《1 Rise of material science of room-temperature liquid metal》

1 Rise of material science of room-temperature liquid metal

Most people get their knowledge of liquid metal from the science-fiction movie “The Terminator,” where all the powerful robots are made up of liquid metals. With the continuous advancement of scientific research and technologies, advanced equipment made up of liquid metals are gradually becoming a reality. Liquid metal is a kind of advanced functional material bridging machines and humans, and there are many scientific, technological, and application issues inside [1]. In reality, room-temperature liquid metal belongs to many emerging operational matters, whose typical type generally includes gallium-based alloy, bismuth-based alloy, and their allied materials. This material has many novel characteristics, offering important inspirations and large research spaces for many cutting-edge sciences and technologies. With the pioneering endeavors from China and international scholars in basic research [1] and industrial practice [2], liquid metal material has become a major research topic in science and technology worldwide with a rather widespread impact.

Dan Shechtman, 2011 Nobel Prize winner in chemistry and a professor at Israel Institute of Technology, pointed out that the materials’ limitation is the biggest drawback of the present technology. With the emergence of liquid metal and its allied materials, many bottlenecks in the technological application were lifted, opening tremendous unconventional industrial opportunities. Since the beginning of this century, the research team in China has played a pioneering role in the major scientific and technological fields of liquid metals and disclosed many scientific phenomena, basic effects, and revolutionary technologies [1]. They also promoted the formation of a series of high-tech industry, putting forward the establishment of “The China Liquid Metal Valley” and the new liquid metal industry [2]. Continuous progress has been made in liquid metal research because more international laboratories joined the research. The exploded endeavors on liquid metal reflect the formation and evolution of an important field combined with science, technology, and industry.

The purposes of this article were to interpret the liquid metal’s basic problems and typical progress and evaluate the important frontier toward promoting breakthrough science and industry, especially in electronics, information, energy, advanced manufacturing, soft robots, biomedical, and other fields. The article also discusses the role and functions of liquid metal material science in opening up new industries, elaborating the preliminary practice of establishing “The China Liquid Metal Valley” and the industrial clusters, and discusses major developmental opportunities. This article would be a valuable reference for further advancing the new material industry in China.

《2 Classic liquid metal materials and their properties》

2 Classic liquid metal materials and their properties

Liquid metal refers to liquid-state metals at room temperature or higher. It is also known as low melting point metals. Among them, gallium-based metal, bismuth-based metal, and their alloys are becoming revolutionary materials because of their high safety, nontoxic, and excellent performance properties. Mercury, cesium, and sodium alloy are also liquid-state metals at room temperature; however, they would encounter serious application problems because of their toxicity, radioactivity, and other danger factors. High-melting metals, such as metal and its alloy, can present a liquid state at high temperatures (e.g., 600℃ or 700℃); thus, they are widely studied as classic metallurgical material.

Unfortunately, room-temperature liquid metals are not receiving attention from researchers worldwide. Unlike the old days, recent disruptive discoveries and technological breakthroughs reveal the basic scientific phenomena and major liquid metal applications at room temperature. Liquid metal can flow at room temperature and has high electrical conductivity, excellent thermal properties, and is easy to realize solid–liquid conversion. Liquid metal is also hard to boil like water because of its high-boiling point, allowing it to remain in a liquid state up to 2300℃. In other words, it can integrate the advantages of many cutting-edge functional materials via a single material style only. Therefore, liquid metal is expected to break many application bottlenecks faced by the traditional technologies, enabling broad industrial opportunities.

However, there remains limited room-temperature liquid metal available for direct use. Pure metals in a liquid state at room temperature mainly include mercury, gallium, and cesium with melting points of −38.87℃, 29.8℃, and 28.65℃, respectively. With the limited number of pure liquid metals, liquid alloy materials are used because of their (1) good physical and chemical properties, such as high thermal and electrical conductivity and low viscosity, (2) environmental friendliness (i.e., toxic-free, nonflammable, easy for reuse, and low steam pressure and volatility), and (3) low cost. The limited number of available materials and the poor understanding of their properties are the challenges hindering the rapid development and application of liquid metal. To improve such a situation, Wang and Liu [3] proposed the liquid metal material genome project to find new liquid metal functional materials and fulfill material shortage. Hence, the exploration and discovery of more liquid metal composite materials will remain a research interest to meet the various growing practical demands.

