《1. Introduction》

1. Introduction

With the further development of oil and gas exploration, unconventional oil and gas reservoirs, deep and ultra-deep oil and gas reservoirs, and tight oil and gas reservoirs are becoming the main development goals. However, reservoir conditions are becoming increasingly complex and inferior in quality, causing both the difficulties and the cost of exploration and development to escalate. New complex oil and gas reservoir conditions such as high temperature and pressure, a high and steep structure, strong heterogeneity, and deep water bring new challenges to oil and gas engineering technology. As most of the old oil fields in China have gradually entered into high water cut and high recovery stages, it is crucial to solve the problem of improving oil recovery. At present, the low price of oil is having a great impact on the effective development of the oil and gas industry, so there is an urgent need to achieve low-cost development. However, no single technology can solve the problems encountered in current oilfield development. A deep integration of geoscience and engineering technologies is necessary to crack the resource bottleneck, improve productivity and recovery, and reduce exploration and development costs. In this way, profitable exploration and development of oil and gas resources can be fulfilled.

Geoscience–engineering integration has been successfully applied in the development of deep oil and gas reservoirs [1], shale gas reservoirs [2,3], reservoirs with tight and low permeability [4], and other complex oil and gas reservoirs in China [5,6]. It has not only promoted the rapid development of ‘‘sweet-spot” evaluation, reservoir engineering, horizontal well drilling, multi-staged fracturing, and enhanced oil recovery (EOR), but also accelerated the integration of various forms of technology within geoscience and engineering. Geoscience–engineering integration has also changed the reservoir development management mode, improved engineering performance, and increased economic benefits. It has become an important commercial development method for complex oil and gas reservoirs.

Although good performance has already been achieved, many problems remain when geoscience–engineering integration is applied on a larger scale. This paper puts forward the implications of and a basic framework for the integrated management mode and summarizes the application of geoscience–engineering integration.

《2. Implications of and management mode for geoscience– engineering integration》

2. Implications of and management mode for geoscience– engineering integration

《2.1. Implications of geoscience–engineering integration》

2.1. Implications of geoscience–engineering integration

Integration theory originated from system theory, which considers a system to be composed of many interconnected subsystems. Through the collaboration and cooperation of various subsystems, the performance of the system’s functions can be maximized [7]. Before the 1970s, the exploration and development of oil and gas fields generally adopted a straight-line development mode; more recently, this was followed by a mode combining geoscience and engineering. Cosentino [8] proposed the concept of an integrated reservoir in the early 21st century, and the integration of exploration and development has become a trend.

In order to develop complex oil and gas reservoirs, geoscience–engineering integration is proposed as an effective management mode. More specifically, in contexts including the production capacity construction, development deployment, development adjustment, and EOR of oil and gas fields, geoscience–engineering integration refers to the overall management, integration, and optimization of various key elements such as geoscience, engineering technology, experts in the field, and economy through technology and management innovation. The essential purpose is to realize the integration of engineering technology and management, improve quality, reduce cost, and increase efficiency.

Geoscience–engineering integration is based on the following four aspects:

(1) Materialization theory: Geoscience–engineering integration is a process of integrating, transforming, and materializing various elements [9,10]. It is embodied by the transformation of material and non-material things, such as resources, technology, the environment, and human effort, into engineering practice. The theory, method, and technology of such integration are intended to be both inspected and improved through engineering practice.

(2) Maximum value: The goal of geoscience–engineering integration is to enhance the value of oil and gas reservoirs through the coordinated development of humans, engineering, and the environment [11]. For a specific oilfield, the value consists of two aspects: high production and efficiency, in order to realize effective exploration and development; and high recovery, in order to recover as much of the crude oil in a formation as possible. Geoscience–engineering integration aims to solve the geological, engineering, economic, and environmental problems encountered in different exploration and development periods, and transform the internal value of the oilfield into external benefits.

