《1. Introduction 》

1. Introduction

Carbon neutrality is an important strategy to address the acute problems of resource and environmental constraints. Currently, afforestation, energy conservation, emissions reduction, and other measures have been adopted to offset the total amount of carbon dioxide and other greenhouse gas emissions generated by countries, businesses, products, activities, or individuals, with the aim of finally achieving zero net emissions (Fig. 1(a)). According to the latest distribution of global electricity generation (Fig. 1(b)), most electricity (61.3%) is still generated from fossil fuels (coal, gas, and oil) [1]. Despite being the mainstay for eliminating carbon emissions, renewable energy (e.g., solar power, wind power, hydropower, geothermal energy, and biomass) accounts for only 27.7% of the total. Thus, in order to realize carbon neutrality, the world’s energy structure must be optimized [1]. Renewable energy has developed rapidly, with its installed capacity increasing from 754 GW in 2000 to 2799 GW in 2020. Among all sources of renewable energy, solar photovoltaics (PVs) exhibit the fastest growing rate due to their huge energy source (i.e., the sun) and rapid cost decline. The cost of PV electricity generation is expected to decrease to 0.02 USD·(kW·h)–1 by 2050. At that time, renewable energy will become the main source of electricity generation, with a projected 86% of the world’s electricity coming from renewable energy (Fig. 1(c)) [2]. Moreover, the installation capacity of PV devices is expected to exceed 8500 GW by 2050 (Fig. 1(d)), reducing carbon dioxide emissions by 4.9 Gt [2]. Thus, promising PV technology presents both tremendous development opportunities and unprecedented challenges, and it is expected to make a significant contribution to carbon neutrality.

《Fig. 1》

Fig. 1. (a) Diagram of carbon neutrality; (b) global electricity generation distribution [1]; (c) development and prediction of global electricity generation to 2050 [2]; (d) breakdown of electricity generation and total installed capacity by source from 2017 to 2050 [2]. CSP: concentrated solar power.

《2. Development of perovskite solar cells》

2. Development of perovskite solar cells

Solar cells, which convert ecologically friendly and inexhaustible solar energy into electrical power using the PV effect, are expected to meet all the global energy demand. To effectively capture sunlight for power generation, many types of light-harvesting semiconductors have been invented, produced, and commercialized. Among them, crystalline silicon (c-Si; monocrystalline or polycrystalline) and thin-film technologies [3,4] have dominated the current PV market. However, their manufacturing usually requires high-vacuum and high-temperature processes, leading to dramatic energy consumption and high production costs. Recently, lead halide perovskite solar cells (PSCs) have gained aggressive research attention due to their high efficiency and low production cost. More specifically, the record efficiency of PSCs has reached 25.7% [5], which is comparable to that of c-Si. PSCs can be produced via low-temperature solution processes and have unique properties in terms of mechanical flexibility and light weight; moreover, they have good prospects for the use of low-cost roll-to-roll manufacturing processes. Furthermore, PSCs with tunable bandgaps can be integrated with other types of solar cells to construct tandem cells (e.g., perovskite–Si tandem cells, all-perovskite tandem cells, perovskite–copper indium gallium selenide (CIGS) tandem cells, and perovskite–organic photovoltaic (OPV) tandem cells), which is predicted to lower the levelized cost of electricity (LCOE) of PV devices. Thus, PSCs are a crucial link in balancing module efficiency and cost, contributing positively to the strategic goal of carbon neutrality. Nevertheless, the issues of PSC efficiency, lifetime, and toxicity remain challenging and will be discussed in subsequent sections.

