《1. Introduction》

1. Introduction

The transportation infrastructure disciplines are among the most important in the domain of civil engineering. This field covers a variety of engineering facilities built on the ground, underground, and in water, such as tunnels, bridges, and roads, requiring advanced techniques for surveys, designs, construction, maintenance, elimination, and so forth [1]. The field of transportation infrastructure has undergone a long process of development throughout history. Three stages of development—namely, ancient transportation infrastructures, early modern transportation infrastructures, and modern transportation infrastructures—can be identified according to breakthroughs in construction materials, construction theories, and construction technologies [2]. In recent decades, the demand for structural performance under all expected possible conditions has been met using manual approaches to improve structural design, enhance material performance, intensify construction management, and conduct regular inspections and maintenance. Several outstanding problems in the traditional construction industry—such as overly extensive production methods, low labor efficiency, vast resource elimination, severe environmental pollution, and potential safety issues—have made the launch of fundamental intensive development a top priority for the industry. Relying on new-generation information technologies and their applications, a new era for the intellectualization of transportation infrastructures, which involves integrating building information modeling (BIM), the Internet of Things (IoT), fifthgeneration (5G) telecommunication, big data, cloud computing, artificial intelligence, and blockchain, is rapidly approaching.

The complete life-cycle of a transportation infrastructure involves the design, construction, maintenance, and elimination phases. The intellectualization of transportation infrastructures refers to the incorporation of information technologies into infrastructures; it is characterized by three transformations (i.e., digitalization, networking, and intelligentization) and three computation-related features (i.e., calculation data, algorithms, and computing power) [3]. Intelligent construction is powered based on the digitization of the engineering resources of construction elements and through standardized modeling, network interaction, visual cognition, high-performance computing, and intelligent decision support. Driven by a digital chain, intelligent construction realizes the integration and high-efficiency coordination of project design, construction, production, operation, maintenance, and elimination services. Finally, intellectualized structures can achieve self-sensing, self-diagnosis, self-adaptation, selfrestoration, and self-cycling.

Therefore, the core of intelligent construction is the information interconnection of the entire industrial chain of transportation infrastructures. More specifically, the creation, integration, management, display, and service of basic information are provided through BIM technology. Information sensing, collection, transmission, and feedback in the processes of production, logistics, construction, service, and elimination are provided through IoT technology. Information processing, decision-making, and the operation of all links in the entire life-cycle are supported with artificial intelligence technologies. The digitalization of transportation infrastructures can be regarded as the initial stage of intellectualization, which uses digital means to manage the whole process of engineering construction, including project decision-making, planning and design, construction management, operational maintenance, elimination, and recycling. Intellectualization involves a variety of engineering activities without human involvement, supported by interactive digital modeling and simulation technologies, pervasive sensing and broadband IoT technologies, factory manufacturing and machine construction technologies, artificial intelligence and auxiliary decision-making technologies, and key lowcarbon and ecological protection technologies [4].

The fundamental idea of the intellectualization of transportation infrastructures was initiated in the 1970s starting from structural control, when Yao [5] developed the original concept of intelligent civil structure through theory, experiment, and engineering applications. Further developments of this concept focused on vibration isolation, energy dissipation, and active control. The development of smart materials, such as high-performance sensing materials, intelligent driving materials, and self-healing functional materials, allows for intelligent monitoring, diagnosis, and even automatic structural healing [6]. In the mid-1980s, many sensors were installed on bridges in the United States (e.g., the Sunshine Skyway Bridge in Florida) to verify design assumptions, control construction quality, and monitor operational conditions. In the late 1980s, monitoring instruments and equipment were independently developed in the United Kingdom, and long-term monitoring schemes were investigated and compared through applications in long-span bridges. Along with the prosperous construction of infrastructures in the 1990s, structural healthmonitoring systems containing many sensors were broadly applied during the construction stages of several modern bridges (e.g., Qingma Bridge and Hong Kong–Zhuhai–Macao Bridge) and landmark buildings (e.g., Shanghai Central Tower and Guangzhou TV Tower). The massive data collected during the operational stage not only serves for the real-time monitoring and analysis of vibration control and health conditions but also provides beneficial guidance for the design of similar structures. This development forms a closed loop that includes design, construction, operation, and maintenance, and finally returns to feedback for optimal design. In the 21st century, industrialized countries such as the United Kingdom, Germany, Japan, and the United States have implemented the intellectualization of transportation infrastructures in the entire structural life-cycle based on the latest generation of information technology (IT). In 2003, a project titled ‘‘Sustainable Bridges: Assessment for Future Traffic Demands and Longer Lives” was launched in Europe [7] to improve the transport capacity and extend the service life of railway bridges. In 2005, a project titled ‘‘Long-Term Bridge Performance” was launched in the United States [8]. High-quality automatic inspection and monitoring data from highway bridges in the United States enabled engineers to better understand bridge aging and degradation mechanisms, which helped them to implement reasonable maintenance and management during the bridges’ long life-cycle. The United Kingdom took the lead in launching ‘‘British Construction 2025” in 2013 [9]—an initiative that proposes strategic measures to implement digital design, intelligent construction, and lowcarbon and sustainable buildings. In 2013, the Japanese Ministry of Land, Infrastructure, and Transport launched a project titled ‘‘National Fundamental Plan for Long-Life Infrastructures” [10] based on the concept of preventive maintenance. This project aimed to achieve timely identification, repair, and reinforcement prior to bridge damage becoming fatal, thereby helping to extend the service life of transportation infrastructures such as bridges and tunnels. Germany released the ‘‘Road Map for Digital Design and Construction” in 2015 [11], which proposes a transformation path for digital design, construction, and operation in the field of engineering construction. The core of this program is to continuously optimize design precision and cost performance through the promotion and application of BIM technology. Also in 2015, Japan proposed the ‘‘i-Construction Initiative” [12], which aims to improve the production efficiency of construction sites with the support of the IoT, big data, and artificial intelligence. Japan plans to achieve full integration of building construction and threedimensional (3D) data by 2030. In 2018, the United States issued the ‘‘Legislation Outline for Rebuilding Infrastructure in America” [13], which clarifies that construction products and infrastructure must be safe (i.e., resilient), green, and durable. In 2020, the report ‘‘Guidance on Promoting the Developments of Intelligent Construction and Construction Industrialization” issued by China [14] clarified that an intelligent civil structures industrial system that integrates the full structural life-cycle chain, including design, construction, operation, maintenance, and elimination, should be established based on the overall goal of high-quality development in the construction industry, the industrialization of construction, and digitalization and intelligent upgrading techniques. In summary, intelligent construction has become a general trend in the development of the construction industry.

In terms of the time dimension, intellectualization is always referred to throughout all stages within the entire life-cycle of transportation infrastructures. This work systematically reviews and summarizes state-of-the-art intelligent design, intelligent construction, intelligent operation and maintenance, and intelligent elimination technologies for typical transportation infrastructures, including tunnels, bridges, and roads, along with their major challenges. Recent achievements in the intellectualization of transportation infrastructures are then presented, taking the Beijing– Zhangjiakou High-Speed Railway as an example. A prospect of future development trends in the relevant field is presented at the end.

