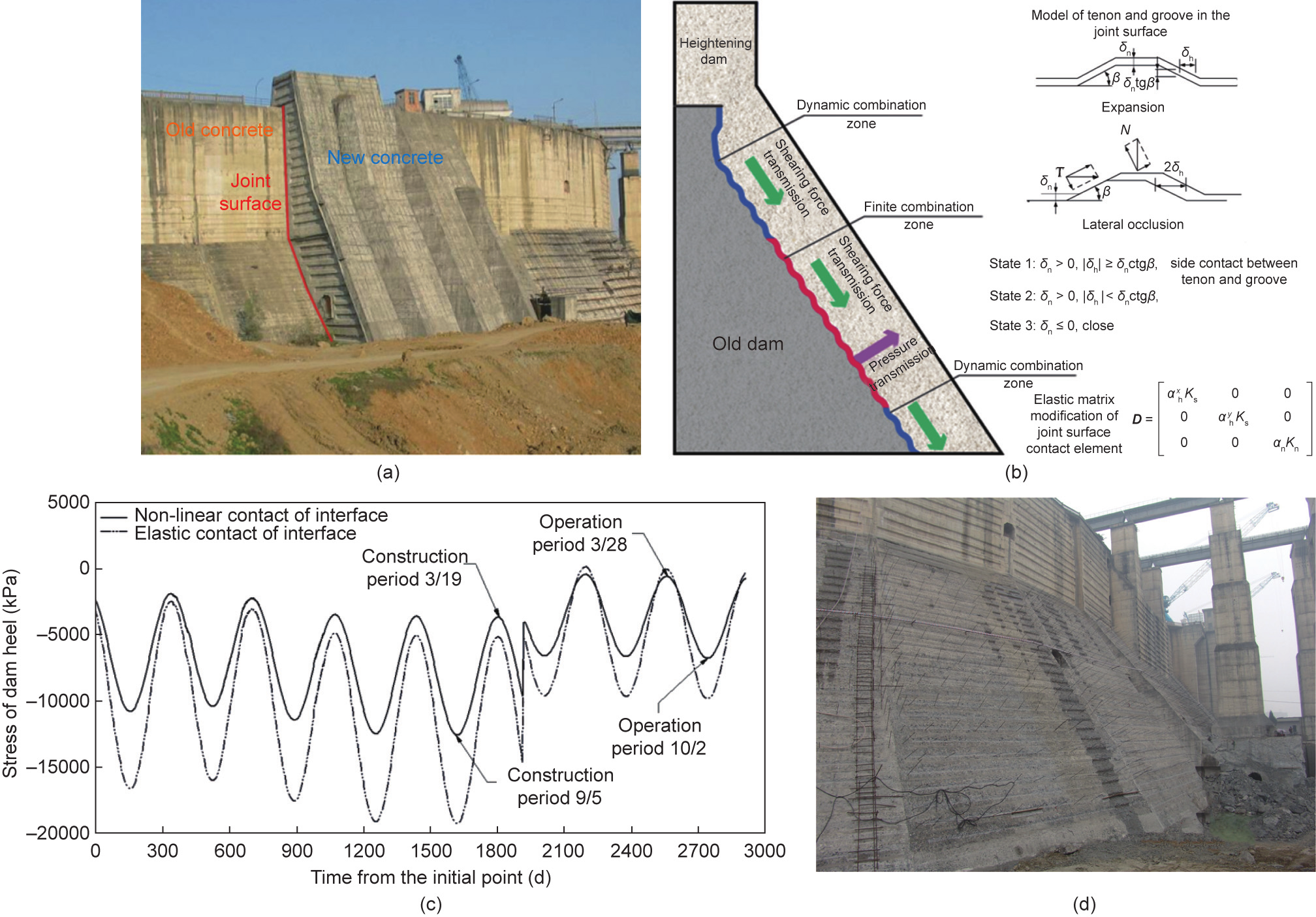

In order to study the combination of new and old concrete, three in situ field tests were successively carried out (Fig. 4(a)). The results showed that a combined surface of new and old concrete has different degrees of opening under various working conditions, and the opening and closing state changes periodically with the temperature [3]. The design of a standard gravity dam assumes that the dam is an integral structure whose stress meets the assumed conditions of a plane section. However, a combined surface is actually in a cracked state. When a force is transmitted by the limited combined part of the combined surface, it is difficult to apply traditional dam design theory based on material mechanics and the rigid-body limit equilibrium method. Therefore, based on in situ field tests and a large quantity of research and analysis, a design theory involving a ‘‘finite combination of the combined surface with back assistance” was proposed for the heightening structure. A mechanical model was established for the tenon and groove shear transmission in the dynamic cracking area of the combined surface of the new and old dam and the joint transmission of pressure and shear in the finite combined area (Fig. 4(b)). Furthermore, a dam design method and a control standard were also established, considering the nonlinear contact between the combined surfaces and the influence of ambient temperature load (Fig. 4(c)). This model was able to truly reflect the actual working state of the dam heightening and solve the problem of the combined load bearing of the new and old dam.

《Fig. 4》

Fig. 4. (a) In situ tests of dam heightening; (b) the ‘‘finite combination of the combined surface with back assistance” stress-transmission model; (c) stress/time history curve of the dam heel (considering the temperature load); (d) combined surface treatment during dam heightening. δh: tangential displacement; δn: normal displacement; β: angle of combined suface; D: elastic stiffness matrix;  : tangential correction factor of x direction and y direction in local coordinate system, respectively; αn: normal correction factor in local coordinate system; Ks: tangential elastic stiffness; Kn: normal elastic stiffness; N: normal force; T: shear force.

