《1. Introduction》

1. Introduction

The Beijing–Zhangjiakou high-speed railway (HSR) is an important transport facility that will serve the Beijing 2022 Olympic Winter Games. Its main line is 174 km long, and its maximum design speed is 350 km·h–1 . It is the world’s first HSR to be designed based on the concept of an intelligent railway. Construction of the Beijing–Zhangjiakou HSR began on 29 April 2016, and the line was put into operation on 30 December 2019, decreasing the travel time between Zhangjiakou and Beijing from at least 3 h and 7 min to just 47 min. This HSR will provide important support for the competitions at three venues in two cities during the upcoming 2022 Beijing Winter Olympic Games and will promote the connectivity and economic integration of Beijing, Tianjin, and Hebei. This paper introduces the construction and operation practices of the intelligent Beijing–Zhangjiakou HSR in terms of its overall architecture design and intelligent construction, equipment, and operation.

《2. Project overview》

2. Project overview

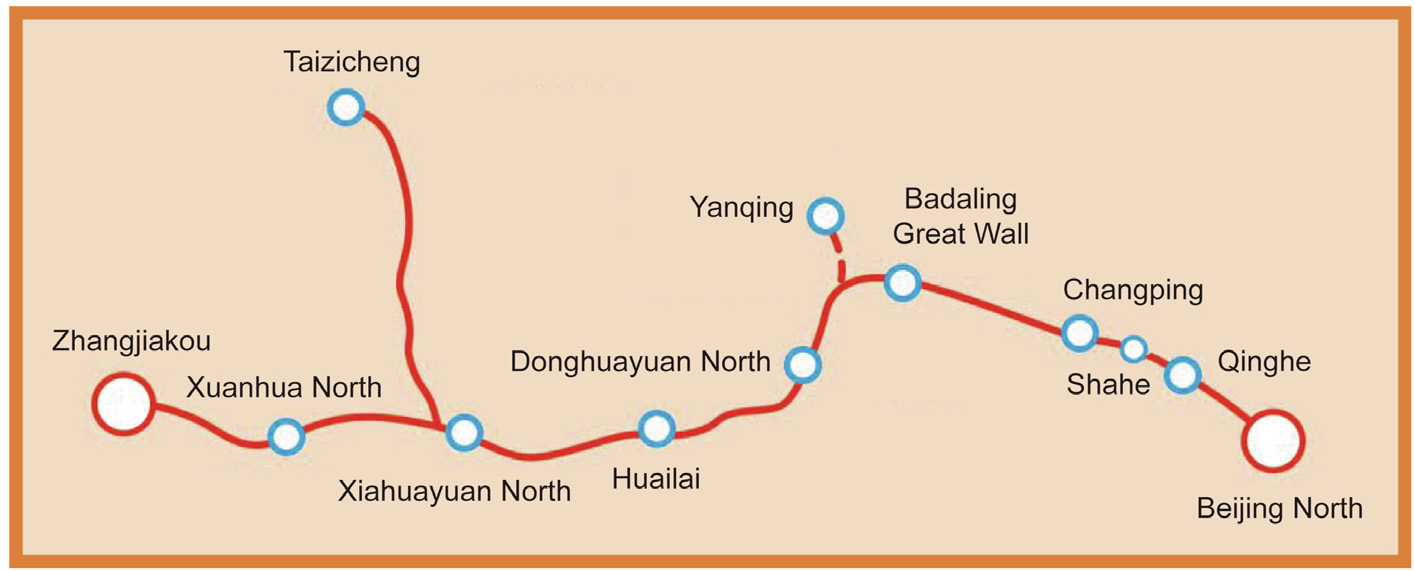

Ten stations are set along the main line of the Beijing– Zhangjiakou HSR: Beijing North, Qinghe, Shahe, Changping, Badaling Great Wall, Donghuayuan North, Huailai, Xiahuayuan North, Xuanhua North, and Zhangjiakou. In addition, Yanqing Station is set along the Yanqing Branch Line, while Taizicheng Station is set and Zhaochuan South Station is reserved along the Chongli Railway. As shown in Fig. 1, Beijing North is the originating and terminating station, and Qinghe and Zhangjiakou are both originating stations and through stations. The line passes through the core area of Beijing, the Badaling Great Wall Scenic Area, and the Guanting Reservoir. The construction of the Beijing– Zhangjiakou HSR overcame many difficulties such as complex geology, challenging construction, and stringent environmental protection requirements. Other challenges included the variety of passengers, concentrated passenger flow periods, high travel service requirements, and great attention from the world during the preparations for the upcoming Winter Olympics Games. To meet the requirements of the 2022 Winter Olympic Games in the construction and operation of the Beijing–Zhangjiakou HSR, the following tasks are both necessary and urgent:① to integrate and apply building information modeling (BIM), big data, artificial intelligence (AI), BeiDou satellite navigation, 5G and other new-generation information technologies; ② to achieve intelligent innovation in the construction, equipment, and operation technologies of the Beijing–Zhangjiakou HSR; and ③ to realize comprehensive perception, ubiquitous interconnection, integrated processing, active learning, and optimized decision-making based on data driving.

《Fig. 1》

Fig. 1. Route map of the Beijing–Zhangjiakou HSR.

Beijing–Zhangjiakou HSR project can be divided into areas of construction, equipment, and operation. The HSR is a complex and giant system composed of multiple subsystems and new technologies. In order to meet the challenges of complex technologies, numerous interfaces, and difficult coordination in the full life cycle of the railway, the construction concepts of ‘‘carrying out top-level design and prioritizing the platform; coordinating the axis and plane; and integrating models and data” were proposed, and several significant technological breakthroughs have been made [1].

Regarding the intelligent Beijing–Zhangjiakou HSR system and its management, the following achievements have been made: ① based on the principle of hierarchy and classification, a ‘‘platform + application” technical system architecture has been built; ② a construction management method that involves ‘‘integrating models and data by taking the full life-cycle management of the HSR as the main axis and all elements as the basic plane” has been proposed.

