《1 Introduction》

1 Introduction

The Paris Agreement focuses on the study of climate change mitigation after 2020; the agreement is the commitment of countries throughout the world to transition to a low-carbon economy. The issue of climate change resulting from an increase in atmospheric CO2 has become a major global issue of universal concern to the international community, having a profound impact on the survival and development of mankind. The large increase in atmospheric CO2 concentrations is mainly the result of the combustion of large quantities of fossil fuels to support economic development and sustain improvements in human quality of life. This is causing global warming, however, which has led to the extinction of some animal and plant species and is increasing the likelihood of extreme weather. The carbon emissions of China rank first in the world, and will continue to increase, though the country is facing increasingly strong emission reduction requirements. Therefore, China urgently needs to implement effective measures to reduce CO2 emissions.

Carbon capture, storage, and utilization is an emerging technology with great potential to reduce CO2 emissions. It is expected to help achieve low-carbon utilization of fossil energy sources and is considered to be an important technology to help address global climate change [1]. However, the development of carbon capture and storage (CCS)/carbon capture, utilization, and storage (CCUS) technology remains controversial because of various safety hazards, high costs and energy consumption, and unknown CO2 utilization market capacity.

In this study, the current status and development prospects of CCS/CCUS technology were investigated, CCS/CCUS developmental ideas and goals were proposed, and CO2 emissions and CCS/CCUS emission reductions were predicted. Safeguarding measures and policy recommendations for CCS/CCUS development in China were then proposed to provide a reference for promoting China’s energy production and consumption revolution.

《2 Developmental status and comparison in China and overseas》

2 Developmental status and comparison in China and overseas

CCS/CCUS covers the entire technology chain, including carbon dioxide capture technology, carbon dioxide transport technology, and carbon dioxide storage/utilization technology.

《2.1 Carbon dioxide capture technology》

2.1 Carbon dioxide capture technology

The carbon dioxide capture technologies that are currently used can be divided into three categories: (1) post-combustion capture technology, (2) oxy-fuel combustion technology, and (3) pre-combustion capture technology.

2.1.1 Post-combustion capture technology

Post-combustion capture technology separates carbon dioxide from the flue gas generated by combustion, usually including chemical absorption, physical adsorption, membrane separation, and low-temperature fractionation. Post-combustion capture is a sound method because it does not affect the upstream combustion process and is not affected by the CO2 concentration in the flue gas. Therefore, it is suitable for all combustion processes [2].

During 2014, the post-combustion carbon capture full-process demonstration project of Unit 3 of the Boundary Dam power plant in Canada was completed and began operation. It is currently the largest post-combustion carbon capture project in the world [3]. Since December 2007, a demonstration post-combustion capture for coal-fired power plants has been in operation in China at the Huaneng Beijing thermal power plant. Since then, several demonstration projects have been built in China. In 2017, designs for a 1.5 × 105 t/a CCS full-process project was completed at the Shenhua Guohua Jinjie power plant.

2.1.2 Oxy-fuel combustion technology

Oxy-fuel combustion technology uses high-purity oxygen instead of air as the main oxidant to burn fossil fuels [4]. On the basis of retaining the original power station structure, it combines the cryogenic air separation process with the traditional combustion process, such that the CO2 concentration in the flue gas can reach 95% or higher using the purification process system. Thereby, this technology meets the needs of large-scale pipeline transportation and storage.

Oxy-fuel combustion technology has become a subject of research and development worldwide. Many sets of test devices and systems have been built; China, the United States, and the United Kingdom are actively conducting demonstration projects; however, thus far, there has not been a large-scale full-process oxy-combustion CCS demonstration power station completed [3].

At present, the most pronounced restriction in the development of oxy-fuel combustion technology is the costly investment and energy consumption in producing oxygen [5], though some new oxygen generation technologies such as pressure swing adsorption and membrane separation are expected in the near future. Technologies able to significantly reduce the cost of oxygen production are not yet mature, and there has been no large-scale commercial application.

2.1.3 Pre-combustion capture technology

Pre-combustion capture technology mainly refers to the separation of carbon prior to fuel combustion. The fuel involved in the combustion is mainly H2, such that the fuel does not generate CO2 during the combustion process. The main advantage of this technology is that the CO2 concentration is high, the capture system is small, and the energy consumption is low. The main disadvantage is that the system is more complicated. A typical case of its application is the Integrated Gasification Combined Cycle (IGCC).

Since the first IGCC power station began operation during the mid-1980s, nearly 30 IGCC power plants have been built, are under construction, or have been proposed worldwide. China has more experience in the design and construction of gasifiers for 300-MW-class capacity IGCC units, as well as the design, construction, and operation of gasifiers for IGCC units with a capacity of 200 MW or less.

《2.2 Carbon dioxide transportation technology》

2.2 Carbon dioxide transportation technology

2.2.1 Tanker transportation technology

The technology of transporting CO2 by tanker is now well developed, and China has the ability to manufacture such tankers and the related ancillary equipment.

Tank cars can be classified into road tankers and railway tankers. Road tankers have the advantages of flexibility, adaptability, convenience, and reliability, but their volume is small, their freight is high, and their continuity is poor. Railway tankers can transport large amounts of CO2 over long distances. However, in addition to considering the condition of the existing railway network, it is also necessary to consider the need to install CO2 loading, unloading, and temporary storage along railways, which will inevitably greatly increase transportation costs. Thus, there is no international precedent for CO2 transport by rail.

2.2.2 Ship transportation technology

From a global perspective, ship transportation is still in its infancy, and only a few small ships are currently in operation; there are currently no large ships transporting CO2. However, it must be noted that when the sea transportation distance exceeds 1 000 km, ship transportation is considered to be the most economical and efficient mode of CO2 transportation; the transportation cost decreases to 0.1 yuan/(t·km).

2.2.3 Pipeline transportation technology

Because pipeline transportation has many advantages such as continuity, stability, economical, and environmental protection, and mature technology, pipeline transportation is considered to be the most economical land transportation mode for CCS systems that require long-distance CO2 transport. However, because of the difficulty in the construction of offshore pipelines and the high construction costs, there is currently no offshore pipeline for CO2 transportation.