: tangential correction factor of x direction and y direction in local coordinate system, respectively; αn: normal correction factor in local coordinate system; Ks: tangential elastic stiffness; Kn: normal elastic stiffness; N: normal force; T: shear force.

The Danjiangkou Dam adopted the ‘‘finite combination of the combined surface with back assistance” heightening method. This was supplemented by engineering measures such as concrete temperature control and lock steel bars (Fig. 4(d)) [4–7], which ensured limited dynamic cracking in some areas of the combined surface to release the temperature load. Meanwhile, some combined areas remained in a combined state all the time in order to transmit the loads, so as to enable the joint load bearing of the new and old dam. Observations after the heightening of the dam showed that the actual state of the combined surface was basically consistent with the design, and the minimum combined proportion of the heightening dam was about 50%. In 2021, the Danjiangkou Reservoir was successfully impounded to a normal water level of 170 m after the heightening project was completed, and it has passed the test and is operating normally.

《2.3. Expansive-soil canal-slope treatment》

2.3. Expansive-soil canal-slope treatment

Expansive soil is a kind of over-consolidated and multi-cracking special soil with a significant expansion and contraction effect. An expansive-soil slope is prone to landslides, due to structural cracks and drying–wetting cycles. Building water-transfer canals on an expansive-soil foundation is a problem worldwide. The first stage of the Middle-Line Project canal involved 387 km of expansive (rock) soil with a maximum excavation depth of about 50 m. During the project construction, different degrees of landslide occurred on more than 150 canal slopes along the expansive-soil canal section, which is one of the key technical problems in the project [8]. Figs. 5(a) and (b) provide a comparison before and after the construction of the expansive-soil canal in the Middle-Line Project.

《Fig. 5》

Fig. 5. (a) Expansive-soil landslides blocking the canals; (b) expansive-soil canals in the Middle-Line Project.