In terms of intelligent construction technology, the following achievements have been made: ① A BIM-based collaborative design platform has been developed with all areas of expertise and the entire line in a unified environment, and multidisciplinary collaborative design and nondestructive data transmission have been achieved; ② a bi-block sleeper plant has been built, realizing the automation of all sleeper manufacturing processes and the integration of the data of the whole process, as well as providing support for digital manufacturing; ③ breakthroughs have been made in intelligent construction technologies for subgrades, bridges, tunnels, and passenger stations; ④ a BIM + geographic information system (GIS)-based HSR engineering management platform has been developed.

In terms of intelligent equipment technologies, the following achievements have been made: ① An intelligent electric multiple unit (EMU) system has been developed, realizing intelligent train operation, intelligent operation and maintenance, intelligent service, and safety monitoring; ② automatic operation of a 350 km·h–1 high-speed EMU train has been realized for the first time; ③ an intelligent traction power-supply system has been built, realizing intelligent operation and maintenance; ④ An intelligent safety monitoring and emergency-response system has been built.

In terms of intelligent operation technologies, the following achievements have been made: ① An intelligent ticketing and intelligent passenger station system covering the whole range of travel has been established; ② an integrated infrastructure operation and maintenance system based on BIM + GIS integration has been developed; ③ an HSR intelligent centralized traffic-control system has been built.

The major innovations that have been achieved for the intelligent Beijing–Zhangjiakou HSR are described in four parts below.

《3. The technical system design and management concept of the intelligent Beijing–Zhangjiakou HSR》

3. The technical system design and management concept of the intelligent Beijing–Zhangjiakou HSR

《3.1. The technical system of the intelligent Beijing–Zhangjiakou HSR》

3.1. The technical system of the intelligent Beijing–Zhangjiakou HSR

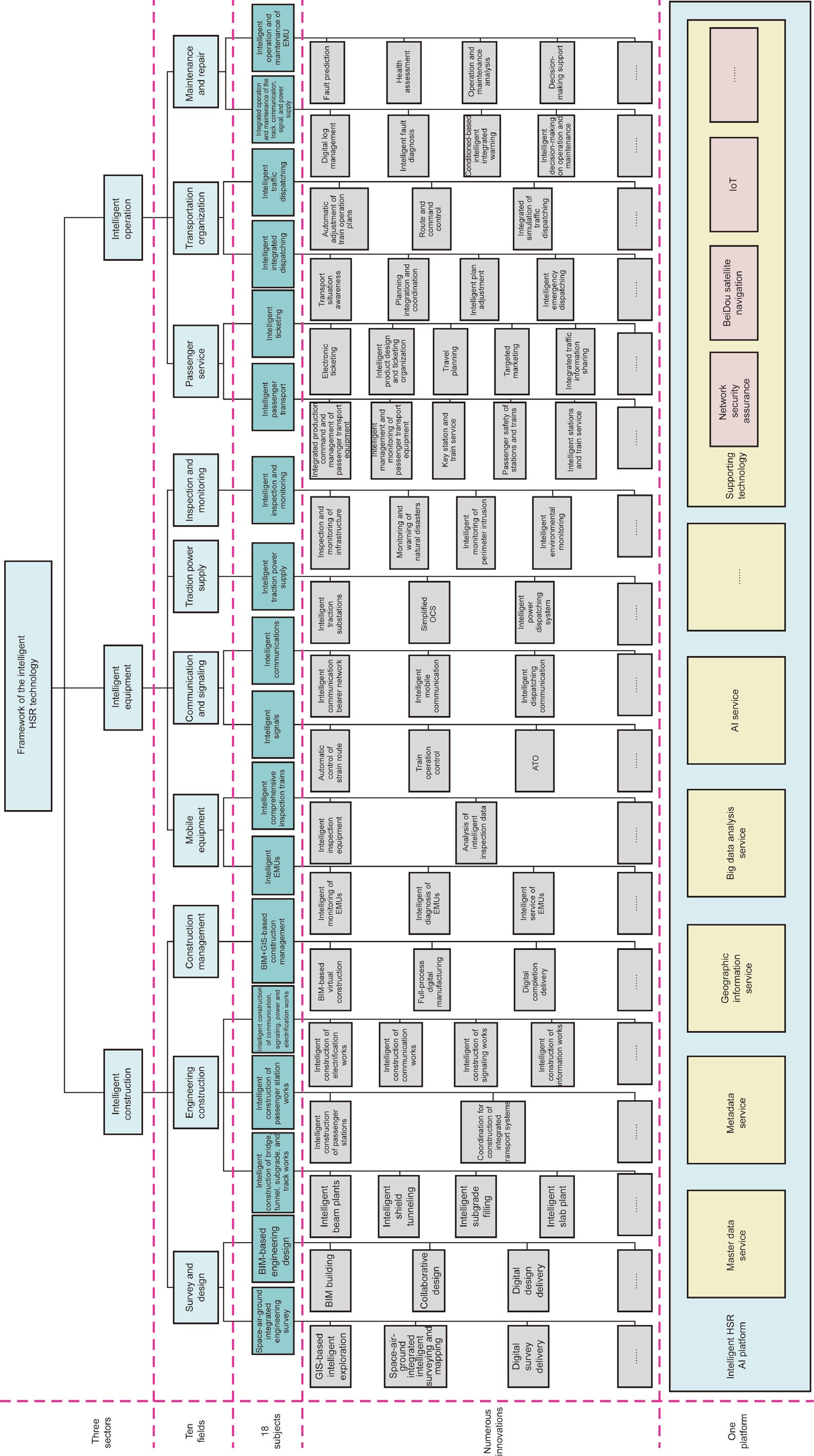

The technical system of the Beijing–Zhangjiakou HSR is an overall design of the core elements of the intelligent HSR and their interrelation at the systemic level [2]. Based on the design concept of ‘‘carrying out top-level design and prioritizing the platform,” the technical system is divided into five levels from top to bottom: sector, field, subject, innovation, and basic platform, as shown in Fig. 2.

《Fig. 2》

Fig. 2. The technical system framework of the intelligent Beijing–Zhangjiakou HSR. OCS: overhead contact line system; IoT: Internet of Things.

