《1 Introduction》

1 Introduction

Significant tasks for ecological civilization construction include accelerating the establishment of legal system and policy orientation for green production and consumption; establishing and improving the economic system of green, low-carbon, and circular development; and promoting green and low-carbon factors as drivers for economic growth and the developmental trend of green and low-carbon industries in the new era [1]. During the 13th FiveYear Plan period, the emerging green and low-carbon industries develop rapidly, represented by energy technology, energy conservation, environmental protection, and new energy vehicles [2]. Emerging green and low-carbon industries in China have significant industrial features and varying development maturity, with regard to core technology level, manufacturing capacity, and market and industrial scale [3,4]. Scientific identification of the maturity level of green and low-carbon industries is beneficial for scientifically judging industrial similarities and differences, thus providing a decision-making basis for industrial development.

The concept of industry maturity level was first proposed by the Chinese Academy of Engineering in 2015, with regard to emerging industry strategy research, and was used to measure or evaluate the development stage or current life cycle of emerging industries via the construction of an evaluation index system. In 2016, Wang et al. [5] were the first to introduce the concept of market maturity level and establish the maturity evaluation method for emerging industries, based on the technical readiness level [6] and manufacturing readiness level [7]; these provided the theoretical foundation for the maturity evaluation research of emerging industries.

In 2017, Sun et al. [4] applied the maturity level method to the energy industry, distinguished between energy utilization/transformation and traditional industrial manufacturing to redefine the industrial product, and constructed the maturity evaluation index system in energy industries, from multi-technology and multi-product perspectives. In general, the research framework of industry maturity level theory has been formed and the evaluation factors cover three basic aspects: technology, product (manufacturing), and market, with the method being applicable to strategic analysis and evaluation research regarding emerging industry development in all fields [8]. However, due to differences between the fields and industries, this basic research framework lacks the analysis of field characteristics and industry attributes, as well as consideration of the national strategic demand under the new international and regional situations. Development of a general evaluation method for the maturity levels of green and low-carbon industries is urgently needed.

Since the theory and method for evaluating the maturity levels of the relevant green and low-carbon industries are currently required, this study will identify green and low-carbon industry characteristics and combine the industrial developmental trend and new international environment to establish the evaluation method for the maturity levels of green and low-carbon industries, based on basic theory and the common evaluation method of industry maturity level. These methods will then be demonstrated for the example case of the biomass combined heat and power generation industry.

《2 Basic theory and method of industry maturity level evaluation》

2 Basic theory and method of industry maturity level evaluation

《2.1 Basic theory》

2.1 Basic theory

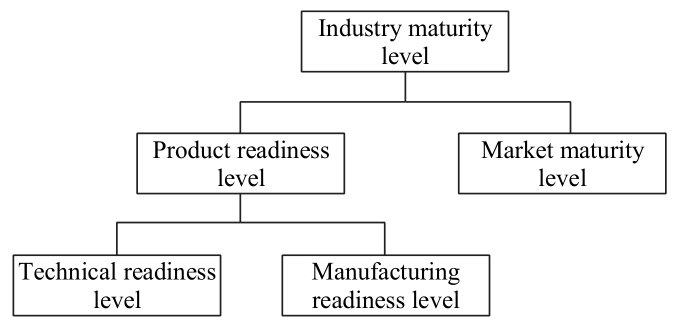

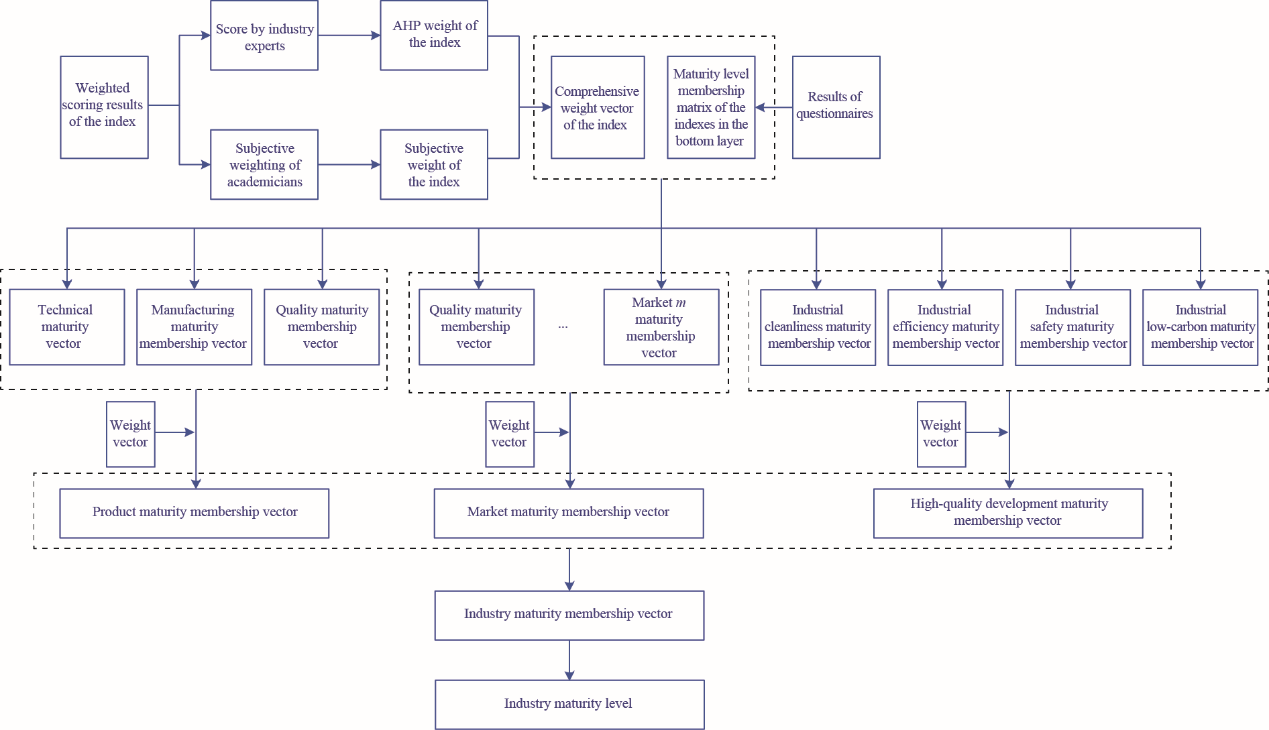

The common theoretical framework of the industry maturity level evaluation system is shown in Fig.1. The system includes two subsystems, product readiness level (covering technical and manufacturing readiness level) and market maturity level (based on the multi-dimensional evaluation index system). The current evaluation index predominantly used is qualitative grading evaluation [2,4,5]; i.e., a quantitative study of the industry’s maturity level via an index score. This evaluation framework can be widely applied to emerging industries and industry maturity level evaluation research in different fields or categories.

《Fig.1》

Fig.1. Basic theoretical framework of industry maturity level evaluation system.

