《1 Engineering research fronts》

1 Engineering research fronts

《1.1 Trends in Top 12 engineering research fronts》

1.1 Trends in Top 12 engineering research fronts

The Top 12 engineering research fronts as assessed by the Energy and Mining Engineering Group are shown in Table 1.1.1. These fronts involve the fields of energy and electrical science, technology, and engineering; nuclear science, technology, and engineering; geology resources science, technology, and engineering; and mining science, technology, and engineering. Among these 12 research fronts, “research on direct hydrogen production from seawater”, “Power-to-X technologies based on renewable energy sources”, and “high-energy density lithium metal batteries” represent energy and electrical science, technology, and engineering research fronts; “mechanism of high temperature superconductor (HTS) material in compact fusion reactor” , “research on hydrogen production process route and critical material by nuclear energy”, and “critical technology in geological disposal of high-level radioactive waste” represent nuclear science, technology, and engineering research fronts; “detecting method of remote sensing image change for energy resources”, “drilling speed prediction model based on artificial neural networks”, and “characteristics and effects of reservoir stimulation in hydraulic fracturing” represent geology resources science, technology, and engineering research fronts; and “multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems”, “theoretical research on quality enhancement and efficiency improvement in the development of oil and gas in complex deepwater geological formations”, and “advancements in deep rock mechanics modeling for safe and efficient underground mining” represent research fronts of mining science, technology, and engineering.

The annual publication status of the core papers related to each frontier from 2017 to 2022 is shown in Table 1.1.2.

《Table 1.1.1》

Table 1.1.1 Top 12 engineering research fronts in energy and mining engineering

| No. | Engineering research front | Core papers | Citations | Citations per paper | Mean year |

| 1 | Research on direct hydrogen production from seawater | 455 | 13 177 | 28.96 | 2020.8 |

| 2 | Mechanism of high temperature superconductor (HTS) material in compact fusion reactor | 468 | 4 595 | 9.82 | 2019.9 |

| 3 | Detecting method of remote sensing image change for energy resources | 36 | 2 342 | 65.06 | 2020.3 |

| 4 | Multiscale fractured modeling and simulation of coupled thermo-hydromechanical processes in rocks for geothermal systems | 11 | 379 | 34.45 | 2021.5 |

| 5 | Power-to-X technologies based on renewable energy sources | 212 | 5 174 | 24.41 | 2020.4 |

| 6 | High-energy density lithium metal batteries | 282 | 75 243 | 266.82 | 2018.6 |

| 7 | Research on hydrogen production process route and critical material by nuclear energy | 174 | 15 263 | 87.72 | 2018.4 |

| 8 | Critical technology in geological disposal of high-level radioactive waste | 387 | 3 058 | 7.9 | 2020 |

| 9 | Drilling speed prediction model based on artificial neural networks | 42 | 686 | 16.33 | 2019.4 |

| 10 | Characteristics and effects of reservoir stimulation in hydraulic fracturing | 162 | 2 474 | 15.27 | 2019.9 |

| 11 | Theoretical research on quality enhancement and efficiency improvement in the development of oil and gas in complex deepwater geological formations | 114 | 783 | 6.87 | 2019.7 |

| 12 | Advancements in deep rock mechanics modeling for safe and efficient underground mining | 30 | 1 309 | 43.63 | 2020 |

《Table 1.1.2》

Table 1.1.2 Annual number of core papers published for the Top 12 engineering research fronts in energy and mining engineering

| No. | Engineering research front | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 |

| 1 | Research on direct hydrogen production from seawater | 19 | 31 | 32 | 55 | 108 | 210 |

| 2 | Mechanism of high temperature superconductor (HTS) material in compact fusion reactor | 56 | 68 | 66 | 74 | 97 | 107 |

| 3 | Detecting method of remote sensing image change for energy resources | 1 | 0 | 7 | 11 | 14 | 3 |

| 4 | Multiscale fractured modeling and simulation of coupled thermo-hydromechanical processes in rocks for geothermal systems | 0 | 0 | 0 | 0 | 6 | 5 |

| 5 | Power-to-X technologies based on renewable energy sources | 13 | 16 | 23 | 48 | 44 | 68 |

| 6 | High-energy density lithium metal batteries | 55 | 92 | 60 | 57 | 17 | 1 |

| 7 | Research on hydrogen production process route and critical material by nuclear energy | 52 | 46 | 44 | 21 | 7 | 4 |

| 8 | Critical technology in geological disposal of high-level radioactive waste | 55 | 42 | 51 | 58 | 71 | 110 |

| 9 | Drilling speed prediction model based on artificial neural networks | 1 | 5 | 8 | 4 | 9 | 10 |

| 10 | Characteristics and effects of reservoir stimulation in hydraulic fracturing | 12 | 28 | 29 | 32 | 24 | 37 |

| 11 | Theoretical research on quality enhancement and efficiency improvement in the development of oil and gas in complex deepwater geological formations | 16 | 20 | 11 | 25 | 21 | 21 |

| 12 | Advancements in deep rock mechanics modeling for safe and efficient underground mining | 1 | 3 | 6 | 7 | 10 | 3 |

(1) Research on direct hydrogen production from seawater

Direct hydrogen production from seawater is a technology that directly decomposes seawater into hydrogen and oxygen without pretreatment processes like desalination. However, due to the extremely complex composition of seawater (up to 92 chemical elements), it faces many challenges such as chlorination, membrane clogging and corrosion. Since the concept of direct seawater electrolysis was proposed in 1975, the four major paths of direct seawater electrolysis for hydrogen production have still been the main focus internationally for half a century. One is direct seawater electrolysis by developing catalysts, through improving electrochemical activity, introducing selective site or constructing protective coatings to avoid the competition between chlorination and oxygen precipitation reactions. The second is direct seawater electrolysis based on asymmetric electrolyte, which is achieved by adding a pure electrolyte at the anode side and seawater at the cathode side. The third is to isolate the purity ions via the hydrophilic reverse osmosis membrane. The last is seawater electrolysis based on physical mechanics, through the construction of a gas-liquid phase interface between seawater and electrolyte, and the use of the difference in saturated vapor pressure between the two as the mass transfer driving force, inducing the seawater in the form of gaseous water migration across the membrane to the electrolyte, completely isolating seawater ions and at the same time realizing the seawater without desalination process, side reactions, additional energy consumption of the seawater for the purpose of direct hydrogen production. The development of direct seawater electrolysis technology for hydrogen production will help promote the global emerging strategic industry of “offshore wind power and other renewable energy utilization— seawater hydrogen production”.

(2) Mechanism of high temperature superconductor (HTS) material in compact fusion reactor

Controlled fusion energy is an ideal clean energy resource for the future, and the most likely method for realizing controlled thermonuclear fusion at present is magnetic confinement fusion. Tokamak are considered to be the most promising magnetic confinement devices for realizing controlled nuclear fusion, and superconducting magnets are one of the key components of tokamak devices. Conventional tokamak devices use low-temperature superconducting magnets. In order to obtain a high fusion energy gain and fusion power density, the devices are often built very large, which increases the cost of the device. With the development of superconducting material technology, second-generation high-temperature superconducting materials have higher temperature margins, current densities, and critical magnetic fields compared to low-temperature superconducting materials. These characteristics promote the birth of more compact, higher magnetic field of high-temperature superconducting magnets. The breakthrough in high-temperature superconducting magnet technology has formed a new compact fusion reactor technology route, which not only greatly reduces the cost, but also dramatically shortens the research and development cycle. MIT Technology Review named the compact fusion reactor as one of the top ten breakthrough technologies in 2022. Internationally representative are the SPARC device from Massachusetts Institute of Technology (MIT) in the USA and the STEP device from Karam Fusion Energy Center in the UK, both of which are currently in the conceptual design stage.

(3) Detecting method of remote sensing image change for energy resources

Remote sensing imaging change detection is the use of multi-source remote sensing images and related geographic spatial data covering the same surface area at different times, in combination with corresponding features and remote sensing imaging mechanisms, in order to determine and analyze the changes in the features of the region through the image and graphic processing theory and mathematical modeling methods, including changes in the location and scope of the features, as well as changes in their properties and states.

In the initial stage, medium and low resolution remote sensing images were used. With the improvement of spatial resolution of remote sensing images, the differences in spatial texture representations of the same ground objects become larger, and the features of the ground objects become more complex and diverse. Traditional change detection methods are no longer sufficient to meet the needs. Hyperspectral image change detection and high-resolution image change detection have become important fields of change detection.

Modern information technologies such as remote sensing big data, the Internet, artificial intelligence (AI), and cloud computing are thriving, driving the rapid transformation and upgrading of remote sensing monitoring technology models. Utilization of existing data and computing resources, surface normalization and intelligent monitoring, and timely and efficient acquisition of land feature change information has become one of the current research hotspots. Future research trends include application scene change detection, construction and application of a dedicated sample set for large-scale change detection, and information mining of multi-source data.