(3) Synergic optimization: Geoscience–engineering integration has the characteristics of multi-discipline and multi-program interaction, as well as multi-department, multi-team, and multiprogress intersection. Thus, it combines different systems, departments, and organizations to achieve mutual complementarity, synergy, and improvement. Through the integration, optimization, and innovation of the relevant specialties and technologies, geoscience–engineering integration can gain a multiplicative effect. Moreover, geoscience–engineering integration can integrate and optimize departments and teams to work together toward difficult goals, which will enhance the overall coordination among them; maximize the advantages and potential of human effort, technology, society, and the environment; improve efficiency; and coordinate operations.

(4) Innovation-driven: As the core of geoscience–engineering integration, innovation includes technological innovation, management innovation, and mode innovation. Basic theoretical innovation, single-technique innovation, and technology-integration innovation will optimize the technologies and stimulate the development of geoscience–engineering integration. Management innovation will solve system and mechanism constraints while enhancing operational efficiency and benefits. Mode innovation will achieve overall project optimization.

《2.2. The management mode of geoscience–engineering integration》

2.2. The management mode of geoscience–engineering integration

Oil and gas development is composed of various geological and engineering factors. Different oil and gas reservoir types, different development stages, and different market environments will result in different management modes of geoscience–engineering integration. However, the following four basic elements are the key to the effective implementation of geoscience–engineering integration: an integrated goal, an integrated data platform, an integrated team, and integrated management (Fig. 1).

《Fig. 1》

Fig. 1. The proposed geoscience–engineering integration model framework. EUR: estimated ultimate recovery.

2.2.1. An integrated goal

The integrated goal of geoscience–engineering integration is to improve the value of reservoirs by seeking estimated ultimate recovery (EUR), EOR, efficiency, and economic profit while being environmentally friendly. According to the specific development objects, factors such as resources, production, the economy, the environment, and society should be taken into account in the integration project. Project targets involving the project lifecycle, progress, quality, technology, cost, and the environment should be formulated, and a corresponding control system should be established.

2.2.2. An integrated data platform

A reservoir is an extremely complex geological body, and its characteristics must be described from various aspects based on a large amount of information and data. The process of oil and gas exploration and development is also associated with data. To ensure the continuity, inheritance, and consistency of data, an integrated data platform must be established to realize data intercommunication and sharing.

The first step in establishing an integrated data platform is the acquirement and analysis of data. It is necessary to make full use of existing data resources. All-encompassing and high-precision realtime acquisition of relevant geological, engineering, experimental, and production data should be conducted to reduce uncertainty. It is also important to strengthen data mining and application, discover physical principles from the data, and establish corresponding mathematical models. In order to construct relationships between the data and the reservoir, the second step is to establish a geoscience–engineering integration knowledge base that covers the entire process of oil and gas development and the entire industry chain. Statistical learning and data deterministic analysis should be carried out based on the reservoir development characteristics. Finally, the data must be updated in a timely manner to ensure its timeliness and authenticity.

2.2.3. An integrated team

During the process of integration implementation, in addition to establishing an integrated data platform, it is necessary to build an engineering team with an integrated concept to enable technicians from different specialties to work efficiently with each other. Team members should focus on learning and self-improvement. To ensure the achievement of goals and tasks, the technical level, innovation ability, and work efficiency of the integrated team should be continuously improved. Team members with different specialties should work together to avoid so-called ‘‘disciplinary bias.” They should understand the overall workflow and targets of the integration project. Furthermore, responsibility, power, and income should be assigned to every staff member clearly and quantitatively.

