《1 Introduction》

1 Introduction

Quality is a barometer of the economy, science, technology, education, and management of a country. The history of developed countries such as Germany, Japan, and the United States demonstrates that quality is of paramount importance to a fast-growing economy. China is now in the throes of rapid transition, with drastic changes taking place in resources and factors that underpin its economy. Hence, it is necessary to offset downward economic pressure by improving quality and efficiency. From a supply-side perspective, China’s manufacturing industry is plagued by an irrational supply-demand structure, excessive low-end capacity that consumes massive resources, lack of quality and effective supply, and insufficient internal impetus for quality improvement. The new mission of China’s manufacturing industry is making headway in quality improvement and brand development while expanding effective supply.

《2 New improvements in the quality and brand of China’s manufacturing industry》

2 New improvements in the quality and brand of China’s manufacturing industry

Although China has become the world’s largest manufacturer and exporter, it has fallen short in the quality of its products [1]. Most consumers still associate “low prices and quality” and “lack of world-class top brands” with China’s manufactured products. Consequently, it is imperative to improve China’s manufacturing quality and build world-class brands. This study will examine new improvements in manufacturing quality and brand in the context of current policy and status quo.

《2.1 Quality landscape after the publication of Made in China 2025 》

2.1 Quality landscape after the publication of Made in China 2025

The Party and the country have attached great importance to the issue of quality and brand in China’s manufacturing industry.Relevant departments of the state have promulgated documents, such as Quality Development Outline 2011 to 2020, Made in China 2025, Standardization and Quality Improvement Plan for Equipment Manufacturing Industry and Consumer Goods Standard and Quality Improvement Plan. Since the 18th CPC National Party Congress in 2012, “quality” has always been the key word of the Central Economic Work Conference [2]. As a national strategy, “a country strong on quality” was enshrined in the 13th Five-year Plan and Report on the Work of the Government. The high premium placed on quality is reflected in the competition for the China Quality Awards and high-profile China Quality Conference [3]. Meanwhile, local versions of Made in China 2025 have been rolled out by provincial authorities, complete with series of quality action outlines and plans. Quality was actively discussed by deputies in the fourth and fifth sessions of the 12th National People’s Congress in 2016 and 2017, respectively [2,3].

The quality and brand of China’s manufacturing industry have improved consistently, with several achievements. Indeed, the overall quality of China’s manufacturing industry keeps improving. In 2014, the national quality competitiveness index of manufacturing companies above the designated scale reached 83.34 [4]. There has also been consistent improvement in corporate quality management. According to the statistical survey of the quality of manufacturing companies in 2015, 52.4 % of manufacturers surveyed have adopted international standards, while the value of products made by companies that meet the requirements of international or foreign advanced standards accounts for 67.3 %, 8.5 % higher than that of the survey of China’s equipment manufacturing industry in 2013 [5]. The quality and volume of exported products continue to increase, while the quality gap between China’s exported products and those of advanced countries has narrowed. Brand cultivation is making strides. In 2015, 1,500 companies were encouraged to participate in the pilot activities of brand cultivation, among which 77 were designated as demonstration companies for industrial brand cultivation [6]. In the 2016 BrandZ Top 100 Global Brands, China’s brands took up 15 slots, in contrast to one brand in 2006 [7].

《2.2 New challenges posed by the economic new normal for quality and brand 》

2.2 New challenges posed by the economic new normal for quality and brand

China’s economy is in transition; the rising costs of production factors are eroding its traditional low-cost advantage, an aging population and a slowdown in the increase of young people entering the workforce are contributing to the loss of demographic dividends. Furthermore, environmental damage due to the traditional policy of valuing economic growth over environmental protection as well as limited natural resources are choking the development of China’s manufacturing industry. Meanwhile, old manufacturing powers are taking the lead in fields such as advanced manufacturing and industrial internet with their advantages in technology and talent. To sum up, China’s manufacturing industry is facing unprecedented pressure from both domestic and international developments, which is one of the most prominent features of the economic new normal.