(4) Multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems

Multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems study refers to the investigation of the thermal, hydrological, and mechanical interactions of rocks within geothermal systems by integrating multiple spatial and temporal scales. This simulation-based research aims to gain a deeper understanding of the impacts of geothermal energy extraction and subsurface water flow on geological fault zones and rock properties, with the ultimate goal of enhancing efficient geothermal resource development and environmental management.

The primary research directions are as follows: ① micro-scale research focuses on the microscopic characteristics of rock, including pore structure, mineral composition, thermal conductivity, and interactions between rocks and fluids; ② at the mesoscale, the research involves simulating the thermal-hydro-mechanical behavior of small-scale rocks, revealing relationships between fluid seepage, heat transfer, and mechanical responses within geothermal systems; and ③ macro-scale investigations explore the thermo-hydro-mechanical coupling behavior of rocks across the entire geothermal system, considering the influence of geological structures and groundwater flow on geothermal resources. Cross-scale simulations integrate information from different scales to provide comprehensive guidance for geothermal energy development.

With the advancement of computational capabilities and interdisciplinary collaboration, multiscale fractured simulation of the thermo-hydro-mechanical coupling processes in geothermal system rocks are expected to progress further. This will be reflected in ① more refined and efficient simulation methods utilizing new numerical algorithms, artificial intelligence, and other technologies to achieve more accurate simulation results; ② increased importance of data-driven simulation methods, optimizing numerical models utilizing real monitoring data to improve predictive accuracy, placing more emphasis on coupling effects, considering the mutual influences of factors such as temperature, pressure, and fluid transport; and ③ enhanced interdisciplinary cooperation, incorporating expertise from fields such as geology, hydrology, and geophysics into simulation studies.

(5) Power-to-X technologies based on renewable energy sources

Power-to-X technology is the use of green electricity generated from renewable energies (solar, wind, hydro, etc.) to produce green hydrogen, green methanol, green ammonia, and other products. This emerging technology can realize the transformation of intermittent renewable energies into storable chemical energy, thus contributing to the large-scale storage of renewable electricity. Meanwhile, Power-to-X enables linking renewable energies to industry, transportation, energy and power sectors. Therefore, it provides a suitable solution for the global economy decarbonization and for the provision of non-fossil fuel products.

At present, water electrolysis toward hydrogen is the key field of Power-to-X technology. Meanwhile, coupling green hydrogen with CO2 and/or N2 can provide a wealth of products. The direct conversion of H2O with CO2 and/or N2 toward green methanol, green ammonia, and other products is also an active field of Power-to-X technolog. Of note, co-electrolysis of H2O/CO2 toward syngas, in combination with distributed micro-Fischer-Tropsch process holds a grand promise for generating carbon-neutral fuels and chemicals. Biomass and bio-derived platform molecules are one family of abundant renewable resources on earth with diverse molecular framework, active functional groups, and flexible molecular tailorability compared with CO2 and N2. Thus, it is a suitable object for green electricity processing. Moreover, biomass-based products are perfectly compatible with the economic system. Therefore, the Power-to-X technology coupled with biomass conversion has a great potential in carbon- neutral economy.

Breaking the key scientific and technological bottlenecks of the whole chain of material-electrode-electrolyzer-system, improving the energy conversion efficiency and the economic value of the products, and optimizing the linking method between the Power-to-X technology and the industrial, transportation and energy and power sectors is at the core of this grand topic.

(6) High-energy density lithium metal batteries

As an anode in second batteries, lithium (Li) metal has a very high theoretical specific capacity of 3 860 mAh/g and the lowest redox potential. Thus, it is the ultimate choice of anode material for high energy second batteries. In the 1970s attempts were made to use metallic Li as the anode in rechargeable batteries. However, it was found that Li dendrites were easily formed during charging (i.e., electrochemical deposition of Li), which could pierce the separator film and cause internal short-circuit, leading to thermal runaway and combustion explosion. In addition, Li dendrites could fracture to result in Li pulverization that will enhance the reactivity and safety risk. These fatal flaws block the commercialization of Li metal second batteries. Then, more attention was paid to Li+ intercalation anode materials. Finally, lithium-ion batteries based on graphite anodes entered the market in 1991. With the rapid development of electric vehicles and energy storage in the recent 10 years, second batteries with a higher energy density are demanded, and Li metal second batteries have come into sight again. Li-S battery and other new systems with an energy density above 400 Wh/kg have been intensively investigated. Nevertheless, two major problems of Li dendrite growth and low cycling efficiency related to Li metal anode still need to be solved. Optimization of the current collector structure, modification of the anode surface and use of Li metal composites can effectively suppress Li dendrite growth. Moreover, the electrochemical performance of Li metal anode is strongly dependent on the paired electrolytes. The optimization of liquid electrolyte compositions can improve the property of solid-electrolyte interphase layer, and in turn, suppress Li dendrite growth and enhance the Coulombic efficiency. In particular, the use of organic/inorganic composite electrolytes or inorganic electrolytes is expected to fundamentally solve the problems of Li metal anode. With the continuous emergence of new materials and the optimization of cell structures and charging mode, the practical application of Li metal second batteries might be realized.

(7) Research on hydrogen production process route and critical material by nuclear energy

As a secondary energy, hydrogen is an energy carrier or energy flow. The combination of nuclear energy and hydrogen energy will basically clean the whole process of energy production and utilization. The use of nuclear power to provide electricity for hydrogen production by electrolysis of water is one of the ways of hydrogen production by nuclear energy. At present, the main problem of hydrogen production from water electrolysis is the high energy consumption and low efficiency. If hydrogen production by electrolytic water in nuclear power is conducted during the low power consumption, the power grid resources can be rationally utilized and the cost of hydrogen production can be reduced. The high temperature generated by the nuclear fission process in the reactor has been extensively studied for direct use in thermal-chemical hydrogen production. Compared with hydrogen production by electrolytic water, the thermochemical process has a higher efficiency and a lower cost.

The principle and typical process of thermal-chemical hydrogen production is based on the thermochemical cycling, which catalyzes the thermal decomposition of water at 800–1 000 ℃ to produce hydrogen and oxygen. More than 100 thermochemical cycles have been developed. One of the keys to this method is to provide low-cost high-temperature heat sources. In recent years, the high temperature generated by nuclear fission in the reactor is an active research topic in the international nuclear engineering field, which may become a new application field of nuclear energy in the future. Hydrogen production by thermochemical process includes biomass thermochemical hydrogen production, thermochemical iodine-sulfur cycle hydrogen production, high temperature solid oxide electrolytic hydrogen production, methane (high temperature) reforming hydrogen production, of which the iodine-sulfur thermochemical cycle process is considered to be a more promising process. Thermal hydrogen production first requires the reactor to provide a high temperature of 750–1 000 ℃ . The cross-contamination of the nuclear system and the hydrogen production system during heat exchange must be prevented. The international roadmap for the 4th generation nuclear energy system (Gen IV) fully considers the issue of nuclear energy hydrogen production. In the recommended six nuclear energy systems, in addition to the very high temperature gas cooled reactor (VHGR) which mainly produces hydrogen, gas-cooled fast reactor (GFR), lead-cooled fast reactor (LFR), and molten-salt reactor (MSR) give consideration to both power generation and hydrogen production.

(8) Critical technology in geological disposal of high-level radioactive waste

High-level radioactive waste refers to the high-level waste liquid and its solidified body generated from the reprocessing of spent fuel in nuclear reactors. According to the classification of radioactive waste in China, high-level radioactive waste is divided into two categories: high-level liquid waste and high-level solid waste. High-level radioactive waste is a special waste that is highly radioactive, highly toxic, with long half-life nuclides and heat, which is extremely difficult to be safely dispose of, posing a series of scientific, technical, engineering, humanistic and sociological challenges. The internationally widely adopted feasible solution is deep geological disposal, that is, the high-level waste is buried in the geological body 500–1 000 m deep from the surface, so that it is permanently isolated from the human living environment. The underground works where high-level radioactive waste is buried are called “high-level radioactive waste disposal repositories”. Through the construction of an underground laboratory for high- level waste disposal, with the underground laboratory as a platform, many countries have determined the disposal site, developed a complete disposal theory and technical system, and entered the construction/preparation stage of the disposal repository. Finland received a permit for the construction of the repository in November 2015 and began construction in 2016; Sweden and France obtained permits for the construction of repositories; The USA allocated funds to restart the Yucca Mountain project in 2017. On May 6, 2019, with the consent of the State Council of the People’s Republic of China, the Bureau of Science, Technology and Industry for National Defense officially approved the underground laboratory construction project, which is a milestone for the geological disposal of high-level radioactive waste in China.

Major scientific issues to be addressed for the safe disposal of high-level waste include accurate prediction of the geological evolution of the disposal site, the characteristics of deep geological environment, the behavior of deep rock mass, groundwater and engineering materials under multi-field coupling conditions (medium-high temperature, ground stress, hydraulic action, chemical action and radiation action), the geochemical behavior of low-concentration transuranic radionuclides and their migration with groundwater, and the safety evaluation of disposal systems under ultra-long time scales, etc.

