《1. Introduction 》

1. Introduction

Controlled combustion is perhaps the oldest human invention, providing food, warmth, protection, and power over millennia. In the last century, for example, it has enabled the United Kingdom to cut its agricultural labor force to near 1% of the population, replacing the horse and muscle power that dominated the 19th and earlier centuries [1]. Nevertheless, like all great inventions, akin to the plastics that have now clogged the globe, the overwhelming success of the combustion engine has brought riches to many countries while being accompanied by disasters such as climate change and air pollution [2].

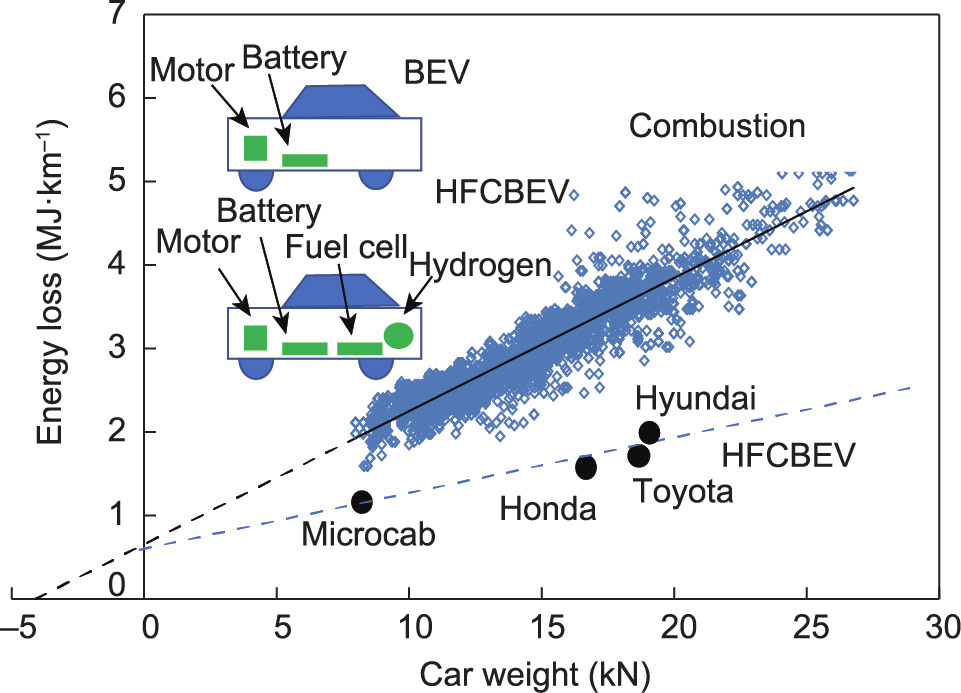

The 1997 global transition from internal combustion vehicles to hybrids with a small battery and electric motor [3] had a significant effect on pollution. However, the European aim to achieve fully electric transportation in this century has led to new targets to replace diesel and gasoline vehicles [4]. In 2009, several different electric models-both battery and hydrogen-were tested and shown to be practical replacements for combustion cars, albeit expensive at low production rates; this was a turning point in the United Kingdom. By 2021, the United Kingdom had achieved 1% penetration of battery electric vehicles (BEVs; Fig. 1 [5]) on United Kingdom roads, and this is now doubling almost every year [6]. Nevertheless, the larger batteries now in use (e.g., 100 kW·h) cannot be easily charged overnight at a residential home, and many families lack the home infrastructure anyway.

As BEVs were being developed in the 1990s, the hydrogen fuel cell bus was created by Ballard in Vancouver, BC, Canada [7]. Since then, the hydrogen fuel cell bus has been fitted with a large battery to aid in acceleration and braking, and is now called the hydrogen fuel cell battery electric vehicle (HFCBEV). Fig. 1 [5] compares the HFCBEV with the pure BEV design. Progress on the novel HFCBEV concept is several years behind that on the BEV, but the advantages of the HFCBEV for heavy, highly utilized vehicles are now becoming clearer, with 30 000 HFCBEVs currently being demonstrated and tested around the world [8]. This paper critically compares the competitive progress and potential of BEVs and HFCBEVs.