Randomness in the selection of the research industry category determines the uncertainty in the core technologies, product, and market division of the industries under the condition of research on various sub-sectors and greatly enhances research complexity. It is difficult to describe the industrial characteristics of different fields with a single technology, product, or market; e.g., the energy field requires multi-technology and a multi-product evaluation system [9]. Therefore, to adapt to industrial development environmental changes and meet different evaluation requirements, proper adjustment/expansion is required, based on this theoretical framework during popularization and application.

《2.2 Routine application method》

2.2 Routine application method

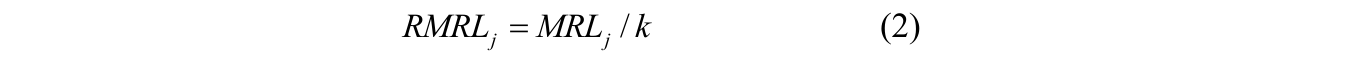

The general operation process for applying the maturity level evaluation method to improve the standard research ability is shown in Fig.2. Determination of evaluation subject and industrial core factors is the major component of evaluation preparation, which can be further divided into industrial subject definition, core technology and key product identification, and market division.

《Fig.2》

Fig.2. Industry maturity level evaluation process.

Note : AHP refers to analytical hierarchy process.

First, the industrial subject to be evaluated requires determining and the scope and research time of the industry require identifying, based on the research requirements; second, the industrial core technologies and products (facility, equipment, or terminal products and spare parts) are to be determined according to the industrial characteristics and current development status; finally, the market division is to be determined. Each kind of product will be approved for market division and a decision made regarding whether the relevant products will be combined to the same market, as per the competitive relation among the products.

To guarantee the flexible method application, there should only be the necessary links in the evaluation organization process after preparation, including rectifying and improving the maturity level evaluation index system (different sub-layer index can be established based on the characteristics of the sub-sectors), organizing the industry experts to mark the evaluation indexes and weights (several online or telephone questionnaires, and field consultations are available), and producing the report (data verification, statistical analysis, and rationality demonstration).

《3 Scope and features of green and low-carbon emerging industries》

3 Scope and features of green and low-carbon emerging industries

《3.1 Industrial definition》

3.1 Industrial definition

In 2016, The 13th Five-Year Plan for the Development of Strategic Emerging Industries was printed by the State Council, which, for the first time, clearly divided green and low-carbon industries into new energy vehicles, new energy, and energy conservation and environmental protection industries. In 2019, the National Development and Reform Commission and other departments co-printed the Green Industry Guidance Catalogue (2019 Edition), which mainly defined energy conservation, clean production, clean energy, and other green industries; it further clarified the industrial boundaries of green and low-carbon industries.

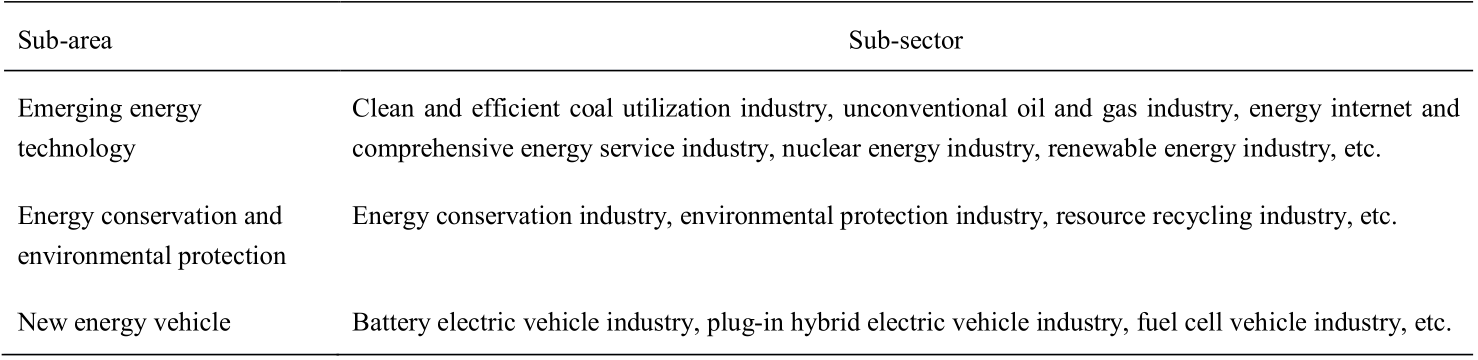

Green and low-carbon emerging industries refer to emerging industries that focus on green and low-carbon technical innovation and application. This industrial category mainly includes emerging energy technology, energy conservation and environmental protection industries, and emerging industries in the new energy vehicle field [1]. The classification and categorization of green and low-carbon industries are shown in Table 1.

《Table 1》

Table 1. Classification and categorization of green and low-carbon industries.

《3.2 Industrial high-quality development features》

3.2 Industrial high-quality development features

According to the developmental trend of the global energy revolution and the green transformation of China’s industries, attention to construction of the ecological civilization, coping with climate change, and the development of green and low-carbon emerging industries meet the high-quality development requirements of emerging energy technology, energy conservation and environmental protection, and the automobile industry in the new era.

“Green” in green and low-carbon technology refers to the clean processes of resource exploitation/production, utilization, and transformation to consumption and application. Utilization of clean energy, realization of clean development, and utilization of resources are some of the core targets in addressing environment pollution and further developing the emerging green and low-carbon industries. Efficiency of this technology represents the highquality development demands of emerging industries. Improving the development and utilization efficiency of energy, mining, and other resources, reducing resource waste, and resolving the curtailment of hydro, wind and photovoltaic power remain significant development goals for green and low-carbon industries. Low-carbon is another core feature of green and low-carbon industries. Low-carbon, and even zero-carbon, technologies have been a key task in the emerging industry fields, e.g., developing nuclear energy, renewable energy, hydrogen energy, fuel cell, and other zero-carbon new energy industries at the supply side; promoting carbon capture, utilization and storage (CCUS) technology, energy conservation and emission reduction technology, and electrical vehicles at the application or consumption side.

China has established the largest green coal power system in the world, as well as the largest new energy power generation scale and annual installed capacity. The proportion of clean energy consumption has risen continuously. In 2018, 80 % of coal power generating units obtained super-low emissions and the power supply coal consumption for thermal power generating units of 6000 kW and above fell to 308 g/kW·h; simultaneously, the consumption of clean energies, e.g., natural gas, hydropower, nuclear power, and wind power, accounted for 22 % of the total energy consumption [10]. During the 13th Five-Year Plan period, the energy conservation and environmental protection industry developed rapidly and its industrial scale, industrial structure, technical level, and marketization degree witnessed significant improvements. The energy conservation and environmental protection industry has become the industrial system with essentially complete industrial categories and a specific economic scale [1]. It has also obtained several achievements in industrial development mode innovation; system mechanism innovation; and technical research and development. In 2018, the production scale and sales volume of new energy vehicles in China reached 1.27 million and 1.256 million, respectively, with an inventory of almost 3 million. China has become the country with the fastest development, highest yield, and largest inventory of new energy vehicles [3].

