《1. Introduction》

1. Introduction

With the opening ceremony of the Gotthard Base Tunnel on 1 June 2016, a new world record was established: the commissioning of the longest railway tunnel in the world. Many challenges have been overcome and many technical innovations have been developed and considered in this project. As of 11 December 2016, the Gotthard Base Tunnel has been an integral part of the new timetable of the Swiss Federal Railways (SBB-CFF-FFS), and is in full operation. With a total length of 57 km and a cruising speed of 200 km·h-1 for passenger trains, the Gotthard Base Tunnel reduces the journey time through the Alps by 40 min, significantly reducing the distance between the south and north of Europe.

After 25 years of design and more than 17 years of construction, a review of the interesting and intensive realization phase of this project of the century is of great interest. By providing insight into the successes and critical moments of this project, this review can enable a remarkable learning process of identifying positive and demanding experiences that are useful for future projects.

This article describes the management and allocation of risks, the procurement strategy, the adopted contractual models, contract and dispute management, and the financing model. These were some of the successful aspects that permitted the Gotthard Base Tunnel to be constructed in accordance with the agreed-upon level of quality, without exceeding the budget, and fully within the time schedule.

《2. The Gotthard Base Tunnel: A brief overview of the project》

2. The Gotthard Base Tunnel: A brief overview of the project

The Gotthard Base Tunnel is an integral part of the so-called Trans-European Transport Network (TEN-T) and is located in the core section of the Rhine–Alps Corridor (Rotterdam–Genoa). Together with the 35 km long Lötschberg Base Tunnel (in full operation since December 2007), the Gotthard Base Tunnel constitutes the New Railway Link through the Alps (NRLA).

The 57 km long Gotthard Base Tunnel stretches from Erstfeld in the north to Bodio in the south. It consists of two parallel singletrack tubes with a diameter varying from approximately 8.80 to 9.50 m; the two tubes are linked by cross passages approximately every 300 m. At two positions—one-third and two-thirds of the way along the base tunnel—multifunctional stations are located for the purposes of train diversion via crossover to the other tube, electro-mechanical installations, and train stoppage and passenger evacuation in the case of an emergency (Fig. 1).

《Fig. 1》

Fig. 1. Scheme of the Gotthard Base Tunnel (tunnel system).

A detailed and sophisticated evaluation demonstrated that this tunnel system was the most suitable for long alpine tunnels. To shorten the construction time and for ventilation purposes, the tunnel was divided into five sections and driven from several sites simultaneously. Excavation took place from the portals as well as from three intermediate construction adits in Amsteg, Sedrun, and Faido.

Thanks to a design speed of 250 km·h-1 for passenger trains and 160 km·h-1 for freight trains, a minimum radius of curves of 5.000 m, and a maximum slope of 12.5‰ for the railway line (6.76‰ for the base tunnel), the new Alpine Link will allow the daily transit of 50–80 passenger trains and 220–260 freight trains (750 m long), after the 15 km long Ceneri Base Tunnel starts operation in December 2020. Compared with the situation before the opening of the new base tunnels, the capacity of rail freight transport on this important north–south link will be doubled and the travel time between northern and southern Switzerland will be reduced by about 40–60 min.

《3. Organization》

3. Organization

Realization of a project—however large it may be—is by definition a temporary undertaking with a defined beginning and end. Thus, it is beneficial to have a temporary organization for this specific task that is intended to fulfill the specified requirements (i.e., project aims) in order to create advantageous changes and added value. This principle was applied to the organization of AlpTransit Gotthard Ltd. (ATG).

Due to the unique size of the project in Switzerland, the Swiss parliament passed a project-related legal framework, which formed the basis for the construction of the corridor of the NRLA.

According to this framework and the principle of direct democracy, all stakeholders were included in the project organization, including the following:

• The Swiss Federation, the sponsor of the project, which was tasked (among others) with the financing and supervision of the NRLA;

• The SBB-CFF-FFS, the sole shareholder of ATG and the future operator of the new railway link;

• The consultants, contractors, and suppliers contracted with ATG;

• The community.

