《1. Introduction》

1. Introduction

Solar photovoltaic (PV) technology is indispensable for realizing a global low-carbon energy system and, eventually, carbon neutrality. Benefiting from the technological developments in the PV industry, the levelized cost of electricity (LCOE) of PV energy has been reduced by 85% over the past decade [1]. Today, PV energy is one of the most cost-effective electrical power sources worldwide. For instance, a PV power price of merely 0.0104 USD·(kW·h)–1 was achieved in Saudi Arabia in April 2021 [2].

In the coming years, innovative technological developments should help further boost the PV power conversion efficiency (PCE), reduce the PV energy cost, and expand the PV industry. With the ever-increasing proportion of PV in the energy system, the challenges posed by the regional intermittence and randomness of PV energy will manifest and provide opportunities for new technologies, including the integration of PV with other forms of energy and/or various energy storage techniques. We believe that, in the long term, extended PV systems with the active participation of green hydrogen energy are key to the deep decarburization and sustainable development of our society.

《2. Development of photovoltaic technology》

2. Development of photovoltaic technology

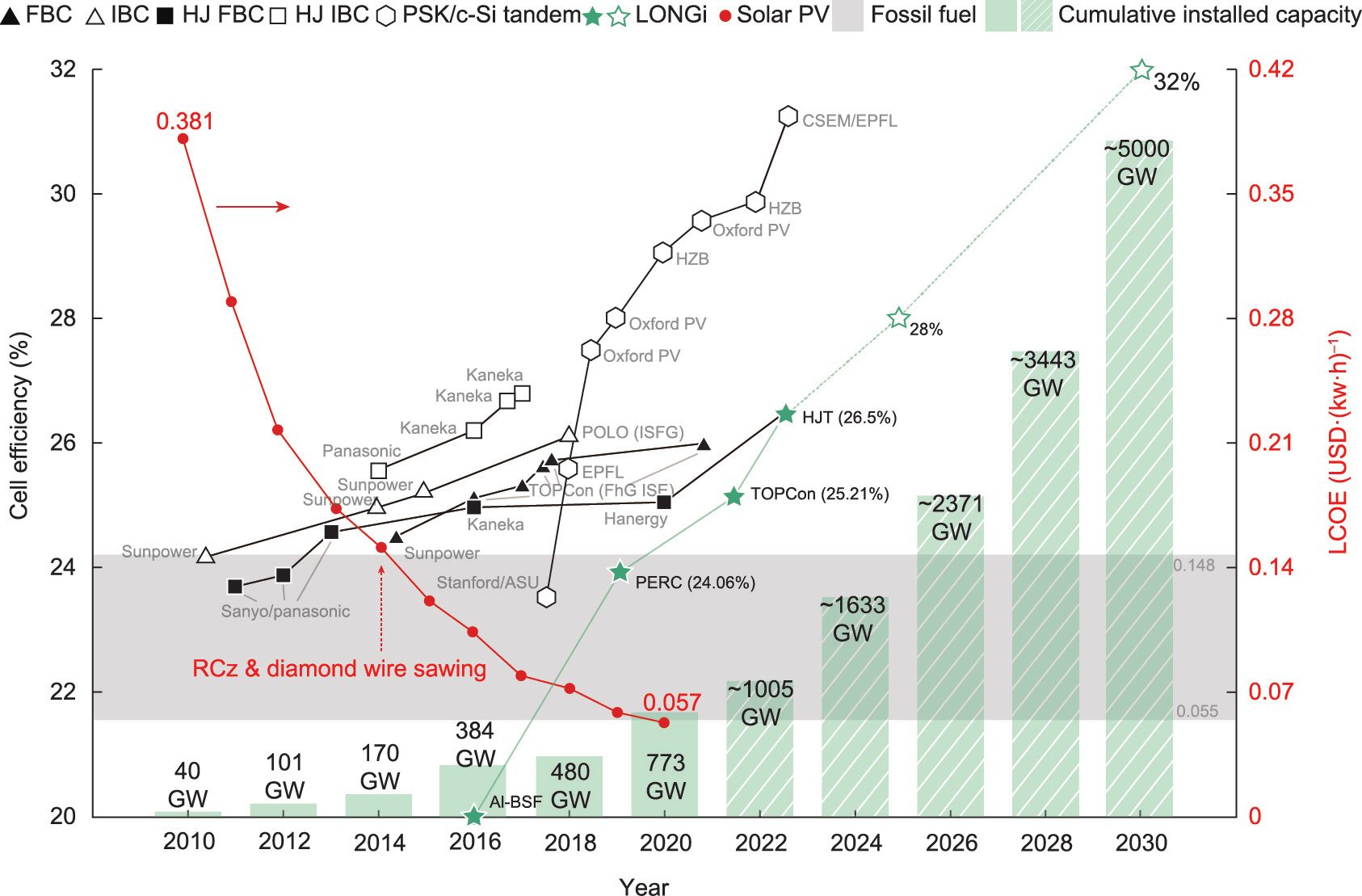

High PCE and low LCOE, which ensure the competitiveness of PV energy, rely extensively on the development of PV technologies. Wafer-based crystalline silicon (c-Si) solar cells have been the dominant PV technology since the 1960s and are still undergoing considerable progress, with multiple technological breakthroughs in both academia and the industry over the past decade (Fig. 1 [3–6]).

《Fig. 1》

Fig. 1. Development of solar PV technology over the past decade and future trends. Efficiency evolution for different types of c-Si solar cells from 2010 to 2022: homojunction c-Si cells with front-and-back contact (FBC, ▲) and interdigitated back contact (IBC,  ); heterojunction (HJ) c-Si cells with FBC (HJ FBC,

