After nearly 10 years of geological surveys, route design, and comparisons of tunnel construction technology and engineering design, the construction of the longest railway tunnel in China— the Gaoligong Mountain Tunnel, which has a full length of 34.5 km—began in December 2014. As the key works of the Dali–Ruili Railway in the west line of the Trans-Asia Railway, this tunnel is located in western Yunnan Province in southwestern China, and passes through the west of the Hengduan Mountains in the southern Qinghai–Tibet Plateau. It can be extended westward to connect with railways in Myanmar and India, thus connecting the Chinese railway system to railways in Southeast Asia, South Asia, and Europe to form an onshore transport corridor from the Pacific Ocean to the Indian Ocean. This linkage will promote commerce and trade along the line, reduce the cost of international trade, and play a positive role in enhancing exchanges between China and other Southeast Asian countries. In this way, it will allow China to adapt to the trend of economic globalization and achieve the sustainable development of its national economy.

The tunnel is designed as a single-track double-tube tunnel, with tube I and tube II being constructed in different phases. The site of the tunnel is located between Baoshan City and Mang-shi City in Yunnan Province; the tunnel passes through the geographically complex Gaoligong Mountain and the Hengduan Mountains, with a buried depth of up to 1155 m and a 26.8 km long section with a buried depth exceeding 500 m. The construction of this tunnel is funded by the Chinese government, the China Railway Corporation,and the Yunnan provincial govern-ment,and the tunnel is expected to open in 2021. The density of freight flow through this tunnel is forecast at 6×106 t a-1 for 2025 and at 9 ×106 t a-1 for 2035, with 8–9 pairs of passen-ger trains per day [1]. Travelling at 140 km h-1, a passenger train will take about 15 min to pass through the tunnel.Once completed, this tunnel and the Dali–Ruili Railway will put an end to the historical lack of railway access to western Yunnan Province;more specifically, it will solve the historical problem of crossing Gaoligong Mountain and the Hengduan Mountains,by providing railway access that takes only 2 h, compared with bus access taking 6–7 h.

The significance of the Gaoligong Mountain Tunnel mainly depends on its transport function.Acting as a natural barrier in western Yunnan Province, Gaoligong Mountain and the Hengduan Mountains lie between the Nujiang River Valley and Mangshi City, with high altitudes, steep slopes, deep cuttings, and a vertical elevation difference of over 3500 m. Due to its complex topographical conditions,Gaoligong Mountain acts as an obstacle to trade and cultural exchange. Considerable efforts have been made in the past to cross Gaoligong Mountain and the Hengduan Moun-tains. In particular, the Yunnan–Burma Highway, a road that mean-ders through Gaoligong Mountain, was built from late 1937 to August 1938 (this was the well-known Stilwell Road during World War II). This road eased the difficulties of crossing Gaoligong Mountain at the time, and helped to meet transport demands during World War II.However,given the rapid social and economic development of the 21st century, the existing Yunnan–Burma Highway struggles to meet the transport demands of the new age, thus creating a need for the construction of the Gaoligong Mountain Tunnel on the Dali–Ruili Railway.

The Gaoligong Mountain Tunnel is a straight tunnel passing through Gaoligong Mountain and the Hengduan Mountains.Its entrance faces Nujiang River, and its exit faces Mangshi City;the two portals have an elevation difference of up to 375 m.

Regarding the tunnel construction method,the drilling-and-blasting method has been adopted for a distance of 21 km at the entrance,where the lithology of sedimentary and metamorphic rocks varies frequently with uneven hardness, is greatly affected by faults and syncline,and has highly developed groundwater. The tunnel-boring machine (TBM) method has been adopted for a length of 14 km at the exit,where the Yanshanian granite is lightly affected by faults and the groundwater is not developed (Fig. 1). A parallel adit will be constructed using a 5.6 m diameter TBM, while the main tunnel will be constructed using a 9.0 m diameter TBM.

《Fig. 1》

Fig.1.Profile of the Gaoligong Mountain Tunnel.

The parallel adit will be constructed in advance in order to establish geological parameters, thus providing support for the rapid construction of the main tunnel of tube I. After tube I is complete,the parallel adit will be expanded and constructed into tube II.