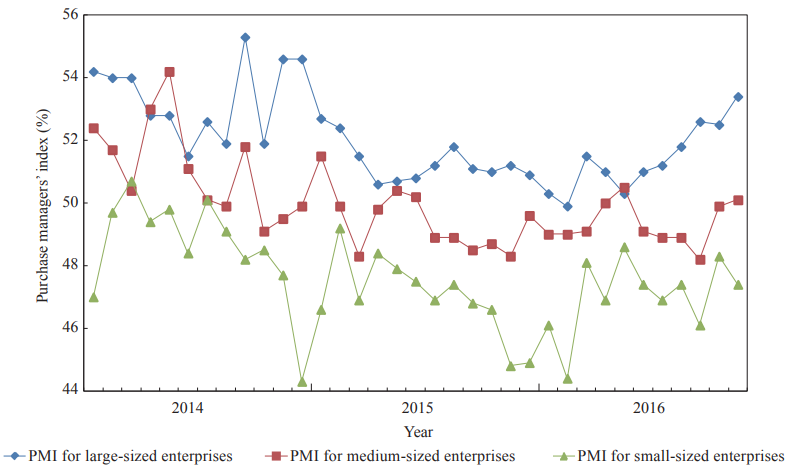

The manufacturing industry is facing increasing downward pressure. Since 2015, China’s economic growth has continued to decline, and its consumer price index has remained low. China’s manufacturing industry is suffering from both manufacturing reshoring in advanced countries, rapid catch-up by other developing countries, and the old extensive model of growth is fading. In the decade between 2004 and 2014, Chinese export items accounted for 50 % and 25 % of all products recalled in the US and EU, respectively, which shows that technical barriers to trade are the main obstacle plaguing exporting companies [5]. The share of value created by the manufacturing sector in China’s gross domestic product (GDP) keeps dropping. According to statistics from the Word Bank database, the share of GDP peaked at 14.2 % in 2007 and nosedived consistently to 6.9 % in 2015 [8]. China’s average purchasing price index for major raw materials in 2016 was 57.1 %, 12.2 % higher than in 2015. The annual average of the purchasing managers index (PMI) for large-sized industrial enterprises was 51.6 %, 0.8 % higher than in 2015. The annual average of medium- and small-sized industrial enterprises was lower than the general PMI for the manufacturing sector and fell to a level that indicates a contraction, which shows the difficulties inhibiting the development of these enterprises. The PMIs for China’s large/medium/small-sized industrial enterprises in 2014-2016 are shown in Fig. 1. In 2016, the top three problems for manufacturing enterprises remained a lack of orders, insufficient funds, and rising labor costs [9].

《Fig. 1》

Fig. 1. PMI for the Chinese manufacturing industry in 2014–2016.

There is a mismatch between the size and competitiveness of China’s manufacturing sector. Although China is the biggest manufacturer in the world, it does not have a very competitive manufacturing sector, as it ranked 13th among the 15 largest manufacturing nations in terms of overall manufacturing competitiveness. Chinese manufacturers in Fortune 500 companies are less competitive and there is room for improvement in the quality and efficiency of Chinese manufacturing. In the national quality inspection sampling conducted in 2016, 8 % of products had a pass rate lower than 80% [10].

The quality of “Made in China” faces numerous difficulties. Apart from new challenges posed by “hard power” such as economic heft and manufacturing technologies to manufacturing quality and brand, it is necessary to focus also on the “soft environment.” Only 11.3 % developers in China’s manufacturing enterprises were responsive to customers and only 2.8 % manufacturing enterprises met the requirements of environmental protection and corporate social responsibility [11], which highlights the necessity of improvement in management expertise and quality awareness. Advanced quality management methods have had limited success. There is no environment where “quality is the top priority.” In particular, there is a huge deficit in honesty about quality, as shown in the rampant number of counterfeit or poor-quality products. In 2015, the “Quality Inspection Sword” program helped in investigating 51,000 cases in which quality-related laws were violated [12]. Quality safety incidents keep cropping up and China’s quality development infrastructure is dismal. For example, the internationally mutually recognized calibration measurement capability of China is 53 % of that of the US [13]. The spillover effect of quality and brand still underperforms.

