《1. Introduction》

1. Introduction

Railway predominates within the national traffic and transportation system of China, due to the vast territory and large population. The design operation speed for most of the earlier railway bridges in China was not allowed to exceed 160 km ·h-1. The first attempt to increase the maximum design operation speed to 250 km ·h-1 was carried out on the Qinhuangdao–Shenyang Passenger Dedicated Line (PDL), the construction of which began in 1999. At the beginning of the 21st century, China started massive highspeed railway projects with a maximum design operation speed of 350 km ·h-1, after the successful construction of the Beijing– Shanghai High-Speed Railway and the Wuhan–Guangzhou HighSpeed Railway. A total of 22 000 km of high-speed railway has been opened to traffic as of the end of 2016.

As an important part of the high-speed railway, half of the total length of high-speed railway that is built in China consists of bridges. For example, more than 85% of the Beijing–Shanghai High-Speed Railway is composed of pre-stressed concrete simply supported box girder bridges with a span of 32 m. However, China is a vast country with diverse geographical features and complicated climates. Western China has dry plateaus, magnificent mountains, large gorges, and torrential rivers, while southeastern China has the sea and wide rivers. Therefore, bridges for long-span highspeed railway in the southeast part of China must be able to cross rivers and straits. More than 60 bridges have a main span longer than 200 m, approximately 10 bridges have a main span over 500 m, and two bridges have a span over 1000 m. Table 1 lists the main design parameters of 16 long-span high-speed railway bridges that have been constructed or are under construction in China.