(9) Drilling speed prediction model based on artificial neural networks

The artificial intelligence-based drilling rate prediction model is a method that employs machine learning and data analysis techniques to forecast drilling rates in oil and gas drilling operations. This model analyzes various factors such as historical drilling data, geological information, drilling parameters, and applies artificial intelligence algorithms such as neural networks, decision trees, and support vector machines to construct a predictive model, providing decision-making support for drilling operation planning and optimization. Its research directions primarily encompass data collection, feature engineering, algorithm modeling, and model optimization. It requires the collection of a substantial amount of historical drilling data, extraction of features relevant to drilling rates, selection of appropriate algorithms for building predictive models, and iterative optimization to enhance accuracy and stability. With the continuous advancement of data technology and artificial intelligence, coupled with the increasing diversity and real-time nature of data, the gradual integration of information from other fields, and the application of automation technology, the model will become more accurate and reliable, offering real-time, comprehensive, and precise drilling rate prediction results.

(10) Characteristics and effects of reservoir stimulation in hydraulic fracturing

Hydraulic fracturing technology is the process of injecting fracturing fluid, which contains various additives, into the reservoir at a high pressure, utilizing the natural or induced fracture system of the reservoir. This process enlarges the fracture network of the reservoir and prevents the fractures from closing after the fracturing fluid is withdrawn, with the help of proppants such as sand or ceramic particles. As a result, the shale gas can continuously release and transport to the surface. China began studying the hydraulic fracturing technology in the 1950s. After years of exploration and reference, the first field test of hydraulic fracturing in shale gas wells was conducted in China from 2009 to 2011, marking the beginning of theoretical research and field application of shale gas fracturing. In 2012, Jiaoye 1 HF Well in Fuling Shale Gas Field achieved high production through hydraulic fracturing, indicating the localization of the fracturing technology in China. Since then, with the steady development of the fracturing technology, the total number of shale gas fracturing wells in China has reached 1 092 by 2020, and shale gas production has been increasing year by year. In 2020, the national shale gas production reached 200.4×108 m3.

From the point of view of the total degree of reservoir reconstruction, the early implementation of the fracturing technology in China mainly includes the conventional staged multi-cluster fracturing technology, the synchronous fracturing technology, the zipper fracturing technology, the repeated fracturing technology, and so on. The staged multi-cluster fracturing technology is the leading technology of shale gas fracturing. With the in-depth development of shale gas development, to improve the transformation effect, especially the transformation volume and fracture network complexity of deep shale gas, the dense cluster forced sand fracturing technology has been developed since 2018. In the process of implementing this technology, to control the equilibrium degree of fractures, the temporary plugging fracturing technology and the non-uniform perforation fracturing technology have been developed to achieve adequate control of fracture extension uniformity.

(11) Theoretical research on quality enhancement and efficiency improvement in the development of oil and gas in complex deepwater geological formations

Generally, oil and gas resources in marine areas with a water depth exceeding 300 meters are generally classified as deepwater oil and gas. Deepwater oil and gas resources are abundant with significant potential, offering extensive prospects for exploration, development, and reservoir enhancement. Deepwater have emerged as a crucial replacement area for oil and gas reserves and production due to their substantial quantities. However, the lifespan of platforms limits deepwater oil and gas development, necessitating the achievement of stable and high production within a constrained timeframe. Quality enhancement and efficiency improvement of oil and gas development is urgently required. Over 70% of global oil and gas resources are located in the oceans, with 40% originating from deepwater sources. Of the 101 newly discovered large oil and gas fields in the past decade, 67% are deepwater fields accounting for 68% of the reserves. China’s current deepwater oil and gas production has reached tens of millions of tons, marking significant progresses. Nevertheless, China’s deepwater oil and gas exploration and development still remain in the preliminary stage. Complex reservoir origins, exploration, characterization, drilling and completion, and production challenges, coupled with heavy reliance on foreign materials and equipment, hinder further progress. Therefore, there is a pressing need to formulate theories for quality enhancement and efficiency improvement of oil and gas development in China’s complex deepwater geological formations. Key research areas include geological exploration methods, refined characterization techniques, safe drilling and completion technologies, research for supportive materials and equipment, and efficient production methods. Active exploration of novel approaches, development of new technologies, materials, and equipment, establishment of theoretical frameworks for quality enhancement and efficiency improvement of complex deepwater oil and gas development, and the formulation of scientifically reasonable development models hold the potential to significantly contribute to national energy security.

(12) Advancements in deep rock mechanics modeling for safe and efficient underground mining

Advancements in deep rock mechanics modeling for safe and efficient underground mining refers to the application of advanced mechanical models and numerical simulation techniques to study the mechanical behaviors of rocks, such as deformation, fracturing, and stress distribution, in deep underground mining, in order to predict and assess geological hazards like rock instability and collapses that might occur. This research provides scientific guidance for safe and efficient mining practices.

In the domain of safe and efficient deep underground mining rock mechanics modeling, the main research directions encompass the following vital areas: ① constitutive modeling of rocks explores the deformation characteristics of different rock types under extreme conditions like high pressure and temperature, providing accurate numerical descriptions of rock deformation behaviors during mining; ② studies on mechanical behavior of porous rock masses concern the influence of groundwater flow on rock mechanics and the response of rock-water coupling within porous media during extraction; and ③ studies on multiscale modeling utilize cross-scale simulations to reveal rock mechanics responses from micro to macro scales.

With the rapid advancement of the computer technology, rock mechanics modeling for safe and efficient deep underground mining is becoming more refined and accurate. This will be reflected in: ① models considering nonlinearities, anisotropy, and damage characteristics of rocks in greater detail to enhance simulation accuracy; ② deeper investigations into coupling effects, encompassing factors such as groundwater flow, temperature, and stress in simulations, leading to more comprehensive predictions of rock mechanics responses; and ③ increased application of artificial intelligence and machine learning techniques for optimizing model parameters, accelerating simulation processes, and improving simulation efficiency. As the depth of deep mining operations increases, rock mechanics modeling will also focus on studying mechanical behaviors at even deeper underground levels.

《1.2 Interpretations for four key engineering research fronts》

1.2 Interpretations for four key engineering research fronts

1.2.1 Research on direct hydrogen production from seawater

Water electrolysis highly relies on freshwater resources, while the shortage of freshwater resources seriously restricts the development of hydrogen production. Ocean is the largest hydrogen source on earth, and obtaining sea water to produce “green hydrogen” is an important strategic direction for future scientific and industrial development. However, the composition of seawater is extremely complex, involving 92 chemical elements, many microorganisms, solid impurities, etc. Its lower conductivity and large fluctuations easily lead to side reactions, catalyst deactivation, and membrane clogging, and other issues in the electrolysis process, which poses a great challenge to the high performance, stability, high efficiency, and compatibility of the electrolysis system.

Desalination followed by hydrogen production is the most mature seawater hydrogen production technology path and has been conducted in China and abroad in large-scale demonstration projects. However, this type of technology relies heavily on large-scale desalination equipment, and the process is complex and occupies a large amount of land resources, which further pushes up the cost of hydrogen production and the difficulty of engineering construction. Since the concept of direct seawater hydrogen production was proposed in 1975, the four major paths of direct seawater electrolysis for hydrogen production have still been the main focus internationally for half a century. Of the four major paths, catalyst engineering is currently the most traditional and conventional way to solve the challenge of seawater hydrogen production, mainly through the improvement of electrochemical activity, the introduction of selective sites, and the construction of protective coatings to avoid the competition between chlorination and oxygen precipitation reactions. The second path is direct hydrogen production from seawater based on asymmetric electrolyte, which is achieved by adding a single, pure electrolyte at the anode side and seawater at the cathode side. The third path is based on membrane isolation, which excludes impurity ions in seawater by utilizing the in-situ membrane screening method of hydrophilic reverse osmosis. The last path is based on the phase change migration of physical mechanics, through the construction of a gas-liquid phase interface between seawater and electrolyte, and the use of the difference in saturated vapor pressure between the two as the mass transfer driving force, inducing the seawater in the form of gaseous water migration across the membrane to the electrolyte, completely isolating seawater ions and at the same time realizing direct hydrogen production without the desalination process, side reactions, additional energy consumption of seawater. This pathway has been validated in the world’s first offshore wind power seawater direct electrolysis hydrogen production sea trial on May 27, 2023 in Xinghua Bay, Fujian Province in China.

