Hydrogen is globally expected to play a key role in the sustainable development of humanity, as it can be produced from renewable energy, which is more evenly distributed than fossil fuels, and can be converted into electricity and heat without the emission of greenhouse gases. The importance of hydrogen energy has become increasingly obvious, especially in the context of large-scale energy storage and transport for the widespread use of renewable energy.

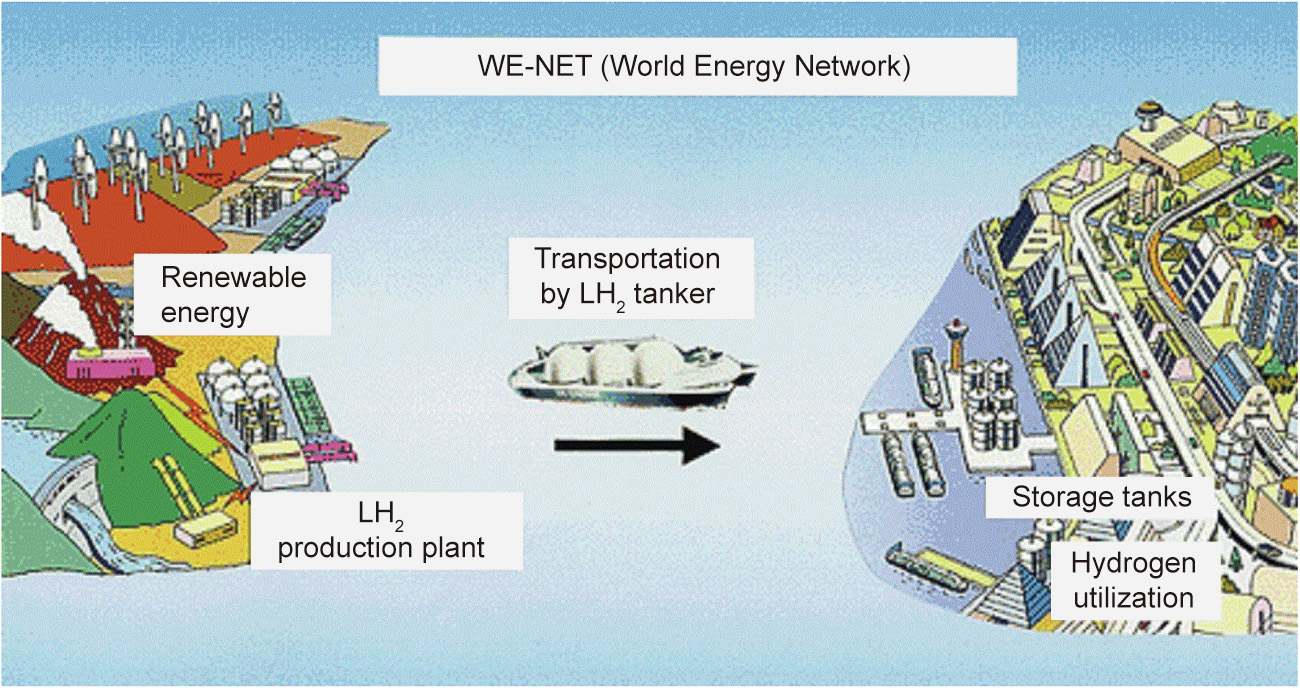

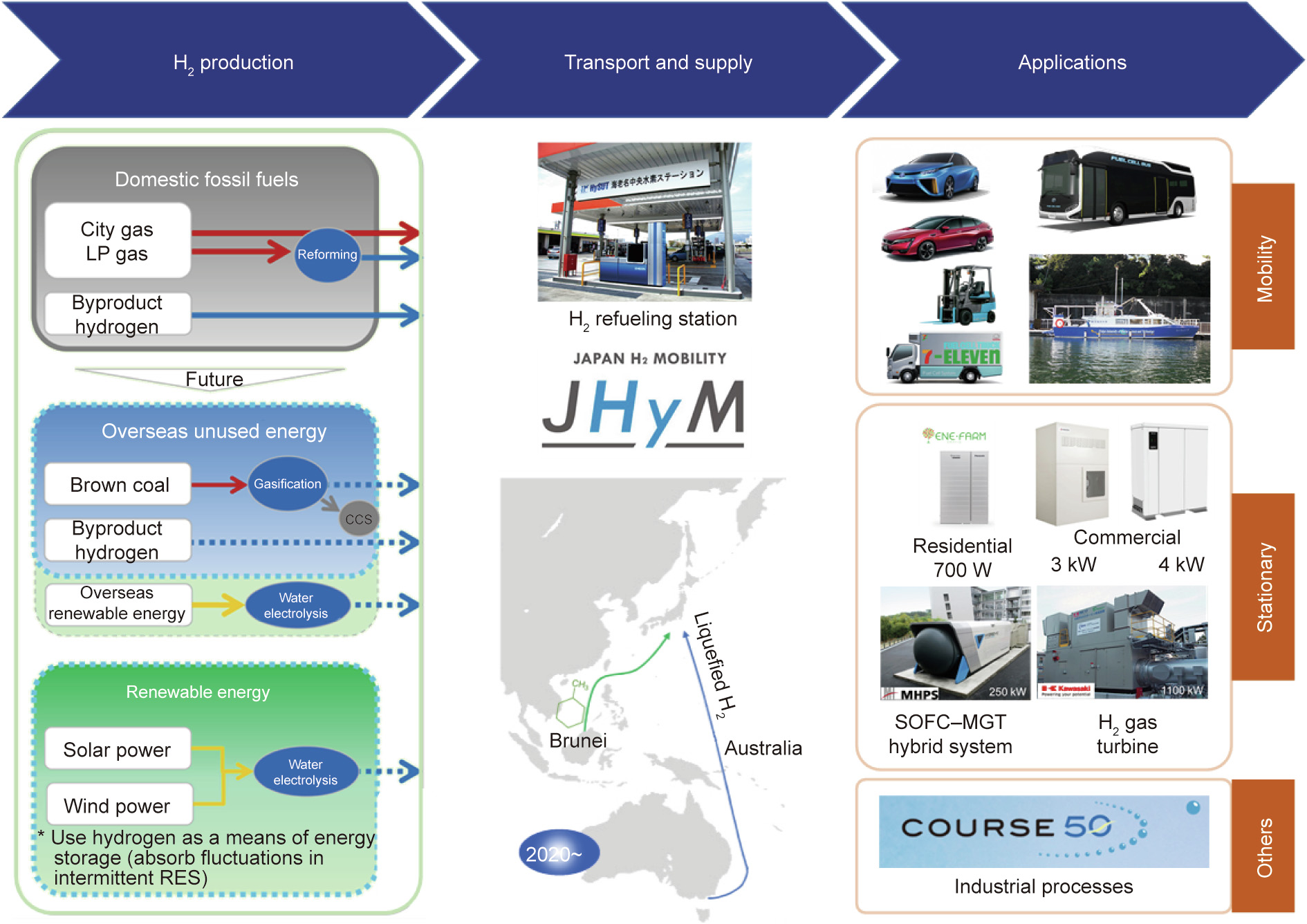

Japan is a world leader in advanced hydrogen energy technologies, based upon its continuous engagement in the development of hydrogen-related materials, devices, and systems for almost half a century. Impacted by the oil shock in 1973, the first national project on hydrogen energy, named SUNSHINE, was launched in 1974; this was succeeded by ‘‘New SUNSHINE” from 1993 to 2000 [1]. The Hydrogen Energy Systems Society of Japan was established in 1973, at the time of the oil crisis. As a prevention measure against global warming, the World Energy Network (WE-NET) project (Fig. 1) [2], which started in 1993, proposed the concept of building a clean energy network in which hydrogen links renewable energy with utilities such as power generation and transportation. The importance of hydrogen energy was strongly emphasized by the Japanese Government in its fourth Basic Energy Plan in 2014, after the collapse of the myth of nuclear power plant safety due to the East Japan Earthquake on 11 March 2011. The first commercialization of a fuel cell vehicle (FCV), Mirai, on 15 December 