2.2.4. Integrated management

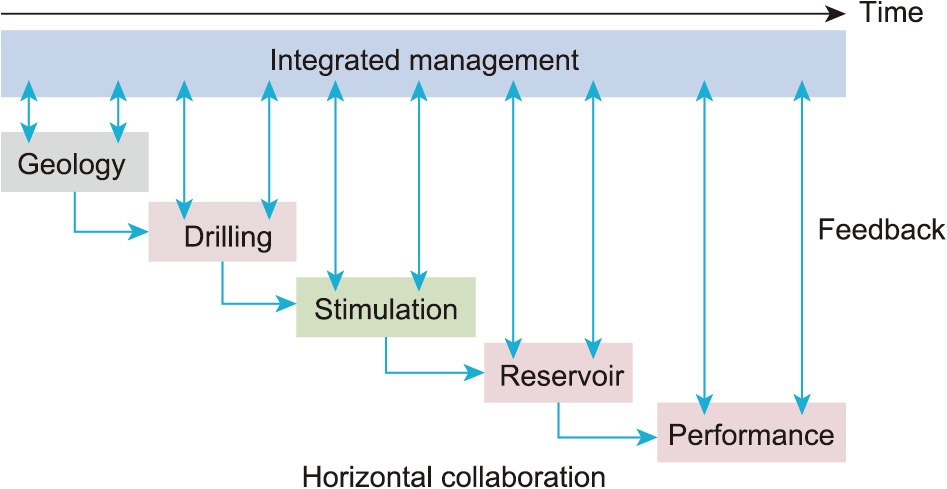

Various departments, specialties, and technologies should be combined together in an appropriate way to achieve efficiency and multiply benefits. Workflow with immediate feedback should be established for integrated management system optimization (Fig. 2). Not only should technical weakness be avoided, but also resources should not be concentrated in one single specific major or technology. In other words, both the cask effect (i.e., the capacity of a bucket depends on the shortest board) and the Matthew effect (i.e., economic advantages tend to accumulate in one area) must be avoided.

《Fig. 2》

Fig. 2. The integrated management operation mode.

Geoscience–engineering integration changes the traditional operation mode and decision-making system. Professional business application in the traditional mode is transformed into cross-professional business collaboration, in which the barriers among different departments are broken down. Traditional piecewise management is changed into closed-loop management in the integrated mode. Moreover, traditional local coordination is changed into online coordination, and inward operation is changed into inward–outward operation. As a result, the processing, decision-making, and implementation levels can be comprehensively improved.

《3. Field application》

3. Field application

The concept of geoscience–engineering integration has been used in the process of oil and gas exploration and development— both in the overall development of oil and gas fields, and in productivity construction and well stimulation—thereby improving the economic and effective development of complex oil and gas reservoirs.

《3.1. Imitation horizontal well-development technology in a lowpermeability reservoir》

3.1. Imitation horizontal well-development technology in a lowpermeability reservoir

China possesses abundant low-permeability oil and gas resources in continental sedimentary basins. The characteristics of these resources can be summarized as multiple hydrocarbonbearing strata, various types of reservoirs, and wide distribution areas. These reservoirs have become the main sources for increased reserves and production in recent years.

The characteristics of a low-permeability reservoir are low porosity, low permeability, low reservoir abundance, high heterogeneity, and well-developed fractures, which are caused by sedimentation, tectonics, compaction, cementation, and dissolution effects during the reservoir-forming process. The natural energy for exploiting these reservoirs is insufficient. Therefore, conventional development cannot achieve high productivity or benefits.