《2. Intelligent design technology》

2. Intelligent design technology

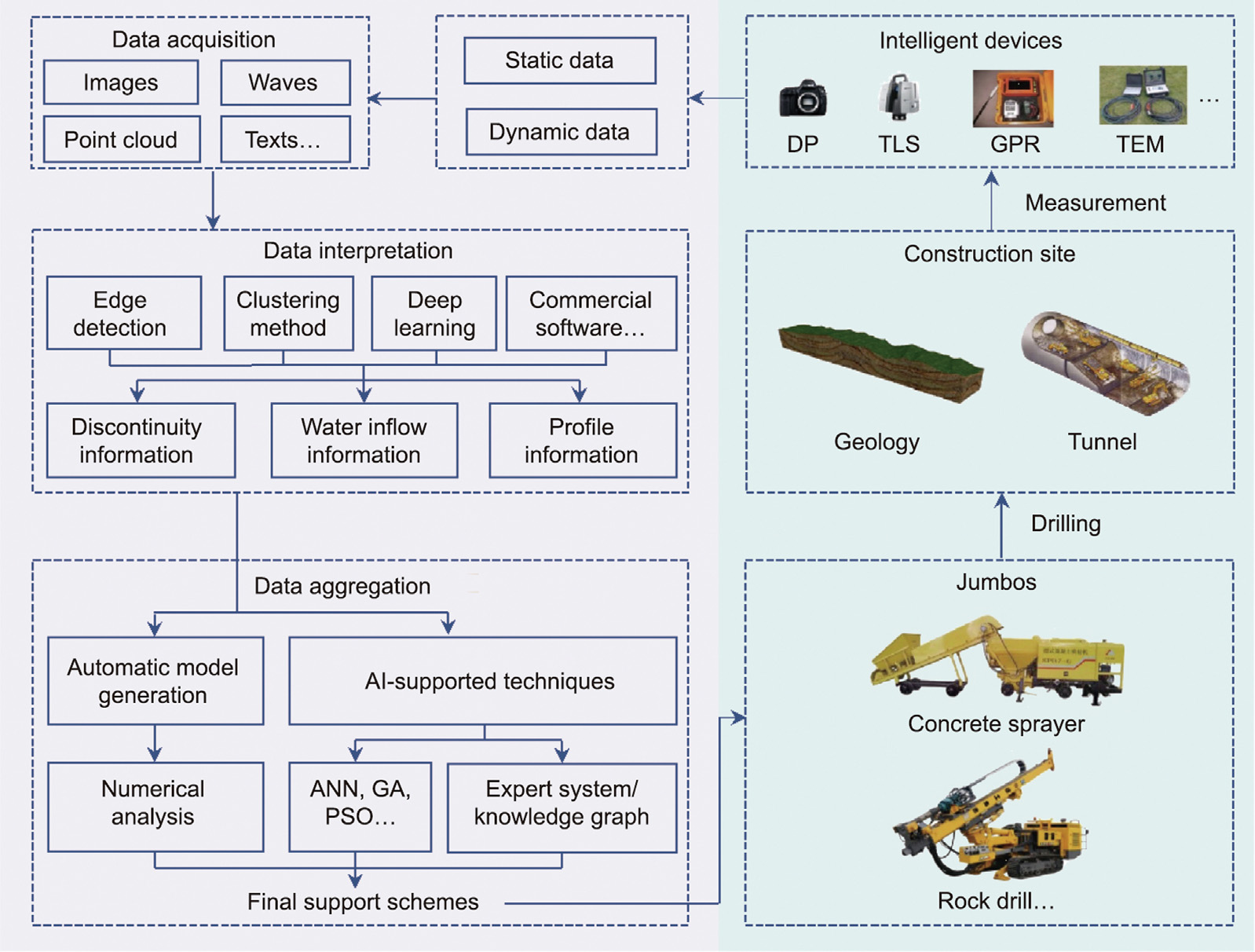

One of the critical aspects of tunnel construction is tunnel design to ensure construction safety. Due to the extremely complex underground geological and geotechnical conditions, the design must be dynamic and should ideally consider all related data and information comprehensively and in a timely manner. Various IoTs and other related IT have been widely applied during tunnel construction to collect a large amount of monitoring data, which in turn demands real-time or just-in-time (JIT) data processing for decision-making [15]. Hence, the intelligent design of tunnels needs to integrate novel design concepts, technologies, and patterns in order to improve construction efficiency and safety, which can profoundly transform traditional design methods. The scientific foundation of intelligent design is to construct a digital twin model with the capabilities of holographic perception, multisource data fusion, process control, and data interaction, and to explore a humanoid design agent that is based on engineering big data and robust artificial intelligence technology. The abovementioned technology shapes an interactive feedback and knowledge-accumulating, decision-making design pattern, transforming digital and networked design into intelligent design. Intelligent design is the primary driving force of intelligent construction. The key elements of its implementation include JIT data acquisition, JIT data interpretation, and JIT data aggregation. Focusing on underground engineering, this paper introduces the development status and scientific problems of intelligent design in this field.

In terms of JIT data acquisition, traditional data-acquisition methods include collecting, sorting, and digitalizing primary data, such as text, images, and drawings, as well as monitoring and detecting data. With advancements in sensor technology, engineering data can be collected with high precision and high efficiency by IoTs, such as digital photogrammetry (DP), terrestrial laser scanning (TLS), measurement-while-drilling technology, and other geological prospecting technologies. Based on these newly emerging technologies, data exposed during tunnel construction can be obtained in real time and can be used to revise the original design schemes. According to a study carried out by Ling et al. [15], the use of different intelligent IoT techniques can greatly improve data-acquisition efficiency. For example, it usually takes less than 1 min to capture an image of the tunnel face using digital photogrammetry. With terrestrial laser scanning, the time required to scan a tunnel face can be controlled to within 10 min. Moreover, for measurement-with-drilling technology and geological prospecting technology, the time required to acquire data can be less than 2 h. In comparison, a conventional manual sketch of the exposed data on a tunnel face can take as long as 4 h [16]. Hence, it can be concluded that the use of advanced IoT techniques can greatly improve intelligent design efficiency.

In terms of JIT data interpretation, the parameters of massive data can be extracted and interpreted by big data analysis, digital numerical integration, natural language-processing technology, and 3D model reconstruction to form an integrated survey scheme of ‘‘air, space, and earth” [17–24]. For example, digital photography is used to obtain point cloud data based on binocular 3D reconstruction technology to reproduce high-precision structural geometric information. Characteristic information—such as the trace length, occurrence, spacing and roughness of the rock mass structural plane—can be obtained automatically. Fig. 1 [25] shows rock mass discontinuity photos and rock mass point cloud data with red, green, blue (RGB) information. After clustering, grouping, trace extraction, connection, linearization, and other steps, the rock mass trace information can be obtained. In general, discontinuity information, rock structure information, water inflow information, and weak interlayer information are the parameters that are often extracted and interpreted from raw data collected onsite. Depending on the interpretation algorithm and hardware computability, the interpretation time can range from seconds to hours [16].

《Fig. 1》

Fig. 1. 3D reconstruction and information extraction of a rock mass. (a) 3D laser-scanning point cloud of the tunnel face; (b) 3D reconstructed face model; (c) automatic extraction of surface trace information; (d) surface trace information analysis. Reproduced from Ref. [25] with permission.

In terms of JIT data aggregation, the early application of artificial intelligence in civil engineering design mainly supported experts’ decisions, using symbolic models (e.g., rules, semantic networks, and frameworks) and expert systems [25–27]. For this purpose, numerical analysis software is commonly utilized in structural systems and bearing designs. Common modeling software used for design purposes includes AutoCAD, Rhino, and Grasshopper, while high-rise building analysis software includes SAP2000, ETABS, and MIDAS GEN. The software generally employed for geotechnical and tunnel analysis includes FLAC, ANSYS, GeoXH, and GeoFBA.

