China’s “Go Global” railway strategy is a full chain output including railway engineering construction, and the standard of railway engineering construction is one of the key factors in the development process of the Strategy. The construction standards will not only provide source restriction on the design and technical scheme, but can also exert a lasting impact on subsequent construction, product, and even operation and maintenance. Therefore, it is important and urgent for research to be directed at finding a method that facilitates the adaptation of Chinese railway construction standards (CRCSs) to the China’s “Go Global” railway strategy.

《1 Issues arising from Chinese railway construction standards in the process of “Go Global”》

1 Issues arising from Chinese railway construction standards in the process of “Go Global”

Chinese railway construction standards were initially developed to serve the domestic railway construction market. It has been verified by the railway construction market, and is in line with the long-term practical experience of China’s national condition and management mode of engineering construction. In the development process of the China’s “Go Global” railway, the following challenges were encountered due to different political, legal, socioeconomic, and cultural conditions as well as the discrepancy in railway construction, operation, management, and maintenance modes:

(1) During the earlier stage of the project, the owner wanted the international or European standards to be applied;

(2) During the preliminary stage of the project, Chinese standards were applied with difficulty due to the existing local standard and national conditions;

(3) During the bidding procedure, the selection of key parameters affected the technical scheme and investment;

(4) During the project implementation, key decisions based on Chinese standards such as the design theory, design process, calculation mode, parameter selection, and environmental protection measures were not readily accepted by the international consulting engineer; and

(5) During the later stage of the project, Chinese standards did not match the local operation, maintenance systems, and so forth.

The above mentioned challenges are unfavorable for the successful development of the China’s “Go Global” railway strategy due to the following root reasons. First, China’s railway construction standards are self-contained and have poor adaptability to coexist with multiple standard systems in the country. Second, the standard levels are not sufficiently clear and are not suitable for flexible application. Finally, there are some differences between the standards and the requirements of the international railway construction sector in terms of theoretical basis, design philosophy, and application of new technology. Therefore, to a certain extent, these issues hindered the smooth development of the China’s “Go Global” railway strategy.

《2 Contrastive analyses of railway construction standards in China and foreign countries》

2 Contrastive analyses of railway construction standards in China and foreign countries

《2.1 Difference in the standard system framework》

2.1 Difference in the standard system framework

This paper analyzes the main attributes of railway construction standards at different dimensions (level, binding force, and object attributes) using multi-dimensional analysis and cluster analysis approaches.

2.1.1 Level attribute

Railway construction standards can be divided into different levels, such as international, regional, national, industrial, local, group, and enterprise standards. These levels have certain compliance and internal relation among each other. The higher the level is, the broader the standard will be and the more macroscopic the requirement will be; while the lower the level is, the more detailed the standard will be.

Chinese railway construction standards can be divided into national, industrial, and enterprise levels. By comparing Chinese and foreign standards, we found that the international standard system is generally comprised of international, regional, national, industrial, and local standards, with clear levels. Various levels take effect at different perspectives. The upper level is for leading and restriction of the lower level, while the lower level is for detailing and support of the upper level. However, for the Chinese railway construction standards, the middle and top levels have weak constraints for industry standards.

2.1.2 Binding force attribute

In terms of binding force, the Chinese railway construction standards can be classified into three types, namely mandatory standard, recommended standard, and instructive technical document. The mandatory standards of Chinese railway construction have a large scope, in addition to components such as safety and environmental protection, numerous industrial standards are also of the mandatory type [1]. International railway construction standards include technical regulations and voluntary standards, among which, related standards are published by decree, including standards for interconnection and interworking, safety and health, environmental protection, administrative regulations for engineering supervision, and land acquisition and resettlement, and are defined as the technical regulations for compulsory execution, while all other standards belong to the voluntary type, which can have the binding force for compulsory execution by contract or decree.

2.1.3 Object attribute

Chinese railway construction standards are drafted in the light of different role objects, discipline objects, and line classes of construction. For instance, classification is carried out in the system as per different roles during Chinese railway construction (survey, design, construction, acceptance, operation and maintenance, etc.): different speed grades of the railway (namely, high-speed, general speed, and inter-city railways) and various subsystems such as for heavy-load railways and for railways in extremely cold areas. In addition, the Chinese railway standards also cover a majority of disciplines involved in the railway.

The international classification of railway construction standards is quite simple. In Germany, for example, the German standard system does not explicitly set standards according to different roles. Instead, it emphasizes design codes and takes the design as the main line. In combination with specific structures, unified provisions are made on construction, acceptance, and maintenance. The German standard system has no separate subsystems such as high-speed and general speed railways, but is directly divided as per the disciplines. However, different provisions are set for the distinguishing parts between high-speed and general speed railways in these standards. The German standards for the civil engineering discipline utilize general standards; there is no special set of professional standards for railway engineering.