《2.1. High efficiency》

2.1. High efficiency

The rapid development of PSC technology has brought new opportunities for the PV industry. The focus of PV development is still cost minimization, and improving photoelectric conversion efficiency and stable performance are the two most effective ways to achieve this goal. Although the certified efficiency of the current mini-PSC is as high as 25.7% [5], there is still a certain gap between the current efficiency level and the theoretical limit of efficiency of solar cells. At present, the most promising material is formamidinium lead triiodide (FAPbI3) perovskite with a bandgap of 1.48 eV (1 eV = 1.602176 × 10–19 J), which is close to the ideal bandgap of single-cell solar cells (1.34 eV); its efficiency is estimated to be over 28% [6]. Furthermore, a large-area PSC-powered module device has been reported to reach an efficiency of 22.72% (24 cm2 ), making it a key device form for commercial development [7]. We are confident that the efficiency of perovskite modules can easily exceed 23% in the near future, reaching a level unmatched by silicon solar cells. After the mass production of perovskite has been achieved, the manufacturing cost will also be promisingly less than 50% of that of c-Si solar cells. However, it should be noted that large-scale PSC production procedures are not compatible with the common spin-coating approach used to prepare small-area PSCs at the laboratory scale. Numerous important methods for large-scale PSCs have been investigated, including slot-die coating, doctor-blading, and spraying printing. However, when the PSC module area is expanded to the square meter level, its performance is still inferior to that of c-Si solar cells. Therefore, the attenuation problem extending from small-area components to large-area components still requires attention.