2.3.1. Deformation and failure mechanism of the shallow and deep layers of expansive-soil slopes

Since the 1970s, many studies have been carried out on the distribution of expansive soil, geotechnical engineering characteristics, slope-failure mechanisms, and engineering treatment measures for the Middle-Line Project [9–12]. It has been revealed that shallow deformation and failure modes are affected by the atmospheric environment and the effect of expansion contraction, and that deep-sliding failure modes are controlled by the cutting of steep and gently inclined fracture structural planes. Shallow deformation and damage are mainly affected by atmospheric drying– wetting cycles in the environment, which cause dense network expansion and contraction cracks to form on the surface of the expansive-soil slope, leading to a broken and cracked soil structure. In this way, multiple tensile cracks are easily generated in the direction parallel to the canal, resulting in shallow sliding deformation and slope damage, as shown in Fig. 6(a).

Deep-sliding failure is mainly controlled by structural planes such as the stratum interface and lithological interface, and by primary extended fractures existing in deeply buried strata. Canal excavation and unloading will cause such fractures to further connect, forming a multi-fracture combined sliding body (Figs. 6(b) and (c)). Conventional-soil slope-stability analysis methods are not suitable for the failure analysis of a deep expansive-soil slope controlled by a large structural plane. To identify the worst combination of large cracks and stratum structural planes controlling the slope stability in an expansive-soil layer, two methods were proposed. One is the broken-line sliding failure model controlled by the deep structural plane in expansive soil; and the other is the grid-search method, which is used for a stability analysis of adverse combinations of cracks based on the rigid body limit equilibrium method (LEM) (Fig. 6(d)). These methods solved the longterm problem of accurately analyzing the stability of an expansivesoil slope.

《Fig. 6》

Fig. 6. (a) Photo of shallow damage; (b) photo of deep structural plane damage; (c) a broken line sliding failure controlled by a deep structural plane in expansive soil; (d) the grid-search method to identify adverse combinations of multiple cracks.