There are three major sectors: intelligent construction, intelligent equipment, and intelligent operation. Under the framework of the three major sectors, there are ten major fields: survey and design, engineering construction, construction management, mobile equipment, communication and signaling, traction power supply, inspection and monitoring, passenger service, transportation organization, and maintenance and repair. The ten major fields cover 18 subjects, including space–air–ground integrated engineering survey; BIM-based engineering design; intelligent construction of bridge, tunnel, subgrade, and track works; intelligent construction of passenger station works; intelligent construction of communication, signaling, power, and electrification works; BIM + GIS-based construction management; intelligent EMUs; intelligent comprehensive inspection trains; intelligent signals; intelligent communications; intelligent traction power supply; intelligent inspection and monitoring; intelligent passenger transport; intelligent ticketing; intelligent integrated dispatching; intelligent traffic dispatching; integrated operation and maintenance of the track, communication, signal, and power supply; and intelligent operation and maintenance of EMU. Under the framework of the 18 subjects, there are numerous innovations, including space–air–ground integrated intelligent surveying and mapping; BIM building; intelligent beam plants; the intelligent construction of passenger stations; BIM-based virtual construction; EMU intelligent monitoring; intelligent inspection equipment; automatic train operation (ATO); intelligent traction substations; natural disaster monitoring and warning; intelligent stations and train service; electronic ticketing; automatic adjustment of train operation plans; and intelligent operation and maintenance decision-making. Finally, there is one basic platform—that is, a basic platform that provides common computing, storage, data, algorithms, and other services for all the systems and subsystems of the intelligent Beijing–Zhangjiakou HSR in order to integrate cutting-edge new information technologies.

This technical system has become the general framework guiding the construction of China’s intelligent HSRs. It is at the forefront of railway technologies in the world.

《3.2. The intelligent Beijing–Zhangjiakou HSR management concept of coordinating the axis and plane and integrating models and data》

3.2. The intelligent Beijing–Zhangjiakou HSR management concept of coordinating the axis and plane and integrating models and data