《3 Invention of new liquid metal material》

3 Invention of new liquid metal material

《3.1 Enhanced or modified liquid metal material via extraneous matter》

3.1 Enhanced or modified liquid metal material via extraneous matter

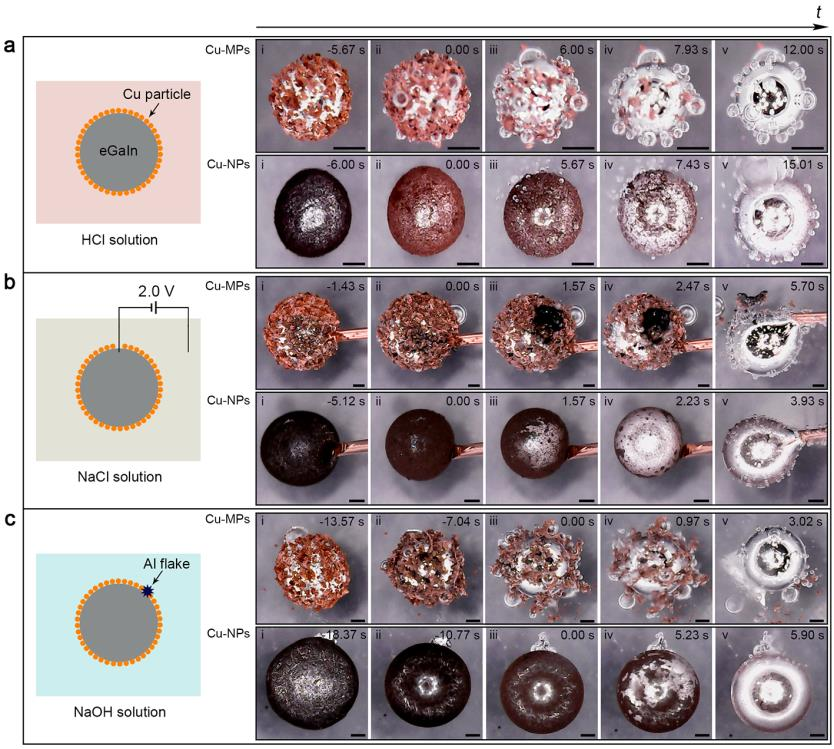

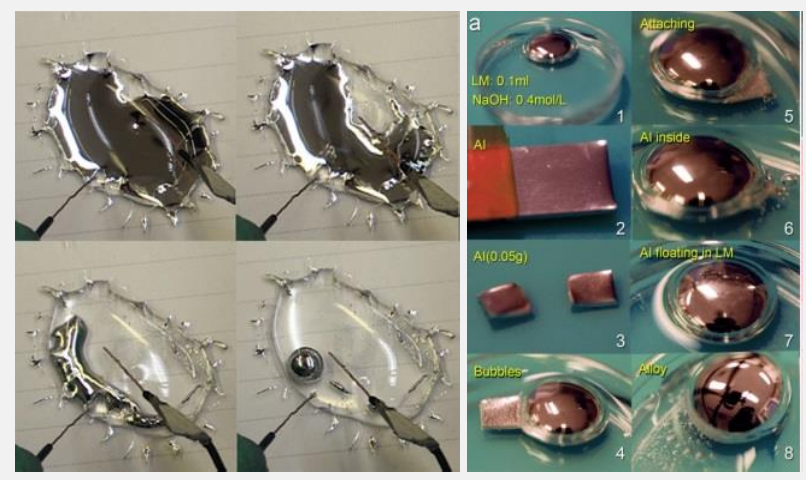

In making a new liquid metal material, in addition to alloying strategy alone, the compatibility among matching materials can be adapted to obtain more materials. Experiments revealed that liquid metal droplets could swallow surrounding particles into themselves by stimulating electric field or chemical substances in the solution (Fig. 1) [4]. This is similar to cytobiology’s endocytosis effect with extremely high efficiency. This discovery opens a way to construct high-performance liquid metal material. Thus, materials with different physical and chemical properties (e.g., liquid metal with adjustable electrical, magnetic, thermal, and mechanical properties [5]) can be produced on demand, including making metal compositions in the state between liquid and solid.

