《1. Introduction》

1. Introduction

The real question is not whether machines think but whether men do.

Burrhus Frederic Skineer

Dedicated manufacturing systems are fading out as future manufacturing (i.e., Industry 4.0 [1]) demands ultra-flexible smart manufacturing systems that can self-adapt to production process changes resulting from the varied batch sizes of personalized products [2–4]. The manufacturing shop-floor can become an unstructured environment where manufacturing systems and processes change their configurations dynamically via adaptive near-real-time decision-making. One emerging trend to make manufacturing flexible and reconfigurable is to introduce collaborative machines that work alongside humans with high productivity [5–7]. While these devices, powered by artificial intelligence (AI) [7], are radically changing how work gets done and who does it in what way, we believe that the more substantial impact will be in augmenting human capabilities and enhancing human well-being. Future societies will see a harmonious ecosystem in which humans and machines cooperate to meld human cognitive strengths with the unique capabilities of smart machines in order to create intelligent teams that are adaptive to rapidly changing circumstances [8,9].

In our view, we are at the point in time at which Rosenbrock’s warning that ‘‘humans should never be subservient to machines and automation, but machines and automation should be subservient to humans” has become a foreseeable possibility [10]. Future smart machines can establish trustworthy relationships with humans via proactive communication, empathic understanding, and need-driven collaborations, which can lead to high-performance human beings and productive yet flexible manufacturing processes. However, little work has been reported on developing a human-centric manufacturing system that places human benefits at the center of the system optimization goal. Research on human– machine collaboration in the manufacturing domain has only focused on human–machine interfaces [11] and human factors in manufacturing systems, such as ergonomics and mental workload, to improve the overall system performance [12]. To bridge this gap, we herein present an anthropocentric human–machine symbiosis framework that augments human capabilities and well-being in an industrial working environment. The essential elements of this framework and the enabling technologies are discussed.

《2. Human–machine symbiosis framework》

2. Human–machine symbiosis framework

In the following sections, we describe a general human– machine symbiosis framework for the future of collaborative manufacturing. Of particular interest are the following features, which are attributed to human–machine symbiosis: ① human centrality—the ability to focus on human desire and judgment; ② social wellness—the ability to detect and respond to human physical and mental performance in order to maximize human wellness; and ③ adaptability—the ability to learn from the environment and change behavior based on that learning.

Fig. 1 presents a human–machine symbiosis framework in which humans and machines form intelligent teams to collectively sense, reason, and act in response to incoming manufacturing tasks and contingencies. The main communication channels between humans and machines are discussed in Section 2.1, while human– machine understandings are addressed in Section 2.2. Section 2.3 presents our perspective on human–machine collaborative intelligence. Section 2.4 discusses human-centered collaboration mechanisms, which are a crucial feature of future human–machine teams.

《Fig. 1》

Fig. 1. Anthropocentric human–machine symbiosis framework. AR: augmented reality; VR: virtual reality.

《2.1. Human–machine communication》

2.1. Human–machine communication

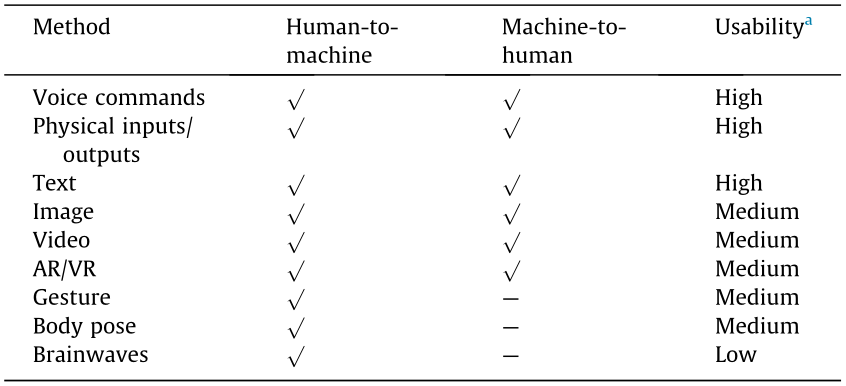

Human–machine communication can be established via a variety of communication channels, such as voice commands [13,14], gestures [13,15–17], body pose [15,18], brainwaves [19,20], and augmented reality (AR)/virtual reality (VR) [21–23], in addition to traditional human–machine interfaces. These new communication channels, which are enabled by AI technologies such as image processing and speech recognition, have brought human–machine communication much closer to natural human interactions. Table 1 lists typical human–machine communication channels according to application scenario and usability. Voice commands, physical interactions, text, image, video, AR, and VR can be used for bidirectional communications between humans and machines, and are generally easy to use if developed properly. Gesture, body pose, and brainwave recognition, although promising, are more suitable for human-to-machine communication and can be cumbersome to implement in a factory environment.

《Table 1》

Table 1 Human–machine communication channels.

a The usability evaluation of these technologies is the authors’ qualitative assessment of their effectiveness, efficiency, and satisfactoriness. No solid quantitative comparison between these technologies in the context of human–machine communication is available yet.

In addition to exchanging information between humans and machines, communication must adapt to content, context, and identity. Human–machine communication is dynamic, contingent upon the messages being exchanged at a specific moment within a particular context. Effective machine-to-human communications tailor the communication style based on ① the nature of the content, such as whether the content is a suggestion, warning, or instruction; ② the context, such as whether a machine is taking an assistive role or not, and whether the situation is time-critical or not; and ③ the culture, education background, and communication style of the human partner, such as whether the human partner is from a high-context or a low-context culture [24].