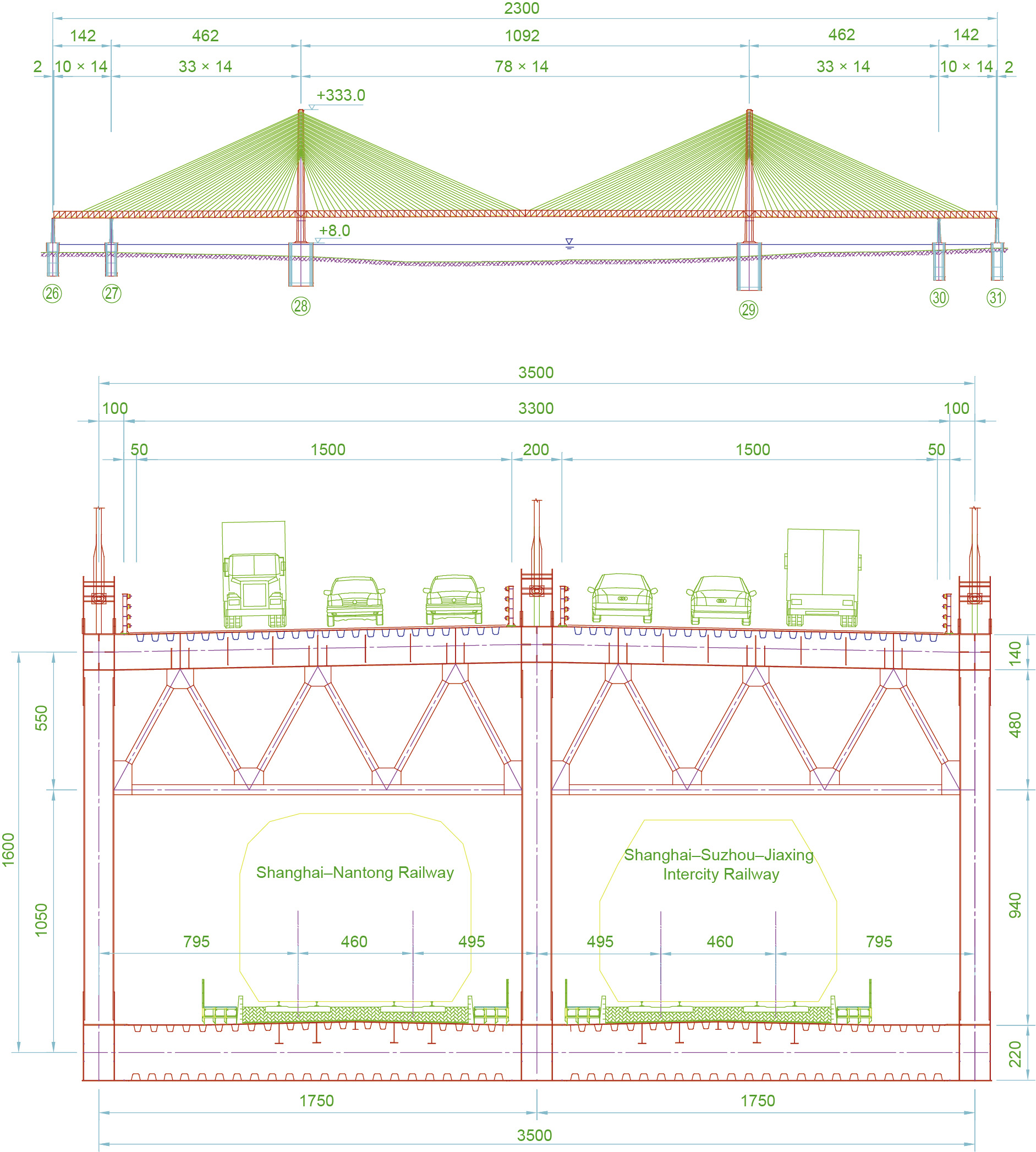

《Table 1》

Table 1 Main design parameters of 16 long-span high-speed railway bridges in China.

Therefore, it is necessary to develop a coupled dynamic analysis model of long-span high-speed railway bridges for the running safety and comfort of high-speed railway on long-span bridges. The effect of bridge structure, vehicle, track, and so forth should be synthetically considered in the model in order to evaluate the dynamic performance of the bridge structure, of which the key point is to obtain greater structural stiffness and better track regularity. Table 2 presents the requirements for track regularity.

《Table 2》

Table 2 List of requirements for track regularity.

A systematic study of bridge structures, materials, and construction technologies should be carried out to realize the requirements for track regularity for long-span high-speed railway bridges.

In the Function column, R represents railway and H represents highway; e.g., 4R 6H represents a four-line railway and six-lane highway.

《2. Multi-function combined bridge-construction technologies》

2. Multi-function combined bridge-construction technologies

Sites for bridge projects are a sort of natural resource. Since the Yangtze River is the “golden waterway,” with busy shipping, the waterfront area along the river is very precious. A good choice for a bridge site should not only minimize the impact of bridge construction on the shipping, environment, and economy of the river, but also meet the ever-increasing demand to cross the river via railway, highway, and other forms of transportation. Therefore, the scheme of a multi-function combined bridge that consists of a highway, railway, urban road, and rail transit is proposed in order to balance conflicting needs.

