《1. Introduction》

1. Introduction

An industry is a set of enterprises that are connected in a benefit chain in order to provide goods and services, and it is a meso economy between the micro and macro one [1,2]. “Maturity” means that a fruit is ready to be picked, from which its meaning is extended to reflect the degree of improvement of things and to describe and measure the degree of comprehensive development of a thing or person [3]. The method of maturity evaluations can be regarded as a way to solve practical engineering problems using systems engineering, which is an organization and management technique to achieve the optimization of a system as a whole.

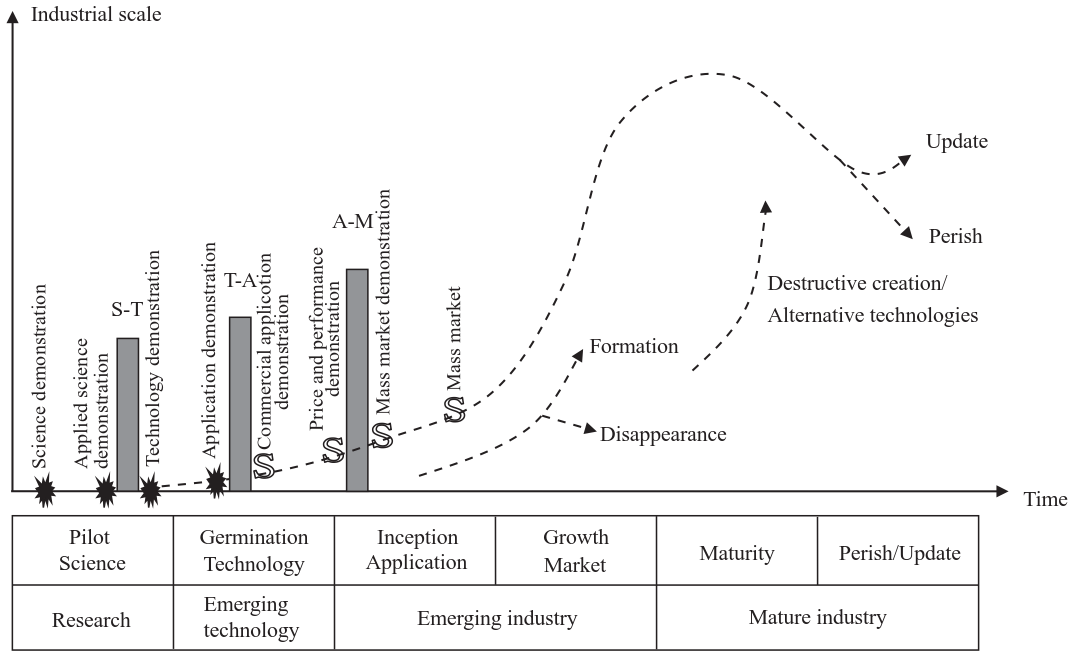

Industrial maturity levels (IMLs) assess and measure the development of an industry from its beginning to maturity. They are quantitative standards that reflect the degree of development of a new industry. The formation and development of the industry follow a particular law of evolution. The industry formed in early stage corresponds to the emerging industry, while that formed in mature stage after its initial and growth stages is the developed industry. The Center for Technology Management at the University of Cambridge analyzed the formation of 25 industries and concluded that the development process of these industries had a common process framework. This framework described the alternating development of dominant factors, such as the science, technology, application, and market in the development process of the emerging industries, and it also elucidated the general law of the evolution of emerging industries, which is also called the S-T-A-M process framework for the development of new industries (Fig.1) [3].

《Fig. 1.》

Fig. 1. The transition, milestone, and evolution stages of industry formation and development [3].

