《1 Introduction》

1 Introduction

According to the definition in China’s Renewable Energy Law, biomass energy refers to energy converted from natural plants, manure, and urban and rural organic waste [1]. Biofuel is a carrier of biomass energy, which refers to solid, liquid, or gas fuel, which is either composed of biomass or is processed.

Ethanol fuel is currently the most widely used form of renewable energy in the world. The production of bioethanol fuel is one of China’s strategic emerging industries, and hence has been subject to much development in line with the direction of China’s energy supply-side structural reform and energy development strategy. Bioethanol production is a nationally strategic industry that combines the agricultural and energy sectors with environmental protection interests. It is expected to play a significant role in ensuring national food security, solving the energy crisis, and strengthening environmental goverance [2]. On the one hand, bioethanol fuel, as one of the alternatives to traditional petrochemical energy, can help further optimize China’s energy structure, reduce external dependence on oil, and ensure energy security. On the other hand, bioethanol is the “thruster” and “control valve” of food security. The production of bioethanol fuel can help to stabilize food production, solve issues around “problem food,” and effectively promote the healthy development of agriculture. At the same time, bioethanol is the most environmentally friendly gasoline oxygenator and octane accelerator and a clean energy source. It can effectively reduce greenhouse gas and PM2.5 emissions and has a positive effect on the quality of the atmospheric environment.

At present, the United States and Brazil take the world’s leading positions in terms of bioethanol production and consumption, mainly due to the stable supply of cheap raw materials and incentives for renewable energy in place in these countries. For example, the United States produced and consumed a total of 4.717 ×107 t of bioethanol in 2019, replacing gasoline extracted from 500 million barrels of imported crude oil. This created 32 billion US dollars in revenue and supported more than 68 000 direct jobs and 280 000 indirect jobs. For more than a decade, China has produced and consumed more than 1.98 ×107 t of bioethanol and almost 2 ×108 t of blended gasoline, which improved China’s existing energy consumption structure and indirectly reduced its crude oil imports by 3.2 ×108 t. China’s bioethanol industry also digested 1.43 ×107 t of corn, rice, and wheat materials inedible to human and animals, and produced 1.24 ×107 t of high protein feed by-products. In addition, bioethanol reduces carbon dioxide emissions equivalent to 2.52 ×107 t, reduces the emission of harmful substances in automobile exhaust fumes, eliminates the need for methyl tert-butyl ether, and protects groundwater. The bioethanol industry has achieved initial results in three of China’s major strategic directions: the promotion of agriculture, protection of the environment, and development of alternative energy sources, with significant social, economic, and ecological benefits.

In recent years, a series of national policies have been issued to accelerate the development of China’s bioethanol industry. In 2016, the National Energy Administration issued The 13-th Five-Year Plan for Biomass Energy Development, stating that it is necessary to accelerate the demonstration and promotion of bio-liquid fuels, especially the application of ethanol fuel. In 2017, China developed a strategy for accelerating the development of ethanol, and 15 ministries and commissions jointly issued a report entitled, About Expanding Biofuel Ethanol Production and Promoting the Use of Bioethanol in Vehicles. The report vigorously promoted the use of ethanol fuel, after which the “Overall Layout Plan of National Biofuel Ethanol Industry” was determined. In 2018, China’s bioethanol plant capacity was increased by nearly 1 ×106 t to a total capacity of 3.7 ×106 t. Following nationwide promotion of bioethanol in 2020, annual demand for bioethanol is expected to exceed 1 ×107 t, resulting in a gap in production of at least 7 ×106 t [3]. China’s bioethanol industry is about to usher in significant development opportunities. Although a complete industrial system—from production, mixing, storage, and transportation to sales—has essentially been constructed, the overall level of development is still far from that of the United States. Against a backdrop of deep integration of national industrialization and informatization, China is in a strong position to explore intelligent and safe modes of bioethanol production, given its advantages in the Industrial Internet and 5G technology, and the role of new technologies such as big data, digital twins, and blockchain which can be harnessed to achieve this goal.