《2.3 New mission of quality and brand in supply-side structural reform 》

2.3 New mission of quality and brand in supply-side structural reform

China is now suffering from an irrational supply-demand structure and insufficient internal impetus for quality improvement. Statistics show that 122 million outbound Chinese tourists spent about RMB 760 billion in 2016 [14]. Quality improvement action is one of the most important measures to reverse this consumption outflow, adapt to the trend of upgraded consumption, and accelerate supply-side structural reform in the real economy [15]. Improvement in brand will also benefit supply-side structural reform. The General Administration of Quality Supervision, Inspection and Quarantine of the PRC (AQSIQ) also confirmed in its quality and brand improvement action plan in 2016 that “all efforts should serve the supply-side structural reform.”

Improving quality, both urgently in the short term and the main driver of supply-side structural reform in the long term, is conducive to reducing ineffective and low-end supply, expanding effective supply, meeting consumers’ needs, improving export competitiveness, and increasing the benefits of total factor productivity [16]. Quality is now a supply-side weakness, which can be improved to expand effective supply, as follows. First, focus on customer demands, and enhance product appeal. Second, it is important to expand effective supply with new quality or technological innovations. Optimize product structure to accelerate the shift from low- and medium-end manufacturing sectors to medium- and high-end ones. Third, establish diversified supply systems to personalize products or services and meet the differing needs of consumers. Fourth, strengthen society-wide joint quality management to build environments and mechanisms conducive to quality improvement.

Brand is one of the most important measurements of upgrading in the supply-demand structure. Brand economy is an advanced economic form that consolidates economic factors in a fashion that serves quality improvement in a bid to drive economic growth. It plays a key role in upgrading the supply-demand structure, improving the quality and efficiency of the supply system, and promoting the transition to medium- and highend industries [17]. Brand is a reflection of high quality in all aspects, and the making of a brand entails a combination of excellence in innovation, honesty, marketing, culture, brainpower, and environment. Making branded products the main driver of supply structure upgrading is highly recommended. Meanwhile, the rich culture of domestic-owned brands should enjoy more publicity to improve consumer confidence of consumers in them, contributing to the upgrading of the consumption demand structure.

《3 Major problems in quality and brand of China’s manufacturing industry》

3 Major problems in quality and brand of China’s manufacturing industry

Field investigation, conducted in industries such as marine engineering, high-tech shipbuilding, automotive, and power equipment in places such as Shanghai, Xi’an, and south Jiangsu as well as some enterprises that won Chinese Quality Awards (including nominations), shows that China’s manufacturing industry has accumulated successful experience and sharpened its competitive edge after years of efforts in serving the national strategy, participating in international competition, strengthening reforms and innovation, and focusing on factors and capabilities. However, there are still many pressing problems that demand resolution, which are listed below.

《3.1 Imbalanced development of quality in different regions/ industries/enterprise scales》