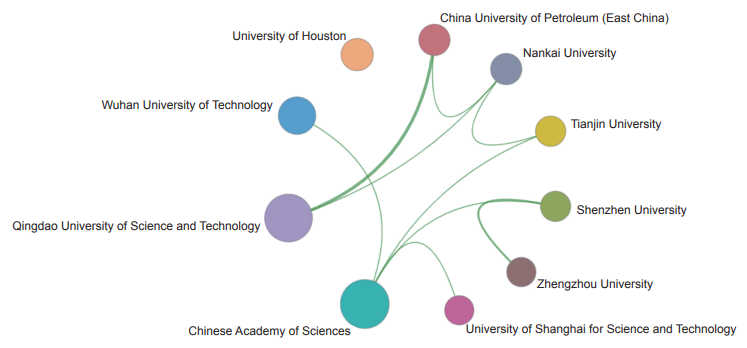

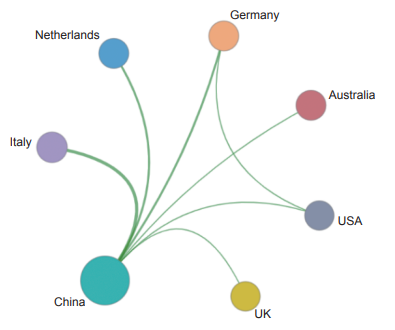

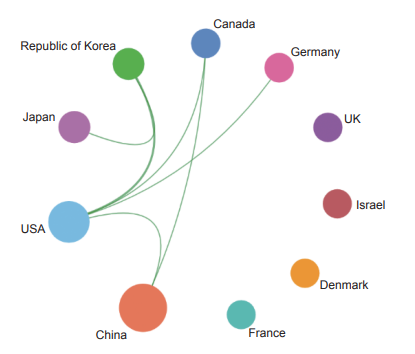

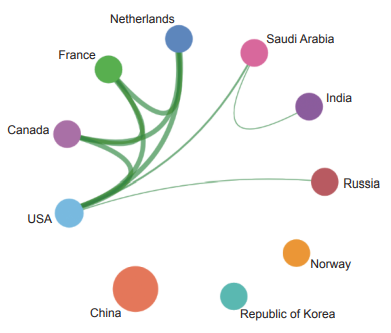

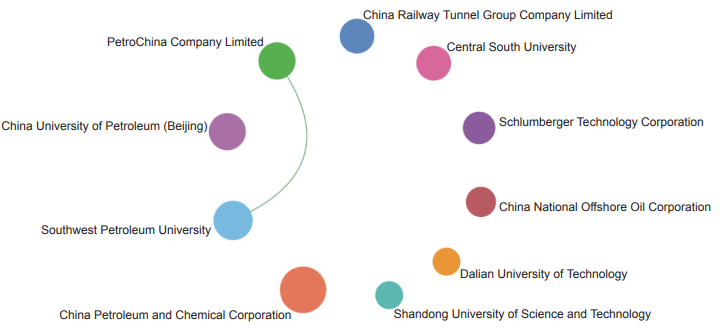

In the engineering research front of “research on direct hydrogen production from seawater”, the countries with the highest publication of core papers and the average citations per paper are China and the USA, respectively (Table 1.2.1), and there are lots of collaborations among China, the USA, and Australia (Figure 1.2.1). In the top ten institutions in terms of the number of papers published, Chinese Academy of Sciences and Qingdao University of Science and Technology rank top two, and the institutions with the highest citations per paper are University of Houston and Tianjin University (Table 1.2.2). There are many collaborations between China University of Petroleum (East China), Qingdao University of Science and Technology, Shenzhen University, and Zhengzhou University (Figure 1.2.2). Countries and institutions with the greatest output of citing papers are shown in Tables 1.2.3 and 1.2.4.

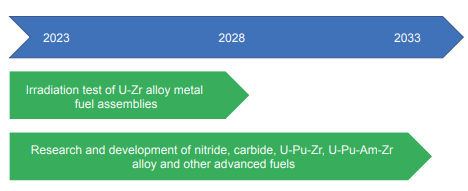

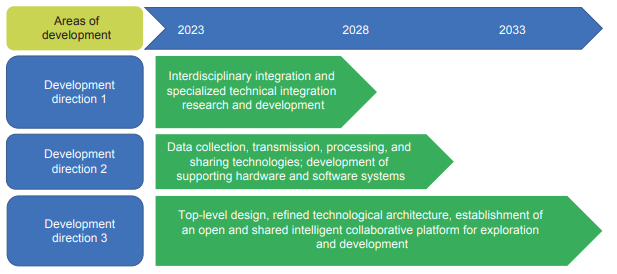

At present, the phase change migration of seawater direct electrolysis hydrogen production technology route has begun to take advantage, is expected to realize 100 Nm3/h H2 seawater hydrogen production system mass production by 2025, before 2028 to realize 1 000–3 000 Nm3/h H2 seawater hydrogen system mass production, before 2033 to realize the application scenario to the sewage, wastewater, and other non-pure water resources of the direct production of hydrogen on a large scale (Figure 1.2.3). Countries and institutions with the greatest output of citing papers are shown as Tables 1.2.3 and 1.2.4.

《Table 1.2.1》

Table 1.2.1 Countries with the greatest output of core papers on “research on direct hydrogen production from seawater”

| No. | Country | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | China | 249 | 54.73 | 7 803 | 31.34 | 2021.3 |

| 2 | USA | 79 | 17.36 | 3 432 | 43.44 | 2020.5 |

| 3 | Republic of Korea | 31 | 6.81 | 584 | 18.84 | 2021 |

| 4 | Australia | 25 | 5.49 | 1 162 | 46.48 | 2020.7 |

| 5 | Japan | 23 | 5.05 | 280 | 12.17 | 2020.2 |

| 6 | UK | 19 | 4.18 | 223 | 11.74 | 2020.7 |

| 7 | Germany | 15 | 3.3 | 939 | 62.6 | 2019.7 |

| 8 | Canada | 15 | 3.3 | 566 | 37.73 | 2020.5 |

| 9 | India | 15 | 3.3 | 262 | 17.47 | 2021.1 |

| 10 | Netherlands | 12 | 2.64 | 516 | 43 | 2020.3 |

《Figure 1.2.1》

Figure 1.2.1 Collaboration network among major countries in the engineering research front of “research on direct hydrogen production from seawater”

《Table 1.2.2》

Table 1.2.2 Institutions with the greatest output of core papers on “research on direct hydrogen production from seawater”

| No. | Institution | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | Chinese Academy of Sciences | 28 | 6.15 | 632 | 22.57 | 2021 |

| 2 | Qingdao University of Science and Technology | 27 | 5.93 | 318 | 11.78 | 2021.8 |

| 3 | Wuhan University of Technology | 17 | 3.74 | 435 | 25.59 | 2021.5 |

| 4 | University of Houston | 12 | 2.64 | 1 703 | 141.92 | 2021 |

| 5 | China University of Petroleum (East China) | 11 | 2.42 | 244 | 22.18 | 2021.5 |

| 6 | Nankai University | 11 | 2.42 | 213 | 19.36 | 2021.5 |

| 7 | Tianjin University | 10 | 2.2 | 467 | 46.7 | 2020.9 |

| 8 | Shenzhen University | 10 | 2.2 | 198 | 19.8 | 2021.4 |

| 9 | Zhengzhou University | 9 | 1.98 | 155 | 17.22 | 2021.8 |

| 10 | University of Shanghai for Science and Technology | 9 | 1.98 | 60 | 6.67 | 2021.7 |

《Figure 1.2.2》

Figure 1.2.2 Collaboration network among major institutions in the engineering research front of “research on direct hydrogen production from seawater”

《Table 1.2.3》

Table 1.2.3 Countries with the greatest output of citing papers on “research on direct hydrogen production from seawater”

| No. | Country | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | China | 561 | 57.54 | 2020.4 |

| 2 | USA | 119 | 12.21 | 2020 |

| 3 | Australia | 56 | 5.74 | 2020.3 |

| 4 | Republic of Korea | 54 | 5.54 | 2020.3 |

| 5 | Germany | 35 | 3.59 | 2020.3 |

| 6 | UK | 33 | 3.38 | 2020.4 |

| 7 | Singapore | 28 | 2.87 | 2020.2 |

| 8 | Japan | 25 | 2.56 | 2020.3 |

| 9 | Iran | 23 | 2.36 | 2019.8 |

| 10 | Canada | 22 | 2.26 | 2020.4 |

《Table 1.2.4》

Table 1.2.4 Institutions with the greatest output of citing papers on “research on direct hydrogen production from seawater”

| No. | Institution | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | Chinese Academy of Sciences | 77 | 26.55 | 2020.1 |

| 2 | Soochow University | 27 | 9.31 | 2020 |

| 3 | Tsinghua University | 24 | 8.28 | 2020.5 |

| 4 | Hunan University | 24 | 8.28 | 2020.4 |

| 5 | Zhengzhou University | 23 | 7.93 | 2020.6 |

| 6 | Tianjin University | 21 | 7.24 | 2020.3 |

| 7 | Wuhan University of Technology | 21 | 7.24 | 2020.4 |

| 8 | Beijing University of Chemical Technology | 19 | 6.55 | 2020.3 |

| 9 | University of Science and Technology of China | 18 | 6.21 | 2020.4 |

| 10 | Qingdao University of Science and Technology | 18 | 6.21 | 2020.4 |

《Figure 1.2.3》

Figure 1.2.3 Roadmap of the engineering research front of “research on direct hydrogen production from seawater”