In recent years, machine learning algorithms have been applied to a selection of engineering structures and their preliminary design. Machine learning methods facilitate current engineering practices by extracting information from existing engineering design projects, in addition to expert knowledge [28–30]. For example, neural networks, genetic algorithms, and swarm intelligence methods have been successfully applied in rock classification and intelligent design. For the failure criteria of geological bodies and structures, many scholars have successfully employed accurate models and correction methods and integrated them to form an automatic design system [31–35].

In intelligent tunnel design, inefficient, traditional, four-party coordination, meeting-based design change is replaced by a dynamic design and feedback process that is based on a complete understanding of the construction site using digital technologies. The next step in the intelligent design pattern is to fully utilize digital twin technology [36,37] to create a virtual model corresponding to the physical entity, interactively optimize the physical design using an interactive feedback system through data-fusion analysis, enhance the performance, and extend the capabilities of the physical entity. The digital twin system carries geographic and geological information in the civil engineering domain while loading civil engineering design information into a virtual model. These two kinds of digital information can be integrated for information searching, visual communication, digital analysis, scene experience, and project management, thereby enabling an accurate representation of the whole construction process with full simulation.

With the continuous development of civil engineering IT, intelligent design will gradually replace traditional design. At present, the scientific and technical problems that urgently require solutions fall under the following three aspects:

(1) The JIT design method. This method applies the new generation of IT as the carrier and utilizes the data flow as the core through the seamless connection of software and hardware systems, such as acquisition, interpretation, and aggregation. Although the existing methods can improve the design efficiency to a certain level, the time consumption is still be too long in some cases. For example, interpretation of the point-cloud takes approximately 2.5 h in a workstation (an Intel Core i7-2600 CPU and 16 GB RAM) with a triangular mesh size of 4 cm and 382 085 facets [38]. Hence, to meet the intrinsic quick-response requirement of tunnel design, more efficient algorithms and computational methods can be employed to improve the interpretation and aggregation speed. State-of-the-art deep learning technologies can be used to resolve problems such as image interpretation, while computational methods such as parallel computing and cloud computing can be used to solve numerical modeling and point-cloud datainterpretation problems.

(2) An intelligent design platform. The intelligent design platform is a heterogeneous and multiagent system that can integrate and visualize techniques, as shown in Fig. 2 [15]. This platform should have the characteristics of robustness in a complex environment, credibility and security in human interaction, and collaboration of emergency tasks. The key technologies include targetrecognition and reverse-modeling algorithms, multisource heterogeneous data-fusion algorithms, optimization algorithms for multiagent collaborative work, expression and correlation methods for rock physical properties, semantic information-extraction methods, the interaction of dynamic models, informatization identification of all elements, soil and structural analysis methods for the dynamic evolution of civil engineering performance, and digital-twin-based intelligent construction control algorithms.

《Fig. 2》

Fig. 2. A dynamic tunnel-design method integrating acquisition, interpretation, and aggregation. GPR: ground penetration radar; TEM: time electromagnetic method; AI: artificial intelligence; ANN: artificial neural network; GA: genetic algorithm; PSO: particle swarm optimization. Reproduced from Ref. [15] with permission.

(3) An intelligent design pattern based on digital twins. The core technology of the digital twin includes a virtual and real dynamic blending of physical space and virtual space, bidirectional mapping of virtual entity with physical entity manipulation, and real-time accurate comparison and cooperation throughout the entire lifecycle. Underground engineering involves the complex action of multiple twins (e.g., for the geology, structure, and mechanical environment), accompanied by uncertain geological conditions and interaction mechanisms; moreover, there are multifieldcoupling space–time effects. In the future, mapping from a physical entity to its virtual counterpart should be further enhanced by means of numerical models and 3D point cloud models. The virtual model should be accurately represented and should be manipulatable in real time. An innovative 3D visualized information system should be constructed to support the knowledge modeling, selfadaptation, self-learning, and self-optimization of the digital twin model, real-time data-based model prediction, dynamic parameter adjustment, and iterative process optimization. The final objective is to provide an accurate and optimized design plan.

《3. Intelligent construction technology》

3. Intelligent construction technology

With the advancement of industrial technology, mechanization, assembly, standardization, and digital construction have gradually supplanted extensive construction methods [39–42]. These technologies have seen widespread application in the field of engineering construction. Adopting sophisticated construction technology considerably reduces labor costs while increasing construction efficiency and engineering construction quality. Since the turn of the century, several major transportation infrastructures, including the Sichuan–Tibet Railway, the Shenzhen–Zhongshan Passage, and the Bohai Bay Cross-Sea Passage, have been built or planned in China. Developing control nodes in the form of deep tunnels and supersized bridges has introduced new requirements and challenges to construction technology. Because of the increasingly complicated and severe construction environment, the construction method has shifted to include fewer people and be autonomous wherever possible [43]. As a result, intelligent construction technology has emerged as an important development trend in the construction of transportation infrastructure.

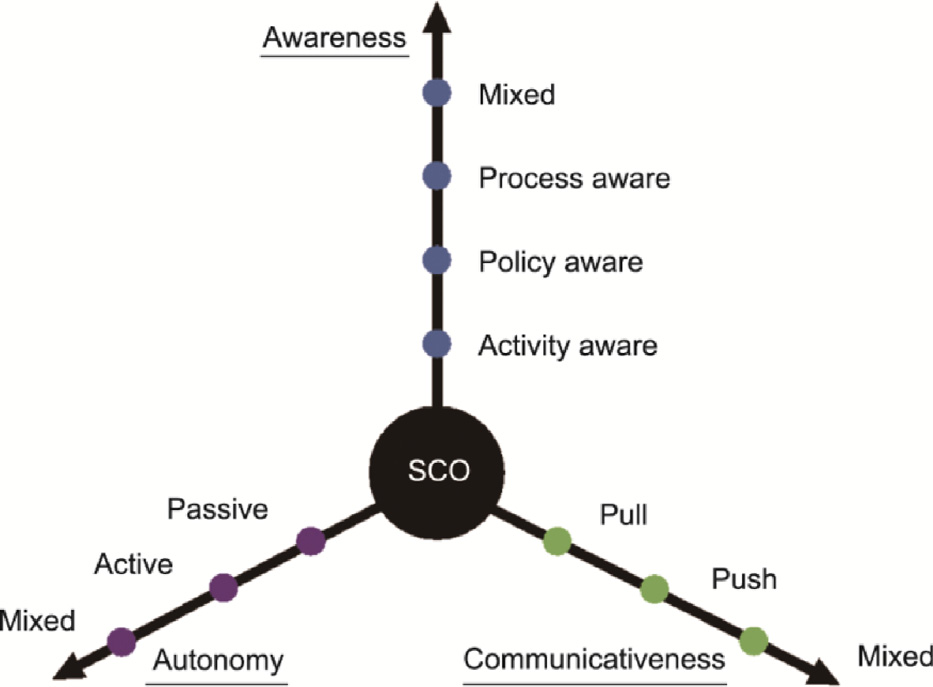

Intelligent construction integrates advanced construction machinery and equipment, factory prefabrication technology, an assembly construction mode, a standardized construction process, and digital construction management to meet intelligent design requirements within a specified time and space range [44]. Artificial intelligence and other information technologies are used to achieve intelligent empowerment and efficient control. Intelligent construction is a complicated engineering system with two levels (Fig. 3): smart construction objects (SCOs) and the smart construction platform (SCP) [45]. An SCO is the fundamental unit of intelligent construction, which comprises building materials (i.e., natural conditions, machinery, human resources, materials, and other elements). By enhancing each unit’s sensing, processing, and communication capabilities, the units can be granted the three essential characteristics of consciousness, communication, and autonomy (Fig. 4, [44]), in order to facilitate interaction between units, as well as between units and platforms. Information technologies, such as machine learning and deep learning, enable the SCP to make intelligent optimization judgments. This ensures that the allocation of all types of construction resources can be autonomously extremely well adapted to the engineering environment. Intelligent construction generally refers to the provision of a ‘‘brain” for construction organization and the endowment of a construction process with multisource perception, environmental adaptation learning, and independent decision-making optimization capabilities [46]. For intelligent construction, perception is the foundation, learning is the method, and making wise decisions is the end goal. Based on the intelligent empowerment of construction machinery, construction technology, and construction control, it is possible to enable the SCOs and SCP of a construction project to perceive the environment more accurately, adapt to it to reduce the construction safety risk, and ultimately achieve the project’s compatibility with the natural environment.