《Fig. 1》

Fig. 1. Phagocytosis effect of liquid metal on particles and material preparation strategy [4].

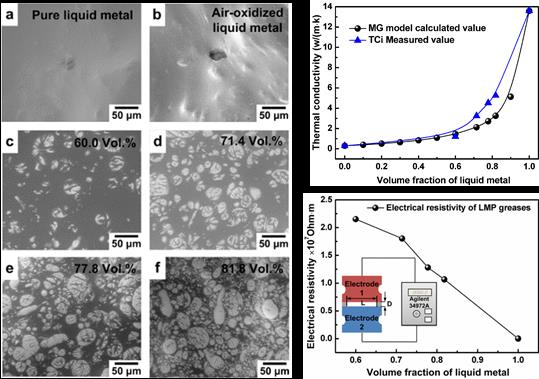

In addition to introducing an extraneous matter to realize functional materials, liquid metal can also be used as fillers to modify other materials. Since the proposition of liquid metal fillers [6], liquid metal materials with high thermal conductivity and electrical insulation (Fig. 2) were developed. Integration of such two contradictory properties of heat conduction and electrical insulation has brought tremendous research and development (R&D) of liquid metal composite material.

《Fig. 2》

Fig. 2. High thermal conduction and electric insulation material made from liquid metal fillers [6].

《3.2 Porous liquid metal material》

3.2 Porous liquid metal material

Although most existing liquid metals are continuous media, liquid metal can be made into porous materials to realize more peculiar functions and behaviors. For example, Wang et al. [7] found that liquid metal can be made into flexible porous metal materials with good electrical conductivity and magnetism by loading iron nanoparticles into liquid metal (e.g., gallium–indium alloy) and introducing a chemical reaction mechanism (Fig. 3). Such material’s pore size can be adjusted flexibly and repeatedly swelled (up to seven times in extreme cases) when heated. After swelling, the flexible porous metal can even carry heavy objects and float on the water surface.

《Fig. 3》

Fig. 3. Preparation process (swelling and floating behavior in the water) and internal structure of porous liquid metal material [7].

This is the first creation of such material. The revealed mechanism will promote further R&D of liquid metal smart materials and equipment to an ever-new horizon. For example, such characteristics can be used to manufacture underwater transformable machines, flexible manipulators, exoskeletons, flexible-intelligent robots, and others.