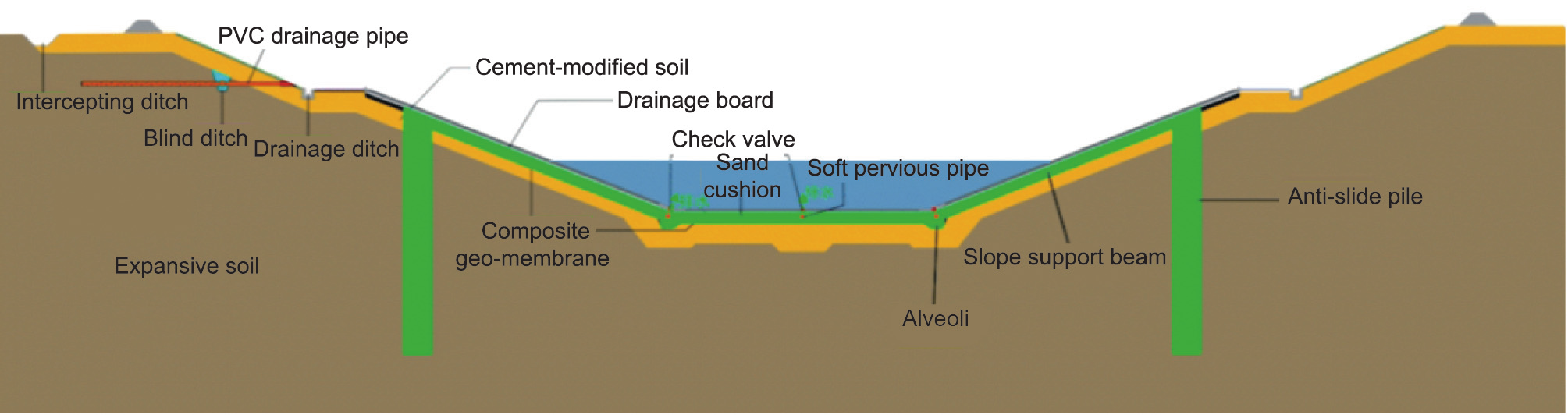

2.3.2. Comprehensive treatment technology for expansive-soil canal slopes

For shallow damage in expansive soil, the main treatment plan is to isolate the influence of the atmosphere and reduce rainwater scouring. For sliding failure of a deep structural plane, the main idea is to reduce the damage caused by groundwater in the slope and reinforce the soil. Based on these concepts, a new comprehensive treatment technology involving the protection, interception, drainage, and reinforcement of an expansive-soil canal slope is proposed (as shown in Fig. 7). The slope surface is protected by measures such as cement-modified soil to reduce the impact of the atmospheric environment. Intercepting ditches are set at the top of the slope to intercept rainfall or external water in order to reduce confluence and scouring on the surface of the canal slope. Blind ditches and check valves are set within the slope for drainage, to control changes in the soil moisture content. Finally, multiple anti-slide piles are used to reinforce the slope. This comprehensive treatment technology has solved the problems of shallow-surface creep deformation and deep structural planecontrolled landslide stability of an expansive-soil slope [13–16], making it possible to establish corresponding controlled technology standard systems.