In accord with this analysis of industrial evolution, this paper considers industrial maturation as a process from product maturity to market maturity that follows a gradual sequence. Only when the technical characteristics of a product stabilize and mature firstly, can the product create a new market demand or satisfy the existing one, thus ultimately achieving the maximum value of the product and sustainable industrial development. Industrial maturation can be divided into four stages or levels (this paper only investigates the law of industrial development from pilot to maturity stage): embryonic, cultivation, developing, and maturity stage [4–6]. In the embryonic stage (IML1), main activities are to carry out basic research and development on the technology. In the nurturing stage (IML2), the commercial application of new products and/or services is successful, and the advantages of the products and/or services in terms of performance and cost are confirmed with the popularization of its commercial application. In the developing stage (IML3), after a successful market demonstration, a large number of competitors enter the market, and sales of the products and/or services can maintain a higher growth rate in this period. The maturity stage (IML4) is a period dominated by a developed industrial chain, in which a new industrial chain is formed, the industry standards are applied, and the industrial chain is perfect gradually. With the supply and demand of products and/or services tending to saturation, the growth rate of them slows gradually. In addition, there is a large-scale merger and recombination of enterprises within the industry, which results in that industry concentration continues to improve and leading enterprises stand ou

《2. IMLs assessment model and indicator system》

2. IMLs assessment model and indicator system

A IMLs assessment involves the integration of qualitative and quantitative methods. First, the maturity conditions of technology and manufacturing are evaluated, and these are then integrated into product readiness levels. Next, the comprehensive results of assessment for the product and market maturity conditions are integrated to form the IMLs. The IMLs assessment model and indicator system are illustrated in Fig. 2.

《Fig. 2》

Fig. 2. The indicator system for IMLs assessment

《2.1. Product readiness levels》

2.1. Product readiness levels

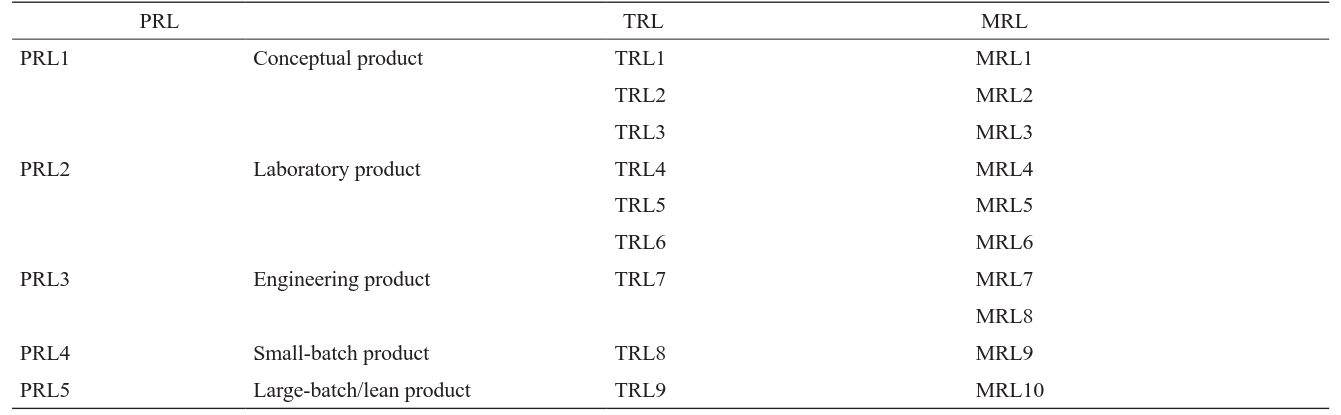

Products are the goods or services that meet customer demand in the market. From an engineering perspective, a product is the result of the development of technological research and manufacturing capacity [7]. Product readiness levels (PRLs) are used to evaluate and assess product development status against quantitative standards that reflect the extent to which the products meet the intended application target. PRLs assess and evaluate the maturity of a specific product in terms of standards and criterion, which can be divided into five levels (degrees), rising gradually from Level 1 to Level 5: conceptual, laboratory, engineering, market-oriented, and lean market-oriented products. The lowest degree is Level 1, and the highest one is Level 5. Therefore, there are two important aspects of product maturity [7]. The first is a gradually maturing process of external technical performance, which can be determined by technological readiness levels (TRLs). The second is the maturation of the internal manufacturing processes, materials, and process control, which can be assessed by manufacturing readiness levels (MRLs). Subsequently, PRLs integrate the assessment results of the technological and manufacturing maturity.