); heterojunction (HJ) c-Si cells with FBC (HJ FBC,  ) and IBC (HJ IBC, □) [3,4]. Cell efficiency records from 2016 to 2021 (

) and IBC (HJ IBC, □) [3,4]. Cell efficiency records from 2016 to 2021 ( ) and the anticipated best cell efficiencies over the next decade (

) and the anticipated best cell efficiencies over the next decade ( ) for LONGi Corporation as a representative of PV companies. Global weighted average LCOE of solar PV (

) for LONGi Corporation as a representative of PV companies. Global weighted average LCOE of solar PV ( ), compared to fossil fuel-fired power generation cost (gray band) [5]. Cumulative installed capacities of global PV energy from 2010 to 2020 (green column) and predicted cumulative installed capacities of PV energy from 2022 to 2030 (shadowed green column) [6]. ASU: Arizona State University; RCz: recharged-Czochralski; TOPCon: tunneling oxide passivating contact; POLO: polycrystalline silicon on oxides; ISFG: Institute for Solar Energy Research in Hamelin; EPFL: École polytechnique fédérale de Lausanne; FhG ISE: Fraunhofer institute for solar energy; PSK: perovskite; HZB: Helmholtz Zentrum Berlin; CSEM: Swiss Center for Electronics and Microtechnology; PERC: passivated emitter and rear cell; HJT: heterojunction technology; Al-BSF: aluminum-back surface field.

), compared to fossil fuel-fired power generation cost (gray band) [5]. Cumulative installed capacities of global PV energy from 2010 to 2020 (green column) and predicted cumulative installed capacities of PV energy from 2022 to 2030 (shadowed green column) [6]. ASU: Arizona State University; RCz: recharged-Czochralski; TOPCon: tunneling oxide passivating contact; POLO: polycrystalline silicon on oxides; ISFG: Institute for Solar Energy Research in Hamelin; EPFL: École polytechnique fédérale de Lausanne; FhG ISE: Fraunhofer institute for solar energy; PSK: perovskite; HZB: Helmholtz Zentrum Berlin; CSEM: Swiss Center for Electronics and Microtechnology; PERC: passivated emitter and rear cell; HJT: heterojunction technology; Al-BSF: aluminum-back surface field.