At present, the expansive-soil canal in the Middle-Line Project operates well and has successfully withstood the test of two severe rainstorms in 2016 and 2021.

《Fig. 7》

Fig. 7. The comprehensive treatment technology of protection, interception, drainage, and reinforcement. PVC: polyvinyl chloride.

《2.4. Yellow River-crossing tunnel sub-project》

2.4. Yellow River-crossing tunnel sub-project

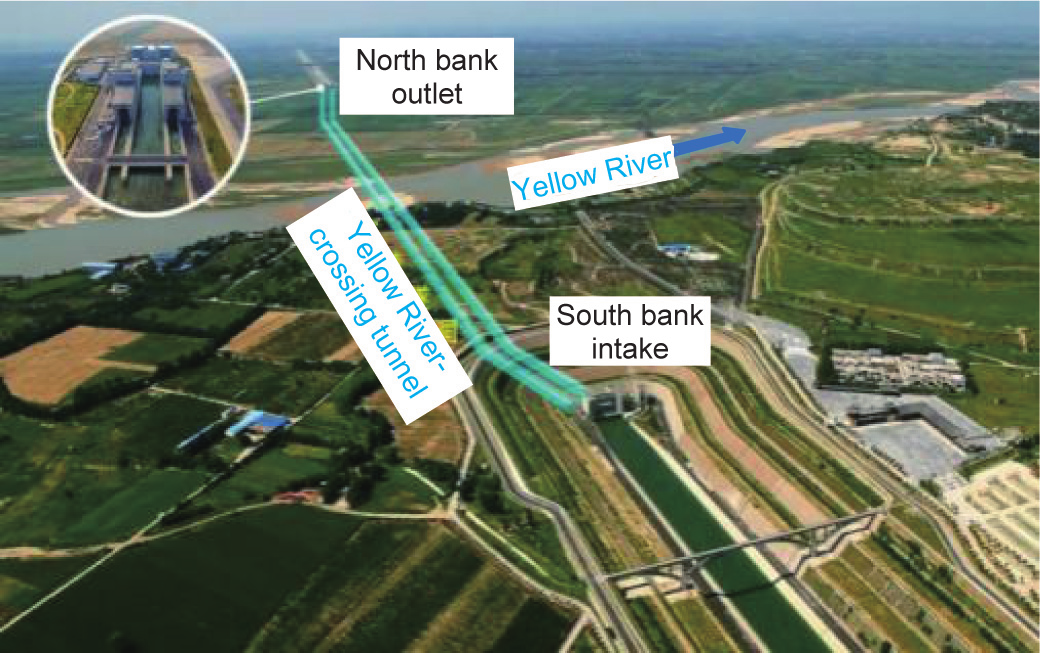

The Yellow River-crossing tunnel sub-project is located about 30 km upstream of Zhengzhou City, Henan Province. The main canal crosses the Yellow River through this construction (Fig. 8), which was the key sub-project of the main canal, with the largest scale and the most complex technology. Two tunnels were set up in the Yellow River-crossing sub-project, with a single tunnel length of 4250 m and an inner diameter of 7 m. The shield tunnel crosses the Yellow River through a wandering river section. The riverbed of this section is a saturated layer of sandy soil with complex geological conditions. The water pressure in the tunnel is as high as 0.51 MPa, which presents two key technical problems: preventing high-pressure internal water seepage, and adapting to the large longitudinal dynamic deformation of the tunnel caused by the wandering river regime.