Since the overall development of carbon dioxide transportation technology, there have been more than 40 years of commercial CO2 pipeline transportation practice in foreign countries, which has accumulated considerable transportation experience. The main method used for pipeline transportation is to pressurize the captured gaseous CO2 to more than 8 MPa to increase the CO2 density (making it supercritical and avoiding twophase flow) in order to facilitate transportation and reduce costs. Currently, there are approximately 6 000 km of CO2 transport pipelines throughout the world, transporting approximately 5 × 107 t CO2 per year, with more than 5 000 km of CO2 transport pipelines in the United States.

When using pipelines to transport CO2, the most important problem is to control the water content of the upstream gas source to meet the pipeline transportation requirements. At the same time, an alarm for CO2 leakage detection should be implemented. If such conditions occur, a sound leakage detection system can be used to detect the leakage point of the pipeline in real time. In the case of high-pressure relief, it is necessary to prevent frost damage. Considering the solubility of CO2 in rubber, a rubber material of high strength should be selected as the pipeline inspection gauge, valve, and pump sealing material.

Regarding CO2 transportation costs, a point-to-point CO2 pipeline has a lower construction cost and higher economic efficiency than a pipeline network during the initial stage. However, as the operation time lengthens and the scale is increased, the cost of a CO2 pipeline network will be greatly reduced and is thus more suitable for large-scale CCS/CCUS technology applications.

China’s CO2 transportation is mainly based on low-temperature storage tanks on land. There is no commercial CO2 pipeline, and there are only a few short-distance test pipelines. For example, the 6.5 km CO2 pipeline constructed by the Daqing Oilfield in the CO2-EOR pilot test conducted in the eastern transition zone of Sanan is used to transport low-pressure CO2 as the by-product of the Daqing Refinery hydrogenation plant. At present, China’s research on CO2 transportation technology has just begun. Compared to other countries, the main technical gaps are in pipeline network planning and optimization design technology matching the CO2 source and sink, key equipment for pipeline transportation such as large displacement compressors, safety controls, and monitoring technology.

《2.3 Carbon dioxide utilization technology》

2.3 Carbon dioxide utilization technology

Carbon dioxide utilization technologies mainly include CO2 geological utilization, CO2 chemical utilization, and CO2 bio-utilization technologies.

2.3.1 Carbon dioxide geological utilization technology

CO2 geological utilization refers to the process of injecting CO2 into the ground, using underground minerals or geological conditions to produce or strengthen valuable products, and reducing CO2 emissions compared to traditional processes [6,7]. At present, CO2 geological utilization technologies mainly include the following:

(1) CO2-enhanced oil exploitation technology: CO2 is injected into the reservoir and its physical and chemical interaction with petroleum is used to realize the industrial process of increasing oil production and sequestering CO2;

(2) CO2 flooding CBM technology: CO2 or a CO2-containing mixed gas is injected into deep non-recoverable coal seams to achieve long-term CO2 storage and improve coal bed methane mining;

(3) CO2-enhanced natural gas extraction technology: CO2 is injected at the bottom of the gas reservoir to be depleted, replacing the residual natural gas that cannot be mined because of a natural failure to enhance oil recovery. At the same time, CO2 is sealed in the gas reservoir geological structure;

(4) CO2-enhanced shale gas mining technology: CO2 is used instead of water to fracture shale. CO2 has a higher shale adsorption capacity than CH4, and by replacing CH4, increases the shale gas extraction rate and achieves CO2 storage.

2.3.2 Carbon dioxide chemical utilization technology

CO2 chemical utilization refers to chemical conversion as the main feature, converting CO2 and co-reactants into target products, thereby realizing resource utilization of CO2 [8]. At present, commercialization technologies that have achieved large-scale chemical utilization of CO2mainly include, but are not limited to, the following technologies:

(1) CO2 and methane reforming Syngas technology: the process of reacting CO2 and CH4 to form syngas (a mixture of CO and H2) under the action of a catalyst;

(2) CO2 preparation of liquid fuel by CO: the process of cracking CO2 into CO and O2 and combining it into various liquid fuels or chemicals with subsequent mature technologies;

(3) CO2 hydrogenation to methanol synthesis technology: H2 and CO2 are used as feed gas at a certain temperature and pressure, catalytically converting hydrogen to produce methanol by hydrogenation on a catalyst (usually a copper-based or other metal oxide catalyst);

(4) CO2 synthesis of dimethyl carbonate technology: a series of technologies for synthesizing dimethyl carbonate by direct or indirect methanol under the action of a catalyst using CO2 as a raw material.

2.3.3 Carbon dioxide bio-utilization technology

CO2 bio-utilization technology refers to the use of bio-transformation as a main feature, and the use of CO2 for biomass synthesis through plant photosynthesis, thereby realizing CO2 resource utilization. At present, CO2 bio-utilization technology remains in the initial stages of development, and research is mainly focused on the following aspects:

(1) Microalgal fixed CO2 conversion to biofuels and chemicals technology: using photosynthesis of microalgae, CO2 and water are converted into monosaccharides and oxygen in chloroplasts, and then monosaccharides can be converted into neutral glycerol in cells. The ester (TAG) triglyceride is esterified to form biodiesel;

(2) Microalgal fixed CO2 conversion to bio-fertilizer technology: the photosynthesis of microalgae is used to convert CO2 and water into monosaccharides and oxygen into chloroplasts, while filamentous cyanobacteria convert inorganic nitrogen in the air into organics that can be used by plants;

(3) Microalgal fixed CO2 conversion to food and feed additive technology: the photosynthesis of some microalgae is used to convert CO2 and water into chloroplasts and then into monosaccharides. Then the monosaccharides are converted into unsaturated fatty acids and astaxanthin in cells. There is an additional value of secondary metabolites;

(4) CO2 gas fertilizer utilization technology: this is a CO2 utilization technology that injects and purifies CO2 from energy and industrial production into a greenhouse, increasing the concentration of CO2 to increase the photosynthesis rate of crops, and in turn increasing crop yield.