2.1.1. Technological readiness levels

Each TRL is a development status related to a particular system or project, and reflects the extent to which technological maturity has satisfied its intended target [8,9]. TRLs focus on assessing the development situation of technological carriers, integration states, and verification environment (Table 1).

Table 1. The assessment standards for TRLs.

《Table 1. 》

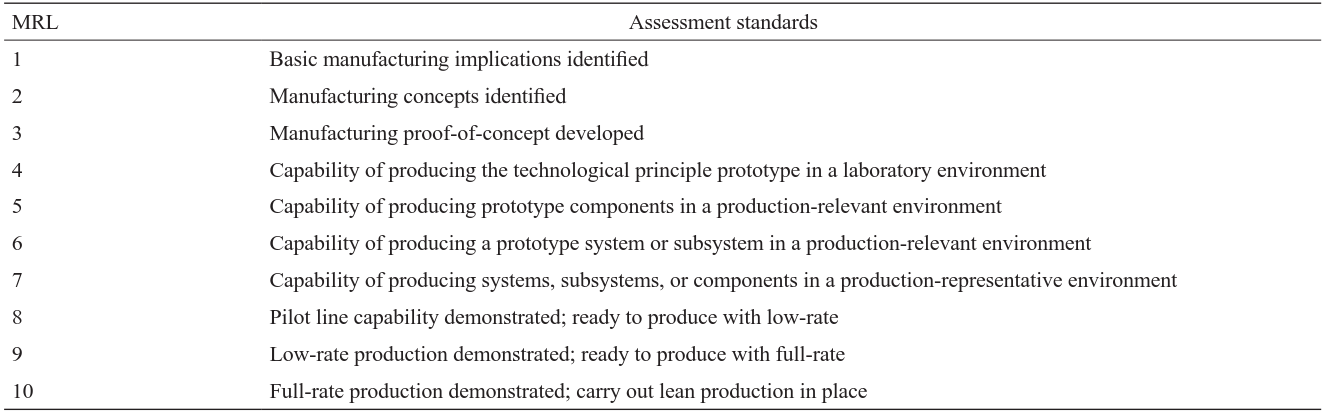

2.1.2. Manufacturing readiness levels

MRLs are used to represent the maturity of the key manufacturing factors, and they quantify the extent to which manufacturing capacity meets anticipated project target during the process of a new technology transforming into a product or system [10]. During research and development, the technological readiness is not the only concern, while the manufacturing readiness is another crucial focus. According to the best practices of project management, the whole maturation of manufacturing involves proposing manufacturing concept and forming the mass production and lean production capacity, which reflects the general development process from research to production. MRLs and their standards are shown in Table 2.

Table 2. The assessment standards for MRLs

《Table 2.》

MRLs focus on assessing the developing status of manufacturing objects, environment, and capacity. Manufacturing objects are the carriers of new technologies, the mature stages of which can be divided into concept samples, principle samples, demonstration samples, engineering products, and approved products. Manufacturing environment is the place where the manufacturing takes place, including laboratory, related production, prototypical production, trial production, and batch production environment. Manufacturing capacity in various stages refers to laboratory simulation, trial manufacture, and low-rate or full-rate production.

2.1.3. Product readiness levels

The integrated relation between the TRLs, MRLs and the PRLs is shown in Table 3.

Table 3. The Integration of PRLs.