《2 Current status of China’s bioethanol industry》

2 Current status of China’s bioethanol industry

The ethanol industry is a new industry that is currently being vigorously developed in China. It is one of the emerging green industries, the promotion of which is based on the oil crisis and the need to control air pollution. At present, bioethanol production in China mainly comes from grain ethanol and cellulose ethanol. The production of ethanol using the biological fermentation method has undergone three developmental stages in China. The first generation used corn, wheat, and other old grains as its raw materials, whereas the “1.5th” generation used non-grain crops (e.g., cassava). Both stages involved the conversion of starch from the raw material to ethanol using biological fermentation. Although this second route can avoid the problem of competing with food production, it depends on imports for the source of the raw material. The second generation mainly uses cellulose-based biomass as its raw material. China has not yet achieved a breakthrough in the key technologies required for cellulose ethanol production, so its cost is relatively high compared with grain ethanol. In general, China’s bioethanol production level is in a transition period from the first to the 1.5th generation. The second generation of cellulosic ethanol is expected to be the mainstream route for future bioethanol production [4].

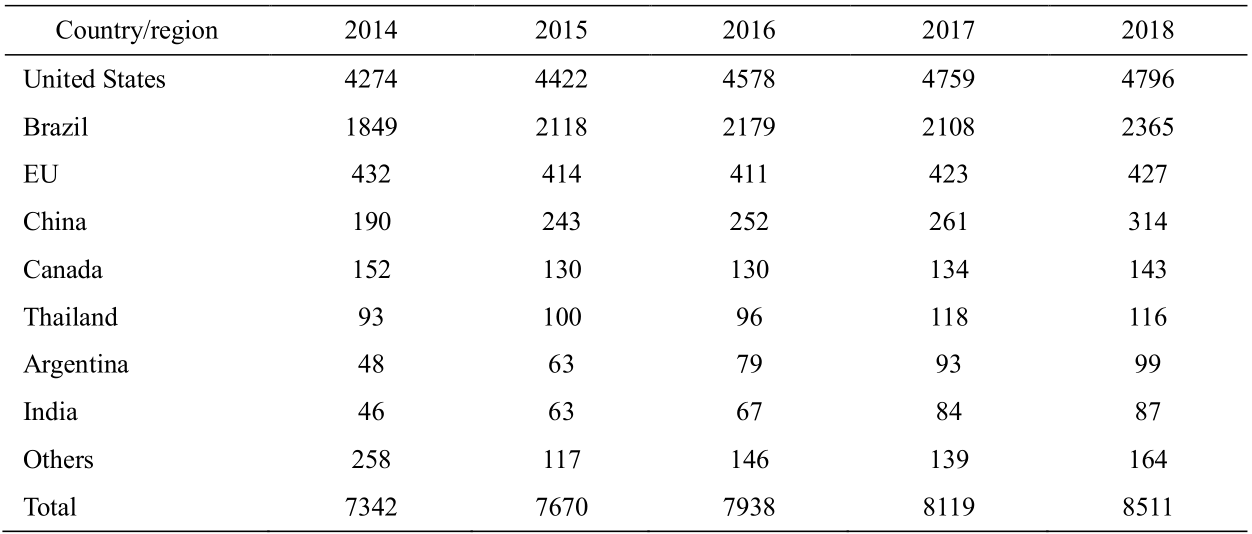

In 2018, there were 2000 bioethanol plants in operation around the world. Annual bioethanol production in 2018 reached 8.5 ×106 t, with a year-on-year growth rate of 5.28%. The International Energy Agency’s Renewable Energy Market Analysis and Forecast Report 2018–2023, released in October 2018, predicts that renewable energy will continue to expand, and will account for 40% of global energy consumption growth by 2023. Of this, biofuel production is predicted to increase by 15%, reaching 165 billion liters (approximately 130 million tons) by 2023. According to data released by the American Renewable Fuel Association, the United States produced 4.796 ×107 t of bioethanol in 2018, accounting for 56% of global bioethanol production and making the United States the main producer of bioethanol fuel in the world. Brazil is the second largest producer, with a total bioethanol production level of 2.365 ×107 t (approximately 28% of the global total) in 2018. In 1993, EU bioethanol production was only 4.8 ×104 t. After more than 10 years of development, it produced 4.2 ×105 t in 2004, after which time production began to increase significantly. In 2006, EU bioethanol production exceeded 1 million tons (1.2 ×106 t) [5] and by 2018, it had reached 4.27 ×106 t (Table 1). Regardless of its start date or growth rate, the EU bioethanol industry cannot be compared with that of the major bioethanol countries such as the United States and Brazil. Nonetheless, the EU has a relatively solid foundation in terms of its bioethanol industry. Most countries in the world have introduced relevant laws that clearly promote the production of bioethanol fuel. Thus, the global bioethanol fuel industry has a bright future.

《Table 1》

Table 1. World fuel bioethanol production (2014–2018).

×104 t

Source : American Renewable Fuel Association.