《Fig. 8》

Fig. 8. Layout of the Yellow River-crossing tunnel sub-project.

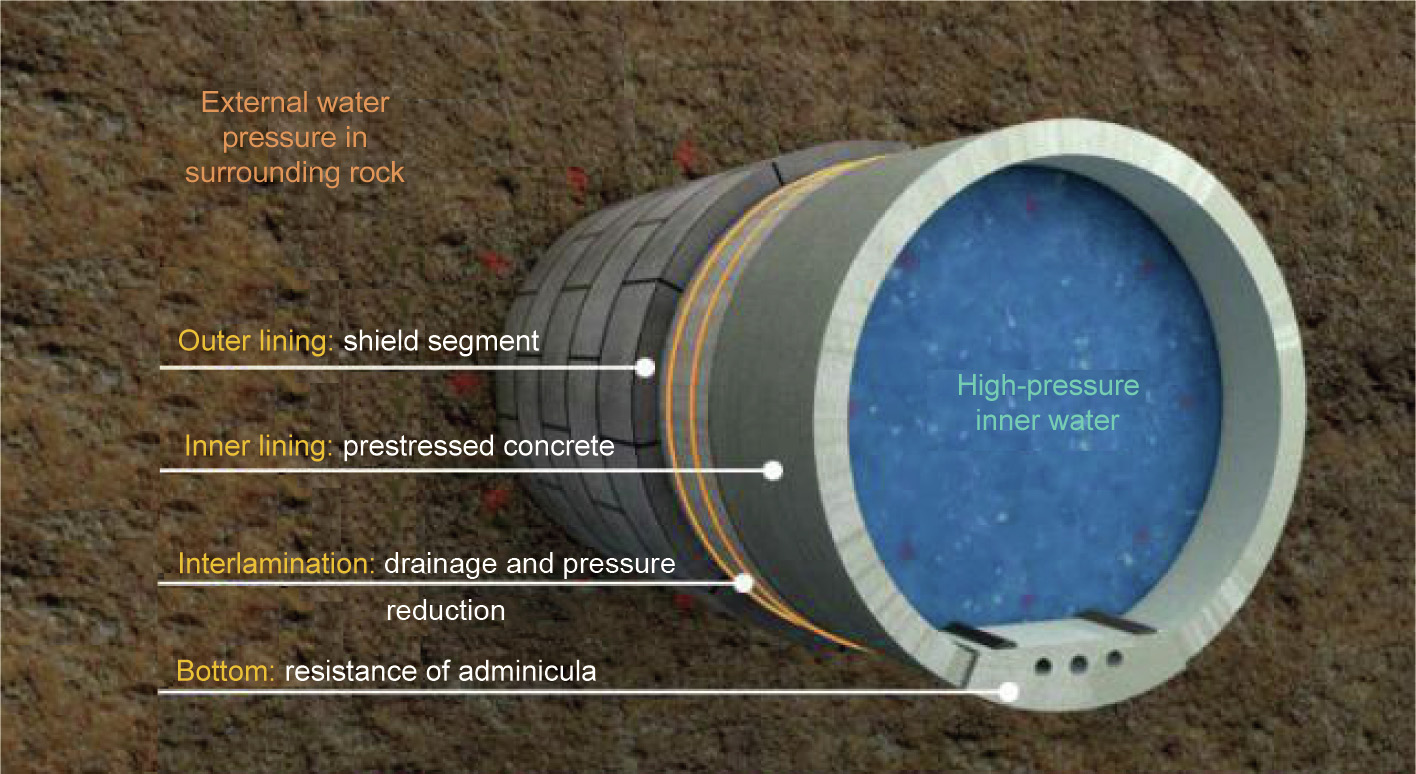

In order to adapt to the wandering configuration of the Yellow River, it was necessary to prevent the high-pressure water from seeping out from the joints of the tunnel’s shield segments, which would induce seepage failure of the surrounding soil and the unstability of the tunnel. Moreover, an inner lining was needed in the shield-segment assembly structure to bear the internal water pressure while reducing the roughness of the water surface and the tunnel diameter. Because an ordinary reinforced lining shall be equipped with high-density steel bar reinforcement, such construction is difficult and uneconomical. Therefore, a new watertransfer tunnel structure comprising a shield tunnel with a prestressed composite lining was researched and invented (Fig. 9). Design theories and structural analysis methods for the composite structure of the water-transfer tunnel were put forward, and a corresponding design control standard system was established. The outer lining of the tunnel resists the water and soil load outside of the tunnel, while the prestressed inner lining bears the high-pressure internal water load, with a drainage cushion set between the inner and outer lining to reduce the interlaminar water pressure. This composite structure can well adapt to the longitudinal dynamic large deformation caused by the depth change of the covered soil outside the tunnel, which is due to the scouring and silting of the wandering river section. It also solves the problems of the structure stress of the high-pressure water-transfer tunnel passing through the multiphase complex soft soil layer, and of possible instability and damage of the surrounding soil caused by internal water seepage [17,18]. At present, the Yellow River-crossing tunnel runs well, and the deformation, structural stress, and seepage pressure of the tunnel all meet the design requirements.

《Fig. 9》

Fig. 9. Structural diagram of the prestressed composite lining of the shield tunnel.

《2.5. Super-large water-delivery aqueduct》

2.5. Super-large water-delivery aqueduct

A total of 27 aqueducts are arranged along the main canal of the first stage of the Middle-Line Project. Among these, the Tuan River aqueduct has a maximum flow of 420 m3 ·s–1 and a single span load of 4800 t (equal to 30 trains), with a minimum wall thickness of only 35 cm. At present, it is the largest U-shaped aqueduct in the world. Thus, there were no standards to follow for the design of this super-large aqueduct. Moreover, this sub-project presented various key technical problems, such as structural load bearing and crack prevention, along with a tight construction period and high technical requirements. These issues were directly related to the realization of the general water-supply goal of the first stage of the Middle-Line Project.