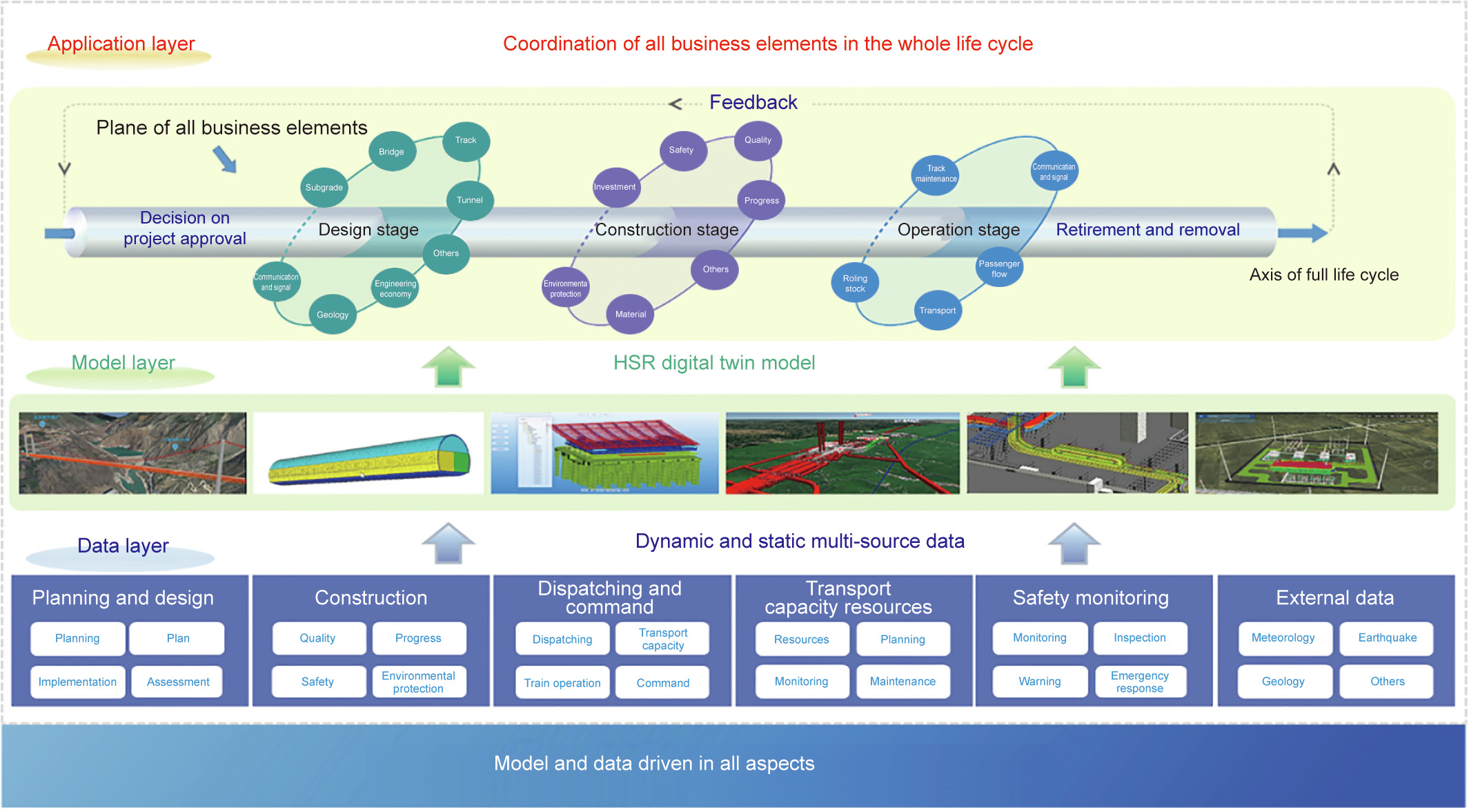

The intelligent Beijing–Zhangjiakou HSR is an enormous system covering the full life cycle of the HSR; it involves many businesses and integrates various technologies, making it extremely difficult to manage its construction and operation. Therefore, the construction management concept of ‘‘coordinating the axis and plane and integrating models and data by taking full life-cycle management as the main axis and all elements as the basic plane” has been proposed in order to achieve optimal overall efficiency throughout the full life cycle of the HSR, as shown in Fig. 3. The full life cycle covers the design, construction, operation, and other stages of the intelligent Beijing–Zhangjiakou HSR. The coordination of all elements refers to the overall coordination and comprehensive optimization of multiple elements of life cycles of different parts of the project. For example, in the design stage, elements such as subgrades, bridges, tracks, tunnels, engineering economy, geology, communication, and signaling should be taken into overall consideration. In the construction stage, elements such as investment, safety, quality, progress, and environmental protection should be taken into overall consideration. In the operation stage, elements such as track maintenance, communication and signaling, passenger flow, transport, vehicles, and safety should be taken into overall consideration. The integration of models and data provides support for the realization of axis and plane coordination. Through the integration and application of multi-grain BIM models involving multiple areas (e.g., tracks, bridges, stations, communications, signals, and power supply) and massive big data of planning and design, engineering construction, dispatching and command, operation and service, and safety monitoring, all business elements can be coordinated in the full life cycle of the HSR, so as to enable the intelligent Beijing–Zhangjiakou HSR system to deliver optimal overall operation efficiency.

《Fig. 3》

Fig. 3. The management concept of ‘‘coordinating the axis and plane and integrating models and data.”

《4. Intelligent construction technologies》

4. Intelligent construction technologies

During the construction of the Beijing–Zhangjiakou HSR, technologies such as BIM-based collaborative design, digital manufacturing, and intelligent construction have been developed, and a BIM + GIS-based engineering management platform has been built. These have enabled the automatic collection of construction data and information interconnection; they also support the collaborative management of and decision optimization among all parties involved in the construction.

《4.1. The BIM-based multi-area collaborative design platform》

4.1. The BIM-based multi-area collaborative design platform

The design of the intelligent Beijing–Zhangjiakou HSR is a huge, complex, and systematic work involving many areas and difficult coordination. It requires close cooperation between different areas of expertise in the design team. At present, two-dimensional (2D) drawings are used by all railway areas in the design process and to represent the final design results. Such drawings have weaknesses, including unclear design expression and understanding, and poor communication among areas.