《3.3 Liquid metal enabled conductor-insulator transition materials》

3.3 Liquid metal enabled conductor-insulator transition materials

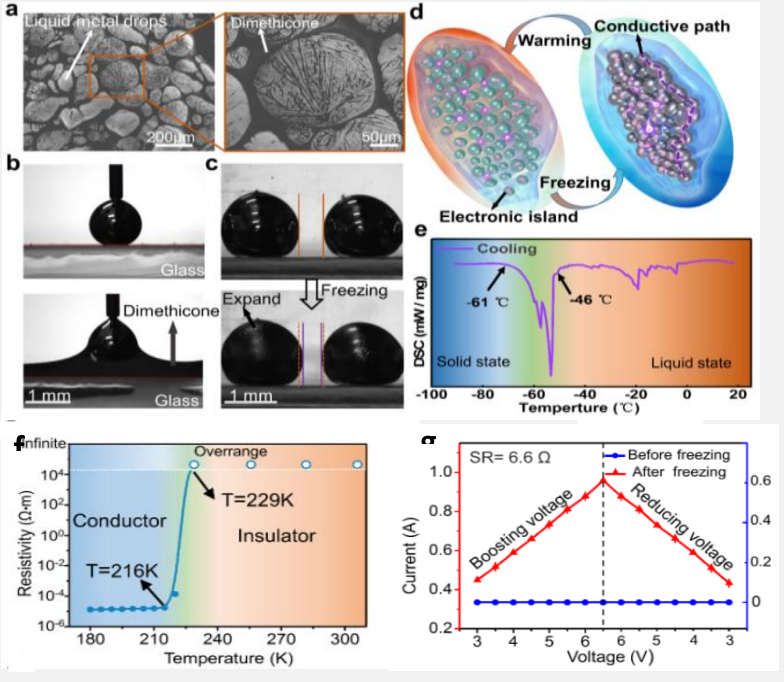

Interestingly, some liquid metal hybrid materials have high thermal conductivity and electrical insulation. Such contradictory properties can be adjusted mutually to produce conductor-insulator transition (CIT) materials. The key common strategy for preparing wide temperature adjustable CIT materials based on liquid metal lies in realizing the CIT material function by mutual coordination of internal matters in composite material [8,9]. One of the typical cases is combining the liquid metal with abnormal volume expansion ratio and the dimethyl silicone oil with good fluidity to produce the liquid CIT material. Therefore, more liquid CIT materials with a wide temperature range can be developed using liquid metals with different melting points and synergistic materials.

Liquid CIT materials are mixed with liquid metal droplets and solvents according to the coordination mechanism of internal matters in composite material (Fig. 4). At high temperature, the liquid metal is in a liquid state and is separated by the solvent, and the composite material is insulated. When the temperature falls, the metal droplets solidify, and the liquid CIT material becomes conductive. With the temperature change, the liquid CIT material’s conductivity can differ by nine orders of magnitude; theoretically, the process is completely reversible and can be repeated infinitely. As a result, the transition temperature of liquid CIT material only depends on the metal droplet’s phase transition point. Therefore, a series of liquid alloys with different phase transformation points (e.g., gallium-based and bismuth-based alloys) can be found to obtain the temperature of different transition points.

《Fig. 4》

Fig. 4. Liquid metal composite material with CIT features in wide temperature range and its reversible conductor insulation mechanism [9].

《3.4 Lightweight liquid metal material》

3.4 Lightweight liquid metal material

The density of conventional liquid metal is usually very high, causing the devices and equipment to require a large mass and excessive energy consumption and restricting its application flexibility. Therefore, according to the basic idea of lightweight liquid metal [10], eutectic gallium–indium alloy and hollow glass beads can be used to prepare liquid metal composite material with a density of only half of water and that floating on the water surface (Fig. 5). Such material retains the electrical and conductivity properties, mechanical strength, and solid–liquid phase transition of pure liquid metal. It also has the characteristics of plasticity, deformability, and magnetism. Various planar and three-dimensional (3D) application scenarios, such as water inside the circuit and underwater robots, can be designed. Different packaging can also be introduced to control the materials’ floating behavior.

《Fig. 5》

Fig. 5. A lightweight composite material made up of liquid metal-hollow glass beads and its corresponding density [10].

Lightweight liquid metal materials should have basic scientific significance and universal application value for manufacturing new liquid metal functional materials. Different liquid metals and lightweight modified materials (e.g., plastics, wood, light metal, and magnetic, optical, and porous materials) can realize more target functions of terminal materials. One material may offer the functions (e.g., electricity, magnetism, sound, light, heat, mechanics, fluid, and chemistry) of different cutting-edge materials, which is not easy to realize in the existing material system while offering a good prospect for various application situations.

《4 Advanced application of liquid metal material》

4 Advanced application of liquid metal material

The application of liquid metal has been extended to almost all-natural science and engineering fields, incubating a new future [11]. The following subsections are the four aspects discussing several standard technology and application directions related to liquid metal.

《4.1 Advanced thermal management and energy technology of liquid metal》

4.1 Advanced thermal management and energy technology of liquid metal

With the application and development of micro-nano electronic technology [12], the thermal barrier caused by high-density integration chips, devices, and systems has become a tough challenge, restricting high-end applications. The pressing task is to overcome the cooling problem [13]. At the beginning of this century, fluidic cooling technology based on low-melting alloy was introduced in chip cooling [14], resulting in forming an international frontier and the emerging industrial direction with a promising prospect.