3.1 Imbalanced development of quality in different regions/ industries/enterprise scales

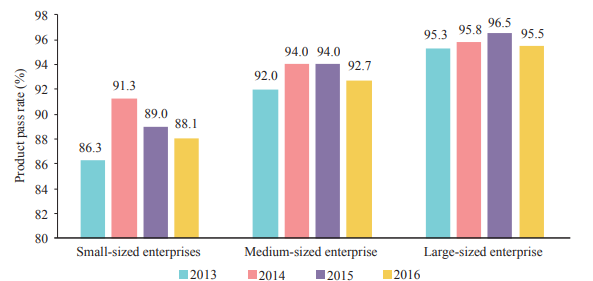

In regional terms, the eastern region is a “plateau of quality.” The quality competitiveness in the south of the central area is superior to that of the north. Most provinces and cities in the western region are “a basin of quality,” which is still underdeveloped in terms of competitiveness. In industrial terms, only two industries in China have strong competitiveness, while most are in stages of medium, primary, and underdeveloped competitiveness with big variances in quality indexes (Fig. 2). In addition, China’s small- and medium-sized enterprises account for 99 % of the total number of enterprises, but they contribute 60 % of the GDP and 50 % of the total tax revenue [18,19]. However, the quality pass rate of small- and medium-sized enterprises is significantly lower than that of large-sized enterprises (Fig. 3).

《Fig. 2》

Fig. 2. Comparison of quality index for various industries in China

《Fig. 3》

Fig. 3. Comparison of sample qualification rate for large-, medium-, and small-sized enterprises in 2013–2016.

《3.2 Lack of methods for quality improvement and brand development》

3.2 Lack of methods for quality improvement and brand development

Improvement in quality and brand is underpinned by development, manufacturing, marketing, and operations techniques. It can be concluded from the manufacturing enterprises surveyed that despite many successes in improving quality and brand, such techniques need further progress. In advanced technological and product development, the long-term accumulation of experience in using related application systems in various industries and operating conditions is necessary to compile related application manuals. The long-term accumulation of databases, design specifications, and mathematical models is also necessary. More investment should be made in relevant basic research. Research finds that less than 10 % of enterprises use quality function deployment (QFD), design failure mode and effect analysis (DFMEA), or other methods and tools for R&D quality. There is an acute lack of advanced methods of manufacturing engineering assurance, such as consistency controls and production stability processes, or an effective combination of intelligent production and internet technology. Only 10.3 % of enterprises achieve automatic collection of on-line data. In a market strategy and marketing model, rational industry division and accurate market positioning are also areas of improvement for the manufacturing industry. From the perspective of excellent operation and management models, the survey shows that only 7.8 % of enterprises continue to perform total production management (TPM) activities, while only 14 % evaluate their suppliers’ performance in a standardized fashion, and less than 3 % have established long-term relationships with suppliers [11]. The cultivation and promotion of the brand itself are also means to improve quality and brand. Chinese domestic-owned brands must employ a “go global” strategy.

《3.3 Problems in the technological basis of quality 》

3.3 Problems in the technological basis of quality

The survey found that 60 % of enterprises had set up higher internal control standards than the national standard. Only 12 % thought their standards reached advanced international standards, and only 6.1 % thought that the prevailing technology of their products reached an internationally advanced level [11]. There is still a wide gap between the overall level of internal standards for Chinese enterprises and internationally advanced standards. International standards and national standards should be viewed as the baselines of quality, and enterprises striving for a competitive edge must adopt standards higher than the internationally advanced level. At present, there are quality problems in key, basic parts in the upgrading of China’s manufacturing industry. The failure of domestically produced, key, basic parts in meeting the required standards results in the use of products manufactured abroad. The importance of key, basic parts is self-evident. To improve the quality of key, basic parts, it is necessary to strengthen the support for manufacturers of basic parts.

《3.4 Lax quality control systems 》

3.4 Lax quality control systems

Over two decades of the international quality management system (ISO) in China has helped Chinese manufacturers adopt internationally advanced quality management ideas and raised product and service quality in all industries. However, there are still many enterprises that have lax quality control systems. Some enterprises still have an accountability problem in terms of product quality. More than 40 % of enterprises have not set up quality indicators in R&D, logistics, and customer service. Only 7.6 % conduct regular production process auditing [11]. On the other hand, China’s manufacturing industry lacks a multi-layer quality control system that suits its conditions. Consider the automotive sector as an example. Based on the series of standards such as the IS09000, the United States, Germany, France, and other countries have established QS9000, VDA6.1, EAQF, TSl6949, and other industrial quality systems. Many enterprises have established internal operation and control systems, such as the global manufacturing system (GMS) of General Motors, and the Toyota Production System (TPS) of the Toyota Motor Corporation.