1.2.2 Mechanism of high temperature superconductor (HTS) material in compact fusion reactor

Fusion energy is clean, safe, and relatively abundant, which is the ideal energy source that is most likely to fundamentally solve the future energy crisis. Tokamak devices are considered to be the most promising magnetic confinement devices for the realization of controlled nuclear fusion. A superconducting magnet is one of the key components of a tokamak device, providing the poleward and ringward magnetic fields that generate and confine the plasma to realize fusion. In tokamak devices, the fusion energy gain and fusion power density have a scalar relationship with the toroidal magnetic field, and the central toroidal magnetic field of magnets utilizing traditional low-temperature superconducting materials can only reach about 7 T, such as the EAST of China, the JT-60SA of Japan, the JET of the UK, and the International Thermonuclear Experimental Reactor (ITER) of international cooperation. With the development of superconducting material technology, the second generation high- temperature superconducting materials have higher temperature margins, current densities, and critical magnetic fields compared to low-temperature superconducting materials. These properties have led to the creation of more compact high- temperature superconducting magnets with higher magnetic fields. Since the cost of a tokamak device is approximately cubic to the large radius of the device, the high-temperature superconducting magnet technology can effectively reduce the overall cost of the fusion device, which plays an important role in further promoting the application of fusion energy in the future. At present, British Tokamak Energy has completed the preparation of the ST25-HTS device, which confirms the feasibility of combining tokamak and high-temperature superconducting materials. In the next five years, MIT plans to use high-temperature superconducting materials to complete a SPARC demonstration device with a center ring magnetic field greater than 12 T, a power gain coefficient Q greater than 2, and a fusion energy greater than 50 MW. Compact high-temperature superconducting tokamak utilizing high-temperature superconducting magnets has become an important research direction for future controlled fusion technology.

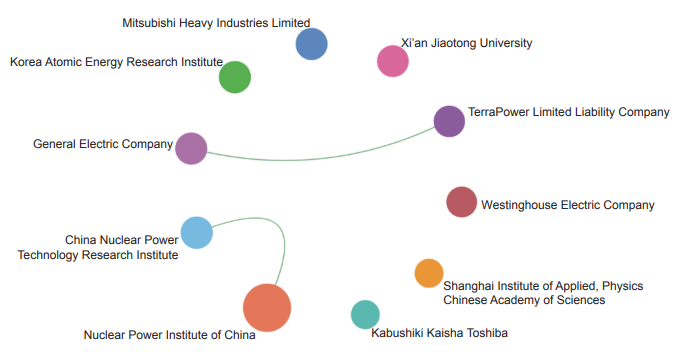

In the research front of “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”, the top three countries in terms of the number of core papers published are China, the USA, and Japan. The top three countries in terms of the citations per paper are the USA, Republic of Korea, Switzerland, and Russia (Table 1.2.5). In the top ten countries, China has more cooperation with the USA, and Germany has more cooperation with Switzerland (Figure 1.2.4). In the top ten institutions in terms of the number core paper published, Chinese Academy of Sciences, University of Science and Technology of China, and MIT are the top three, and the top three institutions with the highest citations per paper are MIT, University of Colorado, and Princeton Plasma Physics Laboratory (Table 1.2.6). In the top ten institutions, there are more collaborations between Chinese Academy of Sciences and University of Science and Technology of China (USTC), and more collaborations between the National Institute for Fusion Science (NIFS) and Tohoku University (Tohoku, Japan) (Figure 1.2.5). The main output

《Table 1.2.5》

Table 1.2.5 Countries with the greatest output of core papers on “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

| No. | Country | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | China | 130 | 27.78 | 959 | 7.38 | 2020 |

| 2 | USA | 116 | 24.79 | 2 238 | 19.29 | 2019.9 |

| 3 | Japan | 72 | 15.38 | 994 | 13.81 | 2019.6 |

| 4 | Germany | 44 | 9.4 | 565 | 12.84 | 2019.7 |

| 5 | Italy | 41 | 8.76 | 379 | 9.24 | 2020 |

| 6 | Switzerland | 40 | 8.55 | 677 | 16.93 | 2020 |

| 7 | UK | 30 | 6.41 | 350 | 11.67 | 2020.2 |

| 8 | Republic of Korea | 25 | 5.34 | 456 | 18.24 | 2019.5 |

| 9 | France | 22 | 4.7 | 271 | 12.32 | 2019.5 |

| 10 | Russia | 18 | 3.85 | 301 | 16.72 | 2019.8 |

《Figure 1.2.4》

Figure 1.2.4 Collaboration network among major countries in the engineering research front of “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

《Table 1.2.6》

Table 1.2.6 Institutions with the greatest output of core papers on “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

| No. | Institution | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | Chinese Academy of Sciences | 87 | 18.59 | 517 | 5.94 | 2020 |

| 2 | University of Science and Technology of China | 42 | 8.97 | 234 | 5.57 | 2020.2 |

| 3 | Massachusetts Institute of Technology | 29 | 6.2 | 1003 | 34.59 | 2019.6 |

| 4 | National Institute for Fusion Science | 27 | 5.77 | 173 | 6.41 | 2019.9 |

| 5 | Tohoku University | 22 | 4.7 | 204 | 9.27 | 2019.3 |

| 6 | Politecnico di Torino | 20 | 4.27 | 195 | 9.75 | 2020.1 |

| 7 | Karlsruhe Institute of Technology | 20 | 4.27 | 178 | 8.9 | 2019.7 |

| 8 | Princeton Plasma Physics Laboratory | 19 | 4.06 | 249 | 13.11 | 2020 |

| 9 | Lawrence Berkeley National Laboratory | 17 | 3.63 | 75 | 4.41 | 2020.8 |

| 10 | University of Colorado | 15 | 3.21 | 265 | 17.67 | 2020.9 |

《Figure 1.2.5》

Figure 1.2.5 Collaboration network among major institutions in the engineering research front of “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

countries of citing papers are China and the USA (Table 1.2.7), and the main output institutions of citing papers are Chinese Academy of Sciences, the USTC, and MIT (Table 1.2.8).

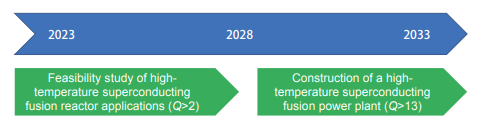

In the next ten years, compact fusion reactors built on an international scale utilizing high-temperature superconducting magnets include the SPARC device of MIT, a small-scale version of the planned fusion power plant. The successful operation of SPARC will prove that a full-scale commercially operated fusion power plant is feasible, and can be expected to be a zero-emission, unlimited energy source, clearing the way for the rapid design and construction of commercially available, controllable fusion power stations, clearing the way for the rapid design and construction of a commercial controllable fusion power plant, making fusion power the centerpiece of future clean energy and changing the future energy landscape of the world. After completing the feasibility study on the application of high-temperature superconducting fusion reactors, the construction of high-temperature superconducting fusion power stations will be conducted to realize fusion power generation (Figure 1.2.6).

《Table 1.2.7》

Table 1.2.7 Countries with the greatest output of citing papers on “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

| No. | Country | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | China | 1 120 | 29.11 | 2021 |

| 2 | USA | 828 | 21.52 | 2020.8 |

| 3 | Japan | 372 | 9.67 | 2020.7 |

| 4 | Germany | 332 | 8.63 | 2020.7 |

| 5 | UK | 246 | 6.39 | 2021 |

| 6 | Italy | 224 | 5.82 | 2020.9 |

| 7 | Republic of Korea | 166 | 4.32 | 2021 |

| 8 | France | 161 | 4.19 | 2020.8 |

| 9 | Switzerland | 150 | 3.9 | 2020.9 |

| 10 | Russia | 145 | 3.77 | 2021.1 |

《Table 1.2.8》

Table 1.2.8 Institutions with the greatest output of citing papers on “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

| No. | Institution | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | Chinese Academy of Sciences | 385 | 32.06 | 2021.1 |

| 2 | University of Science and Technology of China | 153 | 12.74 | 2021 |

| 3 | Massachusetts Institute of Technology | 129 | 10.74 | 2020.6 |

| 4 | Shanghai Jiao Tong University | 86 | 7.16 | 2021 |

| 5 | Oak Ridge National Laboratory | 82 | 6.83 | 2020.8 |

| 6 | National Institute for Fusion Science | 68 | 5.66 | 2020.4 |

| 7 | Lanzhou University | 64 | 5.33 | 2021.3 |

| 8 | Karlsruhe Institute of Technology | 61 | 5.08 | 2020.4 |

| 9 | Tsinghua University | 61 | 5.08 | 2020.6 |

| 10 | Seoul National University | 57 | 4.75 | 2021 |

《Figure 1.2.6》

Figure 1.2.6 Roadmap of the engineering research front of “mechanism of high temperature superconductor (HTS) material in compact fusion reactor”

1.2.3 Detecting method of remote sensing image change for energy resources

Change detection is an important direction in the research of remote sensing image processing and analysis methods. The core is to use remote sensing images from different periods at the same region to analyze the change status and correlation of land features. The utilization of remote sensing spectral information has undergone a process from black and white panchromatic images to multispectral, hyperspectral, and time series, while the change detection methods have also evolved from pixel based algebraic calculations to machine learning algorithms and multi method joint algorithms. For example, the traditional methods are to use time series for change detection, including classification, threshold, image transformation, model, etc. In recent years, with the continuous launch of remote sensing satellites equipped with high spatial resolution optical cameras and the widespread application of mobile and flexible drone remote sensing, the number, detection accuracy, and information integrity of remote sensing images have continuously improved. The frequency of obtaining data for the same area has also gradually increased, providing an important foundation for remote sensing image change detection. In this context, the “artificial intelligence plus remote sensing big data” model has become a common consensus in the construction of industry application systems in recent years. The main research directions include the effective extraction of joint features of “time space spectrum” in multi temporal hyperspectral images, high- precision change detection and calculation methods based on deep learning, and so on. High-precision and automated change detection methods have important practical and strategic significance for mineral resource exploration, national ecological environment protection, and marine environmental monitoring.