2.3.4 Status of carbon dioxide mineralization technology

CO2 mineralization is a CO2 utilization method proposed in recent years. It mainly uses alkaline earth metal oxides such as olivine and serpentine that are widely present in the earth to react with CO2 to convert it into stable carbonate compounds, thereby achieving CO2 emission reduction. The advantages of this technology are that it can avoid the various risks and uncertainties of CO2 geological storage, thus ensuring economic, safe, stable, and sustainable CO2 terminal emission reduction technology. CO2 mineralization is widespread; if 1% of calcium and magnesium ions in the Earth’s crust are used for CO2 mineralization, then according to a 50% conversion rate, approximately 2.56 × 1015 t of CO2 can be mineralized, which could meet the demand of CO2 emission reduction for approximately 85 000 years. If potassium feldspar is reused (the total amount is approximately 9.56 × 1013 t), theoretically it can process more than 3.82 × 1012 t of CO2. Therefore, CO2 mineralization is an efficient and effective method for large-scale emission reduction and development and utilization of CO2. The disadvantage of this technique is that the reaction rate of minerals with CO2 is quite slow at a normal temperature and pressure. Therefore, increasing the rate of the carbonation reaction has become the key to mineral storage technology.

Some researchers have developed chloride-based CO2 mineral carbonation reaction, wet mineral carbonic acid, dry carbonic acid, and bio-carbonic acid technologies. The experimental results are not very satisfactory, however. The China Petrochemical Corporation and Sichuan University have jointly developed a CO2 mineralized phosphogypsum (CaSO4·2H2O) technology. The gypsum ammonia suspension directly absorbs CO2 tail gas to produce ammonium sulfate. One-hundred (Nm3 )/h tail gas CO2 directly mineralized phosphogypsum cement has been developed. In a pilot plant for producing sulfur-based compound fertilizer, direct mineralization of tail gas CO2 to calcium carbonate results in a conversion rate of the solid phase CaSO4·2H2O of phosphogypsum of more than 92%, and the CO2 capture rate of the tail gas in continuous test for 72 h was 70%. Its reaction formula is as follows:

This technology is applied, for the first time worldwide, to a new one-step process where low-concentration tail gas CO2 is used for direct mineralization of phosphogypsum and co-production of sulfur-based compound fertilizer and calcium carbonate. Using ammonia as a coupling medium, CO2 containing flue gas and phosphorus gypsum are conversed and coupled. The CO2 in the flue gas is transferred to the phosphogypsum suspension, and the ammonia gas is introduced to form a gas-liquid-solid threephase circulating fluidization conversion process. The semi-finished slurry is subjected to subsequent processing to obtain a sulfur-based compound fertilizer-ammonium sulfate ((NH4)2SO4) and is precipitated calcium carbonate (CaCO3).

Phosphogypsum is the waste residue formed during the production of wet-process phosphoric acid. Approximately 5–6 t of phosphogypsum waste residue is produced per 1 t of wet-process phosphoric acid. The annual production of phosphogypsum waste residue in China is approximately 5 × 107 t, and a new stacking site requires 2 800 km2 per year. Because phosphogypsum contains small amounts of impurities such as phosphorus and fluorine, these impurities can flow to the groundwater or a nearby watershed through rainwater. Therefore, the long-term stacking of phosphogypsum not only occupies a large amount of land, but also pollutes the surrounding environment because of irregular treatment of the stacking site. Often there is a dam breach. However, China lacks sulfur resources and needs to import large amounts of sulfur every year to maintain the production of phosphate and compound fertilizer. The development of the use of phosphogypsum to obtain ammonium sulfate and calcium carbonate technology can not only solve the problem of comprehensive utilization of phosphogypsum waste residue, but during the preparation of ammonium sulfate as a fertilizer, the by-product calcium carbonate can be used as a raw material for the production of cement.

The innovation of CO2 mineralized phosphogypsum ammonium sulfate technology is to reduce the economics of CO2 and phosphogypsum resource utilization by waste treatment, and realize industrial solid waste mineralization CO2 co-production chemical products. This technology changes the traditional “capture + storage” low-carbon path, eliminating the cost and risk of CO2 capture and storage by direct chemical utilization of CO2-containing gases, and maximizing low-carbon economy and reliability. At the same time, this technology helps to eliminate land occupation and environmental pollution by phosphogypsum stacking by converting waste phosphogypsum into useful thiamine and calcium carbonate.

《2.4 Comparison at home and abroad》

2.4 Comparison at home and abroad

Although CCS/CCUS technology has a history of more than 10 years in some countries, most of the major technologies are in different stages of theoretical research, laboratory research, industrial demonstration, and small-scale commercial operation, and remain economically viable only under certain conditions. In terms of CO2 capture and separation, although the post-combustion capture and pre-combustion capture technologies are mature and can be practiced at a large scale, their energy consumption and cost remain high; the oxy-fuel combustion capture technology is still immature. In terms of CO2 flooding, gassing, and storage, although the oil displacement technology is relatively mature, most countries lack low-cost CO2 gas sources. Coal bed methane is affected by many factors; storage sites have not been fully geologically surveyed, and there is no safety monitoring. In terms of CO2 chemical utilization, most technologies have just begun industrialization, are under-developed, have high product cost, and achieve limited CO2 absorption. In the field of CO2 microalgal oil production, the technology remains immature and in the pilot stage, with large land occupation and high investment, consumption, and cost. In terms of CO2 mineralization, this technology remains in the laboratory stage. In general, there is a lack of large-scale engineering demonstration of the entire chain of technology (capture–transport–burial/utilization).

CCS/CCUS technology research and development originated in developed countries such as those in Europe and the United States, but through international cooperation and exchanges, China’s CCS/CCUS technology has rapidly developed in recent years. At present, China’s carbon dioxide post-harvesting of coal-fired power plant flue gas, coal-to-liquids, and IGCC carbon dioxide pre-capture all have industrial-scale demonstration projects in operation. Therefore, China is not far behind in the research, development, and application of capture technology, and in some aspects is still in a leading position in engineering applications. However, in terms of the construction of carbon dioxide transportation pipelines, chemical chain combustion, and other cutting-edge technologies, as well as carbon dioxide utilization, China is still relatively behind compared to developed countries such as the United States.

《3 CCS/CCUS technology developmental directions》

3 CCS/CCUS technology developmental directions

《3.1 CO2 capture technology》

3.1 CO2 capture technology

3.1.1 Post-combustion capture technology

This technology is mature in China and in other countries, but it is mainly used in cement kilns and smelting furnaces. The post-combustion capture technology applied to commercial-scale power plants is only at the demonstration stage. For post-combustion capture, there is focus on the development of alcohol-amine capture technology prior to 2020. This will involve conducting industrial demonstrations and promoting scaled technology, and the research and development of hot potash-based capture technology. Between 2020 and 2030, the commercialization of alcohol-amine capture technology will be realized, and the demonstration method of hot potash-alkali capture will be conducted. Between 2030 and 2050, a low-cost post-combustion capture technology system will be developed and commercialized.