With changing levels of international cooperation, an independent and controllable core technology and safe industrial chain have become a common demand for emerging industries in various fields in China. In the new era, emerging energy technologies, energy conservation and environmental protection, new energy vehicles, and other emerging industries are not only faced with production safety challenges but the challenges of supply safety of core equipment, key materials, spare parts, industrial technology system safety, and other generalized safety issues.

《4 Maturity evaluation model and index system of green and low-carbon industries》

4 Maturity evaluation model and index system of green and low-carbon industries

《4.1 Construction principle of evaluation index》

4.1 Construction principle of evaluation index

4.1.1 Uniformity and succession

To realize the unified standards of industry maturity level evaluation, an extended research is applied in this study and the grading and evaluation standards in paper [4] are referred to for the technical and manufacturing readiness level index.

4.1.2 Highlighting green and low-carbon features

The common features of high-quality developments in green and low-carbon industries should be fully identified and subsequently combined with the development targets and key tasks of green and low-carbon industries; the maturity level index system can then be extended and improved based on the characteristics of green and low-carbon industries and industrial development demand in the new era.

4.1.3 Whole industrial process analysis

To further promote the applicability of industrial evaluation in non-manufacturing industries, the index construction in this paper is based on the perspective of the entire industrial process; e.g., the definition of the product is not limited to the industrial terminal products or core spare parts and the device/equipment and core spare parts used for manufacturing or production in the entire industrial chain are also included in the core products of the industry.

《4.2 Evaluation index system》

4.2 Evaluation index system

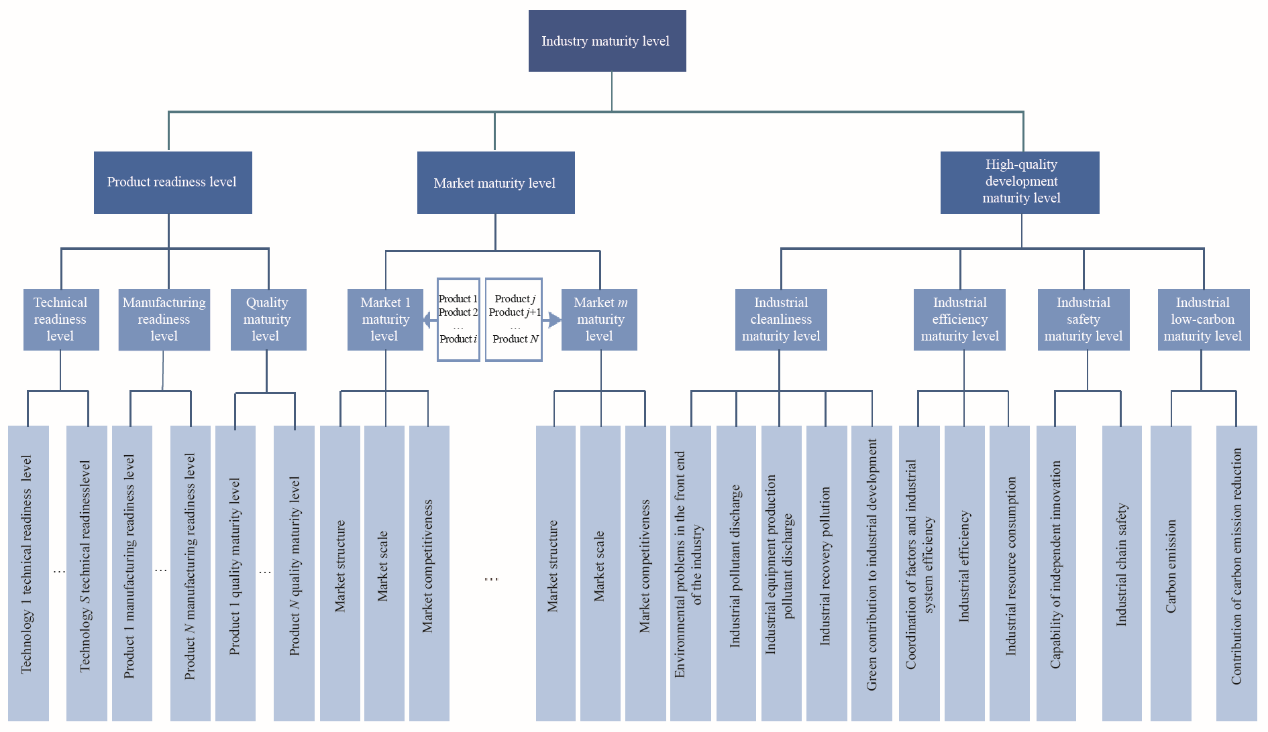

4.2.1 Structure of index system and maturity level classification

The hierarchical structure of a green and low-carbon industry maturity level evaluation index system is shown in Fig.3. It includes three evaluation sub-systems (product, market, and high-quality developments) and is the extension of the basic theoretical framework (Fig.1). In this structure, the multi-technology, multi-product, and multi-market classification method is applied to the product and market evaluation system [9]. The high-quality development maturity level is a new index based on the development characteristics of green and low-carbon industries, consisting of industrial cleanliness, high-efficiency, low-carbon, and safety multi-layer evaluation index systems.

The maturity level classification scheme in this paper is different from the life cycle development description (infant, cultivation, development, and maturity) presented in paper [5] and adopts a more common description of maturity levels (fully mature, mature, less mature, and immature); this is more suitable for the classification of the sub-layer evaluation indexes and scoring by experts.

《Fig. 3》

Fig. 3. Evaluation index system for the maturity level of green and low-carbon industries.