《Fig. 3》

Fig. 3. The intelligent construction system hierarchy. SCO: smart construction object.

《Fig. 4》

Fig. 4. Diagram of the three core attributes of a SCO. Reproduced from Ref. [44] with permission.

Intelligent construction technology has considerably advanced road, bridge, and tunnel-construction projects. Taking tunnel engineering as an example, China has constructed an intelligent tunnel-construction system architecture and has consistently developed and advanced relevant technologies in intelligent equipment, perception, analysis, and decision-making [47–52]. The interaction and synchronization between ‘‘rock” and ‘‘machine” is the key topic to be considered in the tunnel-construction process, and vital technology that enables rock-machine interaction and synchronization must be developed regardless of the construction technology being used [53]. This necessitates a good perception of the geological conditions of the tunnel’s surrounding rock, as well as intelligent identification and intelligent selection of construction parameters. Single pieces of mechanical equipment must first be intelligently improved; then, intelligent construction machinery equipment and an intelligent construction control platform must be developed for the entire process. Intelligent optimization decision-making can be realized in construction resource allocation, construction process organization, construction machinery scheduling, disaster control method selection, and so forth. The following provides an overview of China’s representative advancements in intelligent tunnel-construction technology in recent years, with a focus on drilling and blasting tunnels, shield tunnels, and immersed tunnels.

《3.1. Drilling and blasting tunnels》

3.1. Drilling and blasting tunnels

In comparison with shield tunnels and immersed tunnels, the drilling and blasting tunnel-construction process is complex, and automated construction equipment dispersion and intelligent propulsion are comparatively complicated. However, due to its high adaptability to complex strata construction, the drilling and blasting method remains one of the major tunnel-construction methods in use today. In recent years, the advancement of intelligent construction technology for drilling and blasting tunnels has mostly focused on the geological perception and discrimination of surrounding rock, the development of intelligent construction equipment, and intelligent construction management [54–57]. Among them, predicting rock strength using drilling parameters and deep learning [54], intelligent identification of lithology and adverse geology based on fusion analysis of image and spectrum [55,56], are representative breakthrough in geological perception of intelligent construction in recent years. The China Railway Construction Heavy Industry Co., Ltd. developed an intelligent identification and processing system for surrounding rock parameters while constructing the Zhengzhou–Wanzhou High-Speed Railway Tunnel [57]. The intelligent drilling jumbo parameter collection and analysis system automatically collects surrounding rock data. Drilling and image-analysis methods are utilized to automatically output subclassification results for the surrounding rock, identify the surrounding rock geology and stability in front of the tunnel, and optimize the design parameters.

Furthermore, to collaborate with the project implementation of safe, rapid, and high-quality tunnel-construction technology based on complete process mechanization, a series of intelligent equipment (Fig. 5(a)) has been developed for critical processes, such as advanced support, drilling, and blasting excavation, initial support, and secondary lining, from the three levels of intelligent equipment: single-machine intelligence, the centralized control of machines, and self-sensing, self-judgment, interconnection, and collaborative management. Based on a big data system architecture, the IoT, multisource heterogeneous data fusion, 3D Geographic Information System (GIS) + BIM combined application, and other advanced technologies, a tunnel equipment big data collaborative management platform (Fig. 5(b)) has been built with intelligent capabilities, such as self-perception of the tunnelconstruction environment, self-execution of goal-oriented positioning, self-learning of construction status and feedback, and self-assessment of the effects of construction activities. Taking current development as a starting point, intelligent drilling and blasting tunnel construction should prioritize the intelligent perception and identification of complex geological conditions, the high integration and intelligence of construction equipment, the real-time monitoring and dynamic feedback analysis of construction information, and the development of construction equipment clusters, IoT systems, and collaborative control. The deep integration of mechanized construction equipment and information network technology will considerably increase the efficiency of construction operation and management, making it critical in severe construction settings such as high-altitude and subsea tunnels.

《Fig. 5》

Fig. 5. (a) A series of intelligent tunnel-construction equipment and (b) a collaborative management platform developed by the China Railway Construction Heavy Industry Co., Ltd.

《3.2. Shield tunnels》

3.2. Shield tunnels

Shield construction is one of the most automated and information-based tunnel-construction methods. Intelligent construction technology provides obvious advantages over drilling and blasting tunnels at this stage of development. The advancement of intelligent shield tunnel-construction technology in recent years has primarily focused on the geological perception and intelligent discrimination of the surrounding rock, intelligent excavation, intelligent line type control, intelligent segment assembly, intelligent grouting, intelligent analysis, and control of surface subsidence [58–61]. For example, the Shanghai Tunnel Engineering Co., Ltd. was the first in the industry to manufacture an intelligent shield with independent decision-making and automatic tunneling capabilities (Fig. 6(a)) [62]. The intelligent shield machine, which is based on 5G communication, big data, and artificial intelligence technology, can accurately capture nearly a thousand sets of data during the tunneling process (e.g., geological characteristics, construction parameters, shield posture, and environmental impact), autonomously and quickly determine its state, and perceive the characteristics of the surrounding environment. A series of intelligent models, such as shield tunneling environment identification, the 3D pose planning and control of shield machines, ground deformation planning, adaptive control, and multiparameter collaborative control, are established based on an anomaly-detection algorithm using number–graph–number multiple conversion. A super brain-shield control system platform (Fig. 6(b)) was developed that allows the shield machine to automatically issue instructions to the shield machine based on accurate perception of construction information, resulting in more adaptive, faster, and safer intelligent unmanned tunneling.

《Fig. 6》

Fig. 6. (a) An intelligent shield machine and (b) a shield control system platform developed by the Shanghai Tunnel Engineering Co., Ltd.

Based on the current state of development, the future development of intelligent shield tunnel construction should focus on improving machine learning algorithms and expanding their application in practical engineering excavation, such as shield equipment condition analysis and tunneling performance prediction, geological parameter inversion, surface deformation prediction, and shield segment damage monitoring and prediction. Furthermore, with the extensive development of shield construction and the ongoing maturation of 5G sensing, the IoT, cloud computing, and other technologies, it is critical to establish a database system that collects massive multisource shield construction data, integrates monitoring information from various projects, equipment, and tunnels, and improves the generalizability of machine learning models through big data training.