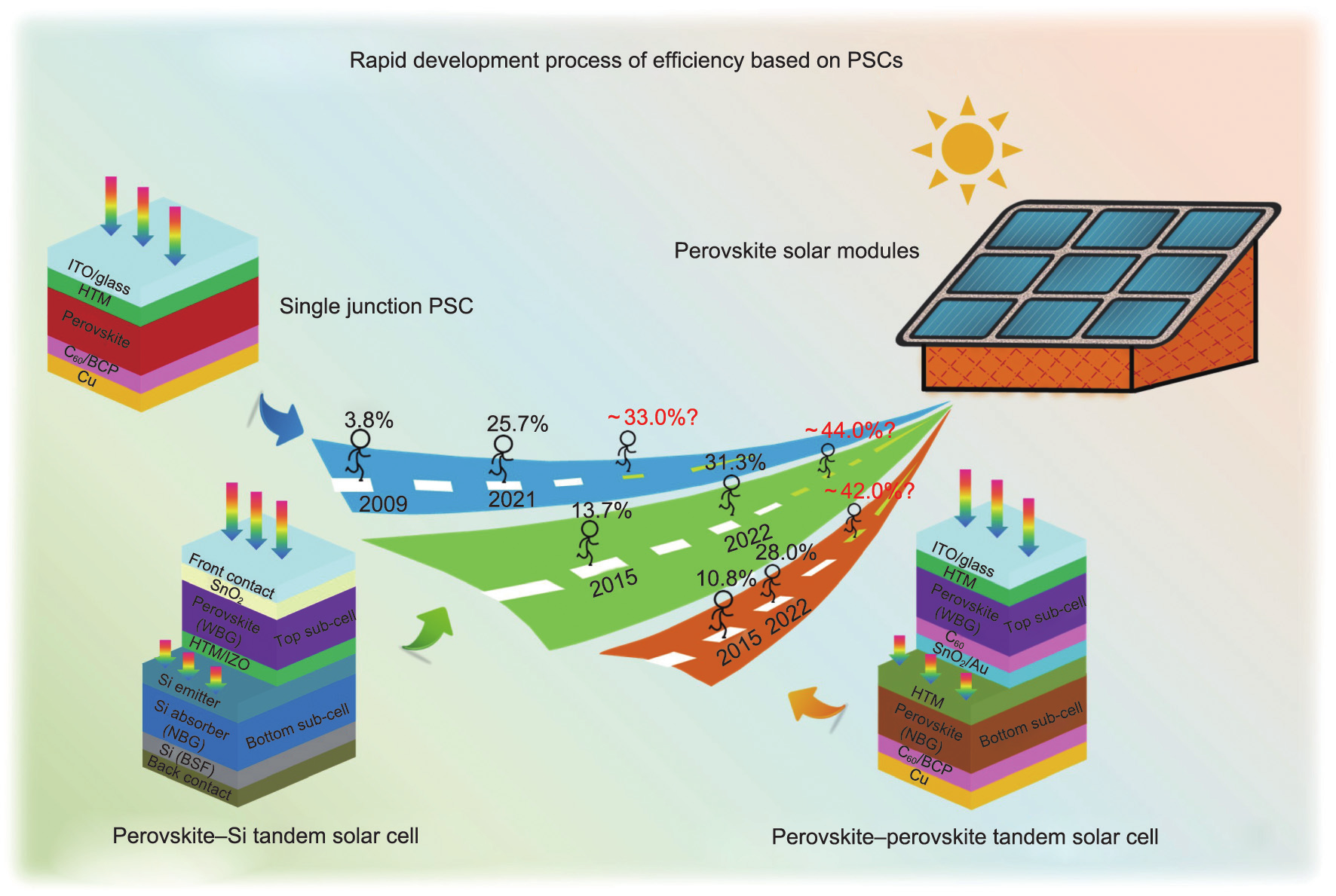

It is known to be difficult for a present-day single-junction PSC to approach or reach the theoretical limit efficiency of ~33%. However, encouragingly, tandem solar cells are considered to be one of the most promising ways to push the theoretical limit. According to theoretical calculations, the efficiency of a two-section tandem device can reach around 45%, while the efficiency of an allperovskite tandem cell can reach around 42%, and the efficiency of a perovskite–Si tandem cell can reach around 44%. The structural optimization and technological innovation of tandem cells will accelerate the development of the PV industry to achieve cost reduction and efficiency improvement (Fig. 2) [8]. To date, perovskite–Si stack devices have achieved a certified efficiency of 31.3%. [5] In addition, the all-perovskite tandem cell has achieved a certified efficiency of 28.0%, which already exceeds the performance of a single-junction perovskite device [9]. Importantly, the power conversion efficiency (PCE) of large-area all-perovskite tandem modules has exceeded 21% with an aperture area of 20 cm2 , which represents huge progress toward the commercialization of PSCs [10]. Moreover, the cost of all-perovskite tandem cells is significantly lower than that of perovskite–Si tandem cells.

《Fig. 2》

Fig. 2. Illustration of the commercialization path for perovskite solar modules [8]. ITO: indium tin oxide; HTM: hole transport material; BCP: bathocuproine; WBG: wide bandgap; NBG: narrow bandgap; BSF: back-surface field.

《2.2. Lifetime》

2.2. Lifetime

Whether it is a single-junction PSC or a tandem PSC-based device, the stability problem is a major obstacle limiting rapid commercialization. Since PSCs must pass the International Electrotechnical Commission (ICE) 61215 standard test before commercialization, the operating lifetime of commercial PSCs is required to reach at least 25–30 years, which is a very difficult challenge. During device operation, the volatilization of organic components, ion migration, ion oxidation, and other processes easily occur, causing the intrinsic stability collapse of organic– inorganic hybrid perovskites. For example, perovskite–Si tandem solar cells with carbazole additives can suppress phase segregation and then maintain 87% initial efficiency under a damp-heat environment at 85 °C and 85% relative humidity (RH) for 500 h [11]. In addition, the instability of tin (Sn) in the narrow bandgap component of all-perovskite tandem cells can lead to the formation of irreversible defect states in perovskites, resulting in severe nonradiative carrier recombination and device aging after several days [12]. Therefore, solving the Sn2+ oxidation problem will further improve the efficiency of all-perovskite tandem devices, which will contribute to the further development of perovskite PVs. In this way, improving the stability of PSCs plays a crucial role in reducing the LCOE and will be important in promoting the PSC commercialization process.

《2.3. Cost of PSCs》

2.3. Cost of PSCs

Reducing the LCOE of perovskite-based solar cells during mass production is a vital issue that must be taken into account, once the lifespan issues of PSCs can be addressed. Wang et al. [13] estimated the LCOE for a 25-year single-junction PSC module to be 0.0348 USD·(kW·h)–1 , while the LCOE for a traditional silicon module would be 0.0550 USD·(kW·h)–1 [14], according to the calculation results of a bottom–up cost model. With the emergence of perovskite-based tandem solar cells and the development of advanced large-scale deposition techniques (e.g., screen printing, slot-die coating, and inkjet printing), the LCOE would further decrease, which would make perovskite-based solar cells more competitive in the field of PVs.