《Table 3》

《2.2. Market maturity levels》

2.2. Market maturity levels

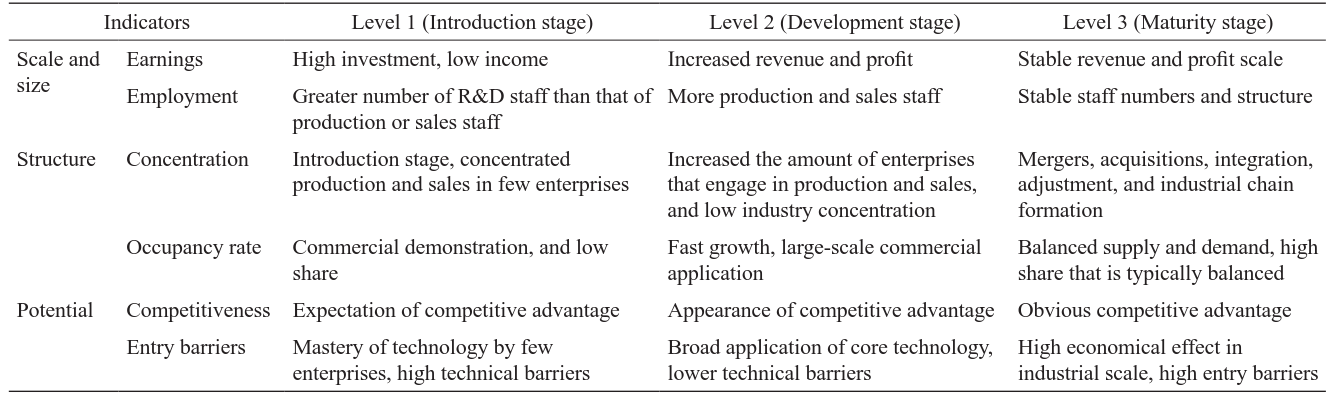

Market maturity levels(MMLs) are the standards for assessing and measuring the market state relative to the fully mature one. They reflect the maturity of market scale, structure and potential relative to the anticipated market target after a new technique or product being introduced into the market. MMLs provide a quantitative method for assessing the process of market development. They are the criteria and standards for assessing and quantifying the market maturity of products and/or services, consisting of three degrees (stages): introduction, development, and maturity (Level 1 is the lowest, and Level 3 is the highest). The criterion and standards of MMLs are listed in Table 4.

Table 4. The assessment indicator system for MMLs

《Table 4. 》

《2.3. Industrial maturity levels》

2.3. Industrial maturity levels

An IML assessment adopts a combination of qualitative and quantitative methods, and it is based on the maturity law from technology and manufacture to products, markets, and industry development. The IMLs can be finally determined by using this method. Therefore, IMLs reflect the comprehensive integration of the product and market maturity, as shown in Table 5.

Table 5. The comprehensive integration of IMLs

《Table 5》

《3. IMLs assessment form and process》

3. IMLs assessment form and process

Collectively, IMLs represent a method for assessing an entire development process of industry. In terms of the analysis on the component of industrial maturity and insight into the perspective of evaluation content, the main emphases of IMLs are TRLs, MRLs, and MMLs. In terms of the assessment methods, the main emphases are the weight determination of indicator systems, the integration of comprehensive evaluation results, and the design of assessment forms. In terms of the assessment processes, the main emphases are self-assessment and comprehensive evaluations.

《3.1. Assessment form》

3.1. Assessment form

IMLs analyze the indicators and statistical data of the technology, manufacturing, and market and then give a comprehensive evaluation of the industrial development process. After the evaluation method has been determined, the main emphasis is on collecting the input indicator data of the IMLs assessment. Therefore, the assessment form is a carrier for carrying out evaluation investigation and collecting assessment data.