The International Society of Photogrammetry and Remote Sensing has established a separate working group for change detection for remote sensing imagery research for many years, dedicated to promoting the development of multi-field change detection utilizing the remote sensing technology. The U.S. National Geospatial-Intelligence Agency has also incorporated change detection for remote sensing imagery detection and analysis into strategic planning. China has also attached great importance to the application of the remote sensing change detection technology in the detection of geographical conditions. Since 2010, the Ministry of Land and Resources has been conducting national remote sensing detection work every year, utilizing change detection for multi-temporal remote sensing imagery technology to continuously update national land survey results.

In the engineering research front of “detecting method of remote sensing image change for energy resources”, the main producing country of core papers is China (35), accounting for 97.22% of the total, while other countries account for less than 10%. Italy (3) ranks second, accounting for 8.33% (Table 1.2.9). In terms of the main producing institutions of core papers (Table 1.2.10), China accounts for 8 of the Top 10 institutions. Among them, Wuhan University (13), Chinese Academy of Sciences (6), and Beihang University (4) rank top three. China (777) is also the main producer of citing papers, accounting for 67.80% of the total. The USA (82) ranks second, only accounting for 7.16% (Table 1.2.11). The top three major producing institutions for citing core papers are Wuhan University (125), Chinese Academy of Sciences (116), and Xi’an University (39) (Table 1.2.12). Cooperation in this field is dominated by China, with Italy, the USA, the Netherlands and other countries cooperating around China (Figure 1.2.7). Collaborative research between institutions is concentrated at Wuhan University, Chinese Academy of Sciences, Beihang University, Nanjing University of Information Science and Technology, and Central South University (Figure 1.2.8).

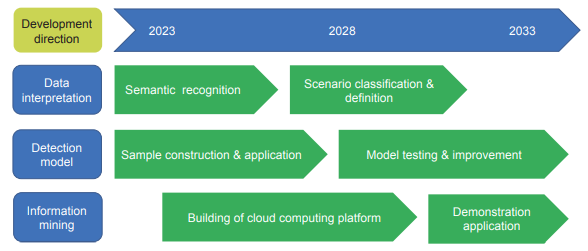

In the next 5–10 years, the detecting methods of remote sensing imaging change for energy resources will usher in a series of important development (Figure 1.2.9). The fusion of high-resolution and multi-spectral data will provide more accurate detection capabilities for resource change, including the application of the multi-source data fusion and hyperspectral technology. In addition, the popularization of machine learning and deep learning technologies will automate the analysis of remote sensing data and reduce the degree of manual intervention. Moreover, time-series data analysis will help better understand the trend and periodicity of resource change, and improve detection accuracy. The use of cloud computing and distributed computing resources will also increase the efficiency of data processing and analysis. These methods will play a key role not only in environmental monitoring, resource management, and climate change research, but also in areas such as smart city planning, sustainable development, precision agriculture, and forest resource management. With continuous development, the application of these detection methods for energy resources will become more extensive, providing more powerful tools for decision-making support and resource management.

《Table 1.2.9》

Table 1.2.9 Countries with the greatest output of core papers on “detecting method of remote sensing image change for energy resources”

| No. | Country | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | China | 35 | 97.22 | 2330 | 66.57 | 2020.3 |

| 2 | Italy | 3 | 8.33 | 193 | 64.33 | 2020.7 |

| 3 | Netherlands | 2 | 5.56 | 398 | 199 | 2019.5 |

| 4 | Germany | 2 | 5.56 | 54 | 27 | 2020 |

| 5 | Australia | 2 | 5.56 | 47 | 23.5 | 2020.5 |

| 6 | USA | 1 | 2.78 | 20 | 20 | 2020 |

| 7 | UK | 1 | 2.78 | 15 | 15 | 2021 |

《Table 1.2.10》

Table 1.2.10 Institutions with the greatest output of core papers on “detecting method of remote sensing image change for energy resources”

| No. | Institution | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | Wuhan University | 13 | 36.11 | 1 153 | 88.69 | 2020.1 |

| 2 | Chinese Academy of Sciences | 6 | 16.67 | 432 | 72 | 2019.2 |

| 3 | Beihang University | 4 | 11.11 | 312 | 78 | 2020.8 |

| 4 | Nanjing University of Information Science and | 3 | 8.33 | 256 | 85.33 | 2020.3 |

| 5 | Central South University | 3 | 8.33 | 179 | 59.67 | 2021 |

| 6 | Utrecht University | 2 | 5.56 | 398 | 199 | 2019.5 |

| 7 | China University of Mining and Technology | 2 | 5.56 | 138 | 69 | 2020 |

| 8 | Southwest Jiaotong University | 2 | 5.56 | 75 | 37.5 | 2021 |

| 9 | University of Trento | 2 | 5.56 | 63 | 31.5 | 2021 |

| 10 | Beijing Normal University | 2 | 5.56 | 28 | 14 | 2021 |

《Table 1.2.11》

Table 1.2.11 Countries with the greatest output of citing papers on “detecting method of remote sensing image change for energy resources”

| No. | Country | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | China | 777 | 67.8 | 2021.3 |

| 2 | USA | 82 | 7.16 | 2021.1 |

| 3 | Italy | 42 | 3.66 | 2021.3 |

| 4 | Germany | 41 | 3.58 | 2021.1 |

| 5 | Republic of Korea | 38 | 3.32 | 2021 |

| 6 | Canada | 35 | 3.05 | 2021.3 |

| 7 | UK | 34 | 2.97 | 2021.3 |

| 8 | Netherlands | 27 | 2.36 | 2020.7 |

| 9 | India | 26 | 2.27 | 2021.5 |

| 10 | France | 25 | 2.18 | 2020.7 |

《Table 1.2.12》

Table 1.2.12 Institutions with the greatest output of citing papers on “detecting method of remote sensing image change for energy resources”

| No. | Institution | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | Wuhan University | 125 | 26.54 | 2021.1 |

| 2 | Chinese Academy of Sciences | 116 | 24.63 | 2021.2 |

| 3 | Xidian University | 39 | 8.28 | 2021.1 |

| 4 | China University of Geosciences | 31 | 6.58 | 2021.4 |

| 5 | Nanjing University of Information Science and Technology | 30 | 6.37 | 2021.1 |

| 6 | Sun Yat-sen University | 27 | 5.73 | 2021.2 |

| 7 | Northwestern Polytechnical University | 23 | 4.88 | 2021.1 |

| 8 | University Trento | 23 | 4.88 | 2021.1 |

| 9 | Beihang University | 20 | 4.25 | 2021.2 |

| 10 | German Aerospace Center (DLR) | 19 | 4.03 | 2021.2 |

《Figure 1.2.7》

Figure 1.2.7 Collaboration network among major countries in the engineering research front of “detecting method of remote sensing image change for energy resources”

《Figure 1.2.8》

Figure 1.2.8 Collaboration network among major institutions in the engineering research front of “detecting method of remote sensing image change for energy resources”

《Figure 1.2.9》

Figure 1.2.9 Roadmap of the engineering research front of “detecting method of remote sensing image change for energy resources”

1.2.4 Multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems

Multiscale fractured modeling and simulation of coupled thermo-hydro mechanical processes in rocks for geothermal systems is a pivotal forefront in the interaction between geothermal energy utilization and geological environment. The research in this field aims to deeply understand the thermal, hydrological, and mechanical coupling behaviors of rocks within geothermal systems, providing a scientific foundation for geothermal resource development and management. Over the past few decades, significant progress has been made in this field due to advancements in numerical simulation, computational capabilities, and data monitoring technologies.

The history of research into the thermal-hydro mechanical coupled processes in fracture rocks for geothermal system can be traced back to the 1980s. Initially, the research mainly focused on single-scale experiments and theoretical models, exploring relationships between elements such as temperature, pressure, and water flow within geothermal systems. With the development of experimental equipment and computer technology, multiscale fractured experiments and simulation methods gradually came into play, enabling researchers to more comprehensively unveil the complex coupling behaviors of geothermal systems. In recent years, with the growing attention paid to deep geothermal resources, multiscale fractured simulation research has gained more significance in predicting and addressing challenges in geothermal energy development.