《4 Action plans for quality improvement and brand development》

4 Action plans for quality improvement and brand development

《4.1 Overall requirements 》

4.1 Overall requirements

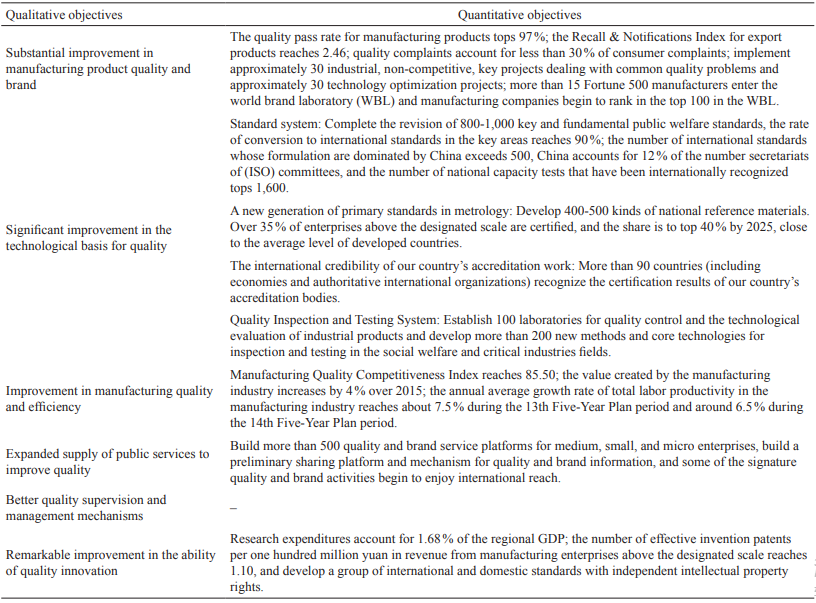

To fully implement the guidelines from the 18th National Party Congress and the third through fifth plenary sessions of the 18th Party Central Committee, China should prioritize the principle of “putting quality first.” We should adhere to the government-led, market-oriented principle and combine supply improvement and demand expansion, quality basis improvement and industrial quality upgrades, and traditional industry restructuring and strategic industry development. It is estimated that an overall improvement of quality and brand in six aspects will be achieved by 2025, as shown in Table 1:

《Table 1》

Table 1. Goals for quality improvement and brand development for manufacturing by 2025.

《4.2 Main tasks for quality improvement and brand development 》

4.2 Main tasks for quality improvement and brand development

Efforts should be made to promote the primary role of enterprises, build effective quality control mechanisms, optimize industrial structure, improve industrial development secure capability, strengthen the effective supply of quality products, improve quality and brand platforms, and accelerate the improvement of quality and brand in key areas. The improvement action plans comprise five aspects.

4.2.1 Establish an effective and concerted joint quality governance mechanism

The market mechanism of “voting with feet” should be put in place and the focus should be on addressing information asymmetry in the market to guide production factors to cluster in high-efficiency industries. Efforts should also be made in improving the quality of supervision, inspection mechanisms, and the responsibility system. Focusing on products that concern health and safety as well as national welfare and livelihood, China should improve early-warning mechanisms for product quality risk and strengthen operational and post-operational oversight of compulsory product certification. We should improve the market mechanisms of quality and brand development, speed up the cultivation of awareness of technology and intellectual property rights, and combat intellectual property infringement and unfair competition according to law.

4.2.2 Optimize the industrial structure and build a talent pool of professionals to ensure quality in industrial development

We should accelerate the phasing out of backward capacity and cultivate quality-oriented industries. Formulating a negative list for market access to sanitize and repeal policy measures that are not conducive to the establishment of a unified national market is necessary. Simultaneously, it is important to formulate a development catalog for quality competitive industries. We should give emerging industries and intelligent manufacturing a more leading role in standardization efforts and implement an improvement plan for standardization in the manufacturing industry. The new standard system is to be shaped by integrating government-dominated standards and standards independently made by markets. We should build a sound training system to cultivate talent with expertise in quality and brand, give full play to universities and research institutes as think tanks, build a multi-level training system for quality and brand talents, and expand the effective supply of these professional talents.