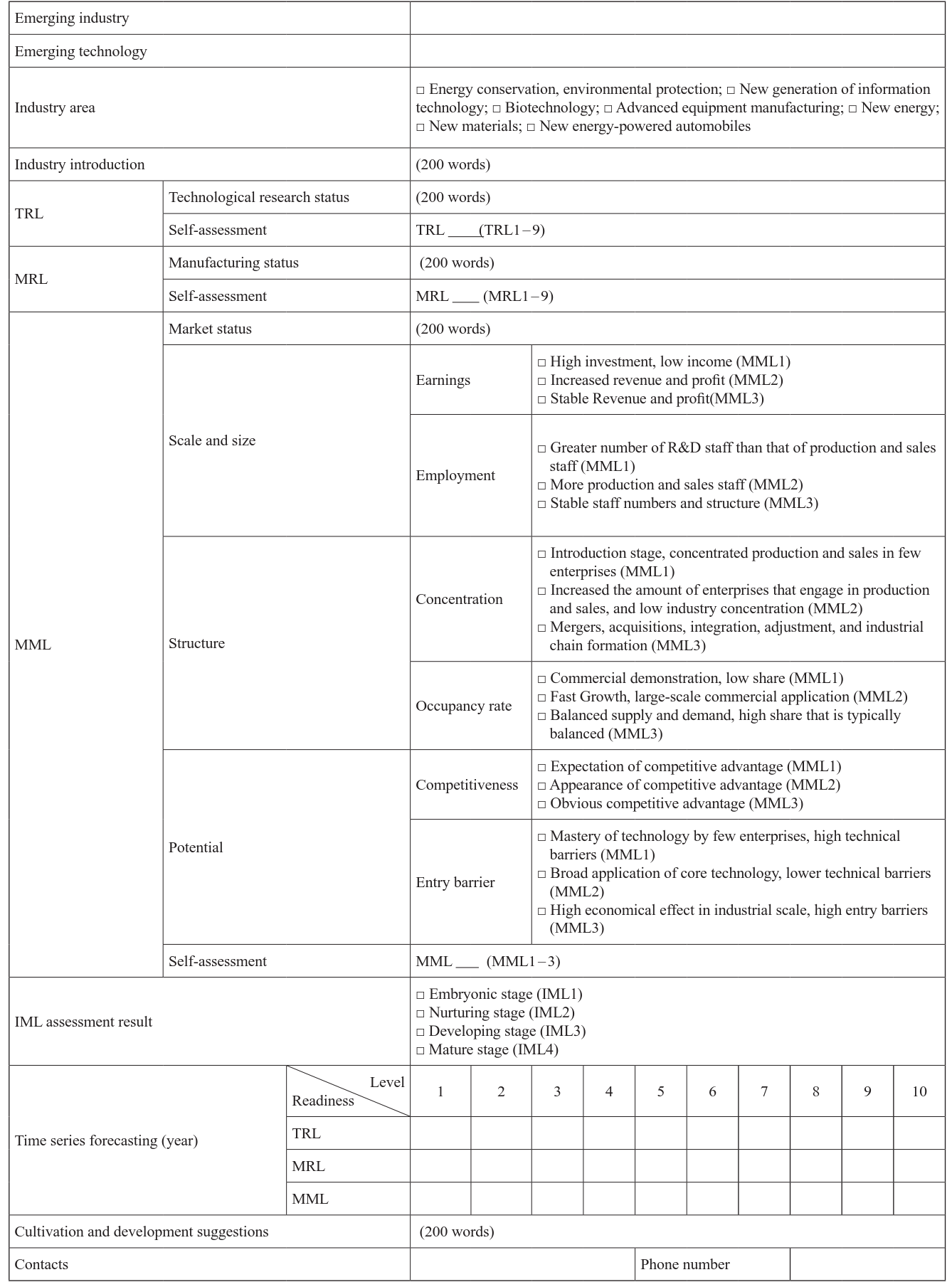

After collecting the data, the indicator weights are calculated by using a fuzzy complementary judgment matrix [11]. Based on the results of the weight vectors and judgment matrix, fuzzy comprehensive evaluation results are calculated. The format of the form should not only meet the data collection requirements for the evaluations but also be straightforward and easy to use. A IMLs assessment form is shown in Table 6.