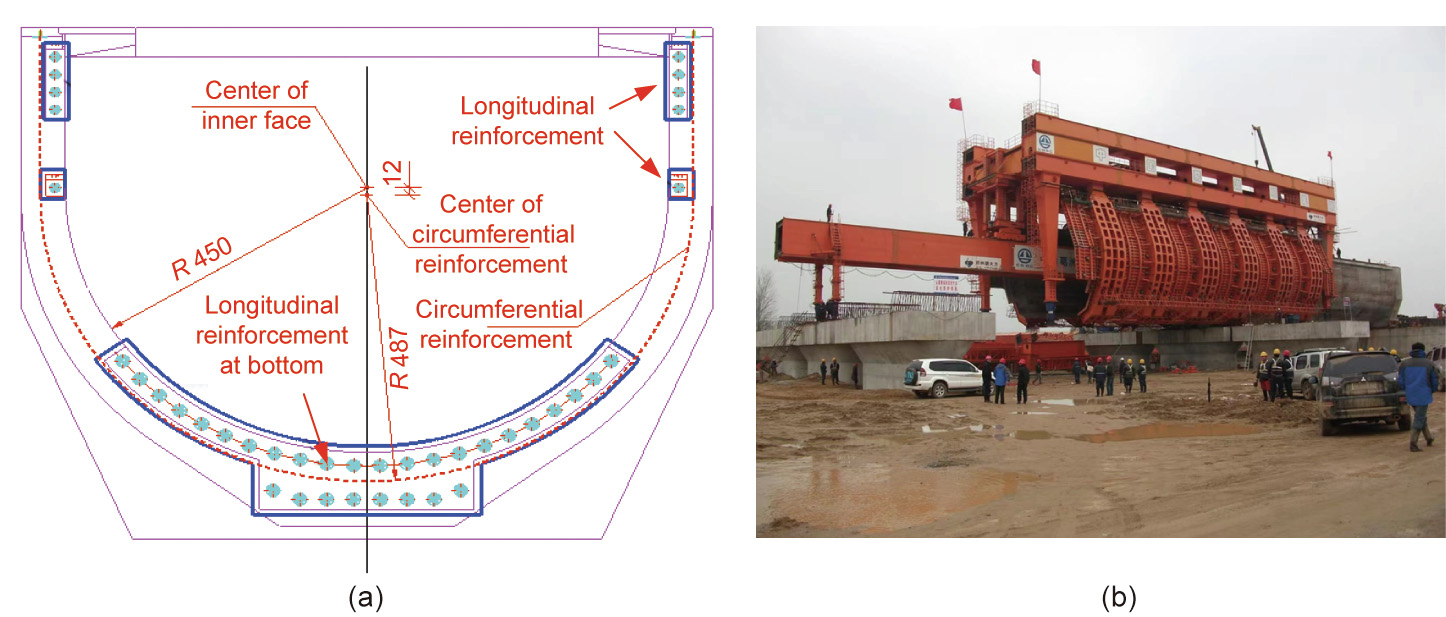

During the design process of the Tuan River aqueduct, the project put forward a new design idea: that the bowl partition layout of the longitudinal prestress and the circumferential prestress does not need to be concentric with the inner surface (Fig. 10(a)). In addition, a temperature load model simulated by broken-line by zone was developed for the aqueduct sections. A theory and method were formed to create a super-large U-shaped prestressed aqueduct design and to solve technical problems such as structure load bearing with a low thickness and crack control of the superlarge U-shaped prestressed aqueduct [19]. At the same time, a complete set of mechanized construction technologies and methods were developed to fill the technological gap in mechanized construction technology for the large cast-in situ prestressed aqueduct [20,21]. These included installation, operation, and pouring technologies and methods, along with the construction of an aqueduct-building machine for a super-large U-shaped aqueduct with a span of 40 m (Fig. 10(b)).

《Fig. 10》

Fig. 10. (a) Layout of the prestressed reinforcement of the Tuan River aqueduct and (b) mechanized construction of a super-large U-shaped aqueduct-building machine. R: radius (cm).

《2.6. Water regulation and operation control technology》

2.6. Water regulation and operation control technology

The water regulation of the Middle-Line Project shall coordinate flood control, power generation of the Danjiangkou Reservoir, ecological and domestic water use in the middle and lower reaches of the Han River, and the development and protection of local water resources in the water-receiving areas. It is also necessary to quickly and accurately respond to changes in the demands of water users in 191 counties or cities along the project, without the use of online regulating reservoirs. For the water regulation and operation control of the project, it is necessary to consider a wide range of factors whose relationships are rather complicated. A key technical difficulty in ensuring that the benefits of the project can be obtained is how to scientifically establish a waterregulation plan and then regulate the check gates and pumps along the project at appropriate times and with appropriate amounts, so as to deliver water to users in a timely and efficient fashion. In order to solve this problem, a multi-objective elaborate waterregulation model that jointly and dynamically allocates water in the waterhead and water-receiving areas was established. Moreover, a real-time self-adaptive operation system that can meet multiple users’ needs was developed.