The standard system of China’s railway classified by phases is conducive to implementation by the management. However, owing to the different management departments in different phases of standards, the lack of co-ordination may result in a standard discrepancy. For instance, there is a discrepancy between the design standard and the maintenance standard. In view of the object attribute, the Chinese railway construction standards have fully reflected the construction characteristics of Chinese railway engineering and are easy for implementation and application.

《2.2 Differences in standards from the discipline perspective》

2.2 Differences in standards from the discipline perspective

The Chinese railway construction standards cover most disciplines of the railway. A comparison of the discipline provisions in the Chinese and foreign standards indicates the following major differences.

2.2.1 Differences in the theoretical basis

The allowable stress method is mostly adopted for subgrade, bridge, tunnel, and similar structures of the Chinese railway, while the limit state method is selected by other countries or international organizations (e.g., German, Japan, European Union) [2]. Such difference makes it difficult for Chinese structural calculations to be successfully approved by international consulting engineers and may affect the project implementation.

2.2.2 Discrepancy in design philosophies

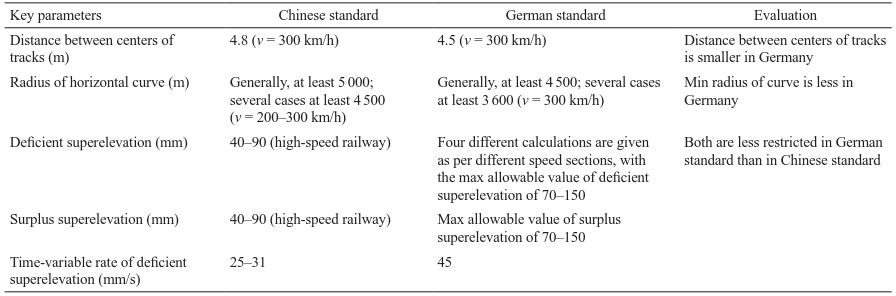

The discrepancy is mainly reflected in the following aspects. First, there is a discrepancy in the systematization and generality of standards. Chinese railway construction standards highly emphasize systematization and generality and highlight coordination and overall planning throughout the country. However, railway construction in foreign countries mainly focuses on the individual demands of project construction and lays greater emphasis on the economic benefit of certain specific projects. Second, there is a difference in the main technical parameters arising from different demands on comfortableness. Higher requirements on comfortableness are implicated in the Chinese standards. Some typical parameters related to comfortableness in alignment discipline are quoted for comparison between Chinese and German standards, as presented in Table 1 [2]. For higher comfortableness, the project investment will be significantly increased, which is obviously unfavorable for overseas projects deeming economic efficiency as one of the key factors to consider. When compared to the Japanese standards, provisions for subgrade, bridge, and tunnel in the Chinese standards are far beyond relevant Japanese standards, which makes China railway less competitive in the international market. Third, there is a discrepancy in the requirement specified in standards and executive situation in terms of health, safety, and environment (HSE). HSE is always drawn particular attention to in overseas projects. Relevant national standards (GB/T24001 & GB/T28001) in China are also formulated and gradually become convergent to international standards in view of standard architecture. However, there is still some gap between Chinese and European countries with regard to the acknowledgement of HSE. In foreign countries, there are stricter standards for HSE and the entire process from design to implementation should be controlled and strictly enforced. Fourth, there are misplaced functional requirements and technical means. In the Chinese railway construction standards, the functional requirements are not clearly defined but the requirements for technical means adopted are stated in detail. In the German standards, the functional requirements are mandatory, and the corresponding technical means are only recommended. In most countries where high-speed railways are developed, the performance design philosophy is introduced while the Chinese standard still remains at the stage of index stipulation.

《Table 1》

Table 1. Comparison of key alignment parameters between Chinese and German standards.

《2.3 Application discrepancy》

2.3 Application discrepancy

The engineering design of Chinese railway employs large quantity of technical standard drawings, which promotes the standardization and modularization of engineering design, construction, and maintenance and shortens the construction period in an effective way. However, this is often questioned in international projects for the following reasons. First, detailed specifications should be provided, including the application conditions and compilation basis of standard drawings, and its adaptation in specific projects. Second, the application of standard drawings will probably lead to waste due to failure of “acting according to the actual circumstances.”

The application of standard drawings is not proprietary for Chinese railway construction and many international companies also make use of standard drawings. However, standard drawings should be such prepared by laying emphasis on applicability of standard atlas, and giving detailed explanations on items, such as the application conditions, calculation principles, necessary calculation process, and application scope.

《3 Development strategies and suggestions for Chinese railway construction standards》

3 Development strategies and suggestions for Chinese railway construction standards

《3.1 Overall objective》

3.1 Overall objective

The overall strategic goal for the development of CRCSs is to transform the standards into international ones that contain Chinese characteristics and match China’s global position in railway.