《2.4. Toxicity》

2.4. Toxicity

The widely reported high-power conversion-efficiency PSCs contain toxic lead (Pb), which severely threatens ecosystems and human health. Due to inevitable natural factors (environmental abrasion, fire, wind, etc.), the potentially huge risk of lead leakage from PSCs is a major barrier to realizing the commercialization of PSCs. It has been found that proper physical encapsulation and a chemical encapsulation coating are facile and economic strategies to address lead-leakage issues. For example, physical encapsulation methods can suppress more than 90% of Pb2+ leakage from degraded PSCs, improving their environmental stability [15].

The toxic solvents involved in dissolving organic and metal halides also require more attention. The use of green solvents such as ionic liquid in PSC preparation can not only effectively reduce the usage of Pb but also remove toxic solvents, making green solvents a valuable concept for large-scale PSC manufacturing. Only 0.6 mmol·L–1 of PbI2 is used to obtain a film with 500 nm thick, which is at least 0.6 times less than the quantity of traditional solvent required [16].

Recycling the toxic Pb sources from aged PSCs may be another benign and promising approach to control lead contamination and cost. Because their transparent conductive oxide glass substrate, noble metal electrodes, and lead sources are the predominant costs of PSCs, reusing these components is the best way to avoid unnecessary ecosystem pollution and resource waste [17]. In the future, dismantling used PSC modules and reusing their components to reduce energy consumption will become the main trend in PSCs.

In addition, vigorously developing lead-free perovskite materials (in which Pb is replaced by Sn, Bi, Ge, Mn, Sb, etc.) is a novel avenue to realize the commercialization of environmentally friendly PSCs [18]. Notably, Sn-based Pb-free PSCs have recently approached an efficiency of 15%, showing great potential. However, the current efficiency of lead-free PSCs is still far below the requirements for largescale commercial applications. Nevertheless, many scientists believe that lead-free PSCs have a promising future and can significantly advance the commercialized applications of PSCs.