3.1.2 Oxy-fuel combustion capture technology

Prior to 2020, focus will be on low-energy, low-cost oxygen purification technology to reduce energy consumption in large air separation processes, and research and development of high-temperature heat-resistant materials and combustion boiler equipment to reduce air pollution. From 2020 to 2030, demonstration of large-scale oxy-fuel combustion and capture technology to further evaluate the feasibility and economy of the technology will be conducted. After 2030, the large-scale application of ultra-supercritical oxy-fuel combustion technology will be realized.

3.1.3 Pre-combustion capture technology

Based on the construction of the IGCC power generation system, the research and development of high-temperature gas purification technology, low-energy and high-efficiency gas turbines, high-efficiency gasifiers, and low-energy oxygen generation air separation systems and steam cycles will be intensified by 2020. Systematic exploration and pilot demonstration of IGCC projects will occur from 2020–2030 through the optimization of new technology research and the integration of new energy processes; the formation of low-cost, low-energy, high-performance pre-combustion technology; and industrial demonstration. After 2030, mature applications, industrial promotion, and commercial operations will occur.

《3.2 Carbon dioxide transportation technology》

3.2 Carbon dioxide transportation technology

Transporting CO2 through pipelines is the first choice for CCS, but this does not mean that transportation methods such as tankers and ships are not feasible for CCS systems. After the development of CCS systems to a certain extent, other modes of transportation can be used as to supplement pipeline transportation, such that the transportation of CO2 is more efficient and complete.

By 2020, a complete CO2 pipeline transportation related standard system should be established and formed, the safety control technology system improved, and a million-ton full-process demonstration built. The delivery pipe length will reach 200 km, the cost control will reach 80 yuan/t, and the annual transportation capacity will exceed 1×106 t. By 2030, the industrialization technical capabilities will be fully developed, with a pipeline length longer than 1 000 km, a cost control of 70 yuan/ t, and an annual transport capacity of more than 1 × 107 t. By 2050, the application of CO2 transportation technology will be fully promoted, and CO2 pipelines longer than 5 000 km will be constructed. The cost control will be less than 70 yuan/t, and the annual transportation capacity will exceed 5 × 107 t.

《3.3 Carbon dioxide utilization technology》

3.3 Carbon dioxide utilization technology

3.3.1 CO2 geological utilization technology

CO2 flooding technology: the earliest and most mature storage technology for CO2 flooding technology. By 2020, based on the detailed resource assessment, combined with the distribution of CO2 centralized emission sources, optimizing the sourcesink matching research, completing the source-sink matching planning scheme design, and carrying out CO2 capture–displacement oil across industries and departments will be completed. Research and development of integrated storage technology, integrated planning, technological implementation, and economic evaluation should be carried out, as well as increasing CO2 flooding application, investing 6 000–12 000 t of reserves for CO2 flooding, and commercializing after 2030. Standardized promotion and application and vigorous implementation of the CO2 capture-displacement-burial integration project should be carried out, with cumulative input reserves of 5×108 –1×109 t.

CO2 coalbed methane technology: this technology is not yet mature, and is currently in the mechanism research and well group test stage. By 2020, the source-sink matching optimization research and planning will be completed, and pilot demonstration project construction will begin. By 2030, CO2 capture– exhaust–burial integration and CO2 capture–burial integration technology will be developed, and large-scale implementation will occur. An integrated demonstration project, implementation of environmental safety monitoring methods, and long-term storage safety monitoring technology research will be completed. By 2050, full-process technology promotion and scale and commercialization of project implementation will be completed.

3.3.2 CO2 chemical utilization

CO2 chemical product utilization: by 2020, the chemical conversion of CO2 to produce new products such as syngas, methanol, and polyurethane will increase, and a demonstration of chemical utilization projects of over 10 000 t will be established. By 2030, a demonstration of large-scale industrialization projects of 100 000 t or more will be established. CO2 chemical conversion to produce energy, chemical product technology industrialization optimization, and equipment research and development will be carried out. By 2050, a complete CO2 chemical application and product system will be established to commercialize the application of technical capabilities and large-scale industrialization of CO2 chemical utilization of new technologies.

3.3.3 CO2 bioavailability

Microalgal bio-fixation CO2 conversion technology: at present, China will focus on low-cost aquaculture and oil-making technology research and development, and establish a micro-algal cultivation and oil-based pilot demonstration project to develop photosynthetic efficiency technology and high-value by-product biorefinery technology. By 2030, a high-value by-product biorefinery technology will be developed to carry out microalgae cultivation, and rational allocation of land resources and high-yield microalgal culture technology will be promoted; low-cost, low-energy harvesting and processing technology will be developed; and demonstration projects will be established. By 2050, the commercial production capacity of oil-making technology and by-product processing technology will be developed and commercialization technology will be promoted.

3.3.4 CO2 mineralization and utilization

By 2020, a number of CO2 mineralization technology industrial demonstration units will be established, and their scale will be gradually expanded; commercialization will be realized by 2050, with mature technology and reduced energy consumption.

《3.4 Technical route》

3.4 Technical route

3.4.1 Carbon dioxide capture technology

For the development of CO2 capture technology, according to the current situation in China, a suggested technical development schedule and milestones during each stage are shown in Fig. 1.

《Fig. 1》

Fig. 1. China’s medium- and long-term carbon capture technology roadmap.

2015–2020:

(1) For post-combustion capture technology: focus on the development of alcohol-amine capture technology, carry out industrial demonstration and scale technology promotion, and carry out research and development of hot potash-based capture technology;

(2) For oxy-combustion technology: focus on low-energy, low-cost oxygen purification technology to reduce energy consumption in large air separation processes; develop high-temperature heat-resistant materials and combustion boiler equipment to reduce air pollution;

(3) For pre-combustion capture technology: increase research and development of high-temperature gas purification technology, research and development of low-energy high-efficiency gas turbines, high-efficiency gasifiers, and low-energy oxygen-creating air separation systems and steam cycle systems; and conduct pilot demonstrations of IGCC projects.