Improvements in production efficiency have always been the core of research and development into key ethanol production technologies. The improvement of production efficiency will benefit production enterprises in many aspects: (1) It will increase the capacity of existing equipment, enhance equipment utilization, and improve the conversion efficiency of each operating unit. (2) It could maximize product value through layered utilization and the optimization of product structure. (3) It could lead to savings in energy and water consumption. (4) It could reduce the emissions from liquid, solid, and gas waste. (5) It will reduce the investment costs associated with increasing the capacity of existing equipment and their associated production costs, and will improve the overall efficiency of the equipment. In the future, the device process will be more concise and green, and the equipment will be more stable and reliable, which will reduce pollutant emissions throughout the product’s life cycle.

As the highest achievement of advanced biotechnology, synthetic biology and molecular biology will play an important role in the future development of the bioethanol industry. Several biotechnologies, including gene breeding, efficient enzyme preparations, and the yeast are entering the bioethanol industry chain. The National NonGrain Biomass Energy Engineering Technology Research Center of China used synthetic biology technology to construct a recombinant strain, YM-27, in which the tolerance of ethanol was improved. Under the condition of 12% ethanol stress concentration, the biomass of the recombinant strain was increased by 1.97 times. The recombinant strain can overcome the problem of insufficient fermentation activity caused by the high concentration of ethanol which occurs in the middle and late fermentation phase of cassava ethanol production [6]. When the ethanol and osmotic pressure tolerance yeast is used in high thick fermentation, the raw materials can be rapidly saccharified. In this case, no sugar remains after fermentation, and the final ethanol concentration is close to 20% (v/v) [7]. In situ separation of ethanol using fermentation-pervaporation-coupled technology can reduce product inhibition and increase the yield per unit volume [8]. In China, although the application of biotechnology has gradually improved product quality and reduced production costs, most bioethanol production still utilizes corn and other food crops. Hence, production costs in China are relatively high when compared with that of the United States and Brazil. In addition, compared with other fuel ethanol production methods, such as coal-to-ethanol, the use of biotechnology presents a disadvantage in terms of production costs.

In recent years, the bioethanol production line has been gradually automated in China. This has resulted in significant improvements in production efficiency and corresponding reductions in labor costs. However, the level of informatization and intelligence of the production line is still low in China. It is difficult to further optimize production line resource allocation and productivity by sensing, obtaining, and analyzing the full factor information of the production line alone. At the same time, it is often difficult for those at the decision-making level of the enterprise to understand and grasp the actual situation at the production site within the required timeframe, resulting in difficulties in management and high associated costs. To ensure the safe and efficient production of bioethanol and to enhance the future core competitiveness of the industry, bioethanol companies urgently need to integrate resources and optimize the production process through the adoption of new technologies to increase their production capacity, reduce production costs, and seek high-quality development routes.