Asia has shown the way forward by defining the technical space for HFCBEVs, the consumer products, and the organized political introduction of such electrical technologies, while Western countries have been delayed by giant fossil fuel and auto companies’ continued reliance on combustion engines [9]. Previous fuel cell predictions have been over-optimistic, including Ostwald’s 1894 prediction that the 20th century would be ‘‘the age of electrochemical combustion” [10]. Although the circumstances have changed significantly since then, we may make the same mistake with green hydrogen if we cannot fully understand our current opportunities. This paper proposes a more reasonable timescale for replacing combustion with HFCBEV technologies, especially for highutilization taxis and heavy buses and trucks, in order to promote consensus in energy and transportation systems analysis.

In essence, the argument restated here is two centuries oldnamely, that electrical devices will eventually take over from combustion engines, despite the following comparative advantages of combustion:

• Fossil fuels for combustion applications have been available at low cost;

• Impure fuels still burn in combustion engines, whereas purity is essential for electrochemical conversion;

• The mass production of electrochemical devices cannot yet successfully compete with that of diesel and other combustion engines;

• Electrical energy storage has been a long-term problem in terms of weight, cost, and recharging time.

The first fundamental advantage of electric vehicles is that the vehicle energy demand is reduced by half compared with that of combustion vehicles (based on the standard drive cycle) [5]. Second, renewable electricity is becoming increasingly available and can be used to electrolyze water to make stored green hydrogen for use in automobiles, which cuts carbon and other emissions to near zero and is getting cheaper every year.

The main conclusion from the standard drive-cycle test results shown in Fig. 1 [5] (which we recognize in vehicle advertising as liters per 100 km but has been expressed here in standard units of MJ·km–1 ) is that no net work has been done, because the car arrives back at its starting point at zero speed. This is not ‘‘efficiency,” as it is often described [11], because efficiency is the ratio of traction energy output divided by fuel energy input. Fig. 1 [5] describes energy dissipation per kilometer rather than energy efficiency, which has units of percent.

《Fig. 1》

Fig. 1. Results for the energy loss of 3800 types of combustion cars in China in 2010, showing that combustion cars have double the energy dissipation of HFCBEV vehicles powered by fuel cell/hydrogen [5]. HFCBEV: hydrogen fuel cell battery electric vehicle.

Thus, dissipation mechanisms in automobiles are crucial. Most fascinating is the theoretical line shown in Fig. 1 [5], which was derived by combining different loss mechanisms in automobiles to obtain a linear Coulomb friction graph when the energy dissipated per kilometer is plotted against vehicle weight. In China, 3800 different models of gasoline cars were put through a standard drive-cycle test, and the lost energy (in MJ·km–1 ) was plotted against weight (in kN). Gasoline cars are powered by internal combustion engines; these energy losses (plotted on the upper line) are compared with those of novel HFCBEVs (on the lower line) in Fig. 1 [5]. The graph shows that the combustion vehicle is much more lossy than the HFCBEVs at equal weight. However, HFCBEVs are still not produced in the millions required in order to cut costs to combustion car levels.

Some vehicle losses are independent of weight, such as the window motor loss, while car tire friction is linear in weight. The theoretical curve was obtained by adding ten different loss functions, which surprisingly results in a straight Coulomb line. Weight is crucial; one of the main reasons for increasing fossil fuel expenditure is the rise of vehicle weight over the past 50 years, which has almost doubled fuel consumption [12]. Hence, the HFCBEV exhibits half the energy loss of a combustion-based car at an equivalent weight (Fig. 1 [5]), while improving by another factor of two by reducing the weight from 30 down to 8 kN. The energy losses of larger trucks and buses, which were also measured [13], fell on the same hydrogen battery electric curve, showing that heavy HFCBEVs are an improvement over combustion trucks and buses.