《2.1. Combined highway and railway bridges》

2.1. Combined highway and railway bridges

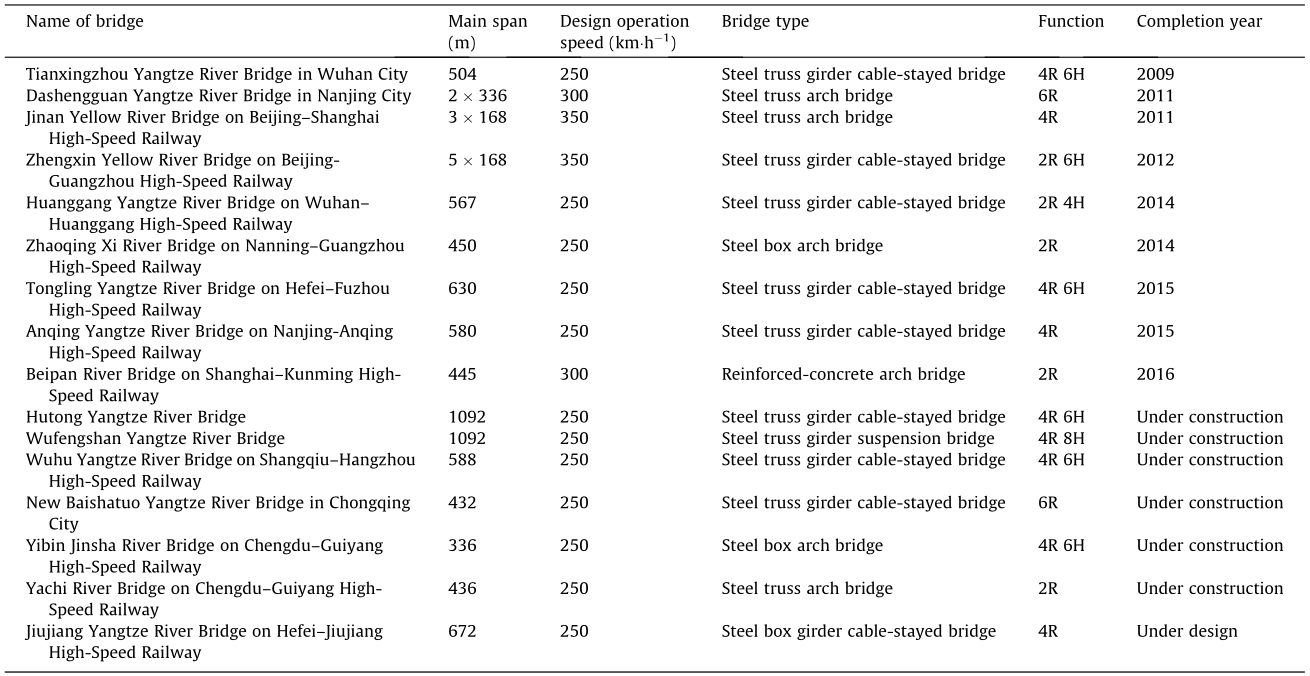

Combined highway and railway bridges are bridges that are shared by highway and rail lines. The highway and railway are segregated so that trains may operate at the same time as cars. For example, Hutong Yangtze River Bridge (Fig. 1) is shared by the Shanghai–Nantong Railway, the Shanghai–Suzhou–Jiaxing Intercity Railway, and the highway from Wuxi to Nantong [1]. Tianxingzhou Yangtze River Bridge is shared by the Beijing– Guangzhou and Shanghai–Wuhan–Chengdu High-Speed Railways, and by the third ring road of Wuhan [2,3] (Fig. 2). Wufengshan Yangtze River Bridge [4] (Fig. 3) and Yibin Jinsha River Bridge on the Chengdu–Guiyang High-Speed Railway are also shared bridges.

《Fig. 1》

Fig. 1. Hutong Yangtze River Bridge (unit: m).

《Fig. 2》

Fig. 2. Tianxingzhou Yangtze River Bridge in Wuhan. (a) Three cable planes; (b) layout of cross-section (unit: m); (c) constructed bridge.

《Fig. 3》

Fig. 3. Wufengshan Yangtze River Bridge.

《2.2. Multi-track railway bridges》

2.2. Multi-track railway bridges

Multi-track railway bridges allow the passing of two or more rail tracks. The Anqing Yangtze River Railway Bridge carries four rail tracks including two double-track railways: the Nanjing–Anqing High-Speed Railway and the Fuyang–Jingdezhen Railway [5]. The New Baishatuo Yangtze River Bridge has six tracks shared by the Chongqing–Guiyang High-Speed Railway, the Chongqing–Changsha High-Speed Railway, and the Chongqing–Guiyang General Speed Railway [6]. Another example of a six-track railway bridge is Dashengguan Yangtze River Bridge (Fig. 4), which is shared by the Beijing–Shanghai High-Speed Railway, the Shanghai–Wuhan– Chengdu High-Speed Railway, and the Nanjing Metro [7,8].

《Fig. 4》

Fig. 4. Dashengguan Yangtze River Bridge.

Combined highway and railway bridges and multi-track railway bridges make better use of the structural width and stiffness of long-span bridges. Compared with separate highway and railway bridges, multi-function combined bridges greatly save the usage of construction materials and therefore significantly reduce the total investment.