2020–2030:

(1) For post-combustion capture technology: commercialization of alcohol-amine capture technology and demonstration of hot potash capture technology;

(2) For oxy-combustion technology: actively carry out demonstration of large-scale oxy-fuel combustion and capture technology, and further evaluate the feasibility and economy of the technology;

(3) For pre-combustion capture technology: through the development of new technologies and optimization of coupled energy processes, create low-cost, low-energy, high-performance pre-combustion capture technologies and establish industrial demonstrations.

2030–2050:

(1) For post-combustion capture technology: develop a low cost post-combustion capture technology system and commercialize it;

(2) For oxy-fuel combustion technology: large-scale application of ultra-supercritical oxy-fuel combustion technology;

(3) For pre-combustion capture technology: reach mature applications, industrial promotion, and commercial operations.

3.4.2 Carbon dioxide transportation technology

For the development of carbon dioxide transportation technology, it is recommended that the technical development schedule and milestones at each stage are as follows:

2015–2020:

Establish and form a complete CO2 pipeline transportation related standard system, improve the safety control technological system, and build a million-ton full-process demonstration. The pipeline length would be 200 km, the cost control 80 yuan/t, and the annual transportation capacity more than 1 × 106 t.

2020–2030:

Fully master the industrialization technology capability, with a pipeline length longer than 1 000 km, a cost of 70 yuan/t, and an annual transportation capacity of more than 1 × 107 t.

2030–2050:

The CO2 conveying technology will be fully promoted and implemented, and a CO2 conveying pipeline length longer than 5 000 km will be constructed. The cost will be limited to 70 RMB/ t or less, and the annual conveying capacity will exceed 5 × 107 t.

3.4.3 Carbon dioxide utilization technology

For the carbon dioxide utilization technology, according to China’s current technological development and economic situation, it is recommended that the technical development schedule and milestones during each stage are as follows:

2015–2020:

(1) For CO2 geological utilization technology: conduct detailed resource assessment and carry out and expand corresponding experimental research;

(2) For CO2 chemical utilization technology: further promote and expand the utilization technology of traditional CO2 chemical products and carry out research on production technology of low-energy consumption and low-cost CO2 chemical products coupled with new energy;

(3) For CO2 bio-utilization technology: promote the use of gas and fertilizer technology and focus on microalgal carbon sequestration, and research and development of advanced CO2 bio-utilization technology [9].

2020–2030:

(1) For CO2 geological utilization technology: complete source–sink matching optimization research and planning and carry out a block pilot test demonstration project construction;

(2) For CO2 chemical utilization technology: increase CO2 chemical conversion to produce new products such as syngas, methanol, and polyurethane, and establish a demonstration of more than 10 000 t of chemical utilization projects;

(3) For CO2 bio-utilization technology: focus on microalgal carbon sequestration, establish a number of large-scale energy farms for CO2 bio-use, and use CO2 to enhance bioenergy production such as biomass liquid fuels and chemicals.

2030–2050:

(1) For the CO2 geological utilization technology: realize technological promotion and implement large-scale and commercialized projects;

(2) For CO2 chemical utilization technology: by 2030, establish a large-scale industrialization project demonstration of 100 000 tons or more, carry out CO2 chemical conversion to produce energy, and carry out chemical product technology equipment research and development, industrialization, optimization. By 2050, establish a complete CO2 chemical application and product system, develop an ability to commercialize and promote the application of technology, and conduct the large-scale industrialization of new CO2 chemical utilization technology;

(3) For CO2 bio-utilization technology: apply advanced CO2 bio-utilization technology focusing on microalgal carbon sequestration.

《3.5 Analysis of technical economy》

3.5 Analysis of technical economy

At present, the core technologies of CCS/CCUS are still immature, and most are in the stages of theoretical research, laboratory research, industrial demonstration, and small-scale commercial operation, and remain in the stage of “economic viability” under certain conditions. The cost and energy consumption of CCS/CCUS technology is relatively high and their economy is poor. CO2 capture and integration account for more than 70% of the total cost of CCS. According to the United Nations Intergovernmental Panel on Climate Change (IPCC), the cost of CO2 capture after combustion is approximately 29–51 USD/t, and CO2 capture in the IGCC is 13–37 USD/t. For the supercritical power plant and natural gas combined cycle (NGCC) power plant, if IGCC power plants are to capture 90% of CO2, energy consumption per kWh will increase by 24%–40%, 11%–20%, and 14%–25%, respectively. Under the current technical level, CO2 flooding, coalbed methane, brine layer storage, and microalgal bio-fuel can achieve a net CO2 emissions reduction, but mineralization and chemical utilization cannot achieve a net reduction. In addition, there are safety problems in long-term storage of CO2 flooding, and there are also risks such as leakage, environmental impact, and induced earthquakes.

《4 China’s CO2 emissions and CCS/CCUS emission reduction forecasts》

4 China’s CO2 emissions and CCS/CCUS emission reduction forecasts

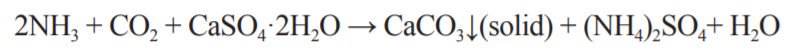

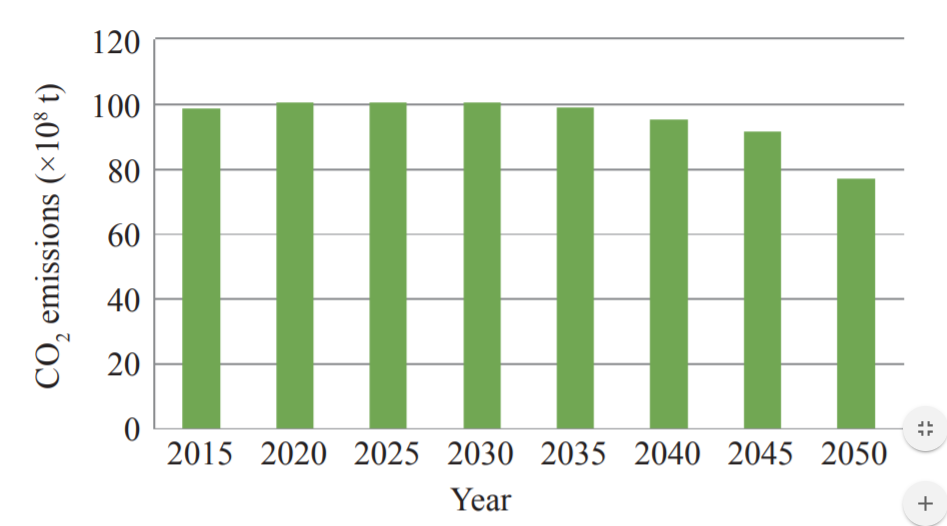

Scenario 1: According to actual CO2 emissions of China between 2005 and 2017, the growth trend method was used to predict the future emissions, and the status quo is essentially maintained. New measures are not considered. The results are shown in Fig. 2.