The thermal-hydro mechanical coupled behavior in geothermal systems profoundly impacts the efficiency and sustainability of geothermal energy utilization. Understanding the physical and chemical responses of rocks aids in optimizing geothermal energy production processes and reducing resource waste. Additionally, the fractured behavior of rocks in geothermal systems is closely related to underground water flow and geological hazards, bearing importance for groundwater resource management and geological disaster prevention.

Multiscale fractured simulation research encompasses several aspects: ① cross-scale simulations from micro to macro scales to deeply understand the thermal, hydrological, and mechanical interactions within rocks in geothermal systems; ② coupling experimental research and numerical simulations to validate the accuracy of simulation results; ③ development of efficient algorithms and simulation tools to enhance computational efficiency of multiscale simulations; and ④ application of real-time monitoring and data acquisition techniques to improve the accuracy of simulation models.

In the engineering research front of “multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems”, the main contributing countries are China, the USA, and Australia (Table 1.2.13 and Figure 1.2.10). The primary contributing institutions are Xi’an University of Technology, China University of Mining and Technology, Chengdu University of Technology, and Purdue University (Table 1.2.14). These four institutions have substantial collaboration (Figure 1.2.11). The top three countries in terms of citing papers are China, the USA, and Australia (Table 1.2.15). The main output institutions of citing core papers are China University of Mining and Technology, Xi’an University of and Technology, Henan Polytechnic University, Anhui University of Science and Technology, and Purdue University (Table 1.2.16).

The roadmap of the engineering research front of “multiscale fractured modeling and simulation of coupled thermo-hydro- mechanical processes in rocks for geothermal systems” is presented in Figure 1.2.12. The future development direction will center on following aspects. ① High-precision model construction, coupling effects study, and data-driven simulation. Future research on high-precision model construction will focus on more refined model construction, including inputting more accurate rock physical parameters, pore structures, and geological fracture characteristics. This will contribute to more realistic simulations of the complex thermal-hydro-mechanical coupling behaviors within geothermal systems. ② Coupled effects study will focus on the coupling effects between different scales and different physical processes, exploring the impact of rock thermal, hydrological, and mechanical interactions on geothermal system behaviors. ③ Data-driven simulation will integrate more actual monitoring data to validate model accuracy, optimize parameters, and enhance the reliability of simulation results.

The future development trend in “multiscale fractured modeling and simulation of coupled thermo-hydro mechanical processes in rocks for geothermal systems” will center on followings. ① Multi-physics field coupling: Beyond thermal-hydro mechanical coupling, future research will consider interactions between multiple physical fields such as chemistry and fluid flow, achieving more comprehensive geothermal system simulations. ② High-performance computing application: As computing capabilities improve, future simulation research will increasingly rely on high-performance computing to enable finer and more complex simulations for accurately predicting geothermal system behaviors.

Geothermal energy, as a sustainable form of clean energy, has tremendous potential. Multiscale simulation research contributes to a better understanding of geothermal resource distribution, variations, and sustainable utilization methods. This is crucial for improving development efficiency and reducing environmental risks associated with geothermal energy.

Multiscale fractured simulation research has broad applications in geothermal resource exploration, development, and

《Table 1.2.13》

Table 1.2.13 Countries with the greatest output of core papers on “multiscale fractured modeling and simulation of coupled thermo-hydro- mechanical processes in rocks for geothermal systems”

| No. | Country | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | China | 11 | 100 | 379 | 34.45 | 2021.5 |

| 2 | USA | 4 | 36.36 | 118 | 29.5 | 2021.2 |

| 3 | Australia | 1 | 9.09 | 65 | 65 | 2022 |

《Figure 1.2.10》

Figure 1.2.10 Collaboration network among major countries in the engineering research front of “multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems”

《Table 1.2.14》

Table 1.2.14 Institutions with the greatest output of core papers on “multiscale fractured modeling and simulation of coupled thermo- hydro-mechanical processes in rocks for geothermal systems”

| No. | Institution | Core papers | Percentage of core papers/% | Citations | Citations per paper | Mean year |

| 1 | Xi’an University of Technology | 8 | 72.73 | 348 | 43.5 | 2021.4 |

| 2 | China University of Mining and Technology | 5 | 45.45 | 221 | 44.2 | 2021.4 |

| 3 | Chengdu University of Technology | 4 | 36.36 | 156 | 39 | 2021.2 |

| 4 | Purdue University | 4 | 36.36 | 118 | 29.5 | 2021.2 |

| 5 | Henan Polytechnic University | 4 | 36.36 | 42 | 10.5 | 2021.5 |

| 6 | Monash University | 1 | 9.09 | 65 | 65 | 2022 |

| 7 | Beijing Research Institute of Uranium Geology (ALBRIUG) | 1 | 9.09 | 49 | 49 | 2021 |

| 8 | Hohai University | 1 | 9.09 | 49 | 49 | 2021 |

| 9 | Xi’an University of Science and Technology | 1 | 9.09 | 43 | 43 | 2021 |

| 10 | Xuzhou University of Technology | 1 | 9.09 | 23 | 23 | 2021 |

《Figure 1.2.11》

Figure 1.2.11 Collaboration network among major institutions in the engineering research front of “multiscale fractured modeling and simulation of coupled thermo-hydro-mechanical processes in rocks for geothermal systems”

《Table 1.2.15》

Table 1.2.15 Countries with the greatest output of citing papers on “multiscale fractured modeling and simulation of coupled thermo- hydro-mechanical processes in rocks for geothermal systems”

| No. | Country | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | China | 190 | 84.07 | 2021.9 |

| 2 | USA | 16 | 7.08 | 2021.8 |

| 3 | Australia | 8 | 3.54 | 2021.8 |

| 4 | Poland | 3 | 1.33 | 2022 |

| 5 | UK | 2 | 0.88 | 2022 |

| 6 | Japan | 2 | 0.88 | 2022 |

| 7 | Iran | 1 | 0.44 | 2021 |

| 8 | Russia | 1 | 0.44 | 2021 |

| 9 | India | 1 | 0.44 | 2021 |

| 10 | Portugal | 1 | 0.44 | 2022 |

《Table 1.2.16》

Table 1.2.16 Institutions with the greatest output of citing papers on “multiscale fractured modeling and simulation of coupled thermo- hydro-mechanical processes in rocks for geothermal systems”

| No. | Institution | Citing papers | Percentage of citing papers/% | Mean year |

| 1 | China University of Mining and Technology | 55 | 28.21 | 2021.8 |

| 2 | Xi’an University of Technology | 30 | 15.38 | 2021.8 |

| 3 | Henan Polytechnic University | 22 | 11.28 | 2021.7 |

| 4 | Anhui University of Science and Technology | 15 | 7.69 | 2021.9 |

| 5 | Purdue University | 14 | 7.18 | 2021.7 |

| 6 | Xi’an University of Science and Technology | 12 | 6.15 | 2021.9 |

| 7 | Chongqing University | 11 | 5.64 | 2021.9 |

| 8 | Xuzhou University of Technology | 11 | 5.64 | 2021.6 |

| 9 | Shandong University of Science and Technology | 11 | 5.64 | 2021.9 |

| 10 | Guizhou University | 8 | 4.1 | 2022 |

《Figure 1.2.12》

Figure 1.2.12 Roadmap of the engineering research front of “multiscale fractured modeling and simulation of coupled thermo-hydro- mechanical processes in rocks for geothermal systems”

management. In geothermal energy extraction processes, it can aid in predicting geothermal system behaviors, optimizing production plans, and reducing production risks. Furthermore, it can be applied to the study of interactions between geothermal energy, groundwater, and geological environments, as well as in designing integrated utilization schemes of geothermal energy and other energy forms.

《2 Engineering development fronts》

2 Engineering development fronts

《2.1 Trends in Top 12 engineering development fronts》

2.1 Trends in Top 12 engineering development fronts

The Top 12 engineering development fronts assessed by the Energy and Mining Engineering Group are shown in Table 2.1.1. These fronts involve the fields of energy and electrical science, technology, and engineering; nuclear science, technology, and engineering; geology resources science, technology, and engineering; and mining science, technology, and engineering. In these 12 engineering development fronts, “fast charging and management technology for batteries”, “long-term and large-scale thermal energy storage and thermo-mechanical energy storage technologies”, and “data-driven technology for security operation and monitoring system of intelligent power distribution networks” represent the engineering development front of energy and electrical science; “fast reactor metal fuels, nitride & carbide fuel and fuel cycles”, “deuterium tritium operation experiment of device Tokamak”, and “nuclear energy hydrogen production-industrial application coupling technology” represent the engineering development front of nuclear science, technology, and engineering; “exploration method for mineral deposits utilizing high- precision ground gravity measurement”, “seismic data interpretation and utilization based on deep learning”, and “research and development of portable geological exploration and sampling device” represent the engineering development front of geology resources science, technology, and engineering; “research on intelligent collaborative platform for oil and gas exploration and development”, “optimal and rapid drilling technology of long horizontal well on large platform in shale reservoir”, and “research and development of intelligent perception drilling detection equipment for coal mines under complex conditions” represent the engineering development front of mining science, technology, and engineering.