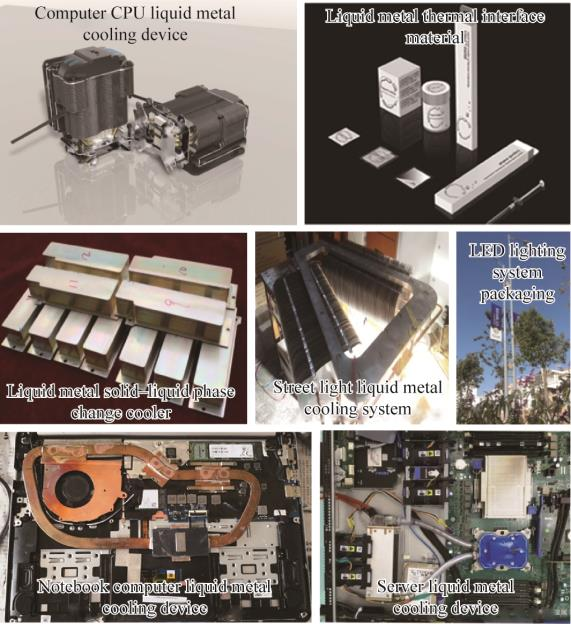

For over 20 years of development, a relatively complete theoretical and applied technology system has been established in room-temperature liquid metal cooling [15], which mainly include enhanced heat transfer, phase transformation and flow theory of liquid metal, electromagnetic/thermoelectric/siphon-driven cooling and heat harvesting, microchannel cooling of liquid metal, blade cooling, mixed fluid cooling, anhydrous heat exchanger, solid to liquid phase transition of low-melting metal with heat absorption, high thermal-conductivity nano-metal fluid, and thermal interface materials. In addition to the important application value in high-power density electronic chips, optoelectronic devices, and extreme heating of new conceptual equipment, liquid metal is also expanding to consumer electronics because of its low-grade thermal energy utilization, photovoltaic power generation, energy storage, smart grid, high-performance batteries, generator cooling, and thermoelectric conversion. The new technologies break the traditional modality. Several achievements have been applied to industrial and commercial fields on a large scale (Fig. 6), which include: liquid metal radiator for desktop computers, liquid metal thermal interface material, phase-change cooling module, liquid metal cooling high-power overhead lamp and LED street lamp, ultrathin liquid metal radiator for notebook computers, and liquid metal radiator for high-performance server cooling.

《Fig. 6》

Fig. 6. Liquid metal-based thermal management applications and commercial products.

The cooling method of liquid metal chips is attracting attention since its initiation. Deng and Liu [16] have won the 2010–2011 Best Paper of the Year Award from the ASME Journal of Electronic Packaging, a flagship journal in electronic packaging, and also many industry awards, including the Innovation Award from the China International Industry Expo.

《4.2 Liquid metal printed electronics and 3D printing》

4.2 Liquid metal printed electronics and 3D printing

Generally, conventional electronic manufacturing involved many complicated fabrication processes such as film deposition, etching, and packaging from substrate material preparation to the interconnection. These processes consume a lot of raw materials such as water, gas, and energy. Therefore, the basic idea of liquid metal printed electronics [17] and room-temperature metal 3D printing [18] was put forward for the first time. Corresponding theoretical and technical systems [19,20] were established, leading to the invention of a series of commercial liquid metal fabrication equipment (Fig. 7). Hence, targeted circuits, components, integrated circuits, and ending user functional devices can be directly manufactured on various flexible and rigid substrates and even on human skin [21–23] via direct printing (Fig. 8). This breakthrough is expected to change the manufacturing rules of traditional electronics and integrated circuits. The WYSIWYG electronic direct writing mode will accelerate the coming of the pervasive personalized electronic manufacturing era.