The resulting organization proved to be a good model and was a key factor in the success of the project. It allowed a direct run, simplified contacts and links, management transparency (thanks to parliamentary control through the specific commission), and clearer and better governance and efficiency (thanks to a lean organization that facilitated the decision-making process) [1,2].

《4. Project financing and cost management》

4. Project financing and cost management

As a result of intensive discussion, a new financing model was produced, which was the object of popular vote on 29 November 1998. With a 63.5% ‘‘yes” vote, the fund for the financing of public transport infrastructure (FinöV)—comprising 30 billion CHF—was agreed upon by the Swiss people. Of the fund amount, 13.8 billion CHF (1998 price level) were intended to finance à fond perdu (lost funding) in the construction of the NRLA.

With the contribution from the FinöV representing about 75% of the total required credit, only 25% of the investment had to be financed on the private capital market. This share of the investment would later be paid back by the future operator—the SBB-CFF-FFS—as in the former finance models. From the beginning, the project financing model ensured a clear and secure financing of the whole project that was independent of the current state budget and of possible political changes, thus avoiding possible delays or stops in the construction phase due to a possible lack of financial resources or political consensus. This secure financing was a fundamental element in the success of the Gotthard project. As the constructor, ATG essentially had to operate two control circuits:

(1) Project and cost management vis-à-vis the federal government as the project sponsor;

(2) Project and cost management vis-à-vis their contractors.

The order placed by the Swiss Federal Government with ATG was regulated in the contract that was agreed upon between these two parties. The cost-management process was generally set up with regard to optimal achievement of the NRLA Controlling Instructions (NCI), which defined the decisive control figures and the type and frequency of reporting (every six months); the handling of variations was established correspondingly.

A management system for engineering changes was to be consistently updated in order to ensure that all project modifications could be processed and documented in a transparent and understandable way. The responsibilities for the approvals were clearly specified in order to permit the necessary decisions to be made at the right time for the right stage. Performance variations that affected costs and deadlines could generally be implemented only after the targets had been adapted. If a performance variation had to be implemented immediately for scheduling reasons, the Swiss Federal Office of Transportation (FOT) was notified in an incident report. After the approval of a change request by the Swiss FOT, ATG could apply for an adjustment of the project terms. The major issues that led to updates of the cost reference basis were related to the upgrading of the project to incorporate new safety measures and state-of-theart technologies (as the project realization spanned over two decades); extra costs related to geology (situations with worse geological and geotechnical conditions than expected were the most impactful here, while other situations had more favorable geological and geotechnical conditions than expected); and cost increases due to contract awards and construction.

The evolution of the probable final costs and the potential risks of financial impact were monitored by ATG on a quarterly basis and reported to the control authority every six months.

For the Gotthard Base Tunnel alone, the increase in credit that occurred—from the original 6.3 billion CHF to 9.9 billion CHF (part of the abovementioned 13.8 billion CHF), corresponding to 53% without inflation—was not unexpected, but was nonetheless impressive. Almost half of the extra costs came from variations resulting from orders issued by the Swiss FOT, which consistently aimed to deliver a tunnel with state-of-the-art safety measures and technology. The extra costs from ground risks, which could not be influenced directly, made up only 9%, or a sixth of the total increase [1,2].

《5. Contractual model, risk allocation and management, and contract and disputes management》

5. Contractual model, risk allocation and management, and contract and disputes management

The contractual model that is adopted for the realization of a large underground work significantly affects the project’s organization, development of the design, bid procedure and, finally, implementation of the construction contract itself during the entire construction phase.

A reasonable risk allocation is important in order to allow the contractor, at the bidding stage, to make an appropriate calculation of the offered unit prices, establish a bid strategy, and build a relationship between client and contractor after the award and contract’s signature.In fact, an analysis of the experience acquired in various continents, as conducted by Working Group No. 3 of the International Tunneling and Underground Space Association (ITA), shows that only a suitable and balanced risk sharing allows the client to optimize (minimize) the construction costs [3,4].