《Fig. 2》

Fig. 2. Scenario 1: China’s CO2 emissions forecast.

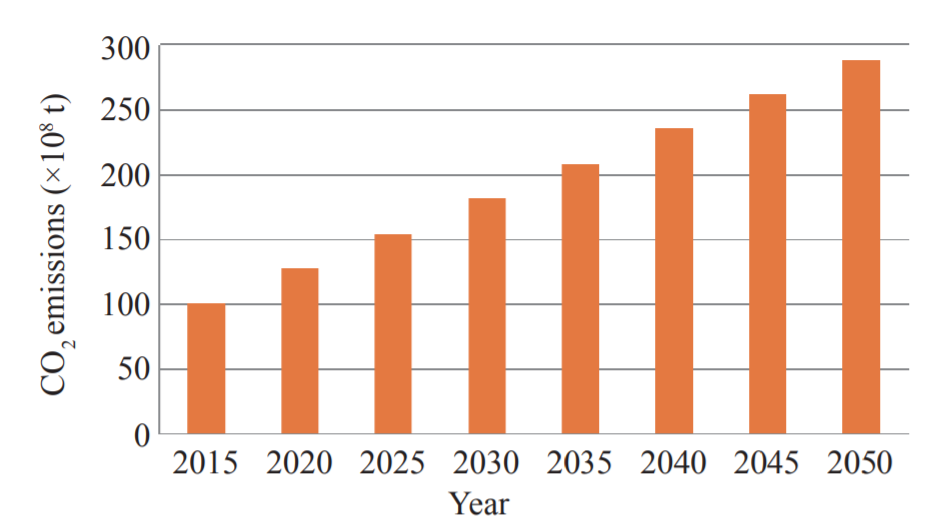

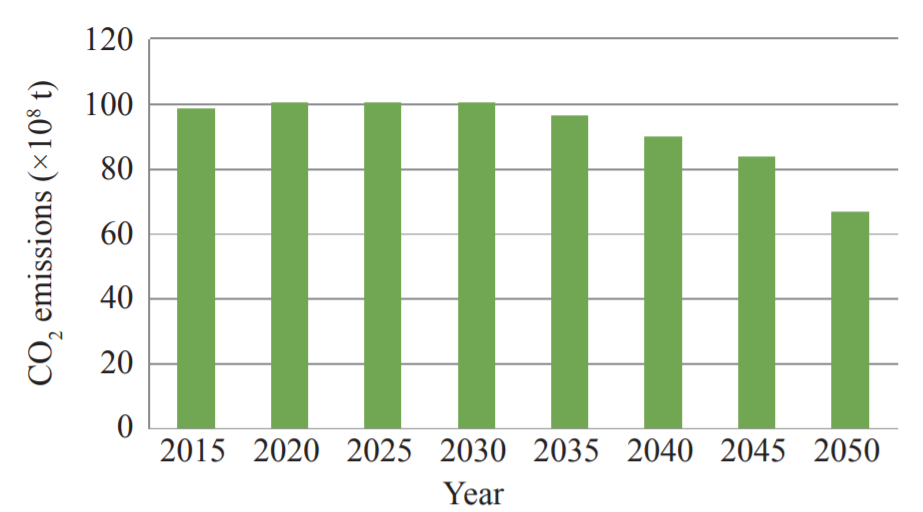

Scenario 2: Regardless of the adjustment in energy structure, CCS/CCUS measures are not adopted, and only energy-saving measures are taken to reduce CO2 emissions in China. The results are shown in Fig. 3:

《Fig. 3》

Fig. 3. Scenario 2: China’s CO2 emissions forecast.

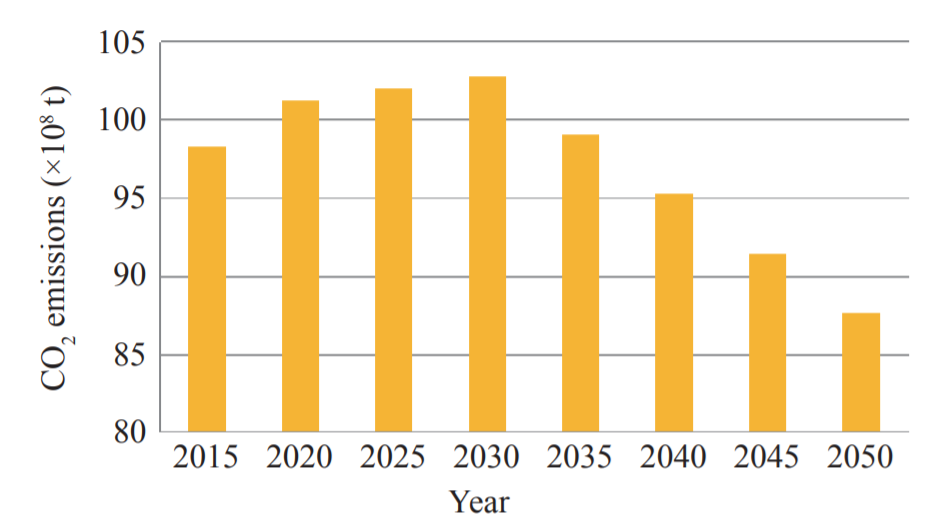

Scenario 3: Considering the energy-saving measures and Scenario 2, a national energy consumption structure adjustment and stable development plan was developed, and CO2 emissions in 2020, 2030, and 2050 were forecast.

Considering the reasonable control of total energy consumption and adjusting the energy structure, based on the existing predictable policies and technical conditions, we forecasted the total primary energy production and structural targets of China by 2020, 2030, and 2050. The forecast used the indirect method to establish a production energy demand forecasting function based on gross domestic product (GDP) and energy consumption per unit of GDP. The historical data cited are derived from the China Statistical Yearbook, Energy Statistics Yearbook, and published research data [10,11]. The results are shown in Fig. 4.