《3.2 Step-by-step implementation stage》

3.2 Step-by-step implementation stage

The current CRCSs have long been applied in the domestic railway construction market. They are in line with both the national and traffic conditions in China and the Chinese modes of project constructions and railway survey and designs. When these construction standards start penetrating the international railway market, a process of transition will surely take place before the CRCSs can be widely utilized. The transition process can be roughly divided into the following three stages.

3.2.1 Initial stage

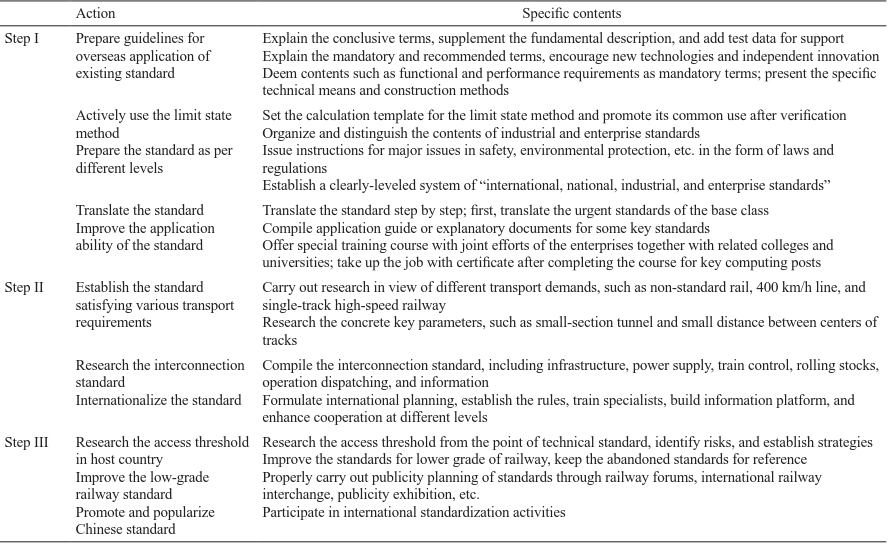

The main task of this stage is to solve the major adaptation issues encountered in the process of CRCSs’ “Go Global.” Measures will be taken in steps based on the level of importance and degree of urgency for the issue that awaits to be solved (Table 2).

《Table 2》

Table 2. Action strategy during initial stage.

3.2.2 Adaptation stage

In this stage, the objective is to review the current CRCSs from international standards and carry out revisions accordingly to make CRCSs adaptable in the global market.

(1) Framework construction for new CRCSs

The new standard system will be established to face the international railway market, with clear cut level divisions, highlighted key points (safety, environmental protection, interconnection, and functional requirement), wide applicability, and so forth.

The new CRCSs are comprised of four levels of standard,namely, the international level of standard, the national level of standard, the industrial level of standard, and the enterprise level of standard. Among these levels, the international standard is applicable for fundamental provisions (terminology, symbol, basic calculation provisions, test provisions, etc.), the national standard is adopted for aspects, such as those involving safety, environmental protection, and electromagnetic compatibilities, the industrial standard is designed for universal provisions, functional requirement, performance index, safety, interconnection, and so forth, and the enterprise (or association) standard can be utilized in the preparations of practical guidelines and instructions or manuals for the process of design, construction, operation, maintenance, and so forth.

(2) Work outline for railway technical standard preparation

The railway technical work outline provides clear provisions for the general fundamental requirements of railway, railway classification system, basic requirements of the subsystem, and so forth. This outline is legally effective, and can be utilized in the direction of standard drafting. It is embedded in the overall basic requirements, which includes factors such as safety, reliability, availability, personal health protection, environmental protection, and technology compatibility.

(3) Table establishment for Chinese railway construction standard system

The CRCSs system table reflects the inter-relationship between various standards (i.e., interconnection and mutual restriction). It also provides indication for cooperative relationship with other industries as well as the standards that need to be established in coordination with other industries. This CRCSs system table depicts the intra-system standards classification, level arrangement, and category division with clear defined fundamental requirements of various standard subsystems.

(4) Specification compilation of functional requirements

With reference to the European standard system that is guided by functional requirements, we are open and tolerant to specific technical solutions. Research and analysis of the functional requirements in the international market are the key and challenging points.

(5) Establishment of the industrial technical standard

The industrial technical standard is established with the aim of satisfying the fundamental requirements of the industry. It is prepared based on the framework of the standard and is constructed in compliance with the requirements stipulated in the work outline and the structural arrangement specified in the railway standard system.

The industrial technical standard should be drafted by making adequate utilization of various associations and mass organizations. It needs to include both compulsory and optional contents, and conducted examinations and verifications. Since the standard will be oriented to the international market, it will be easier for the promotion and application of industrial standard if it is drafted by associations or mass organizations.