《3. Bridge structural innovations》

3. Bridge structural innovations

《3.1. Three-cable-plane and three-main-truss structures》

3.1. Three-cable-plane and three-main-truss structures

The design live load for passenger-and-freight mixed railway is obtained according to China’s standard railway live load, which includes uniform loads with an intensity of 80 kN·m-1 to simulate vehicles and five 220 kN concentrated forces over a distance of 1.5 m to simulate traction locomotives. Larger design loads should be used for the design of heavy haul railway. However, high-speed railway is designed using ZK live load with a load intensity of 64 kN·m-1. The design live load for a single-line railway is equal to that for a six-lane or eight-lane highway. Thus, the internal forces of a railway bridge are extremely large due to the heavy live loads.

Taking recently constructed combined highway and railway steel truss girder bridges as an example, there are usually six to eight highway lanes on the upper deck and four (or even six) rail tracks under the highway and going through the truss. Because the truss of the bridge is fairly wide, the transversal deformation of the cross-sections can be very large and affects the operation of high-speed railway. Since the deformation of the structures originates from structural flexibility, an effective way to reduce the deformation is to increase the transversal stiffness of the girder. If the materials remain the same, two commonly used ways of doing this are to increase the section geometry or to shorten the span of the girder.

A three-cable-plane and three-main-truss structure adds one more truss plane into the conventional two-plane main truss, and divides one rectangular frame into two side-by-side rectangular frames. The four tracks of the railway are divided into two double-track groups, and each double-track railway is placed into one frame. The three-cable-plane and three-main-truss structure is a good solution for the design and operation of the bridge structure, as it makes the force conditions more reasonable by changing from a simply supported to a continuous transverse section, reduces the deformation, and adds to the comfort of track riding. Correspondingly, the cable systems have three cable planes. A three-cable-plane and three-main-truss structure was first applied in Tianxingzhou Yangtze River Bridge in Wuhan [9] (Fig. 2), and has been further used in cable-stayed bridges and steel truss arch bridges, such as Tongling Yangtze River Bridge, Hutong Yangtze River Bridge, Anqing Yangtze River Bridge, and Dashengguan Yangtze River Bridge.

The China Railway Major Bridge Reconnaissance and Design Institute Co., Ltd. (BRDI) developed bridge design software specifically for implementing such complicated spatial structures. This software can carry out not only the loading of various live loads, including the China’s standard railway live load, the ZK live load, and highway traffic loads, but also simultaneous loading on both the highway and railway layers.

《3.2. Inclined main truss structures》

3.2. Inclined main truss structures

As shown in Fig. 5, Zhengxin Yellow River Bridge is the key project of the Beijing–Guangzhou High-Speed Railway. The bridge has a six-lane highway on the upper deck and a double-line high-speed railway on the lower deck [10,11]. In order to have an upper highway deck that is wider than the lower rail deck, inclined main truss structures, which consist of three main trusses with side trusses set in inclined positions, were used. The inclined main truss structure reduces steel usage and was also applied in Huanggang Yangtze River Bridge on the Wuhan–Huanggang High-Speed Railway [12].

《Fig. 5》

Fig. 5. Zhengxin Yellow River Bridge. (a) Cross-section of the main truss girder (unit: mm); (b) sketch-up of the main truss girder; (c) constructed bridge.

《4. Composite structures》

4. Composite structures

Three general types of composite structure bridges are used for long-span high-speed railway bridges in China. The first type is the deck-truss composite structure, in which the deck structures and the steel truss work together to resist the external loadings. In earlier steel truss bridges, small precast decks were put on the main girders and transverse beams to transfer the highway loads only to the joints of the main trusses. The decks of such bridges do not bear the loads together with the truss. Therefore, the capability of the decks has not been fully used. The second type is the steelconcrete composite structure, in which the deck on the steel truss girder is a composite structure made up of orthotropic steel plates and reinforced-concrete deck slabs. Concrete structures in highway decks essentially help to avoid the prevalent problems that are caused by steel decks, such as the fatigue problem of the decks and the life of the pavements.