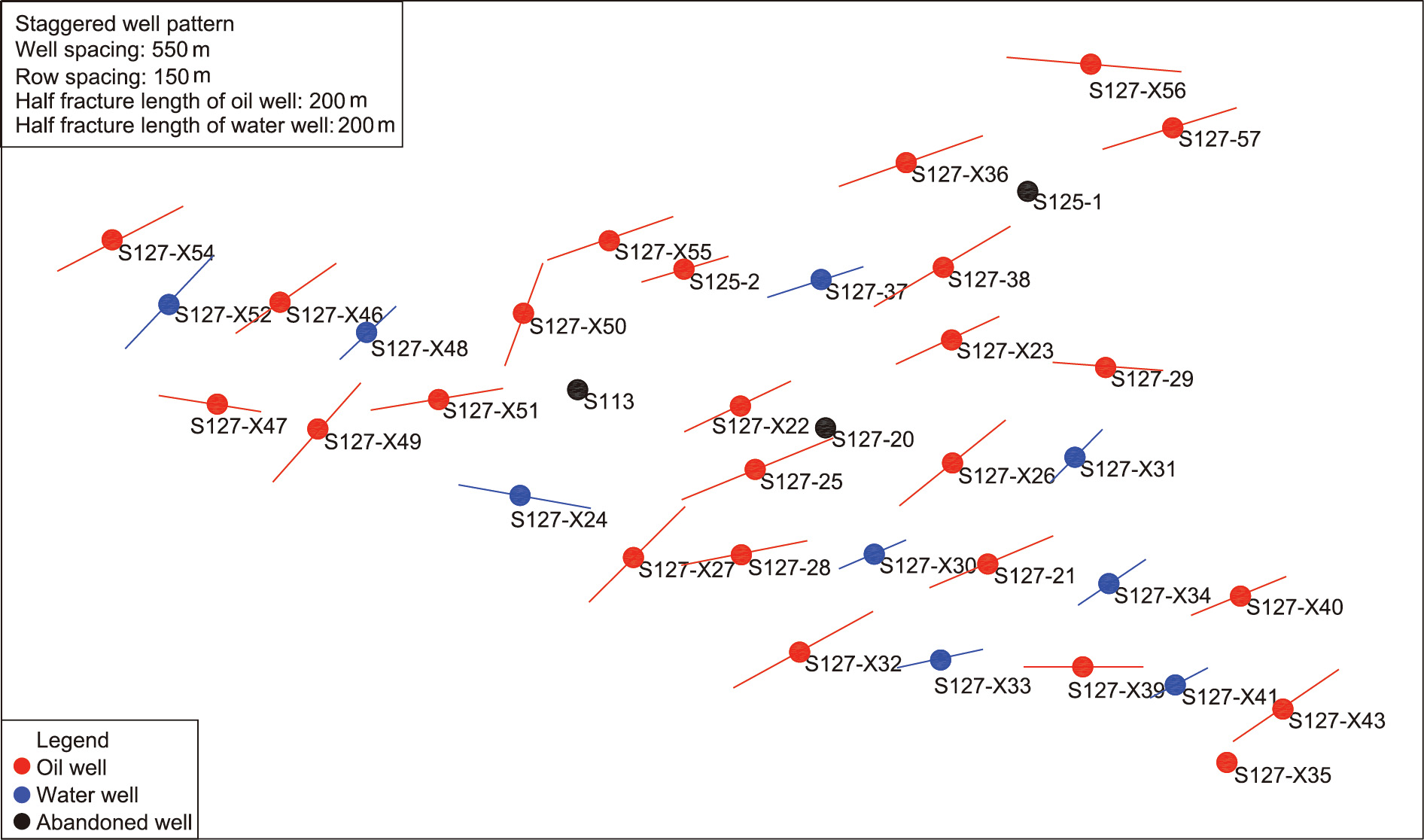

It is difficult to recognize the oil enrichment pattern and precisely characterize such reservoirs. Therefore, to achieve effective development of low-permeability oil reservoirs, Shengli Oilfield established an integrated team of experts in geophysics, geology, reservoirs, drilling, and oil production, and proposed imitation horizontal well-development technology with the concept of geoscience–engineering integration. Guided by this concept, the geological characteristics and previous fracturing experiences of the Shi127 block were comprehensively considered. Then, the length and angle of the fractures were optimized to increase the oil drainage area, and the productivity was increased to the maximum. In addition, reservoir development patterns, fracturing parameters, and economic benefits were considered in order to optimize the development well patterns. As a result, an effective displacement system considering fracture-well pattern matching was established to increase the swept volume and avoid water channeling.