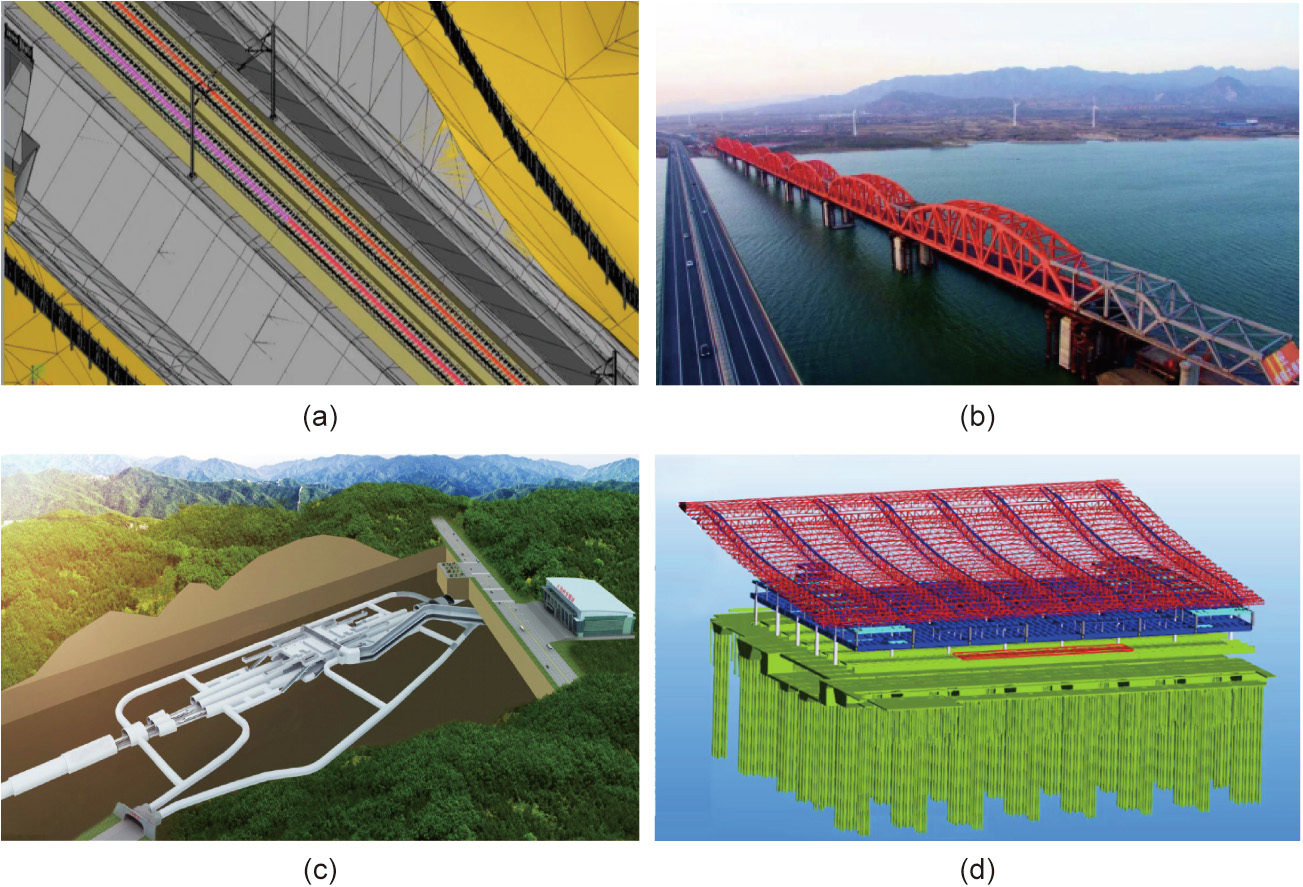

BIM technology enables digitalization, visualization, multiple dimensions, collaboration, and simulation for the entire life cycle of the railway, including design, construction, operation, and maintenance. Therefore, a multidisciplinary collaborative design platform based on BIM has been built for the BIM design of the entire Beijing–Zhangjiakou HSR, as well as the detailed design of three stations and three tunnels. Meanwhile, BIM collaborative design software for multiple areas—including surveying and mapping, tracks, bridges, tunnels, subgrades, overhead contact line system (OCS), and signaling—has been independently developed to improve the design efficiency and design mode. The BIM model has been used to effectively optimize the design scheme and carry out multidisciplinary visualized collaboration in the design of complex nodes, thereby breaking the restrictions imposed by the traditional way of design, in which 2D drawings are used to illustrate structures. Several technical problems have been solved, including the evolvement of map projection; data format fusion and conversion; data source organization and management; and the development of display strategies. Deliverables have been realized, such as rapid parametric design, the calculation of project workload, interdiscipline fitting, the integration management of design results, and intact information transmission among various railway sectors (Fig. 4(a)). The BIM-based collaborative design platform decreases the coordination and liaison time by 8% and the material costs by 3%.

《4.2. The intelligent plant for bi-block sleepers enables digital manufacturing》

4.2. The intelligent plant for bi-block sleepers enables digital manufacturing

Application of the Internet of Things (IoT), automation, intelligent image recognition, and other technologies enables the intelligent bi-block sleeper plant to realize automation and intelligence throughout the manufacturing processes. With all manufacturing data, the plant boasts an intelligent bi-block sleeper production line with the assistance of industrial robots and big data technologies, which decreases the number of workers by 50%. With the introduction of a production management information system built on the Industrial Internet, the plant provides centralized online management of all production elements, increasing the data collection efficiency by 20%. Thanks to laser measurement and deep learning for machine vision, the bi-block sleeper plant is capable of intelligent inspection and testing with a five-fold increase in inspection precision and a 15-fold increase in inspection efficiency, thereby achieve the digital manufacturing of bi-block sleepers.

《4.3. Intelligent construction of subgrades, bridges, tunnels, passenger stations, and other infrastructure》

4.3. Intelligent construction of subgrades, bridges, tunnels, passenger stations, and other infrastructure

4.3.1. New technologies for intelligent subgrade filling

For better relevance and integrity of the sampling that is conducted after the routine quality inspection of subgrade compaction, technologies based on BeiDou satellite positioning have been developed, such as unmanned compaction, automatic route planning, and automatic re-compaction in inadequate areas. In this way, the automatic control of filler transport, automatic identification of filler quality, and real-time inspection of subgrade compaction quality have been realized. Automatic guidance of and collaboration among bulldozers, pavers, and excavators have been realized, making the full-coverage and continuous inspection of vibration and compaction possible. Compared with the conventional construction process, this new approach has proven to improve subgrade filling quality, compactness, and uniformity, as well as inspection efficiency and subgrade quality.

4.3.2. Simultaneous incremental launching technology for the Guanting Reservoir Super Major Bridge

With a total length of 9.08 km, the Guanting Reservoir Super Major Bridge is composed of simply supported curve-chord steel truss girders and registers with an opening number of eight and a span length of 110 m. This bridge, which is located in the Guanting Reservoir Water Source Protection Area, is one of the critical projects of the Beijing–Zhangjiakou HSR. In order to protect the water body to the greatest extent possible, a new construction method has been proposed in which the steel girders are assembled on the bank and then launched incrementally. A gantry-type automatic welding system based on welding robots has been developed, realizing the simultaneous welding of multiple stiffening ribs. Intelligent and simultaneous incremental launching at multiple points and automatic monitoring have been used, breaking new ground in the incremental launching of a bridge with largespan steel girders and multiple openings. This method ensures accuracy, safety, improved construction efficiency, better welding, and better construction quality (Fig. 4(b)).

《Fig. 4》

Fig. 4. Intelligent construction of the Beijing–Zhangjiakou HSR. (a) The BIM-based collaborative design platform; (b) simultaneous incremental launching of the Guanting Reservoir Super Major Bridge; (c) BIM-based intelligent construction of the new Badaling Tunnel; (d) intelligent construction of Qinghe Station.

4.3.3. BIM-based intelligent construction of the New Badaling Tunnel at Badaling Great Wall Station

With a total length of 12 km, the Badaling Tunnel on the Beijing–Zhangjiakou HSR is home to the Badaling Great Wall Station, the world’s largest and deepest HSR station, whose construction has involved the use of subsurface excavation and an extremely complex structure of overlapped-layer tunnel clusters. With the help of a BIM model, design optimization and visualization for technology clarification can be realized for the stacked station entrance and exit passages, circular rescue galleries, parallel twin tubes, and three-dimensional (3D) multi-branch shafts. In this way, the time consumed at different interfaces has been shortened and the onsite construction efficiency has been improved by more than 20%. Based on the BIM model, IoT and big data technologies have been integrated to carry out the real-time prediction and forecasting of the risks to adjacent buildings and structures. This provides support for the intelligent and visualized dynamic monitoring and management of the whole process of shield tunneling and effectively mitigates the impact of construction on the surrounding area (Fig. 4(c)). A quality management system for tunnel sections based on high-speed laser scanning has been developed for the automatic high-precision inspection of overbreaks, underbreaks, clearance, and cavity volume.

4.3.4. Intelligent construction and detail-oriented management of passenger stations

For the construction of large passenger stations, BIM technologies have been used to develop 3D fine and green designs of buildings and structures, including passenger station decoration, steel structures, mechanical and electrical pipelines, and customer service equipment rooms. A BIM + IoT-based construction management system for passenger stations has been established to realize the 3D visualized control of raw material traceability, deep foundation pit monitoring, high formwork monitoring, inspection lots, tower crane anti-collision, steel structure welds, and so on. A BIM-based simulation system for construction organization optimization has been developed to support detail-oriented management and onsite safety and quality control (Fig. 4(d)). With the use of intelligent construction technology, the utilization rate of nonconventional water sources has reached 22.14% and the proportion of recyclable building materials has reached 15.30%.