2014 greatly boosted the progress of the hydrogen energy society, making 2015 known as the first year of hydrogen energy in Japan. Japan was also the first country to issue a basic hydrogen strategy in December 2017 (Fig. 2) [3]. This strategy primarily aims to achieve a hydrogen cost parity with fossil fuels and a wide range of applications for truly realizing a hydrogen society.

《Fig. 1》

Fig. 1. The concept of building a clean energy network proposed by the WE-NET project. LH2: liquid hydrogen. Reproduced from Ref. [2] with permission of New Energy and Industrial Technology Development Organization (NEDO), © 2020.

《Fig. 2》

Fig. 2. Scenario for the basic hydrogen strategy in Japan. CCS: carbon dioxide capture and storage; α: something extra; LNG: liquefied natural gas. Reproduced from Ref. [3] with permission of Ministry of Economy, Trade and Industry (METI), © 2017.

Hydrogen energy activities in Japan cover the entire supply chain from production to applications, as shown in Fig. 3 [4]. At present, gas reforming processes and byproduct hydrogen are the main domestic resources in this field. Carbon capture and storage (CCS) technology can be a way to produce hydrogen from fossil fuels without carbon dioxide (CO2) emission. Using renewable energy is an ideal way to produce hydrogen without CO2 emission, and the world’s largest (10 MW) hydrogen production facility derived from solar energy was completed in March 2020. Meanwhile, international hydrogen supply chains using liquefied hydrogen, methylcyclohexane (MCH), and ammonia can complement the limited domestic capacity and reduce the cost [5].