In addition, the production processes of the chemical industry involve strong continuity, a large spatial scale, complex production processes, and are highly dangerous, among other characteristics. Safe production is the first basic principle of the chemical industry. According to the 2018 National Chemical Accident Analysis Report, there were 176 chemical accidents and 223 deaths nationwide in 2018. Of the 176 chemical accidents, 32 were poisoning and suffocation accidents and 26 were chemical explosions. Chemical enterprises still lack an effective intelligent management and control platform for the production process. Security risks are hidden in the enterprise, and there are many blind spots in monitoring. Chemical production safety and environmental safety remain the focus of most chemical enterprises. The bioethanol industry is a composite industry integrating biological, chemical, and energy industries, with multiple composite characteristics. Safe production is also an important challenge for long-term development.

《3 Future modes of China’s bioethanol industry》

3 Future modes of China’s bioethanol industry

In July 2019, the White Paper on Process Intelligent Manufacturing was released. Against this new background and the opportunities of intelligent manufacturing, process manufacturing will undergo significant changes in terms of the equipment transportation and asset management mode, production model, operation mode, and business mode [9]. To ensure the safe and efficient production of bioethanol and to enhance the core competitiveness of the industry in the future, a new mode for the development of the industry is urgently required.

Utilizing intelligent control, industrial big data, the 5G network, and other advanced information technology will ensure the safe and efficient production of bioethanol enterprises. How to do so is a key issue to be solved in order to find a new mode for the development of the bioethanol industry. China has successively issued documents such as the Guiding Opinions on Deepening the Integration of Manufacturing Industry and Internet, Guiding Opinions on Actively Promoting “Internet+” Action, Smart Manufacturing Development Plan (2016–2020), and Guiding Opinions on Deepening “Internet+ Advanced Manufacturing Industry” Development of Industrial Internet, which provide strong policy support for the development of intelligent manufacturing. The deep integration of information technology and industrialization has been a new strategy for the development of China [10,11]. 5G commercialization has advanced rapidly in recent years, providing network speed and large-scale connectivity not less than 10 times that of 4G networks, with network latency reduced to 1 ms. The flexibility and convenience of 5G networks will directly facilitate digital transformation across industries and provide a solid network infrastructure for smart development. Industrial big data is an important breakthrough point in the Made in China 2025 technology roadmap, and in the next decade, an intelligent system built with data as its core will become the key mechanism with which to support intelligent manufacturing and the Industrial Internet [12].

《3.1 Intelligent production based on big data from the fermentation process》

3.1 Intelligent production based on big data from the fermentation process

In recent years, national policies related to industrial big data have been promulgated, accelerating the deep integration of information technology and industry, and promoting innovation with which to realize new industrial modes. In April 2018, the China Academy of Information and Communications Technology released the China Big Data Development Survey Report (2018). The report shows that from 2016 to 2018, the size of China’s industrial big data market steadily increased, and is expected to remain above 30% from 2018–2020. The biological fermentation process involves diverse and uncertain raw material sources, a complex fermentation process mechanism, numerous variable processes, complex interaction effects, and equipment units with varying characteristics. At the same time, it preserves a large amount of historical production data containing rich characteristic information regarding the production process [13–15].