4.2.3 Strengthen the effective supply of high-quality products

We should improve product structure and product quality while maintaining advantage in traditional industries and product portfolios. Enterprises should be encouraged to formulate and implement advanced technical standards, improve production technology and equipment, accelerate product updating, and optimize product structure. It is advisable to accelerate solving key common technical problems affecting quality. Based on projects that create solid foundations of industrial development, we should implement quality improvement and technology enhancement, focusing on strategic industries with large outputs such as machinery, petrochemicals, steel, and construction materials. We should also promote the overall improvement of product quality in a certain region. According to regional functions and industrial layout, and considering factors such as energy and resources, environmental capacity, and market space, we should prioritize the distribution of key industries for development of products and service quality. We should also improve product quality services that cater to social needs, strengthen social intermediary organizations, and promote market-oriented services.

4.2.4 Improve quality and brand platform and better cultivate brands

We should establish a sound public service platform for quality and brand; improve social intermediary organizations specializing in quality and brand services; and promote quality and brand services that cater to the market, operate in a platform structure, and provide specialized services to enterprises. It is also necessary to establish promotional platforms for quality and brand activities, guide social intermediary organizations to strengthen research on quality and brand index system, information channels and sharing mechanisms, and build quality and brand information sharing platforms with distinctive features. We should develop synergies between government departments, intermediary organizations, enterprises, consumers, and the news media to strengthen information sharing platforms on quality and brand.

4.2.5 Accelerate quality and brand improvement in key areas

We should accelerate the upgrading of regional and industrial quality and brand and build brands for industrial clusters and demonstration zones for nationally renowned branded products. Regional and industrial quality and brand improvement activities such as “quality for prosperity” and diagnosis for quality and brand should also be implemented. We should try to stay ahead of the curve in terms of quality and brands in strategic industries, perform quality analysis of strategic industries, and solve key problems plaguing high-quality products through high-end equipment innovation projects, which strengthen the foundations of industrial development. Quick industrial transitions towards high end value chains, by focusing on traditional and strategic industries, with industrial clusters as a crucial facet, are necessary. We should improve consumer confidence and build a product quality trace-back system for the full life cycle of the product, which emphasizes personal health and safety products.

《5 Policy recommendations for quality improvement and brand development in China’s manufacturing industry》

5 Policy recommendations for quality improvement and brand development in China’s manufacturing industry

Considering the new environment and status quo, we list our policy recommendations based on action plans for quality improvement and brand development.

《5.1 Implement high-quality manufacturing engineering》

5.1 Implement high-quality manufacturing engineering

We should set up a fund earmarked from the government budget to implement “high-quality manufacturing engineering.” A solid technological foundation for product quality should be laid and product quality assurance capacity should be raised, focusing on major equipment concerning health and safety, national welfare and livelihood, and popular consumer products. Quality improvement actions should be conducted in ten major fields; namely, electric vehicles, automotive steel, CNC machine tools, high-speed rail equipment, high-end testing equipment, household appliances, medical equipment, communications equipment, traditional Chinese medicine, and infant formula, while prioritizing solving problems related to technological bases for quality, such as standards, measurement, inspection, certification, and accreditation, and problems of reliability, stability, safety, and applicability. Meanwhile, it is necessary to formulate supporting policies for “High-quality Manufacturing Engineering,” establish a standard cultivation and assessment system for innovative enterprises, and conduct pilot projects for “High-quality Manufacturing Engineering.” We should build a bonus scheme that entitles enterprises winning China Quality Awards and leading the formulation of international standards, to tax benefits. A batch of “National Quality Manufacturers” will be designated after assessment. We should improve the market mechanism that encourages high quality products fetching high prices, incorporate standards and quality safety into government procurement and bidding, encourage the procurement of high quality and low-price products, and promote joint disciplinary action. For instance, enterprises and social organizations in the quality and honesty blacklist should not be included in the government procurement directory. We should set up specialized quality training for small- and medium-sized enterprises and promote education and training networks that fulfill the needs of the regional industrial landscape and are jointly developed by universities, research institutes, and industrial associations. We should also develop a culture that values quality. Departments such as quality inspection, publicity, education, and others should collaborate for training to develop a culture of quality, enhance quality crisis education, promote advanced quality management models, and the spirit of craftsmanship.