Table 6. The IMLs assessment form

《Table 6.》

《3.2. Assessment proces》

3.2. Assessment proces

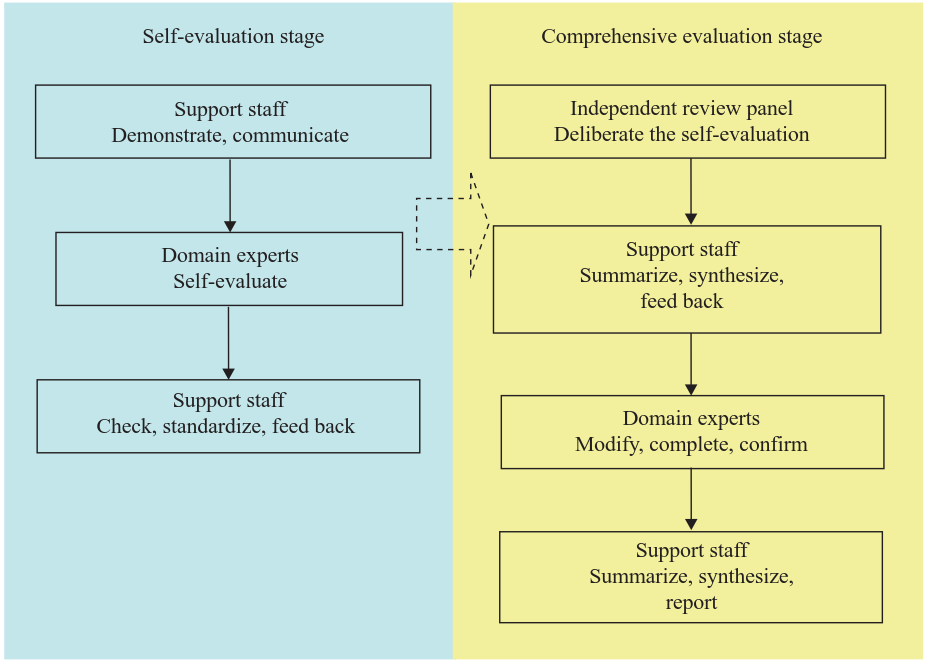

IMLs assessments have been implemented in the project “Research on Promotion and Development Planning of China’s Strategic Emerging Industry in the 13th Five-Year Plan Period,” the process of which is divided into two stages: self-evaluation by internal experts; and comprehensive evaluations. As shown in Fig. 3.

《Fig. 3.》

Fig. 3. The flow chart for IMLs assessment.

The IMLs assessment personnel consist of support staff, domain experts, and independent review panel.

3.2.1. Support staff

These refer to the support personal who help the domain experts and review panel to carry out the work of research and application of IMLs assessment method.

3.2.2. Domain experts

These refer to the specialists familiar with the industry, who have an intimate knowledge of emerging technologies and products, and master the general situation about the market and industry

3.2.3. Independent review panel

The review experts consist of 7–11 experts from research institutes, universities, companies, and industrial management offices, they are all familiar with technologies, manufacturing, market, and industry

《4. Case study of IMLs assessment》

4. Case study of IMLs assessment

Depending on the project “Research on Promotion and Development Planning of China’s Strategic Emerging Industry in the 13th Five-Year Plan Period”, this paper conducts the application research and takes the material industry as a case to assess the industrial maturity. The authors chose four representative key industries as the research subjects and used the IMLs assessment methods to assess the maturity levels, thereby to predict industrial development trend at the end of the 13th Five-Year Plan. They determined the development focus of this industry and its constraints and proposed some concrete suggestions against these constraints, thereby to provide support in perfecting the 13th Five-Year Plan for the government.

《4.1. IMLs assessment results in material industry》

4.1. IMLs assessment results in material industry

The IMLs assessment results of the four key industries in the material industry are shown in Table 7. The technological and manufacturing capabilities reflect the national independent research and development capacities, and the markets and industries present the conditions of national product markets and manufacturing enterprises. According to the assessment results updated in 2015, the technologies of artificial crystal materials, Li-ion batteries and materials, and vascular stents are relatively mature. The key technologies of these industries have made breakthroughs, and their products are in the demonstration application stage. In addition, the technological and manufacturing readiness of the new generation of advanced high-strength steel industry for lightweight automobile applications are still in the primary engineering development stage, and the bottlenecks of key technologies and manufacture still need to be broken through. In terms of markets and industries, Li-ion batteries and materials are more mature industry than other three industries, because the product markets of the latter have yet to be cultivated.