《Fig. 3》

Fig. 3. An overview of hydrogen energy activities in Japan. LP gas: liquefied petroleum gas; RES: renewable energy sources; SOFC: solid oxide fuel cell; MGT: micro gas turbine; JHyM: Japan Hydrogen Mobility. Reproduced from Ref. [4] with permission of METI, © 2019.

The applications of hydrogen energy can be divided into three categories: mobility, stationary, and other. By September 2020, around 3700 FCVs, including the Toyota Mirai and Honda Clarity, had been sold in Japan. Mirai has sold over 10 000 units globally so far, and the new-generation Mirai II, which has an extended driving distance of more than 800 km, has been released in December 2020. To strengthen its global position in the fuel cell (FC) mobility sector, Toyota registered a joint company with Chinese automobile companies. Around 20 FC buses are under operation, with a plan of 100 for Tokyo 2020 Olympic Games. Approximately 160 FC forklifts were sold as of September 2020, and the target for 2020 was 500. In addition, other mobile applications such as FC trucks and FC ships are currently under demonstration. Around 130 hydrogen refueling stations, including mobile ones, are operational in Japan, and the total numbers are expected to increase to 320 by 2025 with support from Japan Hydrogen Mobility (JHyM), a consortium of private companies, financial institutions, and government bodies [6,7]. Cost reduction is one of the most important factors for a wide spread of hydrogen stations, and this requires not only technological advancement, but also regulatory relaxation.

Ene-Farm, a residential system with a 700 W polymer electrolyte fuel cell (PEFC) or solid oxide fuel cell (SOFC), cogenerates electricity and heat using hydrogen produced from natural gas or propane gas. Although there is unavoidable CO2 emission, the total energy efficiency, which is as high as 85%, helps to reduce the CO2 emission by 1.3 tonnes per year for each unit, in comparison with a conventional electricity-powered home. Research and development (R&D) has focused on reducing the cost and size, and extending the working life. The sales volume increased significantly after the East Japan Earthquake; thus far, over 372 000 units have been installed. Industrial and commercial FC systems mainly focus on SOFCs, as they have a higher power-generation efficiency than PEFCs. In 2017, Kyosera began to sell a 3 kW SOFC system with an electrical efficiency of 52% and a total energy efficiency (including electricity and heat) of 90%. In 2019, Miura released a 4.2 kW SOFC system with an electrical efficiency of 50% and a total efficiency of 90%. In 2020, Tokyo gas and Miura began the demonstration of a 5 kW SOFC system with an electrical efficiency of 65%. Earlier, in the spring of 2015, Mitsubishi Hitachi Power Systems (MHPS) began the demonstration of its pressurized hybrid power-generation system (MEGAMIE), which integrates SOFCs with micro gas turbines (MGTs), at Kyushu University Ito Campus. This 250 kW system achieves an electrical efficiency of 55% and a 47% reduction in CO2 emissions compared with a conventional power-generation system. Currently, a 1 MW class MEGAMIE system is under contemplation, and an integrated power-generation system comprising SOFCs, gas turbines, and steam turbines in the 100 MW class is planned as a replacement for thermal power plants in future large-scale projects. It is worth noting that the abovementioned residential and industrial FC systems use natural gas or propane gas as fuels, based on the present infrastructure. Such distributed power-generation systems demonstrate high energy efficiency and lower CO2 emission than conventional electricity transmission. These advantages will be more significant when the fuel is changed to pure hydrogen in the future.

Hydrogen combustion is an approach that can be used for largevolume power generation, such as the present thermal power plants that supply reliable energy to users. In January 2018, MHPS successfully demonstrated a large-scale 700 MW gas turbine using a fuel composed of 30% hydrogen mixed with natural gas, giving a 10% CO2 reduction. This system received an order from a US power plant in March 2020. The development of large turbines for pure hydrogen is more challenging than developing turbines that use a hydrogen mixed fuel like the example above. Kawasaki Heavy Industries successfully tested a 1 MW turbine fueled by 100% hydrogen in 2018. Furthermore, demonstrations of the combustion of hydrogen carriers have been carried out. The National Institute of Advanced Industrial Science and Technology (AIST) successfully generated 21 kW of power by the combustion of kerosene with 30% ammonia in a gas turbine in 2014, and a generation of 41.8 kW was achieved by the combustion of a methane–ammonia gas mixture as well as a 100% ammonia gas in 2015. IHI Corporation successfully demonstrated the co-firing of ammonia and coal in a fuel mix containing 20% ammonia in 2018. AIST demonstrated an MCH supply chain that uses hydrogen produced using renewable energy for hydrogen co-fired power generation in 2020. This cofired system can operate at 300 kW for more than 700 h with 60% hydrogen mixed with diesel fuel.