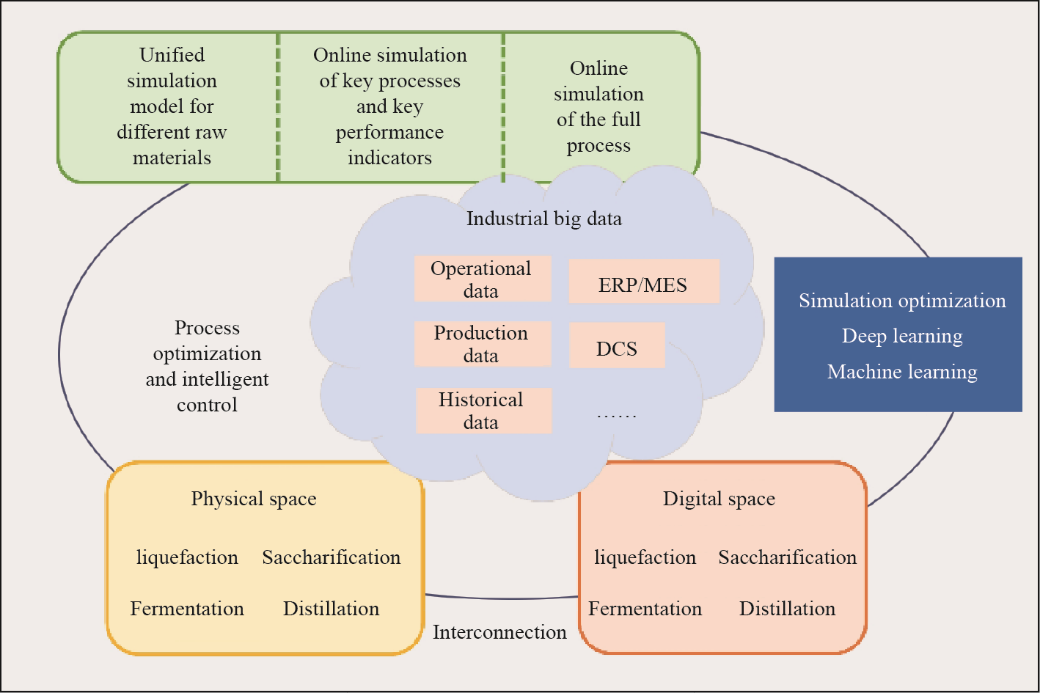

Therefore, the future mode of the bioethanol production process, as a typical biological fermentation process, can be predicted based on historical production line operation data in order to establish a process knowledge map. Big data analysis and deep learning can be used to realize the modeling and dynamic scheduling of the production processes (Fig. 1). For example, to address the difficulty in accurately describing the production process due to the global single model for the uncertainty of the feedstock source, a simulation model based on different types of samples can be constructed. This utilizes the macro-modal identification of production conditions using a hierarchical clustering algorithm. A segmentation technique appropriate to the large amount of historical data involved can be used to provide reliable sampling data for intelligent control. In view of limited mechanism cognition of key processes such as fermentation and separation in the current bioethanol production line, the model can be optimized and corrected for key parameters, structure, and other adaptive selection aspects. It can also compensate for the lack of mechanism cognition through big data mining to achieve the accurate simulation of key processes. At the same time, the online calculation model of the key performance indicators of fermentation, separation, and other key processes can be enhanced via integration with big data, the results of which can be used to guide the global optimization of the production process and realize the intelligent control of the production process. In summary, based on the combination of industrial big data, advanced control, process optimization, and other technologies, a balanced decision regarding the choice of production material can be made, which will significantly improve production efficiency, reduce energy consumption, and ultimately determine the future mode of bioethanol production.

《Fig. 1》

Fig. 1. Model of the future production process of China’s bioethanol industry.

Note : ERP, Enterprise Resource Planning; MES, Manufacturing Execution System; DCS, Distributed Control System.