《3.3. Immersed tunnels》

3.3. Immersed tunnels

Compared with those of drilling and blasting and shield tunnels, the immersed tunnel-construction process has considerable benefits in terms of the factory, assembly, and standardization. The advancement of intelligent construction technology for immersed tunnels in recent years has mostly focused on the intelligent dredging of foundation trenches, the intelligent prefabrication of manufacturing processes, and the intelligent installation of immersed tubes [63–65]. In the Shenzhen–Zhongshan passage immersed tunnel project, substantial advances have been made in intelligent construction technologies for steel shell intelligent manufacturing, steel shell concrete intelligent pouring, and immersed tube intelligent installation (Fig. 7). The intelligent manufacturing of small steel shells in workshops, the digital carrying technology of the middle steel shells, and automatic assembly production lines for large steel shells have been developed based on the Internet, BIM, and intelligent robot technology, realizing the intelligent manufacturing of steel shells and a considerable improvement in quality and efficiency. An intelligent manufacturing production line for the steel box girder has been built, which solves the initial faults of the orthotropic steel bridge deck’s welded joints and improves the fatigue performance of the orthotropic steel bridge deck. An intelligent pouring control system and self-compacting concrete pouring equipment have been created. The intelligent allocation of duties, real-time monitoring records, and the timely identification of construction flaws in each link of immersed tube prefabrication were realized using big data-aided decision-making, which effectively increased the pouring quality of the self-compacting concrete. An intelligent control system for submerged tube transportation, installation, and sinking is being developed. The automatic positioning and efficient installation of the immersed tube in construction waters are realized using digital command navigation of the floating, mooring positioning, highprecision unmanned sinking, and underwater fine adjustment of the immersed tube.

《Fig. 7》

Fig. 7. Immersed tube factory production in Shenzhong channel using (a) an intelligent production line and (b) an intelligent quality control system.

Based on the current state of development, the intelligent construction of immersed tube tunnels should concentrate on constructing a smart immersed tube prefabrication factory that combines intelligent manufacturing with intelligent construction, fully utilizing digital twins, BIM, and other information technologies. It should also focus on developing intelligent robots and constructing standardized production lines to improve the production efficiency and process quality of immersed tubes. Advanced monitoring and sensing technologies are used during the immersed tube installation process to achieve intelligent perception of the state of the immersed tube and foundation trench, develop the entire process collaborative management platform of the immersed tube tunnel project, and improve the anti-risk level of immersed tube tunnel construction.

Intelligent construction enhances the efficiency, economy, and safety of transportation infrastructure construction, resulting in innovations in construction technology and the rapid development of related industries. In essence, intelligent construction is the intelligent empowerment of existing construction methods, such as mechanization and assembly, so that a project can more effectively perceive, learn, and adapt to the environment in the process of transforming nature. This improves the project’s ability to defend against disasters and create an ecologically harmonious engineering construction method. To achieve these goals, future intelligent construction technology should focus on breakthroughs in the following five aspects (based on the acronym SMART):

(1) ‘‘S” for sustainable resilient construction: More attention should be paid to the construction resources of the natural environment of intelligent perception, and the construction machinery, technology, and structure of the construction environment of independent adaptability should be improved. Moreover, more focus is required on the preventability of disaster during the construction period.

(2) ‘‘M” for modularization and fine construction: Intelligent construction and manufacturing splitting should be applied to optimize the complex construction process and increase construction quality, efficiency, cost, and risk.

(3) ‘‘A” for artificial intelligence and decision-making: Data mining and machine learning should be applied to generate a relatively full construction management knowledge graph; implement robust identification, judgment, and decision support; improve the use of construction equipment; and enhance construction management.

(4) ‘‘R” for robots and unmanned systems: Construction robots should be oriented to the construction environment, process flow, structural components, and complicated objects in order to increase the interconnection of intelligent construction equipment clusters. The robots should be made resilient, and human resource investment should be reduced.

(5) ‘‘T” for technology integration and information modeling: The integration of materials, structures, equipment, and other technologies should be promoted and tightly connected with BIM in order to thoroughly, actively, and accurately cover information gaps at the construction site in real time; develop digital twin technologies to create digital archives of engineering facility life-cycles; and improve construction risk management and control.

《4. Intelligent operation and maintenance technology》

4. Intelligent operation and maintenance technology

The intelligent operation and maintenance of transportation infrastructures involves the use of cloud computing, the IoT, artificial intelligence, human–computer interaction, and other technologies to maintain engineering structures at all stages of their entire life-cycle. The aim of this overall technology is for structures to achieve self-awareness of damage, self-memory of information, self-training of data, self-decision-making regarding solutions to problems, and self-processing of maintenance, which can extend the life of a structure and ensure its long-term safety and reliability. The operation and maintenance process is continuous and long-term, starting from construction completion and ending at the complete failure of the structure. This process does not just repair old structures such that they remain ‘‘old but repaired”; it sometimes repairs old structures by making them new again.

The whole process of the intelligent operation and maintenance of transportation infrastructures can be divided into four aspects: intelligent detection/monitoring, intelligent management, intelligent maintenance, and intelligent transformation (Fig. 8). Intelligent detection/monitoring aims to achieve the real-time monitoring of engineering structures and rapid detection of damages through intelligent equipment, information technology platforms, and scientific technology in order to detect fluctuation situations and early abnormalities. Intelligent management aims to use scientific research, deductions, and predictions based on changing trends in engineering structural risk factors using artificial intelligence algorithms, numerical simulation technology, and mechanical analysis. In addition, intelligent management achieves automatic early warning at the decision-making level and provides preventive countermeasures. Intelligent maintenance aims to carry out predictive maintenance and the efficient correction of early damage to engineering structures by means of artificially assisted machinery, industrial robots, and green repair materials, which is the key to ensuring the long life and green, low-carbon operation of structures. Intelligent transformation is a new mode of transformation for major projects that achieves both future performance and future functionality without destroying the structural integrity. It relies on data mining, the prediction of environmental change trends, load-bearing capacity, and functional demand analysis.

《Fig. 8》

Fig. 8. Diagram of an intelligent operation and maintenance system for transportation infrastructures.

Fig. 8 shows the technology to apply, the issues to address, and the target for intelligent operation and maintenance. Taking a bridge as an example, the reliable acquisition of inspection/monitoring data on and visual oversight of structures and environments is the basis for management and maintenance. In the early days, bridge inspections mainly relied on the engineers’ experiences. Subsequently, advanced nondestructive testing technologies began to be promoted. Today, more intelligent structural-healthmonitoring technologies have become popular [66]. The excitation and response of the structure are sensed by means of various detection and monitoring technologies. This information is then processed and analyzed to determine the fluctuation in, deterioration of, and damage to the performance of the transportation infrastructure, thereby providing decision-making support for management and maintenance [67]. In recent years, the preventive management and maintenance of bridges have increasingly become a fundamental strategy in the bridge industry [68], and great advances have been made in operation and maintenance techniques. The Hangzhou Bay Sea-Crossing Bridge in Zhejiang Province, China, is the most convenient way to cross Hangzhou Bay while traveling along the Tongjiang–Sanya Coastal Corridor and the Shenyang–Haikou Expressway, which are the main roads of the five-vertical/seven-horizontal national highways in China. The foundation of the project was laid on 8 June 2003, joint construction was completed on 26 June 2007, and the project was opened to traffic on 1 May 2008. Once a bridge is open to traffic, it must be managed and maintained in order to ensure its lifecycle management. The Ningbo Municipal Highway Administration and Beijing Gongke Bridge Technology Co., Ltd. in China developed a maintenance management system for the Hangzhou Bay Sea-Crossing Bridge, which was put into use in 2010 [69]. The management system includes several subsystems, such as system management, schedule management, and detection management. It can digitally display the bridge and its structural components based on a BIM model. The system establishes an interface between health detection and maintenance systems to complete the processing of inspection data, the analysis of sensitive indicators, and the combination of structural information, damage information, and detection history to ensure the efficiency of bridge maintenance [69,70]. After the completion of this maintenance system, it will truly reflect the bridge’s structural condition and maintenance status, and will thus ensure the effective maintenance and repair of the bridge for several years [69]. With the development of big data and artificial intelligence, management and maintenance technology has been continuously improved. In recent years, a reliable cloud control platform for the Hangzhou Bay Sea-Crossing Bridge has been developed that opens the original independent software system of the bridge for each business system and enables the management and storage of data directly on the cloud control platform, thereby providing more effective support for the early prevention of the damages of the bridge [71]. At present, the management and maintenance model used for the Hangzhou Bay Bridge has been widely promoted in the operation and management of large bridges in China.