4.2.2 Product readiness level index and evaluation criteria

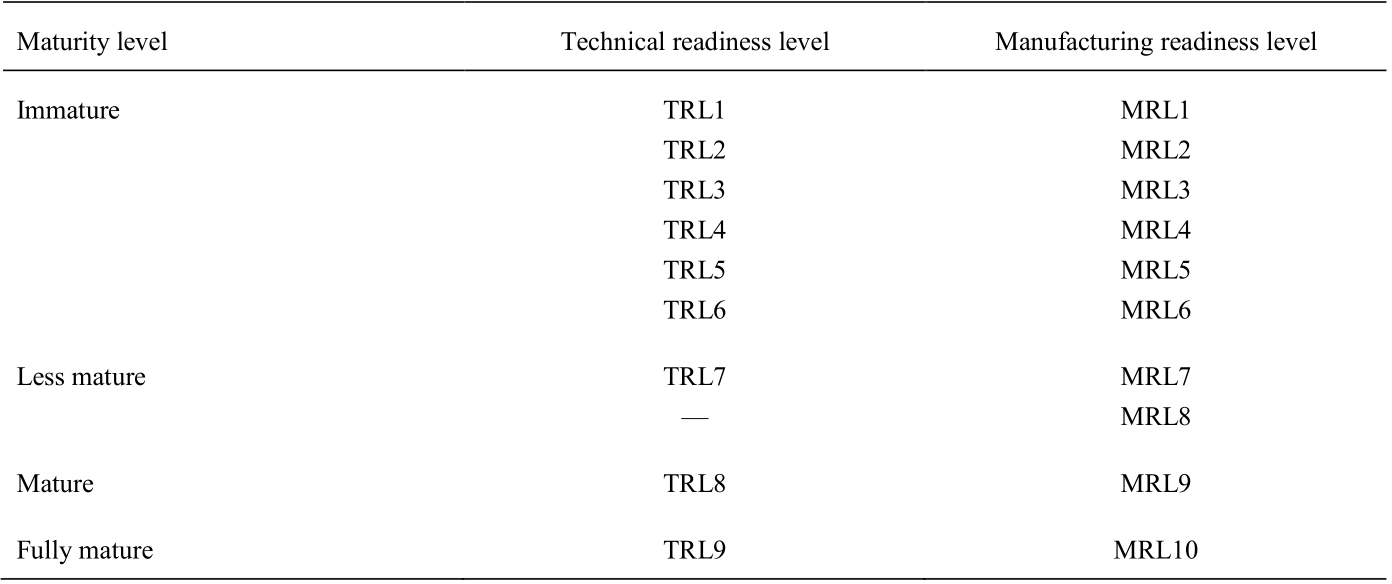

Product readiness level (PRL) is the evaluation result composition for the technology, manufacturing, and product quality maturity levels, which not only displays the maturity performance of detailed products but requires consideration of the general technology and manufacturing condition of the industry. The technical readiness level (TRL) is a measurement of the technological research and development maturity level. Manufacturing readiness level (MRL) is used to weigh the manufacturing capacity of the products, equipment, or devices (including spare parts) of the industrial terminal or intermediate link. According to the setting of TRL 9 and MRL 10 by the US Department of Defense and the detailed level evaluation criteria reference given in [4], the corresponding relation between TRL and MRL and the maturity level description is shown in Table 2.

《Table 2》

Table 2. Integration rules for technical readiness and manufacturing readiness levels.

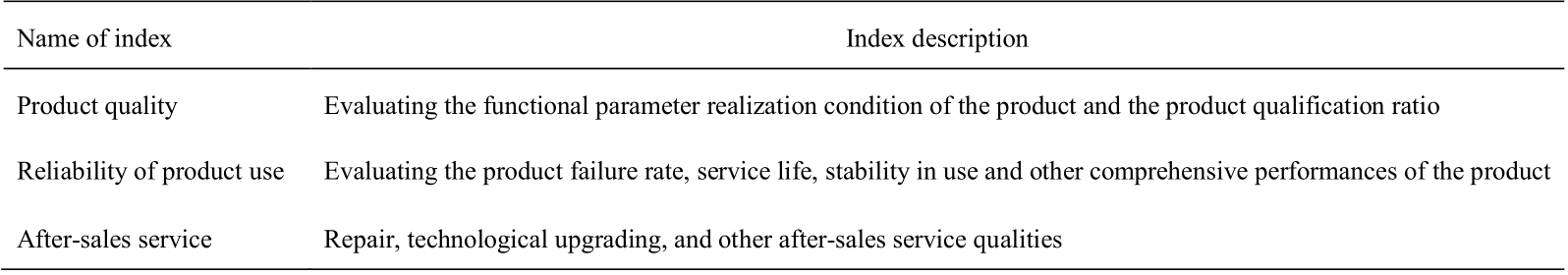

Quality maturity level (QML) is the comprehensive quality evaluation of the product, involving quality and function, application, and after-sales service. The detailed evaluation method is shown in Table 3.

《Table 3》

Table 3. Quality maturity level index system.

4.2.3 Market maturity level

Market maturity level (MML) indicates the market segment division based on the products that have competitive relations. Taking the market segments as the evaluation subject, it comprehensively measures the development level of each market segment from scale, structure, and competitiveness. The detailed index system is shown in Table 4.

《Table 4》

Table 4. Maturity level index system in the sub-sectors.