《3.2 Safe production based on digital twin technology》

3.2 Safe production based on digital twin technology

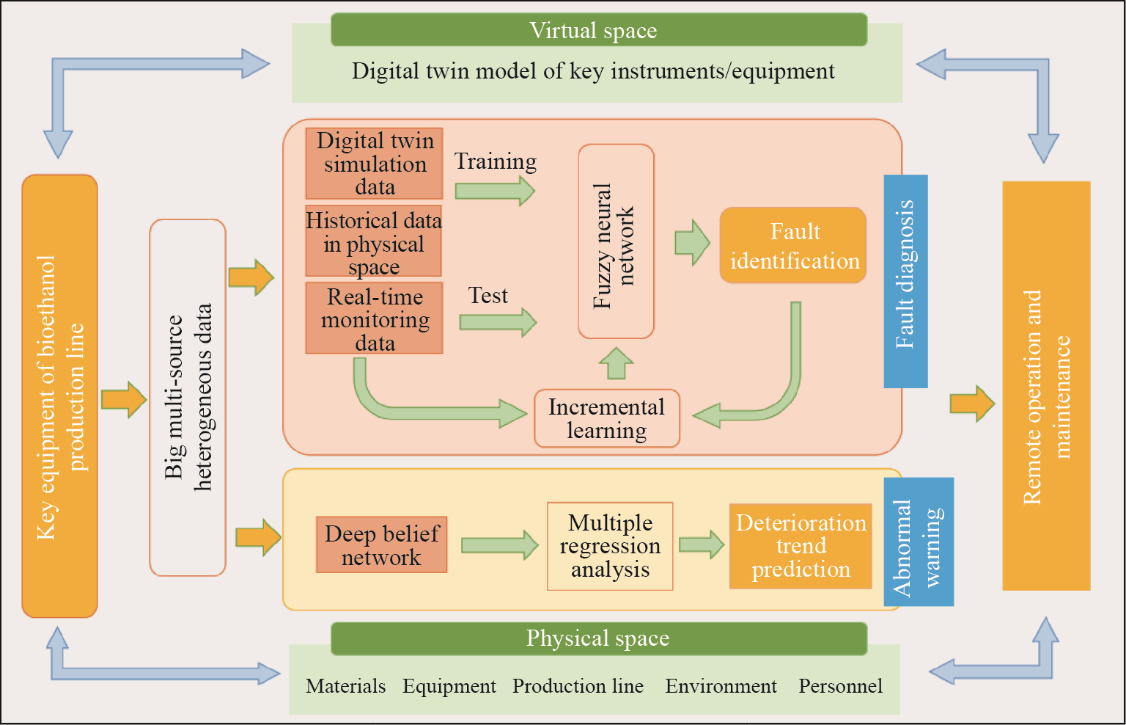

The bioethanol industry requires that production equipment can be operated without downtime, however traditional passive diagnosis and maintenance techniques have difficulty in predicting accident phenomena in a timely and effective manner due to their severe lag effects and low adaptability. Therefore, upgrading traditional diagnosis and maintenance technology with active and adaptive condition assessment capabilities is an effective way to ensure the safe operation of equipment, which improves operational quality, reduces economic losses, and avoids human casualties. Among them, digital twin technology, remote operation and maintenance, and fault diagnosis are the key technologies for the future of equipment operation and maintenance in the bioethanol industry (Fig. 2) [9].

《Fig. 2》

Fig. 2. Future mode of equipment operation and maintenance in China’s bioethanol industry.

The current application scenarios of digital twin technology include manufacturing, construction, medicine, and urban design. Digital twin technology has long been applied in high-end engineering applications,such as in NASA’s lunar rover, fighter jet, and jet engine designs. iFLYTEK Corporation has released plans to build a digital twin city, while Beijing’s new airport was build using digital twins of its building keels and pipe network, which reduced construction costs by 5%–10% and shortened the construction time by 10%. By establishing a digital twin system for the bioethanol production line and a digital twin object model covering multiple spatial and temporal scales, remote online monitoring of equipment can be achieved. Combined with augmented reality technology, real-time transmission of the device could also be achieved. Real-time monitoring data could be sent to the fault diagnosis expert and be used accordingly to guide field personnel to complete the required equipment maintenance and other operational tasks, which would greatly reduce unnecessary labor costs. Simultaneously, the digital twin system could provide functions such as three-dimensional immersive intelligent inspection, process training, operation training, and security monitoring, as well as solving problems such as manual inspection and production line management in large-scale factory areas, high-risk areas, and during severe weather events.