《2.2. Human–machine understanding: Empathy skills》

2.2. Human–machine understanding: Empathy skills

Physical and mental state can have a significant influence on personal work performance [25,26]. Physical responses, such as muscle fatigue build-up [12] and bad posture [27], can lead to increased difficulty in performing manufacturing tasks [28,29]. Mental responses, such as a high cognitive workload, can result in higher stress levels and lower satisfaction, ultimately reducing productivity [12,30]. Therefore, accurate assessment of human physical workload, cognitive workload, and the psychological reactions (e.g., emotions) in human–machine collaborations are essential for improving human performance. In a human–machine collaboration context, dynamic human physical, cognitive, and psychological states can be detected via indirect inference from signals, such as emotional prosody [31,32], facial expressions [33–35], body poses [36,37], electromyography [38], eye gaze, and pupil dilation [38,39]. In the future, machines would have to possess the skills to observe a human counterpart’s physical and mental state, establish a human-centric world model, and generate empathic behaviors that would be perceived as compassionate interactions in human environments. The ultimate goal of developing empathy skills in smart machines is to establish trust and respect between humans and machines—as these have been found to be fundamental to many social interactions [40], including collaborations—in order to boost human–machine team performance and satisfaction.

It is also vital for humans to understand and care about the ‘‘health” of smart machines, through which better human– machine relationships can be developed in return. Machine health can include quantitative measures associated with workload, task fluctuation levels, and so forth. Dynamic task allocation and adjustment based on human and machine states of health can help maximize human–machine team performance.

《2.3. Human–machine collaborative intelligence》

2.3. Human–machine collaborative intelligence

Human–machine symbiosis also requires a rethinking of how control algorithms are developed in intelligent systems. A survey of 1500 companies in 12 industries found that companies achieve the most significant performance improvements when humans and systems join forces to form collaborative intelligence, rather than intelligence being dominated by AI algorithms [41]. In an intelligent human–machine collaboration setting, human and machine agents form a partnership that aims at optimizing team benefits and maximizing their own long-term returns, through interactions with the environment and other agents. A smart machine can generate adaptive execution strategies to tailor to the dynamic working environment and the state of its human partners. In a high-performing team, smart machine and human agents will establish a fully cooperative planning and control relationship by leveraging each other’s complementary strengths. In this regard, learning-based algorithms, such as multi-agent reinforcement learning, could be a promising option to achieve adaptive collaborative decision-making in a human–machine team.

《2.4. Human-centered collaboration mechanisms》

2.4. Human-centered collaboration mechanisms

Based on natural human–machine communications, including empathic understanding, we believe that anthropocentric production [42] will become possible. Future human–machine teams will need to place human needs and well-being at the center of manufacturing planning and control, instead of continuing the current practices of system-oriented optimization in manufacturing control. The transition from dedicated manufacturing systems to flexible unstructured human–machine collaboration creates huge challenges and opportunities in ensuring manufacturing productivity and human worker wellness [43,44]. Highly adaptive and reconfigurable systems with real-time data-processing capabilities are required to address ergonomics issues while ensuring productivity in human–machine collaboration. For example, the physiological or psychological state of a human worker can be considered in human-in-the-loop manufacturing control, resulting in adaptive labor demands planning without affecting the overall production efficiency [45]. More importantly, humans will need to be given maximum working freedom, supported by empathic machines that can adaptively assist human workers in completing manufacturing tasks. Real-time planning and re-planning algorithms are required to handle human behavior contingencies and refine plans based on the real-time observation of task progress and human wellness.

《3. Discussion》

3. Discussion

Human–machine symbiosis can create significant changes to future production systems and human workers. We believe anthropocentric human–machine symbiosis can enable the following long-term benefits:

• Human well-being: Human–machine symbiosis can significantly improve human wellness and satisfaction at work due to the change for human workers from playing a subservient role to taking on a dominant role in manufacturing. The physical and emotional state of human workers will be constantly tracked and optimized in human–machine collaborations.

• Manufacturing flexibility: Human–machine symbiosis can increase the flexibility of manufacturing systems and processes. Manufacturing systems and processes can be reconfigured on the fly to respond to the dynamics of products, human behavior, and production systems. The shift from rigid manufacturing setups to flexible systems will enable on-demand manufacturing strategies for producing individualized products with dynamic batch sizes.

• Human and machine capacity development: With intelligent algorithms based on AI, humans and machines can learn and develop their capacity from coworking experiences. Humans can absorb new knowledge and skills through trustworthy and intimate interactions with intelligent machines that can assist and guide human workers in a socially appropriate way. On the other side, machines can also improve their technical and interpersonal skills based on interactions with different people.

《4. Conclusions》

4. Conclusions

We believe that the advancement of AI technologies will make anthropocentric production possible. Humans will be liberated from repetitive, fixed tasks that were designed to maximize manufacturing system performance; instead, humans can work in a dominant role with on-demand assistance from smart machines. Empathic machines and high-performance human coworkers in dynamic coexistence settings will make manufacturing more resilient, flexible, and sustainable. We encourage more research into redefining human roles in the future of manufacturing.

《Acknowledgments》

Acknowledgments

This study was supported by grants from The University of Auckland FRDF New Staff Research Fund (3720540).

京公网安备 11010502051620号

京公网安备 11010502051620号