2.6.1. A multi-objective elaborate water-regulation model jointly and dynamically allocating water in the waterhead and water-receiving regions

The water regulation of the first stage of the Middle-Line Project requires an overall consideration about the comprehensive utilization of water resources in the upper and lower reaches of the Han River basin and the Huang–Huai–Hai River basin in the North China Plain, as well as the joint operation of the Danjiangkou Reservoir and 97 water diversions in water-receiving areas along the project. To achieve the multiple water-regulation objectives in an accurate way, a cycle-feedback dynamic water-regulation model was built, which includes the Han River basin, the Danjiangkou Reservoir, and the water diversions and water users of the main canal of the Middle-Line Project. The model considers various factors, such as the transferrable water volume of the Danjiangkou Reservoir, the water demands of 191 counties or cities in water-receiving areas, and the water transportation capacity of each section of the main canal (Fig. 11). By analyzing the different water conditions in each area, it was able to propose a water-regulation scheme covering 97 water diversions along the main canal and realizing the balanced allocation of water resources characterized by multiple objectives, objects, timescales, and space scales. These achievements established a solid foundation for the safe, stable, and efficient operation of the Middle-Line Project.

《Fig. 11》

Fig. 11. The multi-objective dynamic joint water-regulation model of the first stage of the Middle-Line Project. (a) Water supply of the Danjiangkou Reservoir; (b) the multiple objects of water regulation of the Middle-Line Project; (c) the time scale of water regulation of the Middle-Line Project.

2.6.2. A real-time operation system meeting multiple users’ needs with self-regulation

The real-time control of the first stage of the Middle-Line Project encountered a variety of difficulties: There are a total of 161 water diversions and check gates along the canal, and the hydraulic response of the canal flow to gate regulation is very slow. Furthermore, there are no online regulating reservoirs, and the allowable variation range of the water level is rather small. The regulation capacity of the canal is poor, while the regulation standard is rather high at the same time.

In order to transport water to users as required in a timely and efficient manner, a real-time operation system for the first stage of the Middle-Line Project was developed that could satisfy multiple users’ needs in a self-regulated manner. As the core of the project’s operation and regulation, this system can regulate water diversions and check gates along the canal regularly and quantitatively, in a scientific and effective way. The system regulates check gates in a coordinated manner according to the designed joint operation rules in order to control the water level adaptively in front of the gates within a certain interval, which allows this water volume to be utilized to respond to water users’ needs rapidly, with little adjustment of the check gates. The system can generate the regulation process of each check gate according to different water demands, making it possible to divert water to users at appropriate times and in appropriate amount, while filling and discharging the canal appropriately. It realizes the real-time automatic control of the project under regular tasks and ensures the safe operation of the main canal, as well as the smooth implementation of the annual water-regulation plan.

《3. Prospect》

3. Prospect

The successful implementation of the first stage of the MiddleLine Project has yielded and accumulated a series of independently developed survey, design, and mature supporting construction technologies. The project has established 42 technical standards for the design and construction of expansive-soil canals and has obtained more than 1000 patents and developed nationally used construction methods, which have effectively guided the survey, design, and construction of the project. The project has now been under operation for more than seven years. During this time, it has withstood the test of natural disasters such as cold waves and extreme heavy rainfalls. During the operation period, the project has been generally stable, and the water-transfer task has been successfully completed every year. The project has become the water-supply lifeline for cities located along the project, such as Beijing and Tianjin, and has powerfully promoted the recovery of the ecological environment of the rivers and lakes along the project, including the Hutuo River, Pu River, and Baiyangdian Lake.

The technical achievements yielded by the construction and operation of the first stage of the Middle-Line Project have been successfully applied to major domestic water-transfer projects that are currently under construction, such as the Yangtze River to Huai River Project, the Han River to Wei River Project, the Middle Yunnan Water-Transfer Project, and the Pearl River Delta Water Resources Allocation Project, resulting in remarkable social, economic, and ecological benefits.

The temporally and spatially uneven distribution of water resources is a major problem restricting the development of human society. Thus, management of the construction and operation of cross-basin and long-distance water-transfer projects is a hot topic in today’s society and will continue to be critically important for a long time in the future. The series of innovative technologies yielded by the first stage of the Middle-Line Project provide a reference for the construction of important domestic and international water-transfer projects, and thus have broad prospects for popularization and application.

京公网安备 11010502051620号

京公网安备 11010502051620号