Predictive maintenance is a new equipment maintenance method based on modern digital signal processing, artificial intelligence, and other advanced technologies, including real-time monitoring and the use of a fault alarm for production line equipment. It can implement remote analysis and the comprehensive management of equipment operation data, and can give bioethanol production lines perfect self-test and self-diagnosis capabilities [16,17]. The use of the latest sensor detection, signal processing, and big data analysis technologies could be used for the dynamic observation of bioethanol production lines. Analysis of data regarding key equipment characteristics can provide real-time monitoring and a diagnosis of production line status, as well as realize the early detection of problems and the timely deployment of maintenance solutions. This would ensure the normal operation of the equipment, thereby minimizing the risk of problems. It can guarantee safe production while reducing the number of spare parts that are required, thereby reducing storage costs. Through this paradigm shift in the mode of equipment operation and maintenance in the bioethanol industry, the efficiency and accuracy of equipment operation and maintenance could be improved in order to ensure the safe production of enterprises.

《3.3 Energy industry management based on the Industrial Internet and blockchain technology》

3.3 Energy industry management based on the Industrial Internet and blockchain technology

Driven by national policies, the bioethanol industry has developed rapidly in the last two years. However, it has also experienced challenges, such as how to make national policies more efficient and how to avoid the impact of pricing mechanism conversion. This means that the implementation of lean (and fully digital) management is essential in the bioethanol market, both at the industry level and at the corporate level. Because the total volume needs to be controlled and the upstream and downstream segments need to collaborate in order to avoid market dislocation, bioethanol production must not only digest excess grain, but must also ensure that the grain reserves are above the safe range. Therefore, the adoption of the Industrial Internet and blockchain technology will help the industry and enterprises to implement lean management, providing a strong guarantee for comprehensive implementation and high-quality promotion of national policies.

China’s Industrial Internet industry has developed vigorously since 2017. Traditional manufacturing enterprises, industrial software companies, industrial equipment providers, and information and communication enterprises have carried out the construction of Industrial Internet platforms. Building an Internet platform for an enterprise or industry can break through upstream and downstream information, integrate data, and improve management efficiency of a given enterprise [18,19]. The Industrial Internet is the key support technology for the fourth industrial revolution and 5G is an important direction for the upgrade of new-generation information and communication technologies. The integration and innovative development of the two will promote the upgrade and transformation of the manufacturing industry and will support the construction of China’s manufacturing and network power. At present, research on and construction of the “5G + Industrial Internet” is still in the developmental stage. The application of these technologies in the bioethanol industry needs a breakthrough, and there is great room for development. Based on the development requirements of enterprises and industry policies, the 5G + Industrial Internet has been used to design, construct, manage, operate, and maintain the Industrial Internet intranet for enterprises and to connect distributed production enterprises. Production data, industrial models, and business services are precipitated through the platform, and industrial knowledge and experience are transferred and copied through the industrial Applications. This allows data sharing and industrial chain information integration and improves the management level of production enterprises. It can also be used to explore the business management implications of sustainably developing the bioethanol fuel industry, thereby allowing for a complete enterprise transformation. Ultimately, these technologies can be used to achieve cross-enterprise value chain extension, industry-wide ecological construction, and configuration optimization.

Blockchain technology is a new generation of information technology. It is a disruptive form of innovation that follows the development of steam engines, electricity, and the Internet, and will bring new opportunities for technological innovation and industrial change [20,21]. The adoption of blockchain technology can help to solve the trilemma of the energy industry: first, it can optimize energy processes and reduce costs; second, it can improve the security of supply; and third, it can provide more renewable energy and low-carbon solutions [22]. According to recent data, within the energy industry, blockchain technology is mainly adopted by power companies and petrochemical companies [23]. The exploration of the application of the “blockchain model” in supply chain financial platforms and product traceability platforms could serve as an important breakthrough for business innovation in the bioethanol industry. The transformation of the business model of the bioethanol industry could transform the industry by enhancing business, improving management efficiency, and reducing transaction costs.