Elon Musk has claimed that the hydrogen vehicle is ‘‘mind-bogglingly stupid” compared with the lithium battery car [14]; however, his argument is incorrect, as both hydrogen and lithium devices share the known electrochemical advantages that reduce energy losses. At peak power, both devices produce roughly half electrical power and half heat from internal resistance losses. The results for typical BEVs fit almost on the same curve in Fig. 1 [5] as HFCBEVs, albeit with an advantage of a few percentage points. It can be concluded that HFCBEVs are similar to BEVs in the standard drive-cycle tests used in Fig. 1 [5], with both having about half the energy consumption per kilometer as compared with combustion vehicles. Still, Musk is right regarding the significant energy losses in manufacturing hydrogen, with about 20% of the energy being lost by electrolyzing water, and is right in that only green hydrogen makes sense. Nevertheless, it should be noted that a Tesla vehicle charged on UK grid electricity is only 50% green, on average.

In practice, the combined hydrogen fuel cell/lithium battery vehicle that was demonstrated in the United Kingdom in 2008 (Fig. 2) exhibits optimum performance at minimal cost. Other vehicles such as the Toyota Mirai used nickel-metal-hydride batteries at first but have now shifted to lithium, while supercapacitors can also be used to store the electrical energy. Integrating hydrogen fuel cells with batteries provides an unexpected yet beneficial solution to the problem of transitioning from combustion to electric vehicles: HFCBEVs have both longer range and faster refueling than BEVs and consequently are good for taxis, vans, trucks, and buses that run 18 h shifts over long distances such as 500 km.

《Fig. 2》

Fig. 2. Past (blue) and projected future (red) growth of fossil hydrogen (solid line) and green hydrogen (dashed line); the former is predicted to be overtaken by the latter later this century. (Inset) Dr. Kendall opens the first UK green hydrogen station in 2008 with five HFCBEVs.

However, batteries alone have been found to be ideal for mobile phones, laptop computers, and many other small applications. China has been the global leader in battery-powered bicycles since 1999, with the market increasing in 2009 due to restrictions on combustion bikes in several Chinese districts. At present, around 17 million battery-powered bikes are sold per year in China, and almost 300 million of such bicycles are in use across the country. Lead acid batteries have dominated the market because of their low cost and recyclability, but other battery types are now competing. This advance in battery scooters has been a precursor to China leading the global manufacture of BEVs and selling 2.9 million in 2021, which represents 11.1% of car sales in China. Still, Norway has by far the highest electric vehicle penetration, with 49% of annual vehicle sales being BEVs and predictions of 100% by 2025 [15]. The question is, why are batteries limited to small vehicles mainly used for about an hour per day?

Although battery performance has been improving, battery weight and charging time remain as key problems. Typically, a BEV can run continuously for 2–4 h but then requires lengthy recharging. At present, a BEV cannot compete with a diesel-powered vehicle, which can run for 18 h and takes only 5 min to refuel. This is where hydrogen can be advantageous: in highly utilized heavier vehicles. China now dominates hydrogen bus and truck manufacturing, with 655 HFCBEV buses from Foton operating at the February 2022 Beijing Winter Olympic Games, demanding 28 t·d–1 of pure hydrogen. In other cities, such as Foshan, there are1400 HFCBEV buses in operation. The total number of HFCBEVs in China is projected to be about 50 000–100 000 by 2025 and 80 000–1 000 000 in 2030–2035 [16].