The disclosure of core patents involved in each development front from 2017 to 2022 is presented in Table 2.1.2.

(1) Fast charging and management technology for batteries

The capability of Li-ion/Na-ion batteries determines the competitiveness and performance of electric vehicles. The full charging time of the existing power battery is about 60 minutes, which is 20 times of the refueling time of the car. As a result, achieving fast-charging can enhance the market share and broaden applications of electric vehicles. The United States Advanced Battery Consortium has proposed specific indicators for power battery charging, requiring 80% of the total battery power to be charged within 15 min. However, due to the polarization from sluggish ion transport, fast-charging often causes metal plating at the anode side, leading to capacity decay and safety issues. Management technologies and battery material modification are two major strategies towards fast-charging. These strategies enhance the fast-charging capability of batteries by lowering the energy barrier of the rate-limiting step for the entire charging process. The aforementioned management technologies include battery intelligent temperature control system and algorithm optimized charging protocol, while material modification mainly focuses on electrode design, anode material, binder, electrolyte, and solid electrolyte interphase (SEI). Nevertheless, rate-limiting step of the entire charging process is hard to identify, and may varies with external conditions or cycling parameters, which makes strategies aiming at a single step less effective. Under this circumstance, it is necessary to switch from suppressing Li or Na plating to regulating Li or Na plating. Through a series of metal plating regulation methods such as SEI engineering, a uniformly-distributed, less-dendritic, and highly-reversible Li or Na plating at the anode side in fast-charging operations can be realized. This not only intrinsically solves safety problems from Li or Na dendrite plating, restoring the cycling life, but also increases the state of charge under fast-charging. Therefore, this Li or Na plating regulation as well as morphology control is one of the most important tendencies in future development of fast-charging, which is an important trend in the development of fast charging technology in the future.

《Table 2.1.1》

Table 2.1.1 Top12 engineering development fronts in energy and mining engineering

| No. | Engineering development front | Published patents | Citations | Citations per patent | Mean year |

| 1 | Fast charging and management technology for batteries | 464 | 15 925 | 34.32 | 2018.5 |

| 2 | Fast reactor metal fuels, nitride & carbide fuel and fuel cycles | 312 | 507 | 1.62 | 2019.9 |

| 3 | Exploration method for mineral deposits utilizing high-precision ground gravity measurement | 342 | 5 472 | 16 | 2018.5 |

| 4 | Research on intelligent collaborative platform for oil and gas exploration and development | 275 | 618 | 2.25 | 2020.4 |

| 5 | Long-term and large-scale thermal energy storage and thermomechanical energy storage technologies | 1 616 | 2 558 | 1.58 | 2020.1 |

| 6 | Data-driven technology for security operation and monitoring system of intelligent power distribution networks | 109 | 3 137 | 28.78 | 2019 |

| 7 | Deuterium tritium operation experiment of device Tokamak | 143 | 216 | 1.51 | 2020 |

| 8 | Nuclear energy hydrogen production-industrial application coupling technology | 142 | 181 | 1.27 | 2019.8 |

| 9 | Seismic data interpretation and utilization based on deep learning | 336 | 4 714 | 14.03 | 2019.1 |

| 10 | Research and development of portable geological exploration and sampling device | 872 | 497 | 0.57 | 2020.3 |

| 11 | Optimal and rapid drilling technology of long horizontal well on large platform in shale reservoir | 392 | 8 076 | 20.6 | 2018.6 |

| 12 | Research and development of intelligent perception drilling detection equipment for coal mines under complex conditions | 178 | 1 930 | 10.84 | 2019.8 |

《Table 2.1.2》

Table 2.1.2 Annual number of core patents published for the Top 12 engineering development fronts in energy and mining engineering

| NO. | Engineering development front | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 |

| 1 | Fast charging and management technology for batteries | 136 | 119 | 96 | 73 | 39 | 1 |

| 2 | Fast reactor metal fuels, nitride & carbide fuel and fuel cycles | 43 | 32 | 54 | 49 | 65 | 69 |

| 3 | Exploration method for mineral deposits utilizing high-precision ground gravity measurement | 92 | 94 | 70 | 56 | 26 | 4 |

| 4 | Research on intelligent collaborative platform for oil and gas exploration and development | 9 | 31 | 40 | 36 | 71 | 88 |

| 5 | Long-term and large-scale thermal energy storage and thermomechanical energy storage technologies | 178 | 210 | 219 | 225 | 319 | 465 |

| 6 | Data-driven technology for security operation and monitoring system of intelligent power distribution networks | 22 | 21 | 24 | 21 | 18 | 3 |

| 7 | Deuterium tritium operation experiment of device Tokamak | 14 | 18 | 25 | 21 | 27 | 38 |

| 8 | Nuclear energy hydrogen production-industrial application coupling technology | 24 | 21 | 17 | 15 | 26 | 39 |

| 9 | Seismic data interpretation and utilization based on deep learning | 51 | 68 | 86 | 70 | 56 | 5 |

| 10 | Research and development of portable geological exploration and sampling device | 51 | 101 | 82 | 176 | 237 | 225 |

| 11 | Optimal and rapid drilling technology of long horizontal well on large platform in shale reservoir | 104 | 84 | 103 | 52 | 47 | 2 |

| 12 | Research and development of intelligent perception drilling detection equipment for coal mines under complex conditions | 18 | 15 | 22 | 58 | 64 | 1 |

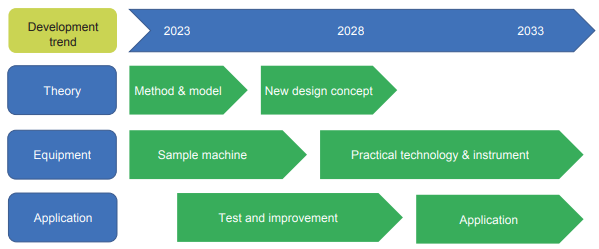

(2) Fast reactor metal fuels, nitride & carbide fuel and fuel cycles

There are two types of fast reactor fuel that have been used internationally, ceramic fuel and metal fuel. Fast reactor metal fuel, nitride and carbide fuel are being developed internationally. Such fuels have a higher breeding ratio than oxide fuels.

Metal fuel has the characteristics of high thermal conductivity, low fuel temperature, and high safety margin. The swelling can be inhibited by the improvement of material technology. Fast reactor metal fuel is recognized as one of the main types of fast reactor fuel in the future. The metal fuel manufacturing process is more simplified, and the metal fuel and dry reprocessing (separated metals are U and Pu) can better directly cooperate with the production of new fuels, forming an integrated fuel cycle system.

The research and development of metal fuel mainly focuses on U-Zr alloy and U-Pu-Zr alloy. The metal fuel usually consists of a binary alloy of U-10Zr alloys or a ternary alloy of U-Pu-10Zr. MAs is added to oxide fuel and metal fuel to become transmutation fuel.

Mixed plutonium-uranium nitride fuel and carbide fuel are new fuel forms under development. The plutonium uranium density of UPuN and UPuC is higher than that of oxide fuel, which can obtain a higher breeding ratio, a shorter breeding time, a better thermal conductivity, and an excellent compatibility with sodium coolant and stainless-steel cladding.

Many countries in the world have conducted the research and development and application of carbide and carbide fuel. The USA, France, Russia, India, and other countries have conducted research and development of a variety of carbides and carbide fuels. Russian Fast Reactor (in addition to MOX) fuel selected mixed nitride fuel (MNUP) as one of the future fast reactor fuel options. The experimental fast reactor FBTR in India uses carbide (Pu, U)C fuel.

(3) Exploration method for mineral deposits utilizing high-precision ground gravity measurement

Ground gravity measurement refers to the method of utilizing the gravimeter to measure the gravity at a certain point on the ground, and utilizing the change of underground density reflected by the gravity for mineral exploration. It is one of the important geophysical prospecting methods to conduct regional geological research, mineral exploration and resource investigation by analyzing the characteristics of relative gravity and absolute gravity.

The technology of ground gravity measurement has been greatly developed in China and abroad. Based on the idea of zero-length spring, the USA and Canada have designed and produced a quartz spring gravimeter which has a measurement accuracy of 5 μGal. China has reached 30 μGal. A quartz spring gravimeter has played a significant role in mineral exploration, and is still the main technical equipment in the world. However, the traditional spring gravimeter has been developed to the extreme level, with little margin for improving measurement accuracy.

At present, based on the principle of atomic interference, a number of ground absolute gravimeters and gravity gradiometers have been developed in China and abroad. The absolute gravimeter measurement sensitivity reaches 4.2–44.0 μGal/Hz1/2, the gravity gradiometer can measure the gravity gradient signal to 170 E, and the probe volume is significantly reduced. As a new generation of quantum gravity sensor, the atomic gravimeter is expected to have a measurement sensitivity of 10–4 μGal. However, it faces with challenges such as miniaturization and improved measurement accuracy. Atomic gravimeter also faces problems such as insufficient scaling factor and low phase extraction efficiency. The atomic gravimeter also faces enormous challenges in practical application.