《Fig. 4》

Fig. 4. Scenario 3: China’s CO2 emissions forecast (stable development plan).

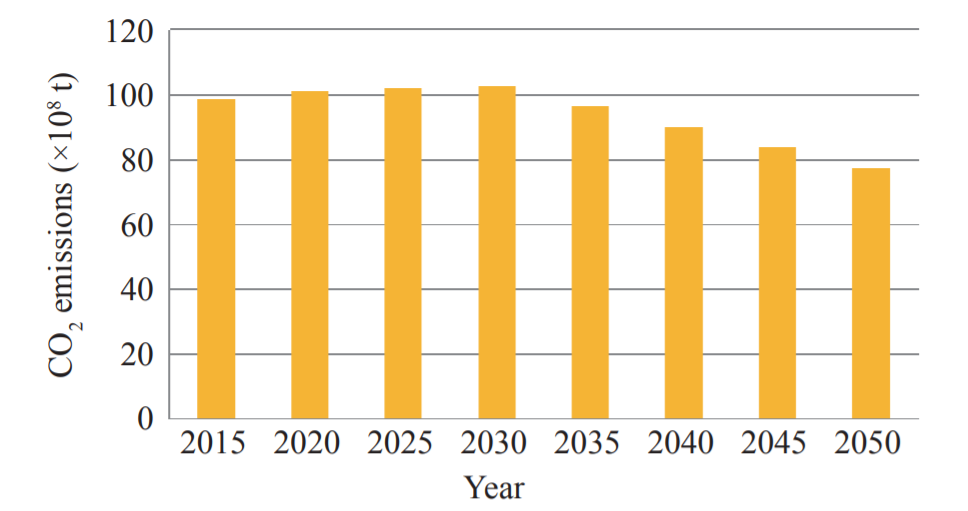

China will consider adopting the energy-saving measures in Scenario 2 and the national energy consumption structure adjustment, and actively promote the plan to predict CO2 emissions by 2020, 2030, and 2050, as shown in Fig. 5.

《Fig. 5》

Fig. 5. Scenario 3: China’s CO2 emissions forecast (active promotion plan).

Scenario 4: Considering the CCS/CCUS technical measures proposed in this paper based on the steady development and active promotion of Scenario 3, CO2 emissions by 2020, 2030, and 2050 were predicted as shown in Fig. 6 and Fig. 7.

《Fig. 6》

Fig. 6. Scenario 4: China’s CO2 emissions forecast (stable development plan).

《Fig. 7》

Fig. 7. Scenario 4: China’s CO2 emissions forecast (active promotion plan).