《4 Suggestions for the development of the bioethanol industry in China》

4 Suggestions for the development of the bioethanol industry in China

《4.1 Policy guarantees》

4.1 Policy guarantees

At the national level, China should strengthen top-level design, guide industrial development from the national strategic level, and accelerate the formulation of special program-orientated documents to promote the intelligent development of the biofuel industry. Organizational leadership needs to be strengthened, and national coordination mechanisms to promote bio-liquid fuel research and development need to be established as soon as possible. The National Bio-Liquid Fuel Leading Group needs to be established to coordinate the production of bioethanol with the promotion of the use of automotive ethanol and gasoline. And the standard systems of the industry need to improve.

Local governments should conduct pilot reforms of institutional mechanisms in accordance with national strategies to actively promote the formation of new industrial forms. Existing industrial-scale enterprises, bases, and clusters can be relied on to introduce relevant policies in order to provide financial support for industrial intelligence upgrades and construction. This would strengthen preferential policy support for related enterprises; attract talent, technologies, and funds for advantageous areas; and lead the characteristic, joint, and intelligent development of bioethanol industry bases. Step by step, China will focus on cultivating a batch of world-class bio-liquid fuel industry clusters and promote the development and demonstration of new technologies for bio-liquid fuel in areas where conditions permit.

At the enterprise level, they should focus on innovative production modes and production technologies, strengthen cooperation with scientific research institutions, and adhere to the principle of combining independent research and development via the introduction of collaborative working. According to the principle of combining basic research and commercial applications, a technology innovation system that combines enterprise orientation, market orientation, and production–university research collaboration needs to be established and perfected. They should strengthen the construction of an innovation platform and the role of independent innovation, focus on breakthroughs in key common technologies, and explore advanced fuel biotechnology routes suitable for national conditions. At the same time, they need to actively cooperate with national policy guidance, improve market competitiveness, and improve the internal efficiency of enterprises thus to ensure the high-quality development of the bioethanol industry.

《4.2 Key technology research areas》

4.2 Key technology research areas

The National Renewable Energy Medium- and Long-Term Development Plan clearly states that, in the long term, we must actively develop biofuel technologies using cellulose-based biomass as the raw material. However, the core problem of the current second generation (cellulosic ethanol development) lies in the lack of advanced, efficient, inexpensive enzymes and industrial strains. The core technology still lacks competitiveness and risk resilience, which is due especially to the poor level of comprehensive utilization of raw materials and low technological integration, among other factors. In order to solve the technical bottlenecks and meet the market demands of cellulosic ethanol technology, China urgently need to effectively integrate different disciplines and specific technical fields while focusing on constraining fibers, such as straw pretreatment, sugar platform, biotransformation, biochemical separation, biorefinery, and co-production. Related technologies should be combined into a complete set of technical integration methods to achieve an overall breakthrough. Integrating the solution into a tightly integrated and complete process package for industrialization demonstration, expanding the scale to accelerate the progress of upgrading, and replacing oil quality will bring considerable economic, environmental, and social benefits.

An entry point for the recent development of cellulosic ethanol should draw on the advanced concepts of mutual benefit and win-win solutions. It should be deeply integrated with existing plant equipment (first or 1.5th generation), rely on public works, and maximize the use of resources to ensure efficient use of the raw material, thereby reducing the investment and operating costs of the plant. This new model is also respected by industry pioneers and is expected to generate considerable benefits.

《5 Conclusions》

5 Conclusions

The bioethanol fuel industry is a complex process industry that integrates the biological, chemical, and energy industries. Huge biomass resources are the most widely used raw materials for bioethanol production; “fusion” will be a future mode for the development of ethanol power plants. Promoted by the strategy of national industrialization and information technology integration, the deep integration of various new technologies through the application of big data, digital twin technology, 5G + Industrial Internet, blockchain technology, and other new technologies can bring about significant changes in the bioethanol production process, including safe production and a business management mode of the industry. They could also be used to establish a new model of digitalization, production, supply, marketing, and the research integration of enterprises, thus realizing the reasonable upgrade and transformation of existing production technologies and the maximization of economic and social benefits of enterprises.

京公网安备 11010502051620号

京公网安备 11010502051620号