In addition to its energy applications, hydrogen can be used to create green industrial processes. A typical example is the use of hydrogen to reduce iron ore in the steelmaking process. An initiative named CO2 ultimate reduction in the steelmaking process by innovative technology for a cool Earth 50 (COURSE 50) was established to develop environmentally harmonized steelmaking technologies, with the aim of reducing CO2 emissions by approximately 30% through the suppression of CO2 emissions from blast furnaces as well as the capture, separation, and recovery of CO2 from blast furnace gas.

A hydrogen-powered town known as HARUMI FLAG is being built for the first time as the Olympic Village for the Tokyo 2020 Olympic Games. This town is the first place in Japan to have a full-scale hydrogen infrastructure system: a hydrogen station for bus rapid transit systems; FCVs and hydrogen delivery to residential blocks by means of underground pipelines; next-generation fuel cells for common-use spaces and commercial buildings; and Ene-Farm for all privately owned residences.

Compared with this new hydrogen town, the creation of a hydrogen society that aligns with local resources and demands is both more challenging and more realistic. In this regard, the Ministry of the Environment in Japan launched a program for the creation of a hydrogen society by constructing regional low-carbon hydrogen supply chains (Fig. 4) [8]. Among these projects, hydrogen can be produced by means of ① hydrolysis using energy from wind mills, solar panels, and small hydro power plant; ② livestock manure and waste plastic; and ③ byproduct gas from the caustic soda-production process. Hydrogen is delivered in various ways (e.g., pipelines, gas cylinders, compressed tube trailers, and hydrogen storage alloy tanks) from production locations to end users (e.g., forklifts, hydrogen stations, hotels, swimming pools, hot springs). These demonstrations provide important hints for the creation of a local hydrogen society with a low-carbon hydrogen supply chain. In other words, it is extremely necessary to create a realistic hydrogen society that suits local conditions.

《Fig. 4》

Fig. 4. Creation of a varied local hydrogen society in Japan. (a) Image of a hydrogen society; (b) projects for constructing a regional low-carbon hydrogen supply chain. Reproduced from Ref. [8] with permission of Ministry of the Environment, Government of Japan, © 2016.

The paradigm shift to a brand-new hydrogen-powered society requires the promotion of public acceptance. According to reported surveys, public awareness of hydrogen energy technologies in Japan has increased significantly, especially in terms of FCVs [1]. Hydrogen energy exhibitions play an important role in providing state-of-the-art information and giving visitors the opportunity to see and experience these advanced technologies. For example, approximately 8000 visitors are accepted annually into the hydrogen showroom at Kyushu University Ito Campus, where the demonstration version of FCVs and the commercialized FCVs (Mirai and Clarity), Ene-Farms, a MEGAMIE, and a hydrogen station are open to visitors. International cooperation is another important aspect to accelerate the realization of a hydrogen economy and to achieve the goal of the Paris Agreement adopted at the Paris climate conference (21st Conference of the Parties, COP21) in December 2015. Japan is also an active contributor to international activities at both the governmental and industrial levels. The Hydrogen Council, a global initiative of leading energy, transport, and industry companies, was launched in January 2017, with the aim of accelerating the development of the hydrogen economy with a united and long-term vision. In October 2018, Japan held the first ministerial-level meeting to encourage countries around the world to promote the global-level utilization of hydrogen and to further consolidate collaboration among member countries in a harmonious manner. In June 2019, the importance of hydrogen was referred to for the first time in the Communique and Action Plan of the Group of Twenty (G20) Summit hosted by Japan.

Fukushima has been struggling with the nuclear power plant disaster, but it will rise via renewable hydrogen. The completion of the Fukushima hydrogen energy research field (Fig. 5) [9] not only brings encouragement to the revival of Fukushima, but is also a showcase to prove that hydrogen can be an optimal solution for a reliable energy supply, improvement of the natural environment, and a sustainable, rich life. 2020 has been called ‘‘the first year of the international hydrogen energy society,” which will be individually defined and specifically designed. Continually advancing the R&D of hydrogen technologies and strengthening international cooperation will accelerate the realization of a true hydrogen energy society.

《Fig. 5》

Fig. 5. The Fukushima hydrogen energy research field. Reproduced from Ref. [9] with permission of Government of Japan, © 2020.

京公网安备 11010502051620号

京公网安备 11010502051620号