《Table 7. 》

Table 7. The IMLs assessment statistics

《4.2. Prediction of industrial maturity and scale for the end of 13th Five-Year Plan (2020)》

4.2. Prediction of industrial maturity and scale for the end of 13th Five-Year Plan (2020)

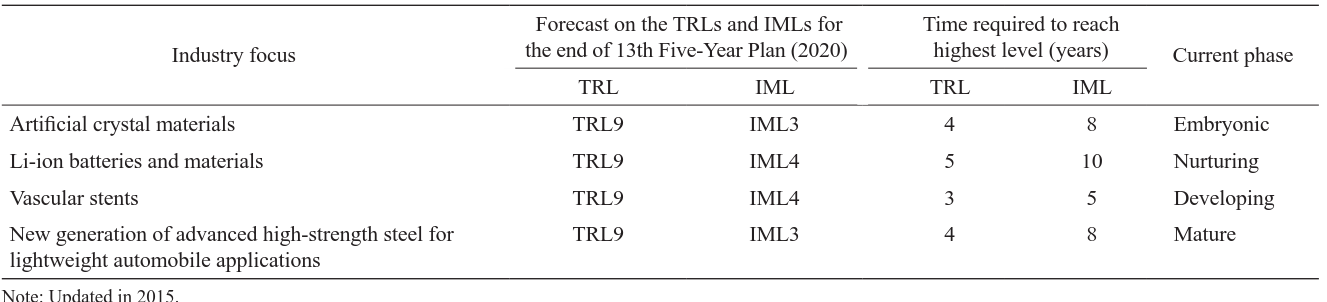

Through assessing and predicting the industrial maturity, the authors got the TRLs and IMLs in 2020 as well as the time required for full maturity of technology and industry, as shown in Table 8.

Table 8. The Forecast of emerging technologies and their industrial development.

《Table 8.》

4.2.1. Artificial crystal materials

During the 13th Five-Year Plan period, the TRL improves by one level to TRL8, and it is expected to achieve TRL9 by 2020. The IML improves by two levels, and it is expected to reach up to IML3 by 2020 from the embryonic stage to the development stage. Full industrial maturity requires eight years

4.2.2. Li-ion batteries and materials

At the end of the 13th Five-Year Plan, the TRL will improve by one level to TRL9. The IML will improve by two levels from the development stage to the mature stage, reaching up to IML4. Full industrial maturity requires ten years.

4.2.3. Vascular stents

In 2020, the technologies and productions with indigenous intellectual property right are expected to be given Conformite Europeene (CE) certification by the EU and to be approved by the Food and Drug Administration (FDA) of the United States. The TRL and the IML are expected to improve by one level and two levels respectively, and they both will achieve fully mature status.

4.2.4. New generation of advanced high-strength steel industry for lightweight automobile applications

In 2020, the TRL is expected to improve by four levels to TRL9, which means full maturity, and the improvement of it is the fastest of the four industries. The IML is expected to improve by two levels to IML3 from the embryonic stage to the development stage, and the full industrial maturity requires eight years. In terms of the experts’ assessment and data analysis, the current market demand is very high, but the major problem is the weakness of the technological research and development. However, if a technological breakthrough is made, the market and industry will develop rapidly