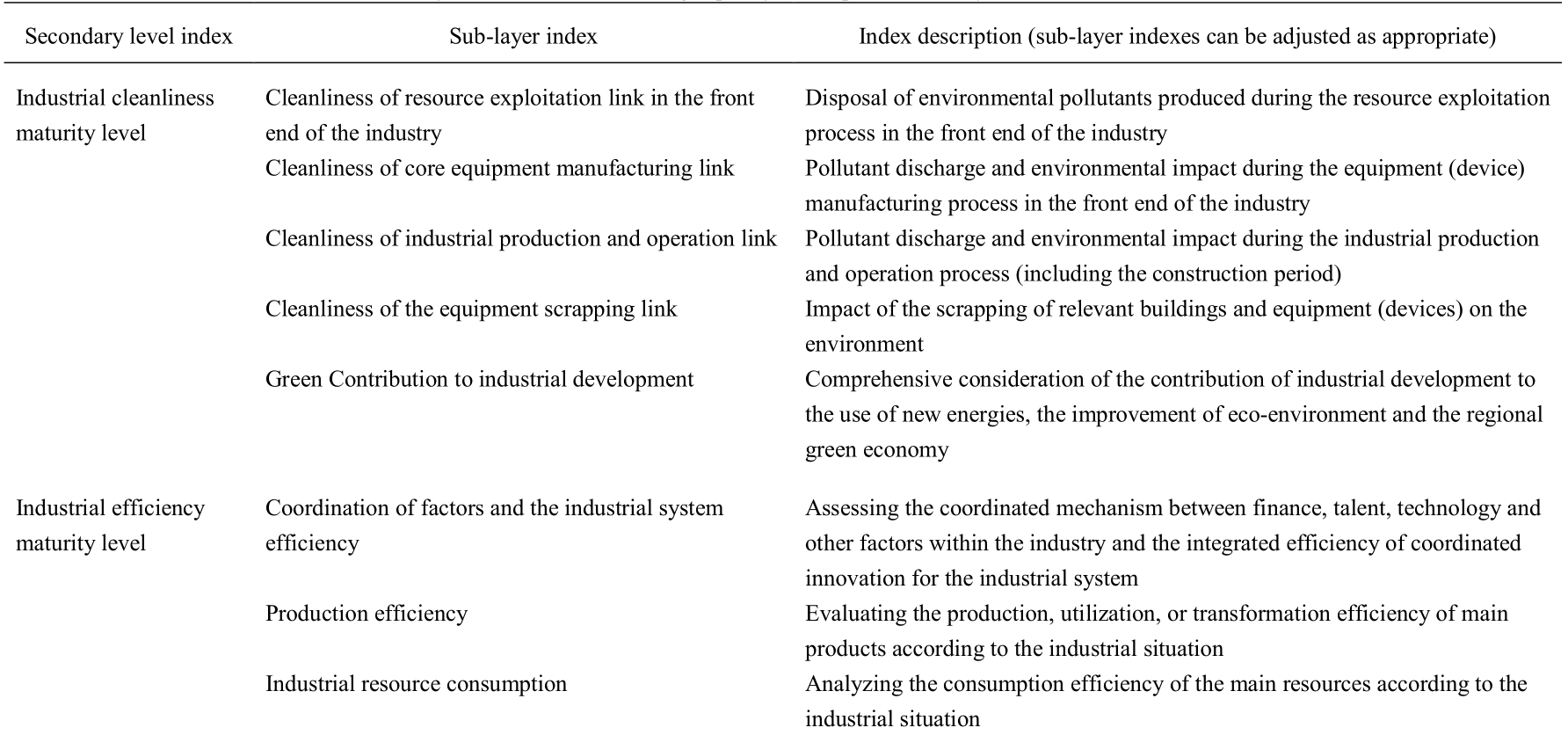

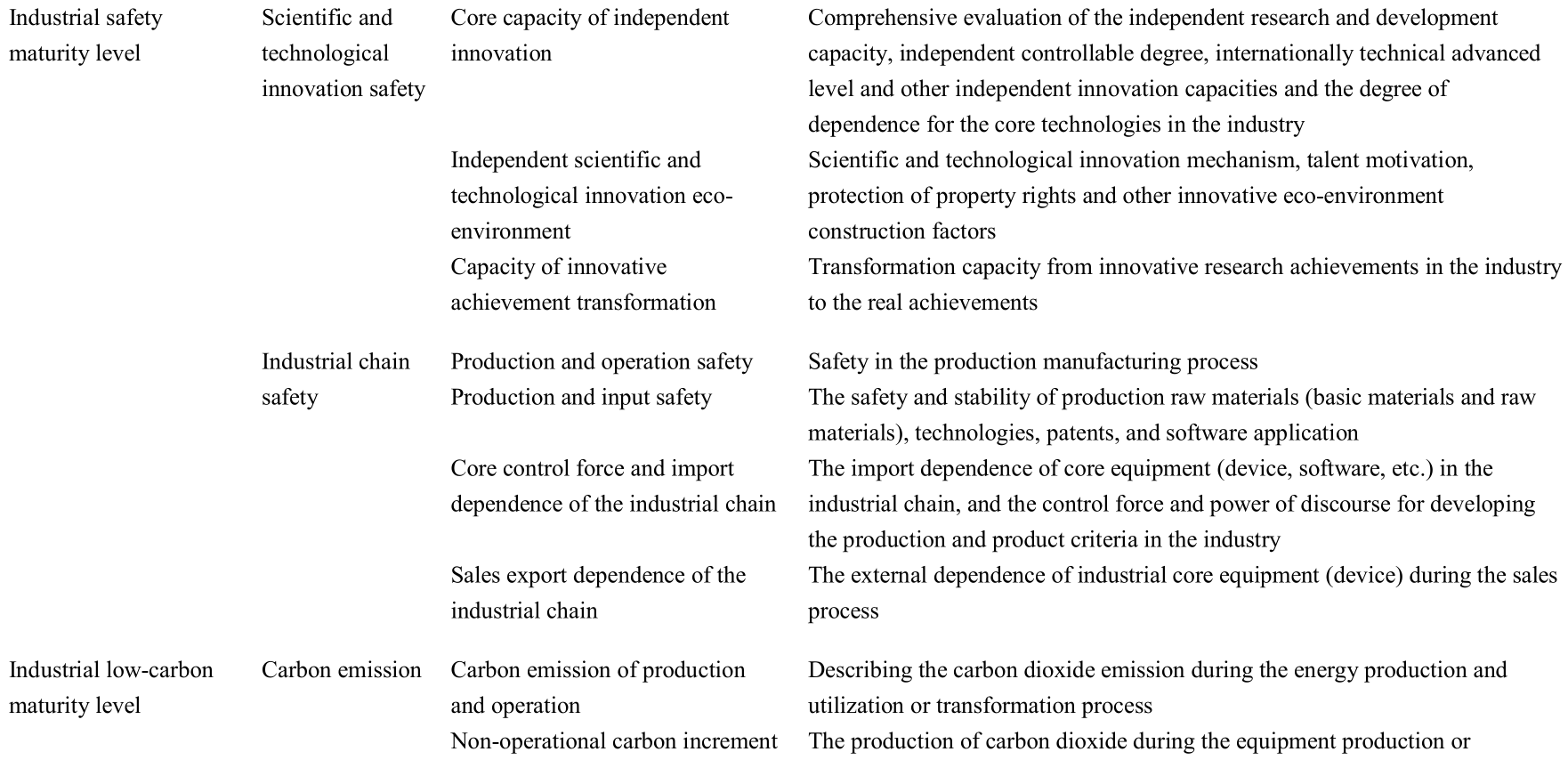

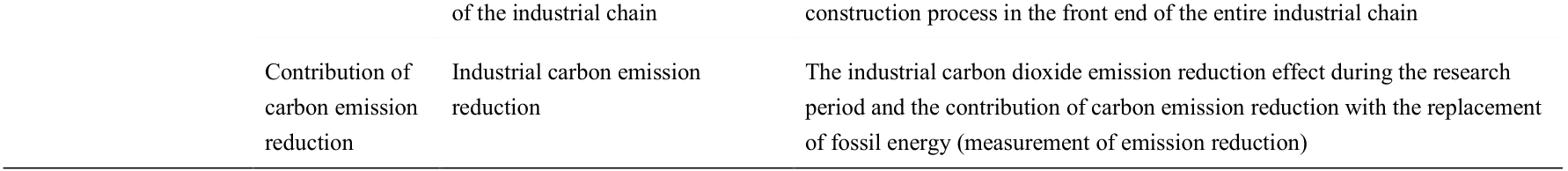

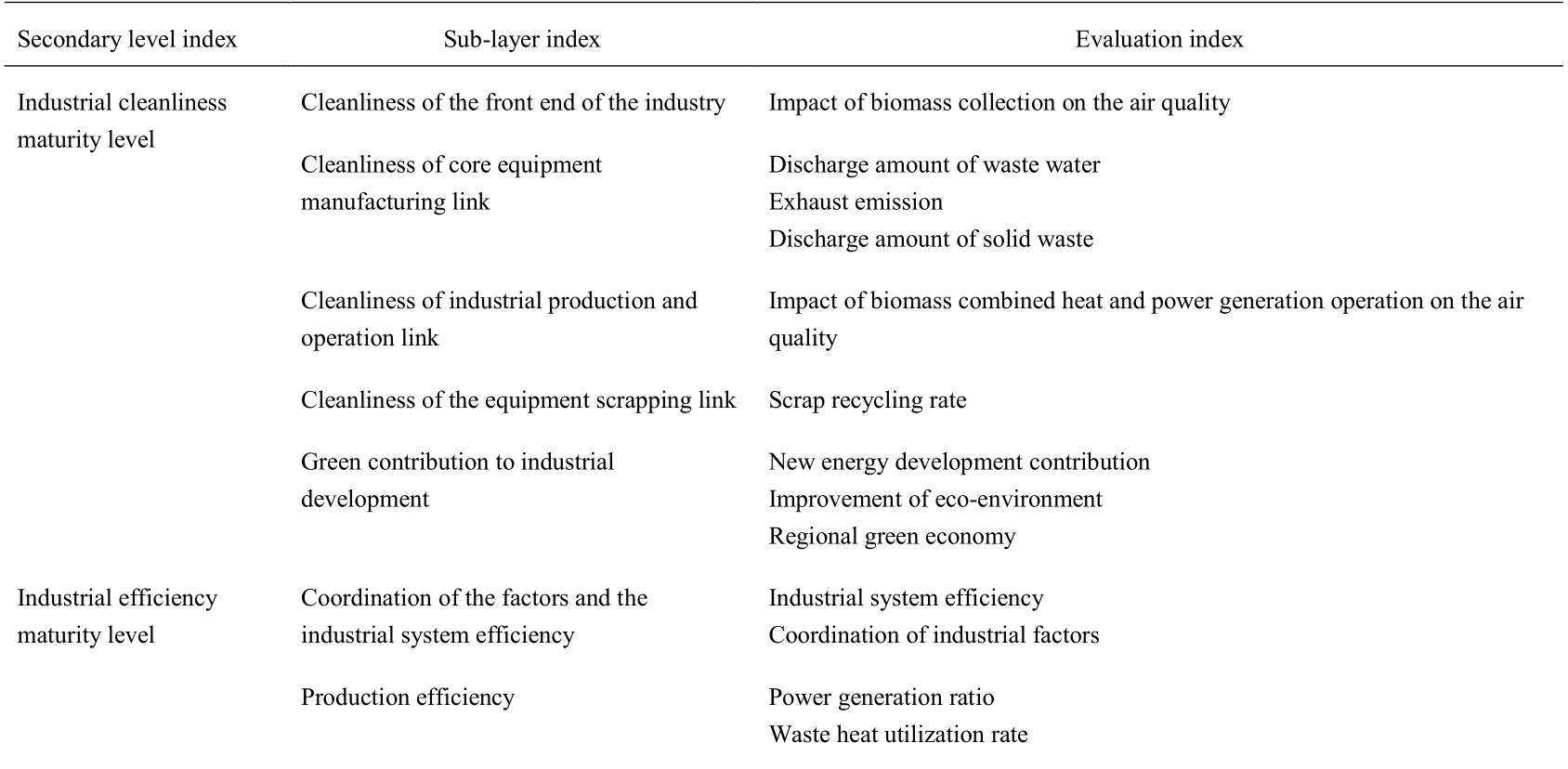

4.2.4 High-quality development maturity level evaluation

High-quality development maturity level evaluation includes four dimensions; cleanliness, efficiency, lowcarbon, and safety. The detailed evaluation index system is shown in Table 5. The industrial cleanliness maturity level (CML) is used to measure the development situation of industrial green production from the perspective of the entire industrial chain and covers evaluation of the entire industrial process, including the clean manufacturing of equipment in the front end of the industrial chain and equipment waste in the back end. Industrial efficiency maturity level (EML) refers to the evaluation of industrial production, resource consumption (as well as utilization, and transformation efficiency), coordination of industrial factors, and the industrial system’s efficiency. The industrial safety maturity level (SML) is a comprehensive measurement of the independent and controllable core industrial technologies and the industrial chain safety degree, including the industrial production and supply safety, export safety, and the generalized safety concepts of scientific and technological innovation and industrial systems. Industrial low-carbon maturity level (LML) is a comprehensive evaluation of increased carbon dioxide emissions and the contribution of carbon dioxide emission reduction from the perspective of the entire industrial chain process.

《Table 5》

Table 5. Evaluation index system for the industrial high-quality development maturity level.

《4.3 Calculation of industry maturity levels》

4.3 Calculation of industry maturity levels

The comprehensive weight and fuzzy comprehensive evaluation methods were applied in the level calculation model constructed in this study and the comprehensive weight method, combining the analytical hierarchy process (AHP) and subjective weight, was adopted for the weight calculation. First, the technical and enterprise experts within the industry constitute the field experts who will mark the questionnaires; the experts will then compare the degrees of importance of indexes from a professional perspective and use the AHP method to calculate the weights of the indexes. The field experts will then determine the subjective weight of the indexes from strategic and macroscopic perspectives. Finally, the weighted calculation of the comprehensive weight based on the AHP and subjective weight will be implemented.