Recently, as high-speed railway bridges become increasingly longer, increasing the stiffness of the bridge structures has become one of the most important design objectives. The most effective and economical way of doing this is to let the decks and the main trusses work together; in other words, to form a plate-truss composite structure. Tianxingzhou Yangtze River Bridge (Fig. 6) used this type of structure. The main span of Tianxingzhou Yangtze River Bridge is a cable-stayed bridge. Both orthotropic steel plates and main steel are used in the 756 m long main span and part of the two side spans, while reinforced-concrete slabs and main steel are used in the remainder of the two side spans (each of which is 168 m long). In subsequent projects, such as the Huanggang [12] and Tongling[13] Yangtze River Bridge, both the highway and railway decks work together with the main trusses. The trusses are combined with the upper and lower chords, respectively, to make up the whole crosssection of the main truss girders. Since the decks and the main trusses bear the overall loads of the structure together, the stiffness of the main truss girders is distinctly increased. This innovation benefits the operation of high-speed trains.

《Fig. 6》

Fig. 6. Composite structures on Tianxingzhou Yangtze River Bridge in Wuhan.

The precast reinforced-concrete slabs in the upper highway decks of Zhengxin Yellow River Bridge were directly composited with the upper chords of the main steel trusses, and work together with the truss [14] (Fig. 5). In addition, reinforced-concrete structures have been used as both the upper highway and lower railway decks of multi-span simply supported steel truss girders in Hutong Yangtze River Bridge and in the Pingtan Cross-Strait HighwayRailway Bridge. These are double-layer steel-concrete composite structures.

The third type of composite structure is the steel truss and concrete composite arch bridge. Yachi River Bridge on the Chengdu– Guiyang High-Speed Railway is a half-through arch bridge with a main span of 436 m (Fig. 7). A steel skeleton was used as the main truss arch. The steel arch feet were coated in concrete, and the upper flange of the arch ribs was filled with concrete at the section near the apex of the arch [15].

《Fig. 7》

Fig. 7. Yachi River Bridge on the Chengdu–Guiyang High-Speed Railway.

《5. High-performance materials》

5. High-performance materials

5.1. High-strength bridge steel

The increase of high-speed railway bridge spans and the usage of multi-function combined bridges have caused structural internal forces to become larger and larger. The maximum member force of Dashengguan Yangtze River Bridge, a steel truss arch bridge with a main span of 2 336 m and a six-track railway, has reached as high as 150 MN. The maximum compression force of the main girder of Hutong Yangtze River Bridge, a cable-stayed bridge with a span of 1092 m, a four-track railway, and a six-lane highway, is as high as 750 MN. Therefore, it is urgently necessary to study and develop high-strength steel for bridges. The Q420q and Q500q bridge steels have been successively developed. The former was developed and used in Dashengguan Yangtze River Bridge [16], while the latter was applied in Hutong Yangtze River Bridge [17].

Steel with different strength grades can be used in different parts of the same bridge to make the structural stiffness and geometries of the bridge more reasonable. For example, Q420q was used in the arch ribs, which suffered larger stresses, while Q370q was used in other parts of Dashengguan Yangtze River Bridge [18]. For Hutong Yangtze River Bridge, Q500q was used for the main girders, due to large compression forces near the pylons and auxiliary piers, and both Q420q and Q370q were used for elements with lower compression [19].

The advantages of high-strength materials include reducing the self-weight of the structure, saving material, and thus reducing the consumption of resources and energy.

《 5.2. High-performance stayed cables》

5.2. High-performance stayed cables

High-performance stayed cables were developed and applied in the construction of long-span high-speed railway bridges. Similar to the evolution of bridge steel, the strength of steel wires for high-performance stayed cables has increased from 1570 MPa to 1670 MPa, 1770 MPa, and 1860 MPa, and on to 2000 MPa (which is planned for use in Hutong Yangtze River Bridge, currently under construction). A zinc-aluminum (Zn-Al) alloy has been coated onto the steel wires to further improve their durability [19]. Tongling Yangtze River Bridge, a steel truss girder bridge with a main span of 630 m and a four-track railway and six-lane highway, is the longest completed combined highway and railway bridge in the world thus far. It used parallel steel-strand cable systems in which each strand was separated from every other strand. Cable-stayed systems with high-performance stayed cables can significantly reduce the wind-rain vibration of stayed cables [20].