《3. Application scenarios of PSCs》

3. Application scenarios of PSCs

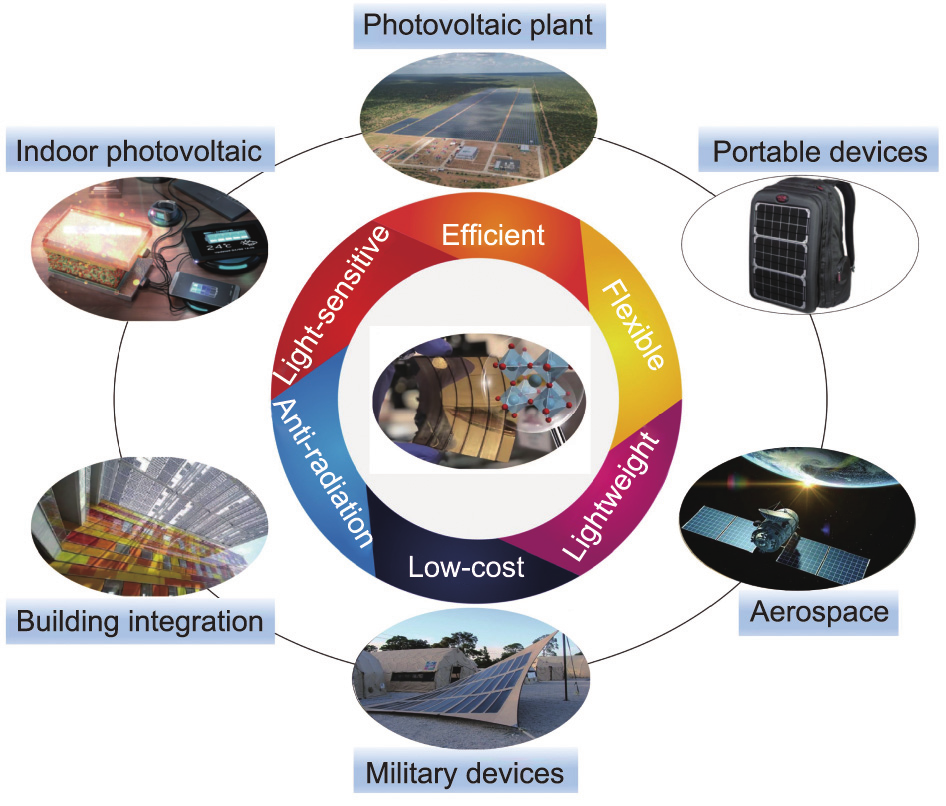

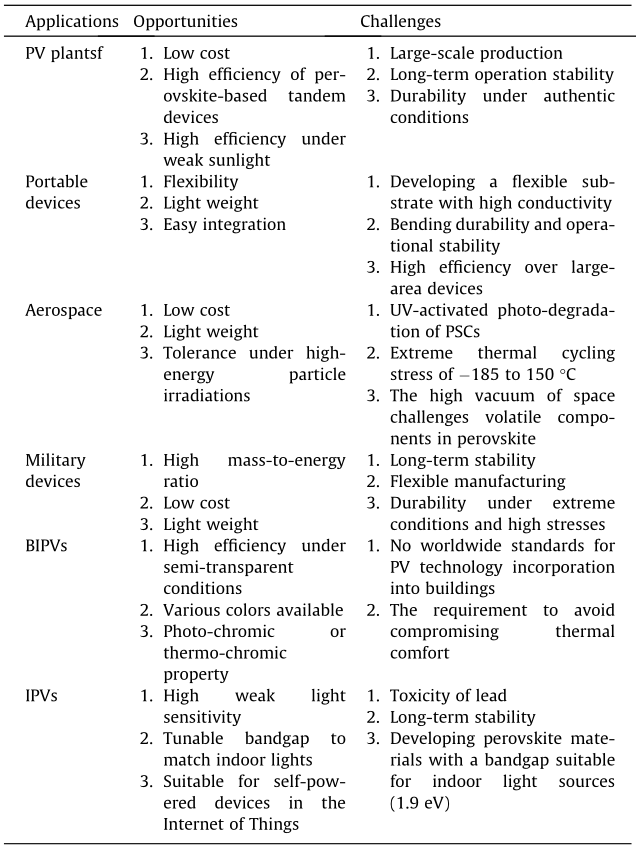

Due to the unique advantages of perovskites, which include low cost, anti-radiation properties, light sensitivity, light weight, flexibility, and high efficiency, PSCs have wide boundaries of application and have been shown to be revolutionary in various applications, including PV plants, portable devices, aerospace, military devices, building integration photovoltaics (BIPVs), and indoor photovoltaics (IPVs) (Fig. 3). In this section, we briefly discuss the opportunities and challenges of PSCs in these application scenarios (Table 1).

《Fig. 3》

Fig. 3. Potential application scenarios of perovskite PVs enabled by the advantages of perovskite materials. Credit: Project Nexus (public domain).

《Table 1》

Table 1 Opportunities and challenges of PSCs in various application scenarios.

《3.1. Photovoltaic plants》

3.1. Photovoltaic plants

Although the breakthrough progress of PSCs in PCE improvement has accelerated the potential application of PSCs in power generation, the enormous challenges of their PV plant application are still their large-scale fabrication and long-term stability under real-life conditions. To achieve this, the community must agree on standardized testing protocols for evaluating the stability of PSCs. New procedures should also be developed to speed up the aging process under real-life conditions in order to accurately predict the lifetime of PSCs.

《3.2. Portable devices》

3.2. Portable devices

In recent years, the technological revolution and the advancement of energy-consuming portable devices have promoted an increasing demand for lightweight and flexible PSCs that allow the integration of portable devices and PSCs into one system. Currently, indium tin oxide polyethylene terephthalate (ITO/PET) or polyethylene naphthalate (PEN) substrates are frequently used to produce flexible PSCs, but the rigidity of ITO causes fractures in the thin layer, which is the primary reason for device performance failure after repeated bending. Therefore, the challenge of PSCs for portable devices lies in the development of conductive substrates with a high bending tolerance.