At present, the key problem in the transition to HFCBEVs is the carbon intensity of hydrogen fuel, as most hydrogen produced worldwide is made from fossil fuels. The solid line in Fig. 2 shows the dominant global ‘‘fossil hydrogen” production, which is mainly sourced from petrochemical plants, rising from 60 Tg·a–1 (1 Tg = 1012 g) in 2000 to 80 Tg·a–1 by 2022; this is subsequently predicted to peak as climate crisis control takes effect. The dashed line in Fig. 2 shows the novel green hydrogen production, which was said to have almost zero demand when the author opened the first UK green hydrogen station, fueling five HFCBEVs in 2008 (Fig. 2). The green hydrogen at that time was sourced from biomass and was rather costly; however, surplus wind power is now cheap and can be used to electrolyze water to make economical green fuel. Biomass, wastewater, and other sources of green hydrogen are also plausible. China plans to produce 100 000–200 000 t of green hydrogen from renewable energy annually and to build 1000 green hydrogen fueling stations by 2025 [17].

Across the world, countries and cities are striving to introduce electric transport, now mainly based on BEVs, with Oslo currently leading among the cities. The contrast between Asia and the West is stark: The United Kingdom manufactured 100 000 BEVs in 2021, in contrast to China’s 3 million, while the growth in BEV manufacturing was 30% for the United Kingdom [18] and 160% for China from 2020 to 2021. HFCBEVs lag far behind BEVs in terms of manufactured numbers but are being emphasized for heavy, highly utilized vehicles requiring a long range and short refueling times. The United Kingdom is currently ordering hundreds of hydrogen buses from WrightBus and Alexander Dennis for Birmingham and other cities and aims to replace the 32 000 diesel buses now in service by 2030. The production of HFCBEVs in China is predicted to rise by 55 times in 2025 compared with 2020 [19].

The global cities with the most HFCBEVs are Los Angeles, USA (13 000 vehicles); Susono City, Japan (6000); Foshan, China (6000); Seoul, the Republic of Korea (1000); and Hamburg, Germany (1000). An additional 30 000 US forklifts could also be included. China’s commitment to hydrogen fuel can be illustrated by the surge in installations of hydrogen refueling stations in China, which have increased from just one in the entire country in 2017 to 174 operational refueling stations in 2022. In comparison, the United Kingdom has only four operating at present. Government subsidies for these developments have been higher in China than in the West, which has caused some volatility in production rates, but has overall stimulated a more rapid transition from combustion to electric vehicles. The economic competition between green hydrogen and fossil fuels for vehicles is a continuing issue. As fossil fuel prices are rising, the production of hydrogen via wind-powered electrolysis is becoming more economical and should be cheaper than diesel fossil fuel in the United Kingdom by 2025.

In conclusion, HFCBEVs have lagged behind pure BEVs (i.e., BEVs) in terms of production numbers. Now, HFCBEVs are increasing in number due to the extra energy-storage requirement for heavy buses and trucks. A typical battery car requires around 50 kW·h of stored energy, which is equivalent to about 1 kg of hydrogen. A taxi requires 250 kW·h, making the lithium battery both too heavy and too expensive for such applications, whereas the Toyota 2021 Mirai can easily run for 500 km on 5 kg (215 kW·h) of hydrogen. A bus may need 30 kg of hydrogen—roughly 1300 kW·h—to travel 400 km, which is equivalent to a 7 t lithium battery; thus, a lithium battery would be far too heavy for application in an equivalent BEV bus.

Thus, the hydrogen fuel cell battery electric technology that was first demonstrated in the 1993 Ballard bus [7] now exhibits significant benefits over pure BEVs for heavy, highly utilized automobiles and is predicted to surge globally by 2030–2035. By that time, several million HFCBEV units are expected to be deployed worldwide, particularly in combination with green hydrogen from renewable electricity, which will decrease energy wastage and cut carbon emissions stemming from current fossil fuel vehicles [20]. The combustion problems of toxic emissions, carbon emissions, and energy dissipation may then be increasingly overcome within the 21st century, with substantial progress expected to be achieved by 2050 [21].

京公网安备 11010502051620号

京公网安备 11010502051620号