《4.4. The BIM + GIS-based HSR engineering management platform》

4.4. The BIM + GIS-based HSR engineering management platform

The construction of the Beijing–Zhangjiakou HSR is characterized by large investments, a long project period, complex technology, multiple interfaces, decentralized management, and complex coordination. Thus, it is difficult to meet the requirements of high quality, high efficiency, and high speed for the construction of the Beijing–Zhangjiakou HSR by conventional management means. To successfully complete the construction of this project, informationbased intelligent means have been adopted to move the conventional offline management mode online; at the same time, standardized management has been carried out as an effective way to develop the HSR engineering management platform, which has BIM + GIS technology at its core and the construction project as its carrier. The platform is divided into three parts—namely, comprehensive management, process control, and site management— in four dimensions—namely, space, data, management, and application. It involves six applications: comprehensive management, progress management, material management, quality management, safety management, and investment control. This platform has shattered the restrictions for the development of BIM + GIS multisource data fusion technology and lightweight modeling technology; realized visualized and integrated component-level control over progress, quality, and safety; and improved the capability of construction data for multi-angle, multidimensional, and multiscale comprehensive analysis and management.

Since the platform has been put into use, railway quality and safety incidents have been significantly reduced. The platform plays a prominent role in demonstration and delivers social and economic benefits.

《5. Intelligent equipment technology》

5. Intelligent equipment technology

《5.1. The intelligent EMU system》

5.1. The intelligent EMU system

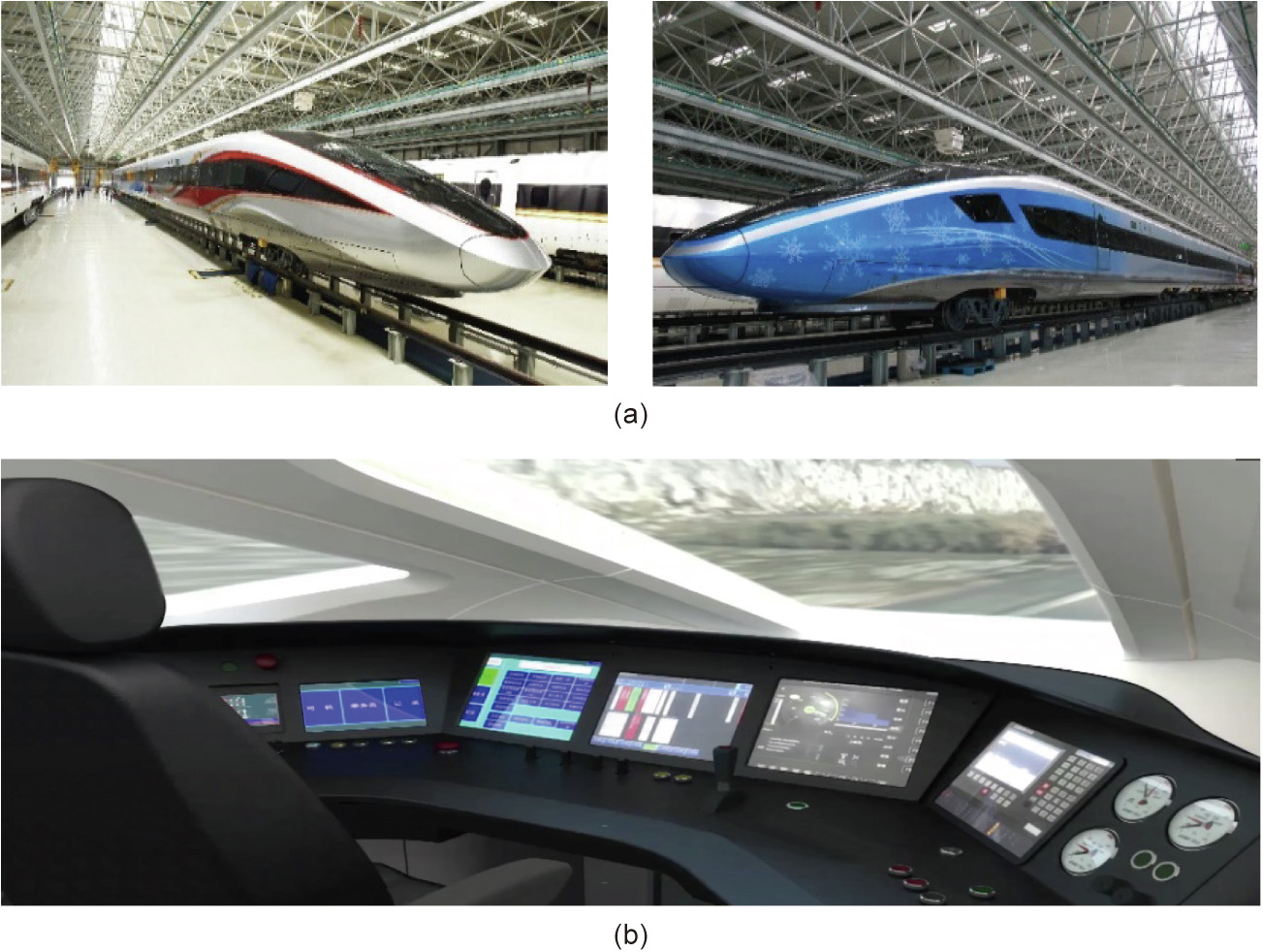

The intelligent EMU system integrates intelligent composite sensors, real-time train-wayside information transmission, big data mining and analysis, automatic control, intelligent information processing, fault prediction, health management, and other technologies; thereby realizing intelligent perception, diagnosis, and decision-making (Fig. 5(a)). As members of the Fuxing China standard EMU series, the intelligent EMU trains serving the Beijing–Zhangjiakou HSR are classified into standard trains and Olympic trains. The standard trains, which are built on the Fuxing model, are equipped with additional intelligent modules and dedicated functions specific to the Beijing–Zhangjiakou HSR, while the Olympic trains are equipped with additional Olympic modules, in an upgrade to standard trains.