For example, in research, the charge carrier-selective contact— that is, the tunneling oxide passivating contact (TOPCon, also called polycrystalline silicon on oxides (POLO)), initiated by Fraunhofer ISE in 2013 [7,8]—shows enhanced surface passivation and carrier extraction, compared to the passivated emitter and rear cell (PERC), the foremost c-Si cell in the market. Based on the TOPCon, the PCE of homojunction c-Si cells can reach 26% for front-andback contact (FBC) cells [3] (▲ in Fig. 1 [3–6]) and 26.1% for interdigitated back contact (IBC) cells (named POLO-IBC by Institute for Solar Energy Research in Hamelin) [9] ( in Fig. 1 [3–6]). In addition, heterojunction technology (HJT), which uses n-type/p-type amorphous silicon (a-Si) as the selective contact and intrinsic (undoped) a-Si as the passivation layer, allows high charge extraction from the c-Si base. By combining HJT with IBC, the HJ IBC cell constructed by Kaneka Corporation (Japan) in 2017 demonstrated a PCE of 26.7% [10], the highest PCE of a single-junction c-Si cell even today (□ in Fig. 1 [3–6]). Also notably, the record PCE of an HJ FBC cell is 26.5%, achieved by LONGi Corporation in 2022 [11,12] (

in Fig. 1 [3–6]). In addition, heterojunction technology (HJT), which uses n-type/p-type amorphous silicon (a-Si) as the selective contact and intrinsic (undoped) a-Si as the passivation layer, allows high charge extraction from the c-Si base. By combining HJT with IBC, the HJ IBC cell constructed by Kaneka Corporation (Japan) in 2017 demonstrated a PCE of 26.7% [10], the highest PCE of a single-junction c-Si cell even today (□ in Fig. 1 [3–6]). Also notably, the record PCE of an HJ FBC cell is 26.5%, achieved by LONGi Corporation in 2022 [11,12] ( and

and  in Fig. 1 [3–6]).

in Fig. 1 [3–6]).

In the industry, the recharged-Czochralski (RCz) method for monocrystalline silicon production and the diamond-wire sawing process for c-Si wafer slicing—both promoted by LONGi Corporation in 2014—considerably expanded the scope for the manufacturing cost reduction of c-Si solar cells and has been indispensable in driving the current PV LCOE to fossil fuel levels (red line and gray band in Fig. 1 [3–6]). Meanwhile, the structural evolution from aluminum-back surface field (Al-BSF) to PERC cells boosted the commercial c-Si cell PCE from 20% to 24% ( in Fig. 1 [3–6]), a major contribution to the LCOE reduction. These technical improvements have made c-Si solar cells the most efficient and economical PV technology in the market. In turn, the cost-effectiveness of c-Si PV energy is stimulating new technological innovations in the PV industry.

in Fig. 1 [3–6]), a major contribution to the LCOE reduction. These technical improvements have made c-Si solar cells the most efficient and economical PV technology in the market. In turn, the cost-effectiveness of c-Si PV energy is stimulating new technological innovations in the PV industry.

In the next decade, c-Si cells will remain the mainstream technical path for the PV industry, and the PCE of commercial-scale c-Si cells will continue to increase with the application of advanced technologies and new technical breakthroughs. During the first stage (in five years), the commercialization of the above-mentioned advanced passivation-contact techniques (i.e., TOPCon and HJT) will be important in driving the large-scale c-Si cell PCE to more than 24%. In fact, cell efficiencies of 26.5% for HJT and 25.7% for TOPCon—all based on large-scale c-Si wafers—have already been reported by PV corporations ( in Fig. 1 [3–6] show LONGi’s record) [12–14]. The mass production of these advanced cells is just around the corner.

in Fig. 1 [3–6] show LONGi’s record) [12–14]. The mass production of these advanced cells is just around the corner.