Moreover, with the establishment of liquid metal printed electronics and room-temperature 3D metal printing method, it is possible to rapidly manufacture personalized functional devices, reduce the threshold of high-end manufacturing, and realize the popularization of the technology. Therefore, scientific and technological societies worldwide have highly recognized the inventions and equipment. The technical achievements have been featured by many science media such as Technology Review, IEEE Spectrum, and Chemistry World and have been selected as R&D 100 Awards Finalists and candidate of China’s Top 10 Science and Technology Progress News in 2014.

《Fig. 7》

Fig. 7. Pervasive liquid metal electronics manufacturing (from 1D to 3D).

《Fig. 8》

Fig. 8. Application scenarios of liquid metal electronics [21–23].

《4.3 Liquid metal biomedical and health care technology》

4.3 Liquid metal biomedical and health care technology

The unique liquid metal feature also brought conceptual innovation in biomedical and health care technology fields. The research team in China took the lead in tackling a series of major biomedical problems and bottlenecks by initiating the new field of liquid metal biomaterial [24,25], which receives intensive attention worldwide. The liquid metal enabling neural connection and repair technology [26] is regarded as the “most amazing medical breakthrough,” leading to a series of neural regulation technologies [27]. The liquid metal high-resolution angiography [28] (Fig. 9) was proven to solve complex problems via a rather straightforward way, revealing many anatomical details.

《Fig. 9》

Fig. 9. Liquid metal enabling high-resolution angiography [28].

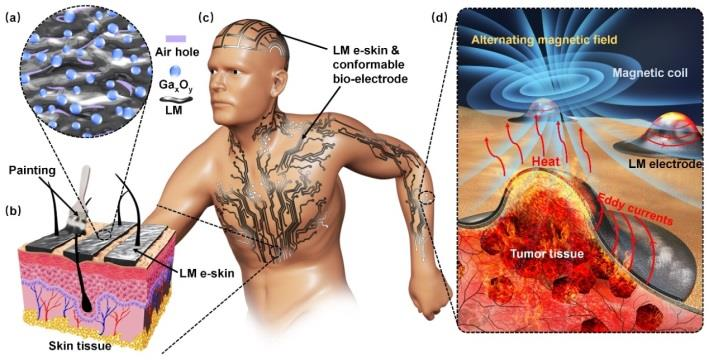

Given the new academic concepts and technological breakthroughs, much attention is obtained with the series of new technologies such as liquid metal embolization and alkali metal fluid thermochemical ablation for treating tumors, injectable low-melting metal bone cement, rigid and flexible liquid metal exoskeleton, printed liquid metal flexible radiation protection technology, implantable medical electronic in-vivo 3D printing and injectable electronics, liquid metal skin photothermal conversion and electromagnetism [29–31] (Fig. 10), and liquid metal medical sensing technology [32]. The progress made in liquid metal biomedicine has been featured in many scientific journals and TV news.

《Fig. 10》

Fig. 10. Liquid metal skin photothermal coating materials for tumor therapy and flexible biomedical electronics applications [29].

《4.4 Liquid metal soft intelligent machine》

4.4 Liquid metal soft intelligent machine

The scientific and engineering society aimed to design a soft machine that can be transformed freely into any controllable shape to help humans perform special and complex tasks. For example, a robot that can timely deform, struggle across narrow space, and restore its original shape while continuously performing tasks during earthquake relief work or certain actions. Hence, it is generally believed in academia that once such a soft robot reaches a breakthrough, it will significantly impact high-end manufacturing, medical rehabilitation, and new conceptual equipment. Hence, tremendous R&D activities have been increasingly carried out. For example, in 2017, the US National Science Foundation set up a soft robot project with total funding of 26 million USD.