(6) Enterprise standard

Enterprise (or association) standard mainly targets the instructions, guidelines, or manuals that are practicable in terms of design, construction, operation, maintenance, and so forth.

(7) Compilation of the international standard

Within the international standardization organization, China should be capable of undertaking more key roles, participate in international standards preparation, and promote Chinese standards through the platforms provided by international standardization institutions. In addition, China should actively participate in activities and events held by relevant international organizations, so as to enhance the international discourse power and integrate Chinese standard into the international ones through participation in the compilation (or revision) of international standards.

3.2.3 Prevalent stage

The objectives of this stage include the reflection of Chinese railway construction characteristics in CRCSs, demonstration of advantages of Chinese railway construction, being actively involved in high-end technology, making CRCSs prevail among other international railway standards, and becoming one of the important internationalized standards. The ultimate goal of this stage is to allow railway enterprises and owners in other countries accept and be willing to make use of Chinese standards. During this stage, focus should be on the advancement of Chinese standard and ensuring that the technical standard of Chinese railway remain at its leading position via the following possible approaches: ① increase the input of scientific research and maintain a leading position in science and technology; ② research high-end technology and maintain advanced status of the standard; ③ explore frontier technology and acquire patents and standardization; ④ involve a large number of high-level professionals with top-level professional skills/management capability, strong foreign language communication background, familiar with international standardization rules, and so forth; and ⑤ implement demonstration railway projects that are superior to foreign or international standards, so as to create an economic and reasonable mode of construction standard in the global market.

《3.3 Strategies and Suggestions》

3.3 Strategies and Suggestions

3.3.1 Adopt flexible strategy in application of standards

Owing to the comprehensive consideration given to various factors, such as market, policy, and technology, a flexible approach should be applied to adopt the strategy of “regionspecified treatment and in-step promotion.”

(1) In countries with developed economic and railway conditions, detailed research should be directed to investigate laws, regulations, and technical standards of the country. The key point is to adapt to the local standard.

(2) In countries with developed economic and less developed railway conditions, besides the laws and regulations, adequate research should also be conducted to investigate the connection between CRCSs and the country’s local standards in terms of factors such as health, safety, environment and interconnection standards, and functional requirements.

(3) In countries with less developed economic and railway conditions, CRCSs will be utilized in a flexible manner in combination with the project conditions and the local technical standards, or the application of CRCSs will be promoted in steps.

(4) In countries with less developed economic and undeveloped railway conditions, CRCSs can be actively adopted, optimized, and improved based on the local economic development level. Assistance in the preparation of standards can be offered to such countries, so as to create favorable conditions for subsequent construction.

3.3.2 Strengthen support received from scientific research

Recent comparisons indicate that the technical standards stipulated for Chinese high-speed railway are generally higher than those adopted in other countries. This is especially the case for the civil work profession. Components involved in this profession, be it horizontal or longitudinal alignment parameters, or the subgrade and bridge standard, all have weak international competitiveness due to strong measures, heavy workload, and high investment. With the development of Chinese railway, standards superior to foreign or international ones need to be established in the process of “Go Global.” However, these standards are generally prepared with supports from numerous scientific research and investigation. In addition, limited research has been conducted for full life cycle railways over standardization factors such as railway life span, reliability, reduced cost, and maintenance, all of which require fundamental investigation. Therefore, strengthening fundamental research should be adopted as a long-term strategy in order to ensure the competitiveness of CRCSs.

3.3.3 Support test and demonstration project construction

At present, China is the nation with the most high-speed railway construction and the longest mileage of operation. Thus, it is a nation with the most abundant experience in railway construction and operation. In order to enhance the competitiveness of Chinese high-speed railway in the international market, beyond making regular summaries, associated Chinese department should also establish demonstrative projects and provide more optimal standards than those that are currently employed at the international level or in other nations. All these will contribute to the setting up of a standard economical and rational construction model within the global market. The demonstrative project can be established by testing selected representative domestic projects, or construction of foreign-aid projects in overseas market.

The railway construction standard exerts source control over the entire technical scheme, and is influential for the various stages involved in the life cycle of the design, construction, product manufacturing, and operation and maintenance. So far, the CRCSs essentially satisfy the development requirements of domestic railways. However, distinctions exist in the system framework and professional contents between CRCSs and international standards, especially the ones pertaining to the philosophy of standard compilation. Therefore, from China’s “Go Global” railway perspective, technical standards for Chinese railway needs further refinement, and support from related government policies are also necessary. It is only when the CRCSs are being adapted in the overseas market that the technological monopoly of western countries can be terminated and China’s “Go Global” railway can be truly promoted.

京公网安备 11010502051620号

京公网安备 11010502051620号