In fact, an analysis of the experience acquired in various continents, as conducted by Working Group No. 3 of the International Tunneling and Underground Space Association (ITA), shows that only a suitable and balanced risk sharing allows the client to optimize (minimize) the construction costs [3,4].

Mechanisms for conflict management are essential for dealing in a professional manner with the difficulties and changed conditions that inevitably characterize the realization of works on this scale. In the specific case of the Gotthard Base Tunnel, the design and the general and local construction supervision were run by the client, ATG, and its consultants. Contractors were generally only commissioned to carry out the construction works defined by the client’s designers.

The civil engineering activities and services related to the provision and commissioning of MEP (Mechanical, Electrical, Plumbing) were contracted according to the classic model applied in Switzerland for underground works, as defined by the standards of the Schweizerischer Ingenieur und Architektenverband [Swiss Society of Engineers and Architects] (SIA), where the designer acts as a direct agent of the client.

The responsibilities of the contractual parties during the execution, provisions regarding payment, determination of quantities, general conditions to apply for variations, adjustment of deadlines, allocation of risks, and so forth are clearly stated in the SIA standards. These standards, which reflect the Swiss perspective on the construction of underground structures, greatly affect, inter alia, both the risk-management aspects and the contract model.

According to these standards, among other aspects, the remuneration of the contractor is based on unit prices and actually adopted quantities. An adjustment of the deadlines is granted in consideration of variations (arising from risks under the client’s responsibility, such as the risk allocation related to the geology), whereas the risks are attributed to the contractor when they are related to the production process and to the achievement of the declared performance as offered.

The conflict-management process was designed to act through progressive levels, starting from the lowest level of the construction site, and hierarchically increasing until—for the few cases where it was not possible to find a consensual solution—the involved figures reached the level of the advisory Arbitration Commission, which was agreed upon in advance between the parties. Thanks to this dispute-management mechanism and the parties’ willingness to dialogue, no dispute ever went to court—a remarkable achievement for a project of this size and duration.

The management of geology-related risks and chances by the client and its consultants, together with the unit prices remuneration mechanisms, was a key aspect of the success of the construction of the Gotthard Base Tunnel.

The following examples clearly demonstrate the importance of the client’s right to choose the appropriate solution in case of unexpected faults in large underground works involving long and deep tunnels in mostly unknown geological conditions due to limited exploratory drillings.

《5.1. Case 1: Unexpected major fault in the multifunctional station of Faido》

5.1. Case 1: Unexpected major fault in the multifunctional station of Faido

The unexpected presence of a major fault zone almost parallel to the alignment of the main tunnels and in correspondence with the planned excavations of the largest tunnel sections (Fig. 2(a))— namely, the transversal cavern and the bifurcations of the northern crossover tunnel—required the involved engineers to adopt a major variation of the scheme of the multifunctional station under a very short timeline, as the excavation was in full progress. This significant modification had to be made while limiting the increase of the construction costs as much as possible and minimizing the impact on the overall construction schedule of the entire Gotthard Base Tunnel.

《Fig. 2》

Fig. 2. (a) Unexpected major fault in the multifunctional station of Faido; (b, c) adopted measures.

The crossovers from one tunnel to the other (i.e., diagonal connections) include bifurcation caverns with the largest tunnel section in the project (up to 230 m2 ). In the original layout (Fig. 2(b)), all large tunnel sections were affected by this unfavorable and unexpected geological condition. In order to optimize the solution to this situation, the scheme was modified by moving both crossovers and the emergency stop along the western tunnel to the south, which has more favorable geological conditions (Fig. 2(c)), rather than applying extreme supports. This modification was combined with an important upgrade of the scheme for safety reasons, with the integration of additional exhaust air-extraction gallery systems (Fig. 2(c), in green).

This case clearly highlights the importance of the client having control over the detailed design and the management of geological risk. Remuneration of the performed works with unit prices made it possible to manage the changes of sequences and quantities, while remuneration on a time and material basis (per labor) made it possible to manage particular situations for which the definition of unit prices was impossible or unfair.