《4.3. Cultivation and development suggestions》

4.3. Cultivation and development suggestions

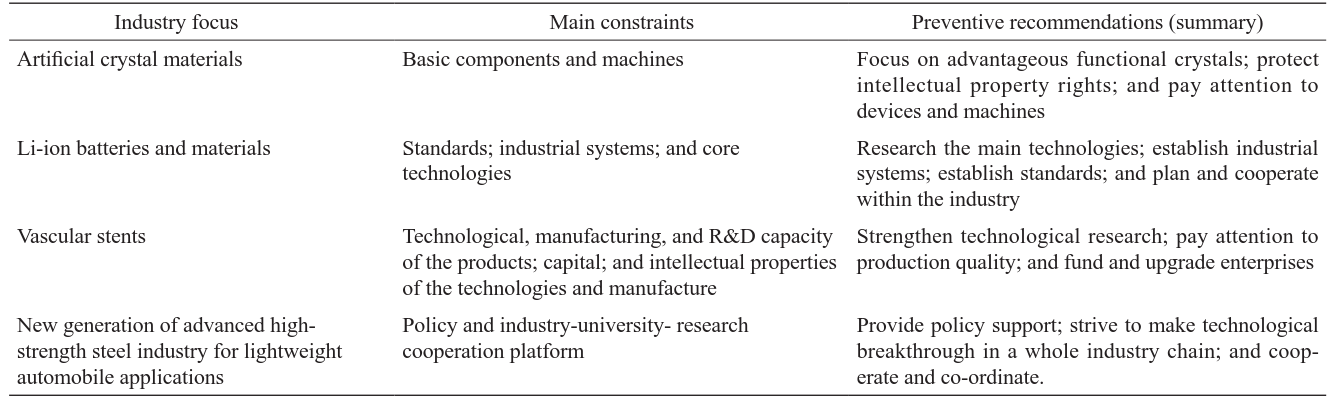

Through self-assessment by the domain experts and reviews by the independent panel, the development situation regarding the technology, manufacturing, products, markets, and industry of the four key industries in the material industry has been confirmed. In addition, the urgent problems have been discussed, and the micro or macro key factors that restrict industrial development have been identified. Finally, recommendations for cultivating and developing these industries have been made, and these recommendations that fit well with the actual situation can provide the reference in further decision making for government officials. Table 9 shows the main constraints for the future development of the four key industries, together with some cultivation and development recommendations

Table 9. The Forecast of emerging technologies and their industrial development.

《Table 9.》

The material industry is an important strategic emerging industry, and it is the basic industry for the national economy. New materials are the forerunner of material industry development. Therefore, it is essential to master a large number of core technologies, to nationalize key equipment, to realize large-scale production and system integration, and to reduce the gap with the advanced global level. Meanwhile, it is necessary to establish the new materials research and development platforms dominated by the enterprises, to strengthen engineering technology research, and to realize the mass production of key new materials. Table 9. The Forecast of emerging technologies and their industrial development. Industry focus Main constraints Preventive recommendations (summary) Artificial crystal materials Basic components and machines Focus on advantageous functional crystals; protect intellectual property rights; and pay attention to devices and machines Li-ion batteries and materials Standards; industrial systems; and core technologies Research the main technologies; establish industrial systems; establish standards; and plan and cooperate within the industry Vascular stents Technological, manufacturing, and R&D capacity of the products; capital; and intellectual properties of the technologies and manufacture Strengthen technological research; pay attention to production quality; and fund and upgrade enterprises New generation of advanced highstrength steel industry for lightweight automobile applications Policy and industry-university- research cooperation platform Provide policy support; strive to make technological breakthrough in a whole industry chain; and cooperate and co-ordinate. By 2020, the self-sufficiency rate of key materials is expected to up to 70 %, which can meet the basic national requirements for major projects construction, national security, and other fields. By 2020, the self-sufficiency rate of key materials is expected to up to 70 %, which can meet the basic national requirements for major projects construction, national security, and other fields.

《5. Conclusio》

5. Conclusio

The IMLs assessment is an integrated assessment method combining qualitative and quantitative analysis. Based on this method, this paper introduces maturity theory and assessment into the market and industry fields from the industrial technology and manufacturing fields, establishing an industrial maturity assessment model and indicator system. Through continuous research, practice, and summary, macroscopic evaluations and counseling models that are suitable for cultivating and developing strategic emerging industries have been built up. Hereon, the research group express gratitude to the experts in the various fields, because they have given guidance and cooperative support to this project “Research on the Promotion and Development Planning of China’s Strategic Emerging Industry in the 13th Five-Year Plan Period”. In the subsequent research, the research group will combine the maturity assessment methods with the return on investment (ROI) analysis to solve the quantitative evaluation problems in making decision for technology transition, commissioning assessment, and civil-military integration, thereby to provide data-based support for investment decisions.

京公网安备 11010502051620号

京公网安备 11010502051620号