《3.3. Space applications》

3.3. Space applications

Recent studies have demonstrated the potential qualification of PSCs for space-related applications due to their abovementioned advantages. However, the space environment presents other hazards, such as high energy radiation, a high vacuum, and extreme thermal cycling stress (from –185 to 150 °C). It is interesting to consider how long PSCs could survive under space conditions. To this end, a serious evaluation of the prospect of PSCs in space applications is highly desired, including the physical mechanism of PSCs under extreme space environments, the comprehensive impacts of the space environment on PSCs, and how to satisfy the specific requirements of space PVs.

《3.4. Military devices》

3.4. Military devices

Perovskite PVs can be used in the military field in applications including silent reconnaissance, drone searching, and individual soldier positioning. As a means of building a personal power supply device, flexible PSCs can improve the functionality and accuracy of military equipment. However, the major challenges presented by the application of PSCs in military devices are still related to the long-term stability and flexible manufacturing of PSCs.

《3.5. Building-integrated PVs》

3.5. Building-integrated PVs

The integration of PSCs into a building, in what is known as BIPVs, is one of the most holistic approaches to exploit PSCs as a next-generation PV technology. BIPV envelopes must be semitransparent or transparent to allow sufficient daylight into the building and reduce the lighting energy demand, as well as the heating and cooling load demands. Although BIPVs hold strong potential for reducing energy consumption and greenhouse gas emissions, the main challenge is to realize these advantages without compromising thermal comfort requirements. PV inclination, orientation, and comfort are the most significant characteristics for BIPVs, and the lack of global standards is currently a major barrier to the BIPV industry.

《3.6. Indoor photovoltaics》

3.6. Indoor photovoltaics

Against the background of modernization, billions of products exist in the demand gap for self-powered devices; thus, IPVs have attracted a great deal of attention with the emergence of the Internet of Things (IoT). Thus far, the record PSC efficiency is over 40.1% for indoor illumination of 301.6 μW·cm–2 with a light-emitting diode [19]. IPVs based on PSCs present many other advantages as well, such as a low cost, large area, and high defect tolerance, making them likely to dominate the IPV market in the near future. Nevertheless, considering the use of IPV devices in IoTs, reduction of the use of lead should be seriously considered. In addition, even under the relatively mild conditions of an indoor environment, the device lifetime of IPVs is still insufficient to support their industrial development.

《4. Conclusions》

4. Conclusions

In this era of striving to achieve carbon neutrality, PSCs have undergone unprecedented rapid development. The emergence of perovskite-based tandem solar cells brings a significant opportunity to break through the theoretical limit of efficiency. The continuous improvement of encapsulation technology has effectively suppressed the problems of device stability and lead leakage. Moreover, the increasing development of lead-free PSCs is beneficial for creating a more environmentally friendly ecosystem. In addition, based on the various advantages of PSCs, their application scenarios have been greatly expanded, and they will play an important role in an increasing number of fields. Although challenging difficulties remain to be overcome before the true industrialization of PSCs, there is reason to believe that, by maintaining the current development speed, the commercialization of PSCs will be realized in the near future.

《Acknowledgments》

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51972172 and 62205142), the Natural Science Foundation of Jiangsu Province for Distinguished Young Scholars, China (BK20200034), the Jiangsu Provincial Departments of Science and Technology (BE2022023 and BK20220010), the Innovation Project of Optics Valley Laboratory (OVL2021BG006), the Open Project Program of Wuhan National Laboratory for Optoelectronics (2021WNLOKF003), Projects of International Cooperation and Exchanges NSFC (51811530018), the Young 1000 Talents Global Recruitment Program of China, Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (CX2021041), the Natural Science Basic Research Plan in Shaanxi Province of China (2021JLM-43) and the Joint Research Funds of Department of Science and Technology of Shaanxi Province and Northwestern Polytechnical University (2020GXLH-Z007 and 2020GXLH-Z-014).

京公网安备 11010502051620号

京公网安备 11010502051620号