The client’s detailed design and management of the geological risk made it possible for the client to make important decisions in a short time, thus avoiding any stoppage of the works without renegotiation of the conditions of the entire framework agreement; instead, the client merely adapted the deadlines and remuneration amount, thereby optimizing the schedule and costs.

《5.2. Case 2: Measures taken to recover a delay of one year》

5.2. Case 2: Measures taken to recover a delay of one year

The challenges to be overcome did not only involve technical matters. The realization of a base tunnel requires coping with geological, administrative, and legal risks that may result in important delays of the project. The general schedule of the works is characterized by numerous interdependencies, such as between the civil engineering works and the equipment (MEP) and railway technology, and these may have repercussions delaying the scheduled commissioning dates.

In this particular case, an accumulation of delays anticipated in 2008 would have shifted the startup of the base tunnel to December 2017, one year later than was expected and had been publicly announced.

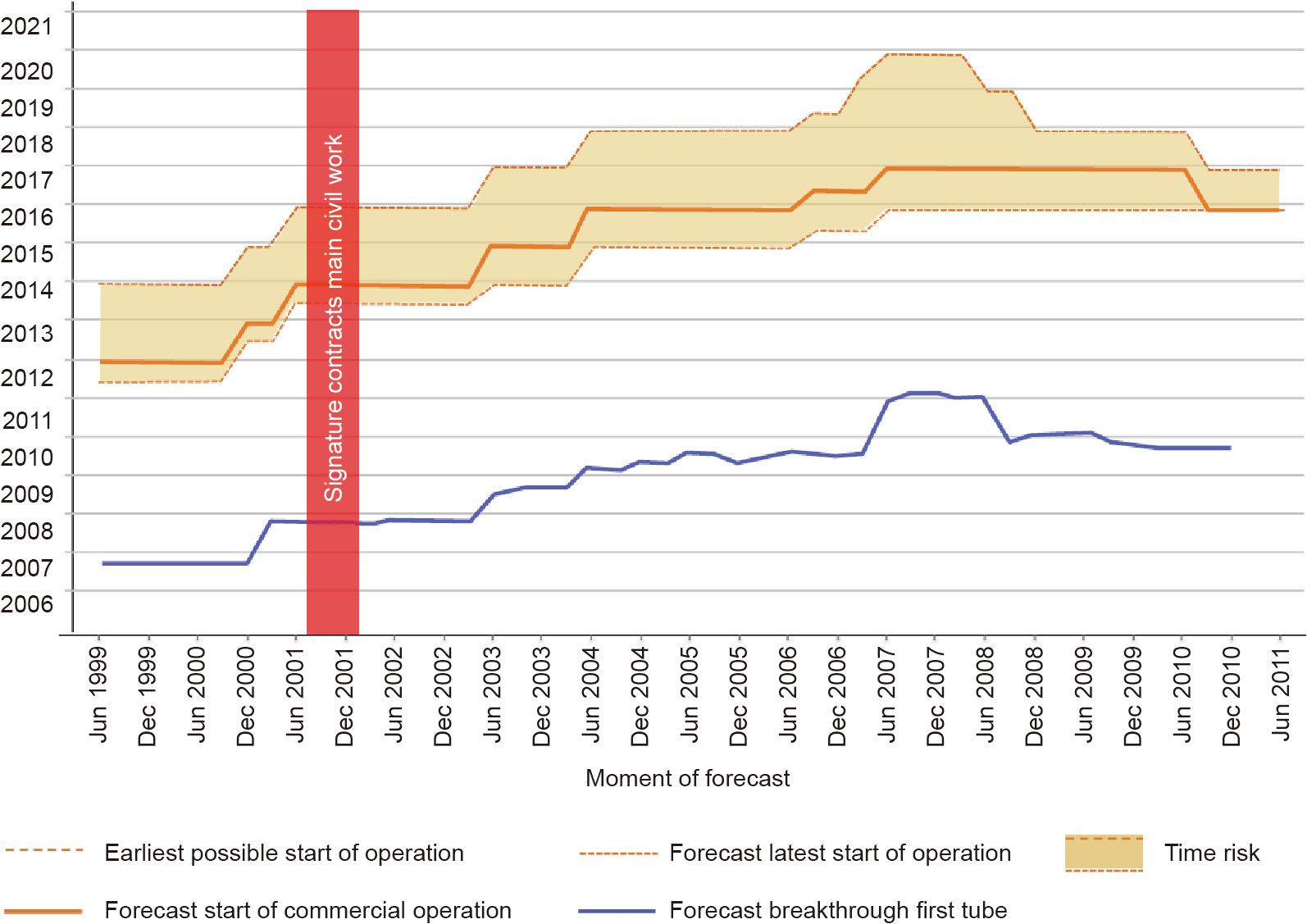

Fig. 3 helps to clarify the situation [5]: After the contract signature for the main lots of the civil engineering works, the date for the commissioning of the base tunnel was updated and fixed as December 2016, due to unforeseen geological conditions in the southern part and difficulties arising in 2003–2004 regarding the start of work at the north portal. Further geological problems arising in the southern part compromised the achievement of this announced milestone. However, the client expressed its clear intention to remedy this negative evolution.

《Fig. 3》

Fig. 3. Forecast for the start of commercial operation of the Gotthard Base Tunnel.

After analysis and weighing of the risks and opportunities, the client decided to change the limit between the main lots of Sedrun and Faido/Bodio. This eventuality was foreseen in the two contracts (and was already an integral part of the tender documents). Unit prices had therefore already been offered in the bid phase (under competition) and defined by contract in order to manage and compensate a possible extension or reduction of the excavated extensions of up to a maximum of 1 km. Since the activation of the optional displacement of the limit between lots of 1 km was insufficient, the client negotiated a further modification with the contractors regarding the limit of the lots. This was possible because the basic concept for this limit modification had already been foreseen. As a consequence of these relevant negotiations, guided by consensus, contractual complements were signed.