Bridges with a long history and long service time present the issue of rehabilitation and renovation, which require targeted renovation to address new needs of physical space, load-bearing capacity, and multiple functions. There are many successful cases in this regard, such as the main bridge deck slab of the Nanjing Yangtze River Bridge, which was newly repaired in 2016 after 48 years of operation [72]. Both the hyperbolic arch bridge and the main bridge deck were renovated, and the bridge performance was considerably improved. Relics of the old Gum Customs site were restored from 2013 to 2016, and the original historical features and appearance were restored [73]. At the same time of development, intelligent operation and maintenance technology also faces many problems. For example, to achieve efficient maintenance of bridges, it is necessary to be informed regarding the time and location of possible catastrophes. Therefore, it is necessary to establish a theory of whole-life design and analysis [74,75]. At present, structural health-monitoring technology has been gradually extended from simple condition monitoring to structural performance evolution analysis [76,77]. However, the effect of structural performance diagnosis has sometimes been unsatisfactory, due to environmental noise interference and equipment sensitivity [78]. In addition, due to the diversity, complexity, and randomness of engineering hazards, the establishment of a whole-life theory remains challenging. Most of the relevant results are at the stage of numerical simulation or model validation. There is an urgent need to develop more precise damage-diagnosis technology, accurate structural life-prediction technology, and reliable risk-warning technology. Moreover, although BIM technology can substantially improve the level of informatization, visualization, and intelligence, it carries a high upfront cost and lacks unified management standards for management and maintenance. Therefore, reducing BIM cost while improving efficiency is a problem that needs to be addressed [79,80].

Overall, the intelligent operation and maintenance of transportation infrastructures is a comprehensive technical system that is still in the early stage of development. The development of this system requires more sophisticated, sensitive, and durable detection/monitoring technologies, as well as more reliable data transmission and integration networks, additional interconnected information-visualization and -sharing platforms, efficient data analysis and predictive warning capabilities, timely earlyconservation measures, accurate reinforcement solutions, and rational transformation techniques. In the future, it will be necessary to comprehensively improve the intelligence level of detection/monitoring, information management, early-warning maintenance, and other technologies in order to build a more accurate and suitable operation and maintenance system. In particular, the following key scientific and technical issues urgently require breakthroughs:

(1) Intelligent sensing and data-acquisition technology. Accurate sensing of structural characteristic parameters is the basis of intelligent operation and maintenance decisions, and is highly demanding for the performance of devices, such as sensors, integrators, and acquisition terminals. It is necessary to develop new detection/monitoring equipment that is applicable to different engineering structures and damages to support the formation of a series of intelligent sensing and data-acquisition technologies. Thus, synchronous collection, stable transmission, efficient storage, fast recall, and intelligent processing of massive data can be realized.

(2) Environmentally friendly maintenance technology. The timeliness and effectiveness of the maintenance of transportation infrastructures are the key to ensuring their safe operation. The focus of maintenance varies due to the different environments (e.g., CO2 concentration, pH value) of different engineering structures. For optimal maintenance effectiveness, it is necessary to apply artificial intelligence technology to intelligently evaluate the maintenance focus and effects under different conditions. Accordingly, it is immensely important to develop intelligent maintenance decision-making and implementation systems in order to provide the most reasonable maintenance solutions according to different environmental and human situations.

(3) Structural precision reinforcement and repair technology. The accurate location of early signs of damages, timely reinforcement, and effective repair are the key to restoring a structure to a healthy state. In the future, it will be necessary to develop new composite reinforcement materials for the various states of a structure in order to improve the compatibility of old and new interfaces, while considering the stress state and historical maintenance details of key structural elements. This will ensure the safety, aesthetics, and long life of engineering structures.

(4) Large-structure transformation and synergy technology. It is not economically and environmentally friendly to demolish and rebuild large transportation infrastructures that have been in service for many years. Instead, it is necessary to establish structural whole-life design, analysis, and prediction methods for different transformation schemes in order to achieve functional and performance improvement based on long structural life. Moreover, the surrounding engineering environment should be fully considered to ensure the regional coordination and unity of a structure.