《6. Integral fabrication of steel truss girders》

6. Integral fabrication of steel truss girders

Traditional steel truss girders were fabricated and installed one element at a time. This procedure only requires simple construction machines and equipment. However, it requires a large amount of aerial work, which decreases the construction quality and increases the risk of personal injury.

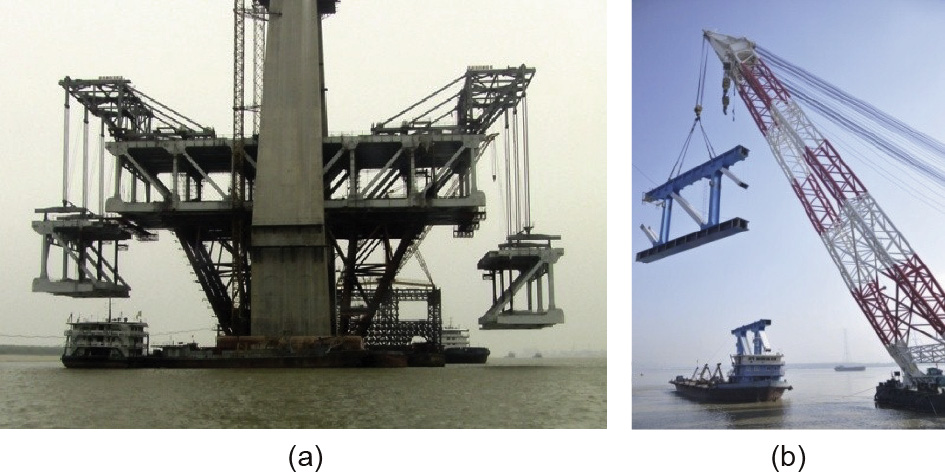

In order to overcome the limitations of traditional construction, Tianxingzhou Yangtze River Bridge was the first to use the new fullsegment erection technology [21], which requires the assemblage of all the members of the truss—such as cross bar members and the longitudinal and cross beams of the railway bridge deck and highway bridge deck—into a full segment of steel truss girder with a weight of 650 t in the factory (Fig. 8(a)). The transportation and fabrication of the single segment significantly decreases the amount of aerial work, compared with the traditional method. Moreover, Tongling Yangtze River Bridge was the first to be constructed using the all-welded truss plane element technology [22]. As shown in Fig. 8(b), this technology takes every two segments as one unit, with all the members of the unit being divided into several fabrication plane elements. Each fabrication plane is manufactured by welding in the factory. For example, two upper chords, two lower chords, two vertical bars, and two inclined bars are welded together in the factory to form the main truss plane element of two segments, which are then subsequently transported and erected onsite. Hutong Yangtze River Bridge was constructed using the truss plane element method with elements that weighed 2000 t, which included all three main truss planes, the railway and highway bridge decks, and the transversal connection members for each two segments. Each element was completely welded in the factory and then transported and erected into the bridge [23]. Pingtan Cross-Strait Highway-Railway Bridge went one step further and was made of both 80 m and 88 m steel truss girders, which were welded together and then transported and erected as a whole span [24].

《Fig. 8》

Fig. 8. Integral fabrication and erection of steel truss girders. (a) Erection of a full segment of the main truss girder of Tianxingzhou Yangtze River Bridge; (b) erection of an all-welded truss plane element of Tongling Yangtze River Bridge.

《7. Technical developments and future prospects of long-span high-speed railway bridges》

7. Technical developments and future prospects of long-span high-speed railway bridges

《7.1. Technologies of multi-pylon cable-stayed bridges》

7.1. Technologies of multi-pylon cable-stayed bridges

China has many rivers and straits with huge expanses of water and busy shipping. Bridge engineers are responsible for maintaining the harmony and sustainable development of both bridge construction and ‘‘golden waterway” protection. Multi-pylon cable-stayed bridges can provide continuous multi-channel long spans and allow the separation of upstream and downstream in different channels; therefore, they have significant economic advantages [25].