To efficiently use the index score information provided by the experts, the fuzzy comprehensive evaluation method has been introduced in this study; i.e., determining the classification membership degree of evaluation indexes in accordance with the statistical distribution of score results. The multi-level composition of membership matrix and weight vector from the bottom up is utilized to comprehensively evaluate the industry maturity level. The composite process of industry maturity levels is shown in Fig.4.

《Fig. 4》

Fig. 4. Schematic diagram of the composite process for the industry maturity levels.

4.3.1 Determination of AHP index weight

(1) Score by expert to construct the judgment matrix An×n

The expert group with k (k ≥ 10) field experts uses a 1–9 scale method, gives scores based on the comparison of important degrees among the technologies, products, or indexes in various layers, and obtain the judgment matrix An×n, where n refers to the number of indexes in the judgment matrix.

(2) Single hierarchical arrangement and weight calculation

As for any judgment matrix A, where the calculation meets the characteristic root and the characteristic vector of AW = λmaxW, the corresponding characteristic vector of the greatest eigenvalue Wi = (w1, w2, …, wn) T is the AHP weight.

4.3.2 Score by subjective weight

The comprehensive industrial expert team, consisting of p (p ≥ 5) industry experts from enterprises, research institutes, and the government, conduct the subjective assignment for the product, market, and high-quality development maturity level indexes (3 first level indexes) from strategic and macroscopic perspectives.

4.3.3 Comprehensive weight calculation

The AHP and subjective weight of the experts are modified and composed. The calculation formula for comprehensive weight is as follows:

where wi indicates the weight calculated via the AHP method and  indicates the subjective weight of the index.

indicates the subjective weight of the index.