To increase the number of working faces and to meet ven-tilation needs during operation,disaster prevention,and rescue,two deep vertical shafts (760 and 642 m deep,respectively) and one 3600 m long inclined shaft are provided at the entrance section, all constructed by the drilling-and-blasting method.Both the vertical shafts will serve as ventilating shafts during operation.

Geological surveys show that the tunnel passes through a region with abnormal ground temperature,a rock temperature above 28°C, and a fault that can distribute the heat through water flow [2]. This geotherm may lead to a harsh construction environment in the tunnel, with high temperatures, heat,and moisture posing a risk to the health of operators and to construction safety,and being likely to affect construction progress. Therefore, measures for cooling using ventilation and a refrigeration plant, and measures to block hot water using advanced grouting will be taken to improve and safeguard the construction environment.

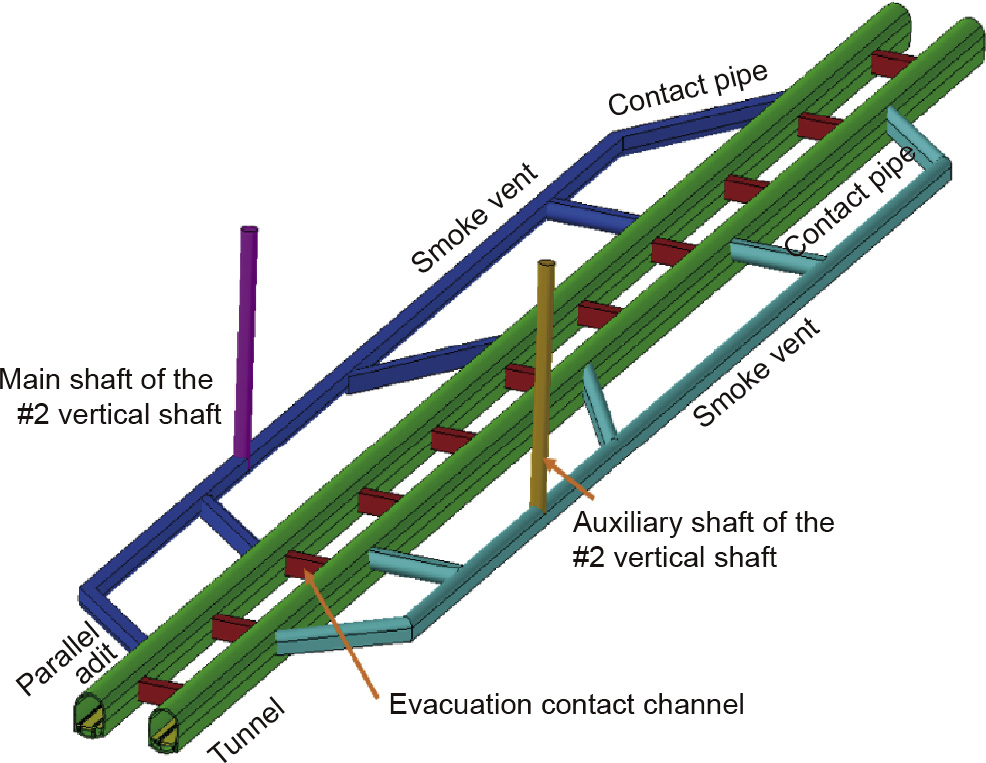

Operation safety of the Gaoligong Mountain Tunnel is a key issue. During operation,the two tubes will serve as each other’s rescue space. Transverse connecting passages will be located at intervals of about 350 m between the two tubes, and a 550 m long emergency rescue station is provided in the middle of the tunnel, 20 km from the adit. For the rescue station, a connecting evacua-tion passage is provided between the tubes.The second vertical shaft will be used as an exhaust shaft for the rescue station in order to achieve rapid smoke discharge (Fig. 2).

《Fig. 2》

Fig.2. Structure of the emergency rescue station for the Gaoligong Mountain Tunnel.

The techniques that are being used for the Gaoligong Mountain Tunnel on the Dali–Ruili Railway, such as the length of the tunnel,the depth of the vertical shafts, the length of the inclined shaft,the geotherm treatment,and the TBM configuration,are unprecedented in the history of the Chinese railway system. The most advanced construction techniques and equipment in China today are being employed for this tunnel,and the construction progress of the tunnel has been smooth to date.

京公网安备 11010502051620号

京公网安备 11010502051620号