• Intelligent modules enable intelligent train operation, intelligent operation and maintenance (up to 2718 monitoring points), intelligent service, and safety monitoring (168 more running gear vibration monitoring points).

• Olympic modules involve Olympic-themed painting, an Olympic-specific layout, storage areas for sports equipment, and live broadcasts of Olympic events.

• Dedicated functions specific to the Beijing–Zhangjiakou HSR include adaptability to severe cold weather (–40 °C) in Beijing, operation ability (including traction and braking) for a grade of 30‰, and emergency self-running capacity.

The intelligent EMU trains serving the Beijing–Zhangjiakou HSR are able to run on a long steep grade of 30‰, which is a significant improvement over all other trains. The EMUs are more environmentally friendly than other HSR trains: their water consumption has been decreased by 10%; they feature a 1–2 dB reduction in noise; up to 75% of their interior materials are recyclable; and 50% of their interior materials are degradable. Their energy consumption has been brought down by 7% through the application of aerodynamic optimization, resistance reduction, lightweight material (the weight of each train has been decreased by about seven tonnes), and the multidimensional alignment of train weight, resistance, and power, along with other modifications. The intelligent technologies of environmental perception and adjustment translate into improved riding comfort.

《5.2. Automatic operation of a 350 km·h–1 high-speed EMU train》

5.2. Automatic operation of a 350 km·h–1 high-speed EMU train

ATO technology is one of the core technologies applied to the intelligent Beijing–Zhangjiakou HSR (Fig. 5(b)). ATO-related equipment has been incorporated based on the Chinese train control system (CTCS)-3, thus enabling ATO. Accurate-positioning balises mounted on tracks at stations enable the trains to stop accurately at the signs. As a result, trains can perform automatic departures, automatic operation in sections, automatic stops, and automatic door opening; they can also realize linkages between train doors and platform screen doors.

《Fig. 5》

Fig. 5. Intelligent equipment in the Beijing–Zhangjiakou HSR. (a) An intelligent EMU train; (b) automatic operation at 350 km·h–1 .

The Beijing–Zhangjiakou HSR has set a world record for the first automatic operation of a 350 km·h–1 EMU train; it has also optimized the movement modeling and speed control of trains at high speeds and improved the strategy calculation and control accuracy for train operation in long sections. By combining the intelligent control algorithm with the train control strategy, the ATO train control algorithm has been optimized, and the HSR’s performance, including train control comfort, stop accuracy, and energy efficiency, has been improved. Practice has shown that the automatic operation of high-speed EMU trains is safe and can reduce the traction energy consumption, decrease the driver’s workload, and improve the travel experience of passengers.

《5.3. The intelligent traction power-supply system》

5.3. The intelligent traction power-supply system

At present, HSR traction power-supply systems are independent. There is little real-time communication and information exchange between traction substations and posts, which makes it difficult to provide a reliable power supply around the clock in all scenarios for the Beijing–Zhangjiakou HSR. The development of the intelligent traction power-supply system of the Beijing– Zhangjiakou HSR is based on intelligent traction substations, section posts, auto-transformer (AT) posts, and other intelligent power-supply facilities. Digital and internet technologies are used to eliminate information blockages between traction substations and/or posts, thus enabling system integration and multisource data sharing. Wide-area protection of measurement and control, reconstruction of error self-recovery, error alarm and warning mechanisms, and a health-assessment system are being established to improve the reliability, operation, and maintenance capacity of the traction power-supply system. In addition, intelligent traction substations featuring holographic perception, multidimensional integration, reconstruction and self-recovery, and intelligent operation and maintenance have been established, thereby enabling the realization of whole-station unmanned operation. The delay in wide-area protection has been shortened from 100 ms to 20 ms, and the primary and secondary equipment of the substations has reached an optical fiber isolation level of 100%.

《5.4. The intelligent safety monitoring and emergency-response system》

5.4. The intelligent safety monitoring and emergency-response system

In terms of safety and emergency response, the Beijing– Zhangjiakou HSR is characterized by the presence of numerous disaster-monitoring devices (for wind, rain, snow, earthquakes, and so on) along the line; the ability to analyze warnings in an extremely timely manner; and wide-range linkage coverage for emergency response. Based on these features, a whole-process intelligent safety monitoring and emergency-response system has been established, with the functions of full-time safety data aggregation, risk prediction, real-time risk warning, and the timely linkage of emergency response. This system can realize the analysis of the time and spatial distribution of disasters based on big data, intelligent warning and comprehensive judgment of risks, and the real-time transmission of safety monitoring information between trains and the ground. It connects other systems such as the disaster-monitoring, traffic-control, and integrated video systems, and coordinates the emergency response of the railway with that of relevant local departments, thus improving the timeliness and coordination of safety warnings and emergency response.