Fig. 4(a) highlights the delay from the lot Faido/Bodio and the need to take additional countermeasures, in order to prevent a final tunnel breakthrough postponement of six months.

《Fig. 4》

Fig. 4. Project Capricorn: Modification of the limit of the main lots Faido/Bodio and Sedrun. (a) Before and (b) after modification of the limits.

The amendment to the boundary of the Sedrun and Faido/Bodio lots was insufficient on its own, however, to regain all of the accumulated delay. Therefore, the client proceeded tomake a proposal to all the other parties involved—namely, the total contractor of the railway technology and the designers—in order to achieve an acceleration of the work and activities. In return, these parties were promised cash rewards if successful. This initiative, called Project Capricorn, represents an outstanding example of a ‘‘win-win” situation, in which dialogue between parties made it possible to reach a common goal based on discussion and confrontation, while avoiding conflict.

This second case also demonstrates the appropriateness of the contractual model that was adopted and the effectiveness of the risk and conflict management. Fig. 4(b) shows the result that was achieved with Project Capricorn.

《6. Conclusions》

6. Conclusions

In conclusion, the success of the Gotthard Base Tunnel construction demonstrates the importance of a fair and flexible contract model, which in this case permitted the parties (employer, designer and contractor) to handle all contingencies and design changes over 25 years of design and 17 years of construction. It also illustrates the importance of an efficient project financing model and adequate project organization.

It is worth emphasizing the importance of open dialogue between parties, and the principle that searching for and identifying a mutually agreed-upon solution should be the first step in the case of problems, with discussions of liability and contractual consequences coming afterwards.

Last but not least, the SIA standards have proven their fitness for the design and construction of large underground structures, and have incorporated the experience gathered during the realization of this outstanding project into their recent revisions. The 1990 SIA standards were used for the construction contracts for the Gotthard Base Tunnel; the SIA standards were then upgraded in 2003–2007 to incorporate the experience acquired in the design and construction of this project.

京公网安备 11010502051620号

京公网安备 11010502051620号