To achieve a PCE higher than the current c-Si cell record (26.7%) [4] the bulk losses induced primarily by Auger recombination, optical losses and front-side resistance losses, which still account for a large proportion of PCE losses in c-Si cells, should be further diminished based on a more profound understanding of the cell property–performance relationship. Currently, several preliminary theories regarding photoexcitation and charge-transfer processes related to cell performance have been established [15,16]. Some future directions have also been recognized, including thinner Si wafers with lower doping concentrations (which can reduce the impact of Auger recombination) and sufficiently conductive contact layers with locally structured or wide bandgap compounds (which can reduce optical and transmission resistance losses) [17]. However, the realization of these concepts with expected results remains challenging. This requires a detailed cellefficiency–loss-analysis theory that can provide comprehensive and quantitative knowledge of the material properties (including the properties of the Si absorber and the contacts) and structural characteristics that influence the photon/charge behaviors. With the guidance of improved theory and advanced Si materials, a new type of c-Si cell, which may be a smart hybridization of TOPCon, HJT, IBC, and dopant-free asymmetric Si hetero-contact (DASH) cells, can be constructed and achieve a cell PCE over 27% [18,19]. A PCE above 28% may also be possible if the optical characteristics of the c-Si cell can be appropriately optimized [20].

Next, to attain a PCE exceeding the Shockley–Queisser (S–Q) limit of a single p–n junction (~33%) [21], multi-junction tandem technology, which has exhibited a lab-record PCE of 47.1% under concentrated sunlight [22], is a feasible objective. Among various Si-based stacking technologies, perovskite (PSK)/c-Si tandem is the most promising, considering its perfect bandgap matching, high process compatibility and high theoretical PCE (44%) [23]. Based on considerable research attention, the PCE record of PSK/ c-Si tandem solar cells, which was 23.6% when first reported, has been improved to 31.25% [24] ( in Fig. 1 [3–6]). However, the low durability and substantial PCE losses in large-area cells remain major obstacles to the commercialization of PSK top cells. The short lifespan of PSK top cells—totaling just ‘‘hours” owing to its rapid degradation under working conditions—is incompatible with the 25-year quality guarantee of Si PV modules. The high PCE (> 25%) achieved in small-area (≤ 1 cm2 ) PSK cells [25] decreases dramatically as the cell becomes larger as a uniform large film is difficult to obtain using current PSK film-fabrication techniques. To improve the lifespan of PSK cells to a level close to that of its silicon counterparts, it is essential to understand the fundamental PSK degradation mechanism and to develop strategies that can block the degradation routes, for example, applying all-inorganic PSK [26], introducing effective defect passivators (such as ionic liquids) [27], and enhancing cell encapsulation [28]. The reduction of PCE losses in large-area PSK requires refined variation control during the PSK crystallization process, which needs to be guided by a deep understanding of PSK crystallization kinetics [29]. For example, when using the most economical and efficient solvent method for PSK film fabrication [30], a detailed design of the solvent system is important to achieve a large process window for a highquality film that ensures uniform PCE distribution across the large-area PSK device [31]. In addition, improving the uniformity of transparent conductive layers and the precision of coating technologies is also critical for alleviating the PCE losses of large-area PSK cells. Optimistically, with joint efforts in related areas, relatively stable PSK/c-Si tandem cells with PCE above 32% could be expected to appear before 2030.