4.3.4 Determination of membership matrix

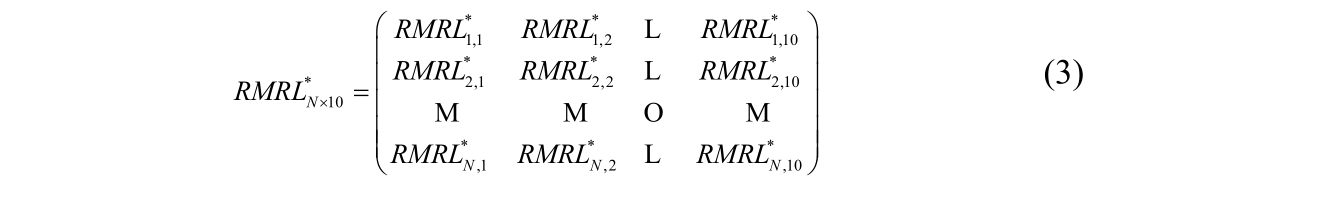

The membership degree evaluation of the language level for the index maturity is determined based on the level distribution of scores by experts. With the manufacturing maturity index as an example, the membership degree at level j is as follows:

where k (k ≥ 10) indicates the total number of experts in the field expert group and MRLj indicates the number of experts at level j.

To simplify the description, the membership degree scores for the index maturity of each single layer is recorded in matrix form; e.g., in the case of N kinds of products, the membership matrix for MRL 10 can be described as:

where  indicates the membership degree of MRL j for the i-th kind of product.

indicates the membership degree of MRL j for the i-th kind of product.

Similarly, the membership matrix of technical readiness level  and the membership matrix of quality maturity level RQMLN×4 can be realized.

and the membership matrix of quality maturity level RQMLN×4 can be realized.

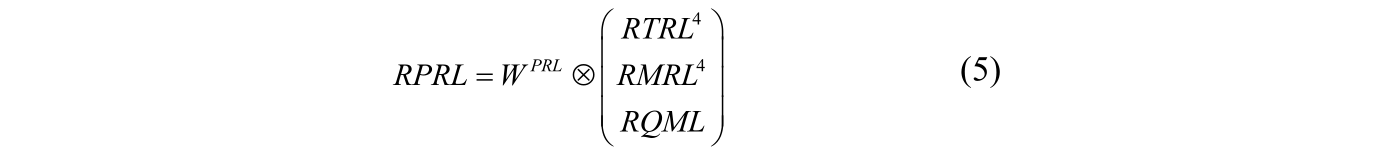

4.3.5 Composition of product readiness levels

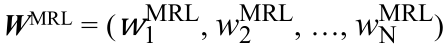

In paper [4], fuzzy composition is applied for the sub-layer indexes and the following membership vector of MRL 10 can be obtained:

where  indicates the weight vector for N products (determined via the AHP method).

indicates the weight vector for N products (determined via the AHP method).  indicates the composition operator of fuzzy comprehensive evaluation (

indicates the composition operator of fuzzy comprehensive evaluation ( ).

).

Similarly, the membership vector of technical readiness level at level 9 RTRL can be achieved. The technical and manufacturing readiness levels are integrated from level 9 and 10 to level 4 and recorded as matrix RTRL4 and RMRL4 , based on the level integration relationship in Table 2.

The composition of technical, manufacturing, and quality maturity indexes leads to the membership vector of product maturity:

where  indicates the comprehensive weight vector of technical, manufacturing, and quality maturity indexes.

indicates the comprehensive weight vector of technical, manufacturing, and quality maturity indexes.

4.3.6 Composition of market maturity levels

The above operations result in the composition of maturity levels for multiple market segments and the MML membership vector can be recorded as RMML (the maturity level of each market segment can be reached through composition operation, according to Table 4).

4.3.7 Composition of high-quality development maturity levels

Four secondary level indexes of the high-quality development maturity level have evaluation index systems of each sub-layer (Table 5). Compositional operation of the evaluation index systems of each sub-layer from the bottom up can result in the membership vectors of indexes of industrial cleanliness, industrial efficiency, industrial safety, and industrial low-carbon maturity levels; recorded as RCML, REML, RSML, and RLML. Further composition of the above matrixes can lead to the membership vector of the high-quality development maturity level:

where  indicates the comprehensive weight vector of the indexes of industrial cleanliness, industrial efficiency, industrial safety, and industrial low-carbon maturity levels.

indicates the comprehensive weight vector of the indexes of industrial cleanliness, industrial efficiency, industrial safety, and industrial low-carbon maturity levels.

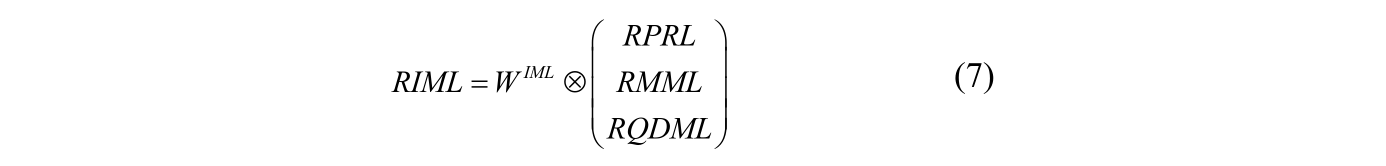

4.3.8 Composition of industry maturity levels

According to the above integration results, the final membership vector of industry maturity level is obtained through composition, as follows:

where  indicates the comprehensive weight vector of indexes of product, market, and high-quality development maturity levels.

indicates the comprehensive weight vector of indexes of product, market, and high-quality development maturity levels.

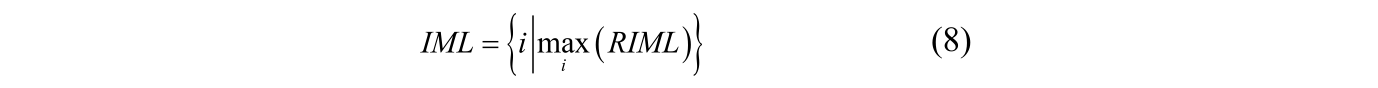

According to the maximum membership principle, the industry maturity level is as follows:

where i indicates the membership level of industry maturity with 1 ≤ i ≤ 4.

《5 Maturity level evaluation of the biomass combined heat and power generation industry, as a green and low-carbon industry example》

5 Maturity level evaluation of the biomass combined heat and power generation industry, as a green and low-carbon industry example