China has made some progress in the construction technologies of multi-channel long-span cable-stayed highway bridges. Many multi-pylon cable-stayed bridges have been constructed. Earlier examples include Yiling Yangtze River Bridge [26], Dongting Lake Bridge [27], and so on. Recent examples are Wuhan Erqi Yangtze River Bridge [28], Jinan Jianbang Yellow River Bridge [29], and the Jiaxing–Shaoxing Sea Bridge [30]. Breakthroughs have also been made in multi-pylon suspension bridges. Three long-span three-pylon suspension bridges with a main span length exceeding 1000 m were built for the first time in the world—Taizhou Yangtze River Bridge [31] (main span length: 2× 1080 m), Maanshan Yangtze River Bridge [32] (main span length: 2× 1080 m), and Yingwuzhou Yangtze River Bridge [33] (main span length:2×850 m). In addition, the 2×800 m main span of Oujiang River North Estuary Bridge [34], which is currently under construction, consists of double-deck steel truss girders. Regarding railway bridges, a three-pylon cable-stayed bridge with a 2 ×408 m main span has been selected as the scheme of Dongting Lake Bridge, which is part of the railway coal corridor from western Inner Mongolia to central China. It is believed that the construction of the above projects, along with continuous technical accumulation, will provide important experience and a good foundation for future combined highway and railway bridges and for multi-pylon cablestayed or suspension bridges with a longer span, which may be used as the design schemes of the Qiongzhou Strait Sea Bridge (Fig. 9) and the Bohai Bay Corridor.

《Fig. 9》

Fig. 9. Design scheme of the Qiongzhou Strait Sea Bridge.

《7.2. Industrialization and large-scale prefabrication of bridge foundations》

7.2. Industrialization and large-scale prefabrication of bridge foundations

As mentioned above, extensive experience has been gained in the industrialization and prefabrication of superstructures for long-span railway bridges in China. In addition, certain achievements in industrialized construction technologies for large-scale deep-water foundations have also been made. For example, spread footing foundations have been used for Wuhu Yangtze River Bridge on the Shangqiu–Hangzhou High-Speed Railway and for the Dalian Xinghai Bay Bridge, instead of pile foundations. Prefabricated steel box spread footing foundations were used for Wuhu Yangtze River Bridge. Prefabricated concrete caisson foundations were applied to support Xinghaiwan Bridge on a sandy site. In future, it is necessary to study new types of foundations, as well as relevant construction equipment and methods that can be used for sites with a deep overburden layer and with water depths exceeding 100 m.

《7.3. Material supports》

7.3. Material supports

The construction of bridges with a larger span requires progress and support from the field of material science. One future direction is to constantly improve the performance of traditional bridgeconstruction materials such as steel and concrete. However, it is too difficult to significantly increase steel strength according to our current science and technology. Since the proportion of the dead load is more than 80% of the total load, the other direction is to reduce the self-weight of the bridge. Thus far, fiber reinforced materials may be considered as an efficient solution.

《8. Conclusion》

8. Conclusion

As an important part of the Chinese high-speed railway, a complete set of key technologies has gradually been formed for longspan high-speed railway bridges with Chinese characteristics in the design theory, structure, materials, technology, and other aspects. Chinese long-span high-speed railway bridges have now reached a world-leading level in their main technical indexes, such as span length, bearing capacity, design speed, and so on. In addition, China’s high-speed railway mileage will reach 30 000 km by 2020. Given the rapid expansion of the high-speed railway, innovations in long-span high-speed railway bridges will surely continue, along with bridge development. In future, these bridges will increasingly serve the sustainable development of the national economy and of society, as well as the implementation of national strategies such as the Belt and Road Initiative.

《Compliance with ethics guidelines》

Compliance with ethics guidelines

Shunquan Qin and Zongyu Gao declare that they have no conflict of interest or financial conflicts to disclose.

京公网安备 11010502051620号

京公网安备 11010502051620号