in Fig. 1 [3–6]). However, the low durability and substantial PCE losses in large-area cells remain major obstacles to the commercialization of PSK top cells. The short lifespan of PSK top cells—totaling just ‘‘hours” owing to its rapid degradation under working conditions—is incompatible with the 25-year quality guarantee of Si PV modules. The high PCE (> 25%) achieved in small-area (≤ 1 cm2 ) PSK cells [25] decreases dramatically as the cell becomes larger as a uniform large film is difficult to obtain using current PSK film-fabrication techniques. To improve the lifespan of PSK cells to a level close to that of its silicon counterparts, it is essential to understand the fundamental PSK degradation mechanism and to develop strategies that can block the degradation routes, for example, applying all-inorganic PSK [26], introducing effective defect passivators (such as ionic liquids) [27], and enhancing cell encapsulation [28]. The reduction of PCE losses in large-area PSK requires refined variation control during the PSK crystallization process, which needs to be guided by a deep understanding of PSK crystallization kinetics [29]. For example, when using the most economical and efficient solvent method for PSK film fabrication [30], a detailed design of the solvent system is important to achieve a large process window for a highquality film that ensures uniform PCE distribution across the large-area PSK device [31]. In addition, improving the uniformity of transparent conductive layers and the precision of coating technologies is also critical for alleviating the PCE losses of large-area PSK cells. Optimistically, with joint efforts in related areas, relatively stable PSK/c-Si tandem cells with PCE above 32% could be expected to appear before 2030.