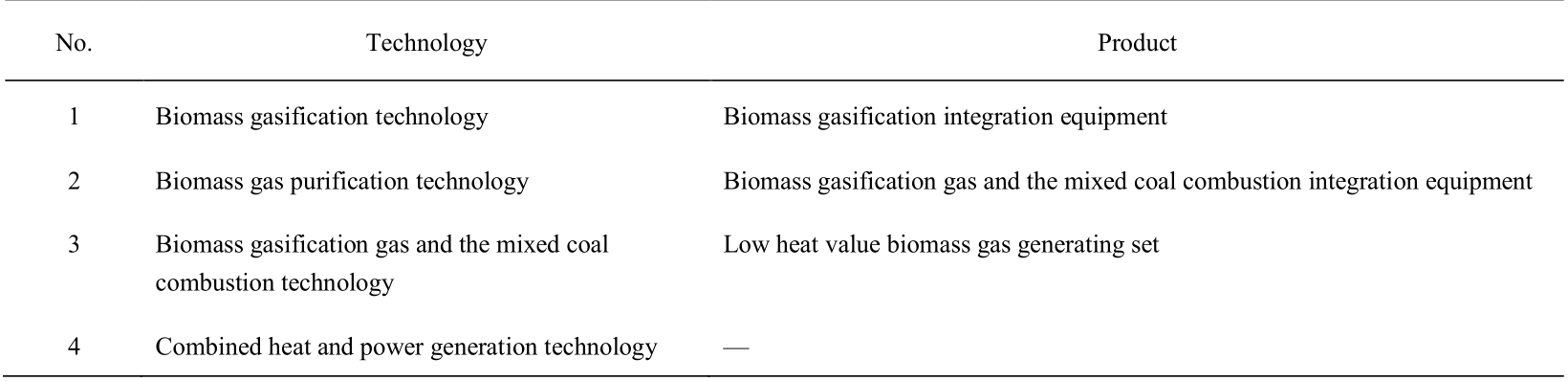

Biomass combined heat and power generation refers to the process ofsimultaneously generating power and useful heat via direct combustion, mixed combustion with coal, and vaporizing combustion, with biomass as the fuel. Thirteen biomass experts were invited to form the field expert group and conduct the case evaluation. Four key technologies and three core products in the industry were determined by the expert group through on-site consultation (Table 6) and the high-quality development index system, applicable to the biomass combined heat and power generation industry, was established (Table 7).

Based on the maximum membership principle, the biomass gasification technology and combined heat and power generation technology were simplified to TRL9; the biomass gas purification technology as well as biomass gasification gas and mixed coal combustion technology to TRL7. With regard to MRL, the biomass gasification gas and mixed coal combustion integration equipment, and low heat value biomass gas generating set reached MRL9; that of biomass gasification integration equipment reached MRL7. The quality maturity levels of the three products were less mature.

《Table 6》

Table 6. Major technologies and products of the industries to be evaluated.

《Table 7》

Table 7. Evaluation index system of high-quality development maturity level for the biomass combined heat and power generation industry.

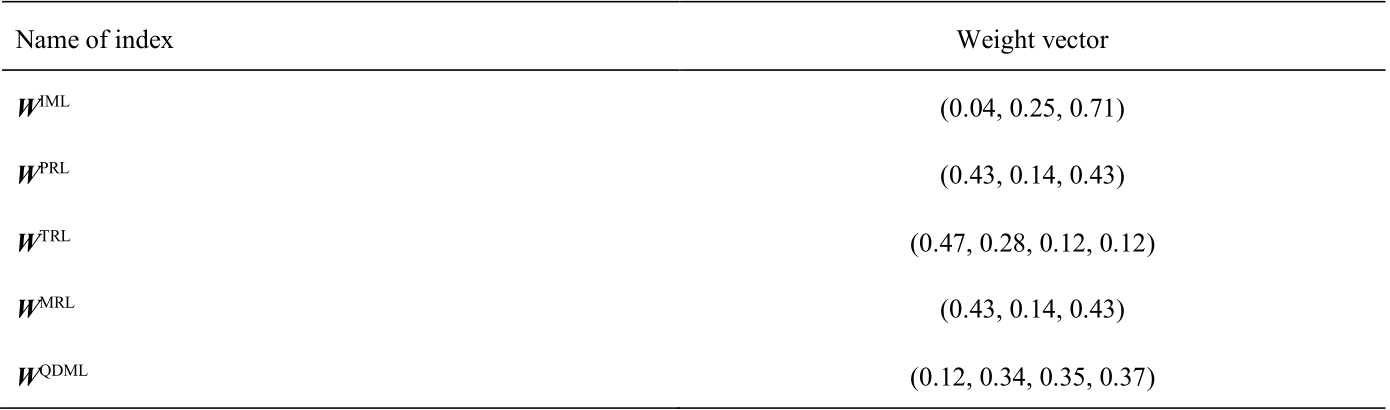

Table 8 presents the comprehensive weight, based on the partial indexes of the AHP and subjective weighting. The weight calculation and integration process of maturity levels are not detailed here; the final results are shown in Fig. 5. In summary, the industry maturity level of biomass combined heat and power generation industry is mature and its technology, manufacturing, and industry high-quality development maturity levels are similar to that of the industry as a whole. Nevertheless, its market readiness level is less mature, and its market development is lagging behind the advancement of engineering science and technology.

《Table 8》

Table 8. Major index weight.

《Fig. 5》

Fig. 5. Comprehensive evaluation results of industry maturity level.

《6 Conclusion》

6 Conclusion

The development of China’s emerging green and low-carbon strategic industries is faced with novel opportunities and challenges under the current circumstances. Accelerating the construction of a green and low-carbon industry system will result in the birth of new sunrise industries and a new economic growth point. This paper has summarized the basic theoretical framework for evaluating the industry maturity level and proposed a common process for popularization and application. Meanwhile, the high-quality development maturity index system has been extended, based on identification of the development characteristics of green and low-carbon industries. The comprehensive weight and fuzzy comprehensive evaluation methods have subsequently been applied to establish the maturity evaluation model of green and low-carbon industries and the evaluation process has been demonstrated for the biomass combined heat and power generation industry.

This research is applicable to sub-sectors in the green and low-carbon field or emerging industries in other fields. In addition, the application of the maturity level evaluation method for green and low-carbon industries in strategic research requires further improvement of the evaluation system and enhanced database construction for the evaluation of organizations and industries.

(1) Constructing the annual evaluation mechanism for the maturity level of green and low-carbon industries; this is needed to promote the practice and application of the industry maturity method in consulting projects and industrial reports and identify the annual development data characteristics of green and low-carbon industries in China via the maturity level method.

(2) Constructing an authoritative news agency for information regarding the development of green and lowcarbon industries; this is needed to accelerate the cultivation of a batch of strategic consulting and research personnel in energy, energy conservation and environmental protection, and new energy vehicle fields; form the research team or unit with global influence and authority of industrial evaluation; and realize the scientific and independent evaluation of China’s green and low-carbon industries.

(3) Strengthening the database construction of emerging industries in China and the objective industry evaluation; this is required to implement dynamic management for the evaluation index system and the industrial database of emerging industries’ maturity levels in China. Furthermore, the smart data collection mechanism should be established and green and low-carbon industry enterprises should be included in the industrial category. Big data information technology is applied to industrial data processing to realize the automatic collection of enterprise information, reduce the subjective evaluation information of the industry, and promote the construction of objective evaluation systems based on real enterprise data.

《Acknowledgements》

Acknowledgements

The support and help from the following project team members were invaluable in the preparation of this paper: Wang Wen, Su Gang, Kong Fantai, Feng Yu, Zhao Peirong, Liu Hongguang, Zhou Jie, He Yujiang, Zhang Jianhan, Cheng Jian, Wang Wenwei, Zhang Tingting, and Chen Xiaohui.

京公网安备 11010502051620号

京公网安备 11010502051620号