《6. Intelligent operation and service technologies》

6. Intelligent operation and service technologies

《6.1. Intelligent travel service》

6.1. Intelligent travel service

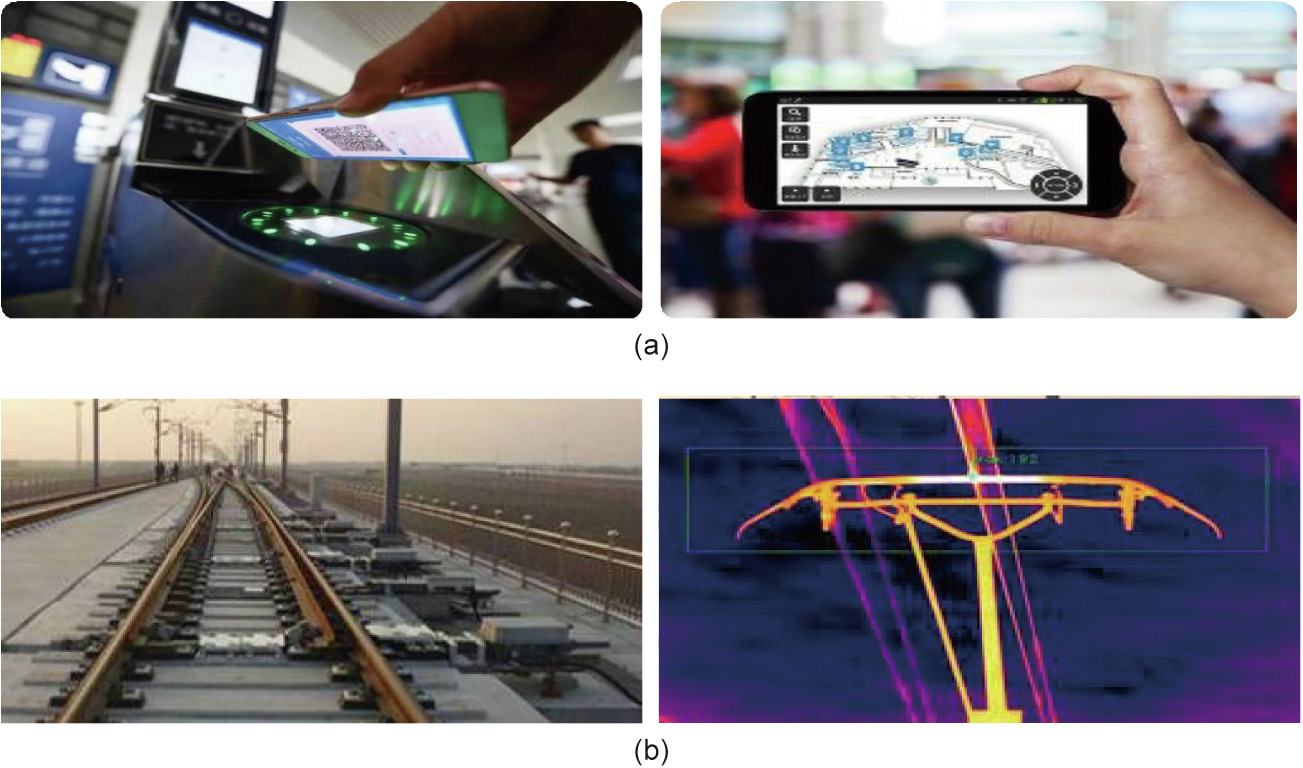

A whole-process travel ticketing-service system has been established, which provides important services such as e-tickets based on passenger service record (PSR), e-ticket checking under high concurrent conditions, online–offline integrated facial recognition, and onboard inspection based on station–train wireless interaction systems (Fig. 6(a)). Breakthroughs have been made in the technology of having a single ticket for all travel modes, thus accelerating the process of ticketing internationalization for the Beijing Olympic Winter Games and providing paperless, self-help, and integrated travel services for passengers.

An intelligent passenger station system has been built, which manages all business and production elements and provides integrated production organization, efficient emergency response, full life-cycle equipment management, and accurate safety control. It can also provide self-help and intelligent services for passengers, such as travel reminders, station entry by face recognition, integrated ticket checking and identity document (ID) authentication, broadcast guiding, e-navigation, intelligent information desk services, self-help ticket refunds, self-help document-making, and remote ticket selling. Technical support is also available, such as passenger flow information sharing, transfer recommendations, and tourism information for integrated transport hub stations.

《Fig. 6》

Fig. 6. Intelligent operation of the Beijing–Zhangjiakou HSR. (a) Intelligent travel service; (b) intelligent integrated operation and maintenance system.

《6.2. The intelligent infrastructure operation and maintenance system》

6.2. The intelligent infrastructure operation and maintenance system

Based on integrated BIM and GIS technology, undamaged delivery from the construction stage to the operation stage and full life-cycle management of infrastructure data such as track maintenance, communication and signaling, and power supply have been achieved. Data acquisition and processing have been standardized for track maintenance, communication and signaling, and power supply. The data access and processing capacity of mobile inspection, fixed monitoring, and static inspection systems has also been improved. A testing and inspection–status analysis–production planning system that integrates multiple areas such as track maintenance, communication and signaling, and power supply has been established to support integrated operation and maintenance. The application of this system improves the utilization efficiency of the HSR maintenance window and reduces costs in the operation and maintenance of infrastructures (Fig. 6(b)).

《6.3. The intelligent centralized traffic-control system》

6.3. The intelligent centralized traffic-control system

As the nerve center of HSR transport command, the centralized traffic-control system performs the important task of organizing and commanding the safe, punctual, and efficient operation of high-speed trains. The development of such a system has become a trend, both in China and abroad.

Based on emerging technologies such as artificial intelligence and big data, the HSR intelligent centralized traffic-control system was developed based on the centralized traffic control (CTC) 3.0 software and hardware platform, with critical functions such as the automatic adjustment of train operation plans, safety control of train routes and commands, and ATO. This system has generally improved the train dispatching and command capacity, the capability of ensuring train operation safety, and the intelligence level of the Beijing–Zhangjiakou HSR.

《7. Conclusions》

7. Conclusions

Since it first entered service two years ago, the Beijing– Zhangjiakou HSR has passed the test as a real-world HSR in terms of its technological innovations in intelligent construction, intelligent equipment, and intelligent operation, and has been widely praised by passengers and all sectors of society. The method of verification before construction has been adopted throughout the construction process of the intelligent Beijing–Zhangjiakou HSR. Before the Beijing–Zhangjiakou HSR opened to traffic, the Liaoning Section of the Beijing–Shenyang HSR was selected as the test section (involving a total length of 256 km, seven stations and six sections). In this test section, integrated tests were carried out on 28 critical intelligent technologies, including the automatic operation system of high-speed EMUs, the intelligent centralized trafficcontrol system for HSRs, autonomous C3 train control, and nextgeneration railway mobile communication. In this way, all the functions and performance parameters of the intelligent HSR innovation technologies were verified.

Along with the constant advancement of the Sichuan–Tibet Railway, the China Railway Program (CR450), and the Go Global Program, as well as the rapid development of cutting-edge technologies such as digital twins, mobility-as-a-service, explainable artificial intelligence, and screenless display, a new wave of technological upgrading and optimization will occur in the construction of intelligent HSRs, and China will usher in a new era as the world leader in the construction of intelligent railways.

京公网安备 11010502051620号

京公网安备 11010502051620号