《5. Intelligent elimination technology》

5. Intelligent elimination technology

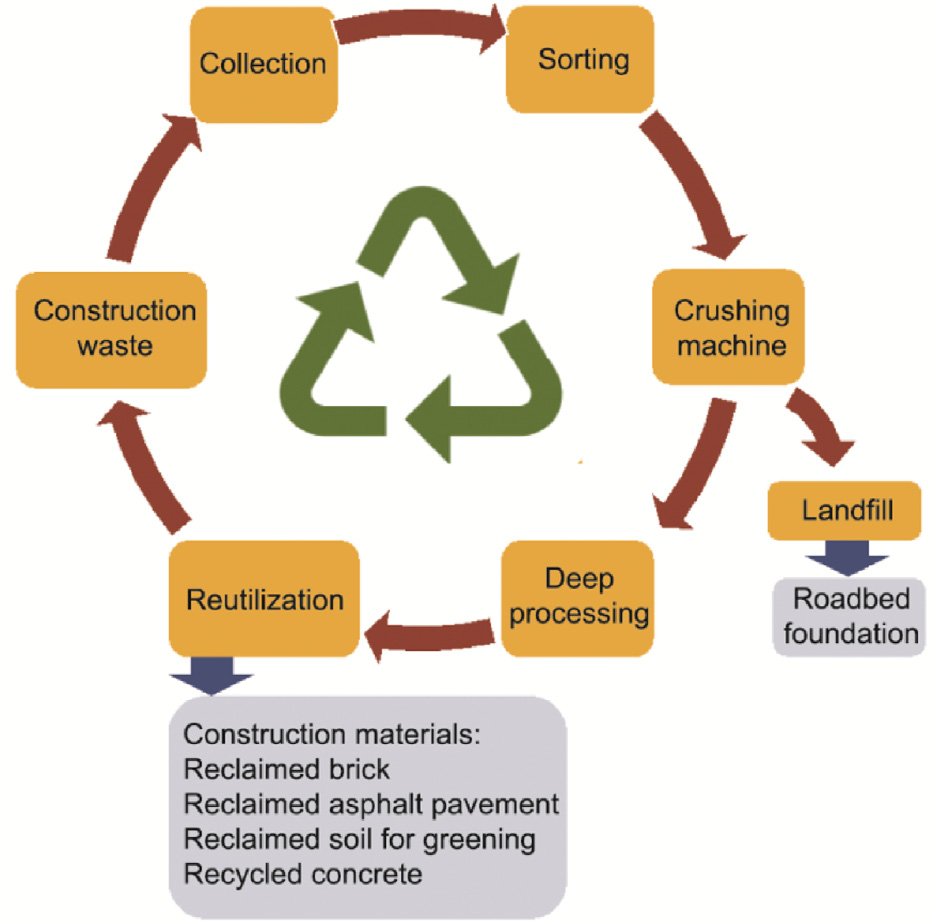

The intelligent elimination of transportation infrastructure refers to the process of using intellectual technology to realize the demolition, clearance, classification, recovery, and resourceful reuse of buildings and infrastructure that have reached the end of their service lives (Fig. 9). It is a technology chain that integrates intelligent classification, efficient transformation, clean utilization, intensive processing, and precise control [81]. The scientific foundations of intelligent elimination are a complete set of technologies, solutions, and promotion modes for the resource utilization of construction solid waste based on the new generation of IT, with the core principles of recycling and harmlessness, supported by the theory of recycling and collaborative pollution control. The establishment of an intelligent elimination technology system can considerably improve the treatment efficiency of construction solid waste, promote the regeneration and recycling of building materials, reduce the energy consumption and carbon emissions of construction, help to achieve peak carbon dioxide emissions and carbon neutrality in the construction industry, and realize the green and sustainable development of transportation infrastructure.

《Fig. 9》

Fig. 9. The elimination process for construction waste.

Taking road works as an example, the development of intelligent elimination for transportation infrastructure is based on the cooperative development of theory and technology, with a focus on green recycling and the utilization of construction solid waste. At the theoretical level, construction solid waste releases pollutants during the processes of generation, storage, transportation, and disposal, which are harmful to people and the natural environment. Therefore, many researchers are committed to investigating the principle of space–time distribution and difference analyses of the environmental attributes of construction solid waste resources. By establishing a quantitative characterization model for the release, migration, and accumulation of characteristic pollutants and toxic components, along with a solid waste fingerprint characteristic database [82], the principles of blocking toxic components can be clarified, and a risk-assessment system for the whole recycling process of solid waste can be established.

At the technical level, innovations in and the development of sorting methods, management, and control strategies have advanced, together with reutilization techniques for construction waste. First, with the rapid development of technologies such as image recognition and processing based on deep learning [83], multifunctional detection, computer vision, and artificial intelligence [84], the traditional manual sorting process for construction waste has been gradually replaced by intelligent methods [85]. The emergence of construction solid-waste-sorting devices (Fig. 10) [86], SpotGarbage [87], ZenRobotics Recycler [88] (Fig. 11), a multiband infrared imaging intelligent device [89], and other intelligent waste identification and classification systems based on sensors and computer vision technology has not only improved the efficiency of sorting construction waste but also ensured the accuracy of classification, making it possible to autonomously and accurately separate metals, concrete, wood, and plastics from numerous construction wastes [90,91]. The intelligent sorting mode helps to quickly screen out the recyclable parts of construction solid waste and exhibits greatly improved accuracy, complexity, and cost savings in comparison with those of traditional sorting methods. Second, ubiquitous sensing and broadband IoT technology are bringing new development opportunities in the formation of control strategies for construction waste elimination [92]. Construction waste can be connected to the Internet by radio frequency identification devices, infrared sensors, 5G communication, and other information equipment in order to realize intelligent identification, positioning tracking, remote monitoring, and management decisions for the generation, transportation, and reutilization processes of construction solid wastes. For example, IoT technology has been applied to the transportation of urban engineering dregs and the management of construction waste recycling facilities [93]. Intelligent information exchange and sharing between vehicles, roads, people, and the cloud have been realized, promoting the rapid traceability and scheduling of construction solid waste resources and improving the recycling and utilization efficiency of construction solid waste. Moreover, reutilization technology for construction wastes and the exploitation of downstream products have gradually been deeply integrated with the application requirements of materials, construction, municipal administration, transportation, environmental governance, and other fields. Construction wastes can be applied for different purposes, such as for fillers in foundations and roadbeds, reclaimed asphalt pavement (RAP) materials, raw materials for reclaimed brick production, reclaimed soil for greening, and reclaimed concrete [94]. While recycled aggregate concrete still has some limitations in mechanical strength and durability, these can be made up for to a certain extent with the use of enhancement methods such as accelerated carbonation [95], crystallization treatment [96], reinforcement spiral constraint [97], and recycled mixed concrete technology [98]. Using RAP materials to build new pavement is a popular development direction with great potential. Although the performance of RAP has some defects, the addition of original asphalt or rejuvenators, such as bio-oil and cooking oil [99], enables RAP materials to have the same good road performance as a new asphalt mixture. The use of in situ milling and mixing equipment has also greatly improved the recycling efficiency of RAP materials, while being an effective way to realize maximum resource utilization by using the recycled materials formed by construction waste processing for subgrade filling [100].

《Fig. 10》

Fig. 10. The construction waste-sorting device. Reproduced from Ref. [86] with permission.

《Fig. 11》

Fig. 11. The ZenRobotics Recycler. Reproduced from Ref. [88] with permission.

At present, an entire elimination chain for construction solid waste, including sorting, recycling, and comprehensive utilization, has gradually been established. Many efficient, high-quality, and high-value demonstration projects on construction waste elimination have been successively built in Guizhou, Guangdong, and Shandong Provinces in China. These projects have centralized production lines for the sorting, classification, deep processing, and reutilization of construction waste. The entire elimination process of construction solid waste can be completed in one industrial park, which greatly shortens the recycling period while effectively reducing energy consumption and carbon emissions.

Intelligent elimination is an indispensable part of achieving the green development of transportation infrastructure. Improvement of the science and technology system of intelligent elimination should be initiated in the following aspects:

(1) Intelligent sorting and recycling technology. Complex and indistinguishable composition is the key problem hindering the efficient recovery of construction waste. Therefore, the development of intelligent sorting technology is a bottleneck problem that must be addressed. Although the development of information technologies such as computer and image recognition is very rapid, their applications still have many limitations, such as careless classification, poor accuracy, and low sorting efficiency. It is necessary to strengthen the integration of multifunctional imaging technology, computer vision technology, and artificial intelligence technology and to develop and improve the intelligent sorting system for building solid waste. Moreover, it is necessary to improve the accuracy of waste classification and work efficiency, and realize the intelligent and efficient recycling of construction solid waste.

(2) Clean and value-added utilization, efficient and safe conversion, and intensive processing. It is necessary to take full advantage of information technology, such as big data and computer-aided decision-making, to establish a management system for the comprehensive reutilization of construction waste. It is also necessary to integrate the production units, quantity, quality, and utilization of construction waste, and to improve the efficiency of resource allocation. Moreover, a series of actions should be taken to develop automation and artificial intelligence technologies, advanced factory manufacturing, and machine construction technologies to improve the comprehensive utilization rate of construction waste and realize the efficient and safe recycling of construction waste.

(3) Precise control and decision-making. Precise management and control have two main aspects: precise management; and safety and environmental risk control. First, IT should be taken full advantage of to establish a precise and efficient control system in order to achieve the long-term planning and scientific organization of construction waste sources. Second, research on blocking principles for toxic components and coordinated regulation mechanisms for multiple components should be conducted, an environmental monitoring system and risk-control mechanism should be established, and computer-aided computing should be applied to scientific planning in order to minimize risk factors in the entire elimination process for construction waste.