Based on entirely new theoretical and technological routes, the research team in China initiated the liquid metal soft robot [33,34], leading to unconventional robotic systems spanning from materials and devices to systems [35]. One of the key progresses is the first-ever discovery of a series of large-scale deformation, rotation, directional motion, merging, and fracture-recombining behaviors of liquid metal by controlling electric field (Fig. 11) [36], marking the beginning of subsequent research in liquid metal transformable robots. The team disclosed a very unusual phenomenon and mechanism of the self-powered liquid metal machine [37,38]. In that category, liquid metal can form an entirely soft self-driven machine by swallowing only aluminum traces. Its running speed can reach centimeters per second with a lasting time of even up to several hours if desired (Fig. 11). According to the design, different autonomic indicators running could be realized without relying on any external power. Such motor swarm can be significantly speeded up by controlling electric field.

《Fig. 11》

Fig. 11. Transformable liquid metal soft machine controlled by an external field and self-powered liquid metal machine [36,38].

The aforementioned findings have laid an important theoretical foundation for developing practical, intelligent motors, vascular robots, fluid pumping systems, flexible actuators, and even more complex liquid metal robots. Combining liquid metal and rigid material can also realize a solid-liquid-combined machine. For example, the liquid metal wheel, which deforms and rotates by the electric control, can drive a 3D printing mini-vehicle to move forward, accelerate, and make complex motions. Moreover, the liquid metal can form any shape on the graphite surface to realize anti-gravity climbing. Suppose that the liquid machine unit is programmed in the group; in that case, a feasible technical approach for a controllable soft intelligent robot can be established (Fig. 12), changing the technical form of traditional robots [39].

《Fig. 12》

Fig. 12. A liquid metal composite material system with a large-scale expansion and transformation [39].

Overall, liquid metal opened up the new concept of transformable machines, accelerating the development of soft intelligent machines significantly. Hence, quite a few progresses have received intensive attention from many renowned publications such as Nature, Nature Materials, Science News, New Scientist, Discovery, and Chemistry World. Liquid metal robots were even listed as one of the top 10 most promising frontiers in the robot field.

《5 Rise of the liquid metal industry》

5 Rise of the liquid metal industry

《5.1 Incubation and development of “The China Liquid Metal Valley” and new industry》

5.1 Incubation and development of “The China Liquid Metal Valley” and new industry

As an emerging scientific and technological frontier, liquid metal represents tremendous industrial value, breaking up many restrictions faced with traditional technology and promoting the formation and development of a new industrial system. In 2008, the idea of establishing “The China Liquid Metal Valley” in Zhongguancun, Beijing, was put forward for the first time. However, the timing and conditions for promoting this idea seemed immature at that time. A few years later, the same idea was presented again and substantially made into a reality in the Yunnan Province.

In 2013, the Technical Institute of Physics and Chemistry CAS implemented liquid metal thermal interface materials and electronic handwriting pen projects launched in Xuanwei City, Yunnan Province. This marks the commencement of the industrialization process.

As a key project of “Introduction of Science and Technology to Yunnan,” liquid metal products greatly impacted the industry in 2014. The concept of establishing the “The China Liquid Metal Valley” by fully relying on the resource advantages of nonferrous metals in Yunnan became clearer and very specific. Therefore, industrialization companies took the lead in building the production lines of liquid metal raw materials and products, with an annual output of 200 t. They also launched liquid metal thermal conducting strips and paste, liquid metal electronic handwriting pens, and liquid metal 3D handwriting pens to meet the market demand. The Yunnan Kewei Liquid Metal Valley R&D Center was established with the local government, relevant enterprises, and other resources to promote the sustainable development of the new liquid metal industry.

In 2015, the first Liquid Metal Industry Technology Development Summit Forum was held in Xuanwei City, Yunnan Province. The Xuanwei City is nominated as the location of “The China Liquid Metal Valley.” The Liquid Metal Science and Technology Museum in Xuanwei City was also officially opened to the public. Many liquid metal enterprises in Guangdong Province, Beijing, and other cities subsequently settled down or worked together.

Since 2016, there is an increase in the number of companies implementing liquid metal industrialization projects. To better guarantee the development of the liquid metal industry, the provincial-level “five centers and one committee” approved and established the following: Yunnan Key Laboratory of Liquid Metal Enterprises, Kewei Liquid Metal R&D Center of Yunnan Provincial Academy of Science and Technology, Yunnan Liquid Metal Preparation Engineering Research Center, Yunnan Liquid Metal Enterprise Technology Center, and Yunnan Liquid Metal Products Quality Supervision and Inspection Center.