《5.2 Implement targeted quality support programs for smalland medium-sized enterprises》

5.2 Implement targeted quality support programs for smalland medium-sized enterprises

Statistics show that China’s small- and medium-sized enterprises account for about 99 % of the total number of enterprises, creating more than 80 % of new products, 75 % of employment, 60 % of GDP, and 50 % of the total tax revenue [18, 19]. However, in the shadow of China’s economic new normal, the development of small- and medium-sized enterprises also faces “new difficulties.” There is a consistent decline in the product quality of small- and medium-sized enterprises and their quality management is plagued by poor integration of quality management across companies and the dependence of product quality on inspection. The focus should be on promoting quality and innovation services for small- and medium-sized enterprises and cultivating hidden champions among them. We should enhance the quality innovation capabilities of these enterprises and help develop many hidden champions who will serve as the backbone of the manufacturing industry.

《5.3 Promulgate Quality Promotion Law》

5.3 Promulgate Quality Promotion Law

We should improve China’s legal framework on quality by implementing quality promotion laws. Domestic laws on quality consist mainly of the Product Quality Law and Law on the Protection of Consumer Rights and Interests. These laws focus on quality safety and the management of quality problems, but ignore the development and promotion of quality. The promulgation of the Quality Promotion Law will transform China’s economic development. We should accelerate the implementation of the Quality Promotion Law, focusing on the general principles of the law, main content, and legal responsibilities. Efforts to improve China’s legal framework on quality to promote quality improvement and brand development are necessary.

《5.4 Implement a “Brand Benchmarking” program for consumer goods》

5.4 Implement a “Brand Benchmarking” program for consumer goods

Consumer goods sold domestically should be produced on the same production lines, meet the same standards, and be of the same quality as products for export, and the practice of “higher price for higher standard and higher quality” should be advocated. We should establish a multi-dimensional brand evaluation system and an international standard database for consumer goods, the information from which should be available to the public free of charge, and also encourage social intermediaries, technical service agencies, and other institutions to use the information they receive for innovation. The improvement in China’s production standards should be accelerated without compromising domestic productivity. High quality standards that reach or surpass internationally advanced levels should be set for key consumer goods and products that meet the standard should be labeled “High Quality.” International promotion should be conducted for Chinese products with the “High Quality” label. A “Brand Benchmarking” program should be carried out to boost the international competitiveness of domestically owned brands and enhance consumer confidence.

《6 Conclusions》

6 Conclusions

The research on a development strategy to improve quality and branding in the manufacturing industry shows that quality is a bottleneck in China’s march towards a strong manufacturing sector. At present, society is placing a high premium on the quality problem. In this crucial period, when the nation rushes to promote supply-side structural reform and the “Made in China 2025” strategy, a combination of policies must be implemented. Product reliability, stability, consistency, and safety are the key areas that should be guaranteed by implementing High-quality Manufacturing Engineering. We should establish an effective and concerted joint quality governance mechanism, build systems of safety assurance, quality culture, and manufacturing talents, and accelerate the promulgation of the Quality Promotion Law to build a strong manufacturing sector and achieve the Made in China 2025 objective.

京公网安备 11010502051620号

京公网安备 11010502051620号