《6. The application of intellectualization technologies in transportation infrastructures》

6. The application of intellectualization technologies in transportation infrastructures

At present, technologies for intellectualization have been initiated and are gradually being developed. Pilot projects have been carried out and have achieved good economic and social benefits in engineering practice. The levels of demand for intellectualization technologies for different types of transportation infrastructures are summarized in Table 1.

《Table 1》

Table 1 Technological demands for the intellectualization of typical transportation infrastructures.

: optional intellectualizations;

: optional intellectualizations;  : suggested intellectualizations;

: suggested intellectualizations;  : necessary intellectualizations.

: necessary intellectualizations.

The Beijing–Zhangjiakou High-Speed Railway is an important component of the Beijing–Lanzhou corridor in the eight-vertical/ eight-horizontal high-speed railway network in China’s mediumand long-term railway network planning. The main line runs from Beijing North Railway Station to Zhangjiakou Railway Station, with a total length of 174 km and a maximum design speed of 350 km∙h–1 . Due to the complex geological conditions, fragile ecological environment, and numerous ancient buildings along the line, the China National Railway Group Co., Ltd. comprehensively applied intelligent design technology, intelligent construction technology, and intelligent operation and maintenance technology to build the world’s first high-speed railway based on intelligent concepts. The Beijing–Zhangjiakou High-Speed Railway adopts the following intelligent technologies:

(1) In the design stage, low-altitude remote sensing, aerial surveys, Beidou satellite navigation, and other so-called ‘‘air-, space-, and earth-integrated” intelligent survey technologies were used to reasonably avoid areas requiring environmental protection, areas sensitive to urban planning, areas with cultural heritage, and other important areas and facilities and to effectively reduce decision-making risks. A BIM-based collaborative design platform for all disciplines and a unified environment across the entire line were established. The China National Railway Group Co., Ltd. also developed multiple BIM-collaborative software programs for surveying and mapping lines, bridges, tunnels, roadbeds, catenaries, signals, and so forth, and achieved multidisciplinary parametric design and engineering calculations, interprofessional assembly, integrated management of results, and nondestructive transmission of information.

(2) In the construction stage, an intelligent, double-block, sleeper production line based on industrial robots and big data was established to accomplish the automation of the whole process of sleeper manufacturing, the online centralized management of all-element data on the sleeper field, and the high-precision inspection of sleeper construction quality. A complete set of technologies for the intelligent construction and fine management of roads, bridges, tunnels, and stations was developed in order to achieve automatic guidance, collaborative operation, the seamless connection of construction machinery, visualization of the construction process, and 3D dynamic monitoring of the construction process. For example, one of the control projects of the Guanting Reservoir Bridge on the Beijing–Zhangjiakou High-Speed Railway innovatively adopted intelligent control, multipoint synchronous pushing, and automatic monitoring technology to solve the challenge of the pushing construction of multi-hole long-span steel truss beams (Fig. 12).

《Fig. 12》

Fig. 12. Synchronous pushing for the construction of the Guanting Reservoir Bridge.

(3) In the operation and maintenance stage, an entire chain of intelligent safety monitoring and multidisciplinary integrated operation and maintenance systems was built to achieve the fulltime acquisition of monitoring data, the comprehensive research and determination of hazardous factors, dangerous situation prediction and early warning, and emergency response coordination. A high-speed-rail project-management platform based on BIM + GIS was developed to accomplish the comprehensive management and control of component-level 3D image progress, quality, and safety; multiangle, multidimensional, and multiscale comprehensive analysis; and the online management of the project’s construction data.

Since its opening in 2019, the Beijing–Zhangjiakou High-Speed Railway has received widespread praise due to its substantially reduced accident rate and extensive and prominent demonstration effects.

《7. Conclusions and prospects》

7. Conclusions and prospects

The rapid promotion of intelligent processes has become the key to the transformation and upgrading of the production mode in the construction industry and is an important way to attain China’s national strategy of reaching a carbon peak and achieving carbon neutralization. Against the background of breakthroughs in artificial intelligence technologies, such as big data intelligence, human–machine-hybrid augmented intelligence, and brain-like intelligence, the unique advantages of these technologies in terms of active perception, independent learning, analytical reasoning, and knowledge application should be fully explored to promote intelligent research in the field of civil engineering and transportation infrastructure. In addition, the construction and gradual implementation of an intelligent technical system framework for transportation infrastructures should be considered in order to provide support and ensure the future construction of modern infrastructures with complete systems, safety and reliability, high efficiency and practicality, and green intelligence. We recommend the following areas as focuses of further research:

(1) A unified standard and evaluation system for the intellectualization of civil engineering structures should be established and improved. Governmental departments should formulate a toplevel plan and prepare guidelines for a standardized construction system of intelligent construction. They should also take the lead in organizing relevant scientific research institutes, consultancy institutions, and large enterprises to strengthen crossinstitutional, cross-organizational, and interdisciplinary cooperative research. An intelligent collaborative innovation system must be established for civil engineering. Moreover, government departments should jointly formulate basic common standards for intelligent construction, such as design standards, construction standards, operation and maintenance standards, and Internet data-exchange standards. They should promote the establishment and improvement of basic regulations, scoring systems, evaluation grades, and management institutions for intelligent construction. Finally, government departments should accelerate the realization of the market-oriented application of intelligent construction technologies and products.

(2) Bottleneck problems in fundamental theories and key technologies that restrict intelligent construction should be solved. First, the basic theoretical system framework of the intellectualization of transportation infrastructure should be gradually improved, and the scientific foundations of and logical relationships among each component of the theoretical system for intelligent construction should be clarified to provide theoretical guidance for the high-quality development of intelligent construction. Second, the development of intelligent construction software and big data platforms represented by BIM technology should be accelerated in order to comprehensively improve the information level of intelligent construction. Third, an intelligent operation and maintenance system with ubiquitous perception, intelligent decisionmaking, and predictive maintenance should be built, driven by human–computer interaction technology and integrated with advanced sensing, 5G telecommunication, laser code scanning, radio frequency identification, and ultra-dynamic, multifrequency, high-precision acquisition technology. Finally, the application of intelligence in the field of civil engineering should be promoted, and intelligent techniques and equipment in the design, construction, operational maintenance, and elimination stages should be strengthened.

(3) The training of innovative interdisciplinary talents in transportation infrastructure engineering should be enhanced. According to the underlying foundations of the multidisciplinary crossintegration of new engineering and the talent needs of intelligent construction, training programs for cross-border traditional engineering majors in construction, civil engineering, telecommunications, machinery, and so forth, as well as emerging artificial intelligence, IoTs, blockchain, and so on, should be continually improved. Moreover, interdisciplinary knowledge reserves that meet the needs of talents in the intelligent construction industry should be established. Simultaneously, an integrated teaching practice for school-enterprise cooperation and collaborative education should be set up by uniting educational institutions with wellknown construction companies worldwide, which would improve students’ creative spirit and practical ability, cultivate a comprehensive range of talents that can overcome professional knowledge barriers, carry out strong cross-border integration, and allow students to be fully engaged in creative thinking.

《Acknowledgments》

Acknowledgments

This work was jointly supported by the National Natural Science Foundation of China (51991390 and 52250011).

《Compliance with ethics guidelines》

Compliance with ethics guidelines

Yan-Liang Du, Ting-Hua Yi, Xiao-Jun Li, Xiao-Li Rong, Long-Jun Dong, Da-Wei Wang, and Yang Gao declare that they have no conflict of interest or financial conflicts to disclose.

京公网安备 11010502051620号

京公网安备 11010502051620号