In 2017, the construction achievements of “The China Liquid Metal Valley” were selected as one of the top 10 scientific and technological progresses in the Yunnan Province, highlighting to “unveil the mystery of the emerging technology of liquid metal.” The ideas and proposals of “The China Liquid Metal Valley” have become a reality.

《5.2 Liquid metal industry and R&D actions》

5.2 Liquid metal industry and R&D actions

In 2016, the liquid metal industry was listed in the 13th Five-Year Plan for science and technology development and the new materials development in Yunnan Province. In January 2017, liquid metal was listed in the Guide for Development of New Material Industry as a major supported industry in China. In June 2017, liquid metal was listed in the First Batch of Application Demonstration Guidance Catalogue of Key New Materials. In May 2018, the Liquid Metal Industry Science and Technology Consortium, initiated by several industrial entities, entered the list of “industry–university–research integration technology innovation service system construction project” of the China Association for Science and Technology. This laid the consensus for China enterprises to promote the emerging industry of liquid metal.

In 2018, the Yunnan Province launched a scientific and technological project called “Rare and Precious Metal Material Genome Engineering” to carry out an industrial chain layout based on the “innovation platform–talent team–project coordination, basic research–key technology R&D–engineering application.” The aim was to promote the leapfrog development of rare and precious metal materials and the major application and demonstration of new materials. As the three major sectors of science and technology projects, liquid metal has been developed significantly in database construction and new material R&D; new materials can be produced using high-throughput calculation or means and big data tools such as phase diagram calculation, first principles, and molecular dynamics. Thus, the research of science and technology projects will be conductive to alleviate the material shortage situation of liquid metal.

《6 Suggestions for the industrial development of liquid metal》

6 Suggestions for the industrial development of liquid metal

The development and application of liquid metal are accelerating recently. In the process of liquid metal industrialization, the close integration of industry–university–research reflects the advantages of Beijing in scientific and technological R&D, the regional resources and geographical advantages of Yunnan Province, and good docking between the capital and the province. The industrial application of liquid metal has been recognized worldwide. However, compared with the eagerness in international R&D in liquid metal, there remain insufficient R&D teams and enterprises in China to concentrate on this field. Instead, most institutions still take a wait-and-see attitude mainly because of the tendency to adopt traditional technology by domestic institutions and the reluctance of research teams to expand new industrial application directions, even when the liquid metal has shown basic strategic discovery in the high-tech field, applied research, and industrial promotion and verification. Hence, the following are the suggestions for the development of the liquid metal industry in China.

(1) Science and technology support is indispensable for the sustainable and healthy development of the brand new industry. It is advised that the institutions seize this historic opportunity, further support the industry in the aspects of human resources, finance, materials, and industrial policies, and build a world-class liquid metal science and application center. More efforts should also be made to improve the industrial application technology system and promote industrial chain development through a pilot application.

(2) It is necessary to set up national and local industrial funds and respective policies for “The China Liquid Metal Valley” and related industries to cultivate a large-scale industrial market. It is also advised that there should be an acceleration in the deployment of liquid metal industrial clusters, promotion in the transformation and upgrading and leapfrog development of relevant manufacturing industries, and guidance in promoting and applying new liquid metal products. Only with these efforts would the R&D of cutting-edge technologies be maintained, and the trial and error of new products and the integration of emerging markets, to encourage constructive interactions.

(3) Liquid metal opens up great opportunities for the transformative development of many cutting-edge technologies and demonstrates a strong driving force. Hence, a series of soft topics and strategic research at the general level should be carried out to predict the key role of the emerging material in energy, electronic information, advanced manufacturing, new conceptual equipment, soft intelligent robot, and biomedical health scientifically. In this way, the development of frontier science and technology can be promoted, molding an entirely new industrial system.

京公网安备 11010502051620号

京公网安备 11010502051620号