《3. Emergence of extended photovoltaic systems》

3. Emergence of extended photovoltaic systems

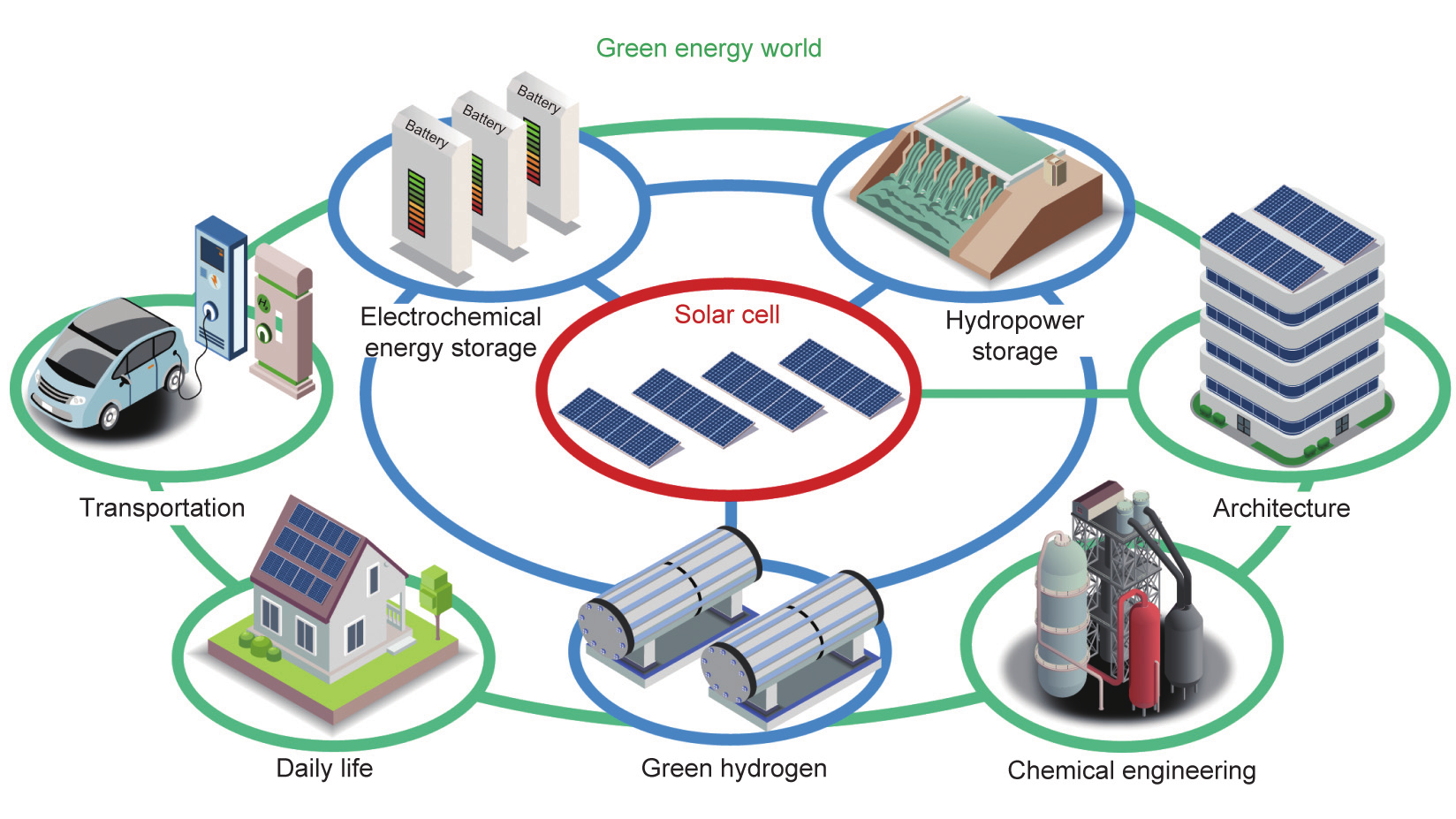

The proportion of PV energy in the overall energy system has been steadily increasing. According to World Energy Transitions Outlook of the International Renewable Energy Agency [6], PV energy will comprise more than 10% of the energy system by 2030, with a cumulative installed capacity of over 5000 GW (green columns in Fig. 1 [3–6]). By 2050, PV energy could account for more than 35% of the overall power supply, with a cumulative installed capacity of 14 000 GW [6]. However, this increasing proportion of PV within the power grid is challenged by its regional intermittence. To overcome this, multi-energy complementary systems with PV and other renewable energies (e.g., hydropower and wind power) are being developed [32]. In addition, extended PV systems comprising PV and various energy storage units, including physical (hydropower), electrochemical (battery), and chemical (hydrogen) solutions, are emerging (Fig. 2).

《Fig. 2》

Fig. 2. Future integrated energy system for a green energy world.

Photovoltaic-electrochemical (PV-EC) systems, which utilize PV power for water electrolysis with the generation of green hydrogen, are an effective strategy for storing massive amounts of solar energy, as well as a prospective way of permitting the intensive participation of PV energy in the energy-structure transformation process. This is because the green hydrogen generated by PV technologies could serve as both a significant energy source and an essential chemical resource in many aspects of a future sustainable world, including transportation, the chemical industry, and daily life. The PV-EC method is the most efficient way to convert solar energy into hydrogen, exhibiting a solar-to-hydrogen efficiency of more than 30% at the laboratory scale [33]. With the continuous LCOE reduction of PV energy, the PV-EC route is expected to become the most cost-effective method for green hydrogen production. In turn, the huge demand for green hydrogen in the future could provide great opportunities for the development of the PV industry with further LCOE reduction. According to the International Energy Agency, the scale of green hydrogen electrolysis could rapidly increase to 850 and 3600 GW by 2030 and 2050, respectively [34].

Eventually, with the development of extended PV systems, the problems associated with the intrinsic properties of PV energy will be eliminated, allowing the global energy industry to shift from resource-driven to manufacturing-driven.

《4. Conclusions》

4. Conclusions

With the rapid development of c-Si-cell-based PV technologies, PV energy is becoming the most cost-effective renewable energy source, leading to the fast growth of PV energy proportion in the global energy system. The future PV market will still be dominated by c-Si cells, while an in-depth understanding of the exact factors contributing to power conversion efficiency losses and the development of effective ways for controlling these factors are desired to achieve a PCE surpassing 28%. PSK/c-Si tandem cells are of great promise for becoming the future high-efficiency (> 32%) solar cell if the stability and large-scale uniformity of the PSK film can be substantially improved in the following years. Meanwhile, with the potential to address the regionally intermittent features of solar energy, extended PV systems, especially the PV-EC strategy with green hydrogen production, can further improve the sustainable proportion of PV in the energy system and pave the way to achieving the Paris Agreement goals.

京公网安备 11010502051620号

京公网安备 11010502051620号