Imitation horizontal wells and water injection were used in the development of the Shi127 block (Fig. 3) and achieved good results. The average daily oil production per well has reached 3 t∙d–1 , and the newly built production capacity is 48 000 t (Fig. 4).

《Fig. 3》

Fig. 3. The well pattern of the Shi127 block.

《Fig. 4》

Fig. 4. Comprehensive development curves of the Shi127 block.

《3.2. Re-fracturing technology for wellbore reconstruction of the Jiaoye4HF well》

3.2. Re-fracturing technology for wellbore reconstruction of the Jiaoye4HF well

Although China possesses abundant shale gas resources, which are comparable to the marine shale gas resources in the United States, the geological conditions of the shale gas reservoirs in China are more complicated. For example, China’s shale is more deeply buried, and its organic matter and brittle mineral contents are low. Furthermore, the relatively large horizontal two-direction stress difference and high closing pressures of these resources result in the formation of fewer complex fractures [12–15]. As China’s first large-scale shale gas field, the Fuling shale gas field had a production capacity of 1.0 × 1010 m3 in 2017. After years of development, the old wells in the Jiaoshiba block have entered the long stage of development with intermittent production. Even with energy supplementation, the wells’ production rate is dropping rapidly.

To improve the productivity and recovery of these old wells, Sinopec Fuling Shale Gas Company has established an integrated team specializing in the fields of geology, gas reservoirs, and engineering. Integrated design and integrated project management have been carried out, resulting in the accomplishment of the first wellbore reconstruction and re-fracturing project in China. During the project, differentiated reconstruction targets were formulated based on a strong understanding of the distribution of the remaining resources and the initial fracturing effect of the old wells. This understanding was conducive to fully exploiting the remaining recoverable reserves. Furthermore, a four-index and ten-parameter well-selection criteria considering the comprehensive geological conditions and project scale were formed to maximize the recoverable reserves of single wells. In terms of development plans, a system of optimized design parameters for the re-fracturing operation was formed. In terms of construction design, temporary plugging and diverting fracturing technologies were used in stages 1–12 to realize the uniform construction of new and old perforations, and flow-limiting perforation and dense fracturing technologies were applied in stages 13–21 to ensure the achievement of project targets. During the process of re-fracturing, the team analyzed the process execution in real time, continuously optimized and adjusted the parameters, and enhanced the adaptability of the operation.

In 2020, the 21 stages of re-fracturing for the Jiaoye-4HF well were accomplished within 12 days (Fig. 5). A dense fracture network was constructed by efficiently reforming old fractures and accurately forming new fractures. Good production performance has been observed since the re-fracturing operation. The production casing pressure has increased from 2–8 MPa to 18–27 MPa, and the well production rate has increased by nearly four times, from 1.1 × 104 to 5.1 × 104 m3 ∙d–1 . This project provides a new technological model and approach for improving the recovery rate in old gas fields.

《Fig. 5》

Fig. 5. Production plots of the Jiaoye-4HF well after re-fracturing.

《4. Conclusions》

4. Conclusions

Geoscience-engineering integration is an effective management mode for realizing the beneficial exploration and development of complex oil and gas reservoirs. It realizes the integration of organizational production methods and optimizes the production process. Based on comprehensive geological-reservoir research, engineering technologies are optimized.

China’s oil and gas resources are characterized by unconventionality, diversity, and heterogeneity, and thus present many challenges in understanding, developing, and stimulating oil reservoirs. In particular, the urgent need to reduce costs and improve economic benefits in the oil and gas industry is increasing the demand for geoscience–engineering integration. In the future, it will be necessary to further emancipate our minds from traditional technological thinking, break through the institutional boundaries, integrate technologies, and deeply merge technological fields and ways of thinking. The geoscience–engineering integration mode will play a greater role in the whole exploration and production lifecycle of complex oil and gas reservoirs, and will concretely solidify the foundation of complex reservoir development in China.

京公网安备 11010502051620号

京公网安备 11010502051620号