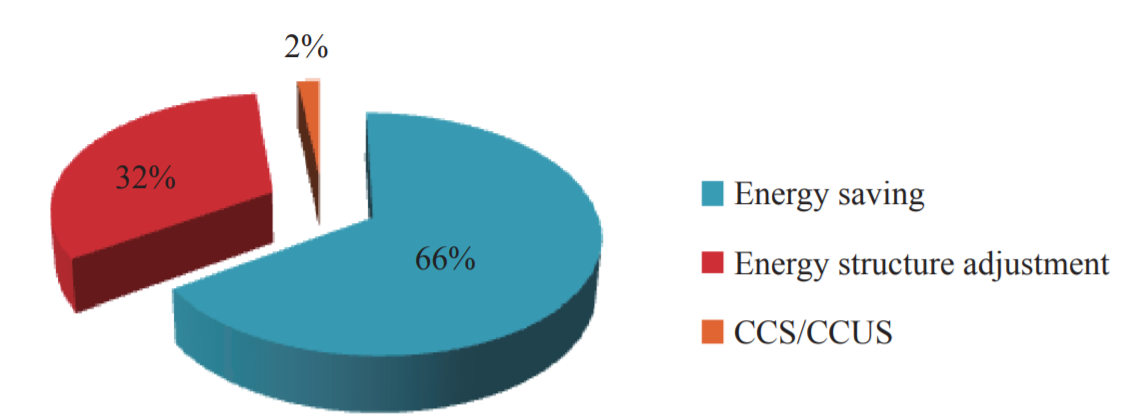

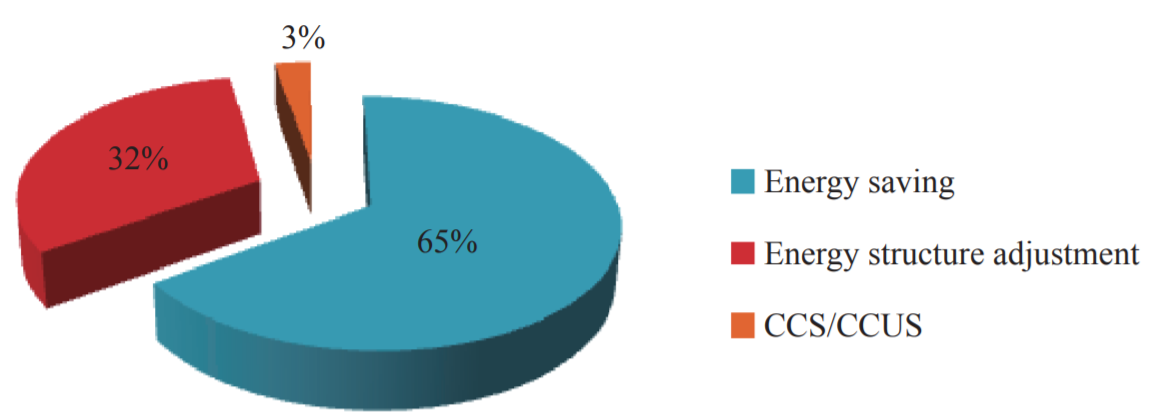

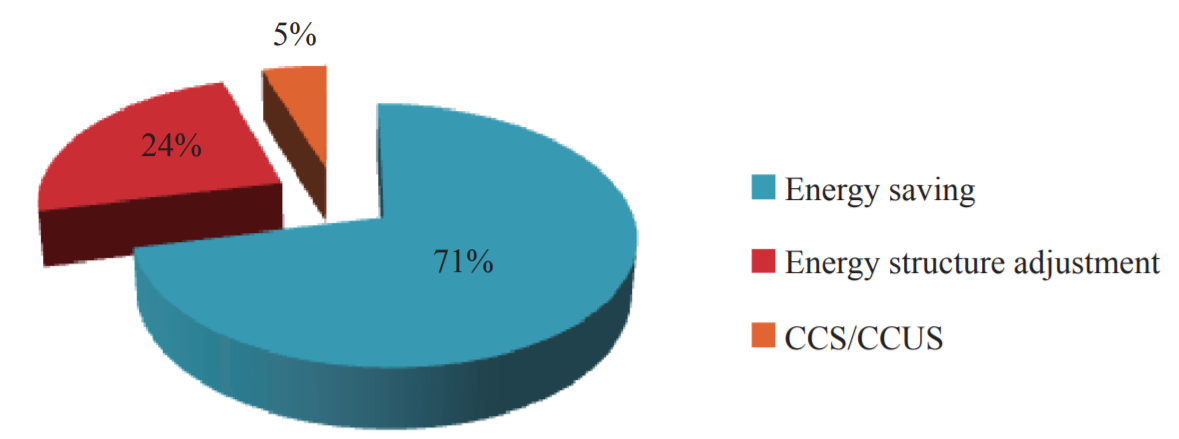

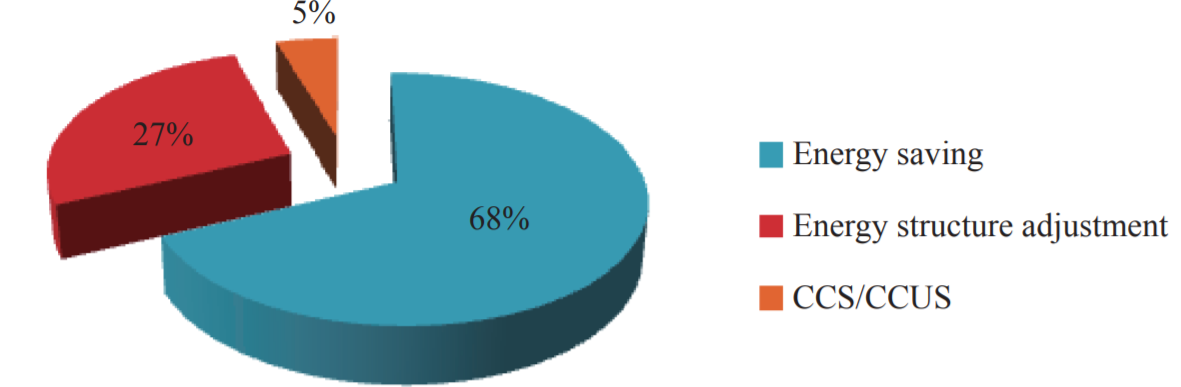

Through the analysis of the aforementioned four scenarios, if China does not adopt any new measures, CO2 emissions will reach 2.8875 × 1010 t by 2050; if energy-saving measures are taken, China’s CO2 emissions will decrease to 1.3781 × 1010 t by 2050. Further adopting an adjustment in energy structure and the development of low-carbon energy measures, under the conditions of stable development, China’s CO2 emissions can be reduced to 8.769 × 109 t by 2050. Under aggressive promotion conditions, CO2 emissions can be reduced to 7.771 × 109 t. Taking the CCS/CCUS measures further, under the condition of a stable development plan, China’s CO2 emissions can be reduced to 7.719 × 109 t by 2050. Under the active promotion scheme, CO2 emissions can be reduced to 6.721 × 109 t. Comparing the four scenarios, the contribution of various emissions reduction measures in different periods is shown in Figs. 8–11.

《Fig. 8》

Fig. 8. Contribution of carbon emissions reduction measures by 2020.

《Fig. 9》

Fig. 9. Contribution of carbon emissions reduction measures by 2030.

《Fig. 10》

Fig. 10. Contribution of carbon emissions reduction measures by 2050 (stable development plan).

《Fig. 11》

Fig. 11. Contribution of carbon emissions reduction measures by 2050 (active promotion plan).

As can be seen from Figs. 8–11, the most important measure for CO2 emissions reduction is energy conservation and consumption reduction, with a contribution of 65%–71%. Second, the energy structure is adjusted, and the contribution is 24%–32%; the contribution of CCS /CCUS is 2%–5%, but in the case of slow growth in CO2 emissions from 2020 to 2030, CCS/ CCUS measures will allow emissions peaks to occur earlier.

《5 Conclusions and policy recommendations》

5 Conclusions and policy recommendations

(1) CCS/CCUS is in the stages of research and development and demonstration, and the related technologies are not yet fully mature. Based on the national conditions in China, we should fully analyze carbon emissions, safety, and economic indicators from the perspective of the whole life-cycle, and selectively research and demonstrate large-scale CO2 capture technologies such as post-combustion capture, pre-combustion capture, and oxy-fuel combustion capture for low-energy consumption. We should promote the innovative development and application of CO2 utilization technologies and processes such as CO2 flooding, coal driven methane, and chemical and biological utilization. This can reduce costs, secondary pollutants, and indirect carbon emissions, and can support the comprehensive benefit of technical, economic, and environmental protection.

(2) CCS/CCUS emissions reduction is limited. It is necessary to prioritize improving energy conservation and emissions reduction measures, followed by adjusting the energy structure and vigorously developing renewable energy technologies for China to significantly reduce CO2 emissions.

(3) The government should accelerate the formulation of laws and policies to address climate change and low-carbon development; this requires the government to clarify the scope, objectives, principles, and main contents of low-carbon development work; standardize the responsibilities, rights, and obligations of different social entities; and strengthen the guarantees of policy measures, institutional mechanisms, and scientific support.

(4) For carrying out forward-looking CCS/CCUS technology research and development, it is necessary to rationalize the enterprise risk investment and financing system, by adopting incentive measures in finance and taxation, and encouraging the development and commercialization of energy-saving and energy-efficient technologies, to encourage enterprises to develop low-carbon and other advanced technologies.

(5) The development trend of international CCUS technology should be determined. The CCUS international scientific and technological cooperation should be actively carried out by incorporating CCUS technology into multilateral and bilateral international scientific and technological cooperation. This should promote the establishment of an internationally cooperative platform.

京公网安备 11010502051620号

京公网安备 11010502051620号