《1 Introduction》

1 Introduction

The gap in production level between China’s industry and its advanced international counterparts is demonstrated by complete machines and final products. This gap reflects the fundamental problems in materials, techniques, and parts in the industry as a whole. Key basic materials, core basic parts and components, advanced basic technology, and foundation of industrial technology account for the essential basis in the enhancement of industrial core competitive capability. After years of development, China’s total industrial strength has stepped into a new phase. Although China has become an important industrial power with a significant influence, some key basic materials, core industrial parts, and components are still heavily dependent on imports, and key technologies are still controlled by others. Problems still exist such as weak research of advanced basic technology, low level of promotion and application, weak industrial technology foundation, and imperfect service system. The weak industrial foundation has become a bottleneck, which restricts industrial transformation and upgrading and hinders the improvement of quality and efficiency of industrial development. To speed up the basic industrial capacity and to promote the industrial base are urgent tasks to strengthen the industrial core competitive capability of China and the objective requirement to empower China’s industry.

Basic industrial parts and components (hereinafter referred to as basic components) are important complementary items of many types of equipment. The performance and quality of the basic components play a decisive role in precision, performance, lifespan, and reliability of complete machines. Low level of quality of overall basic components in China, insufficient supply capacity of high-end products, and low reliability and safety seriously restrict the development of China’s industry and have a severe impact on China’s social economy and national defense security.

《2 Connotation of basic industrial parts and components》

2 Connotation of basic industrial parts and components

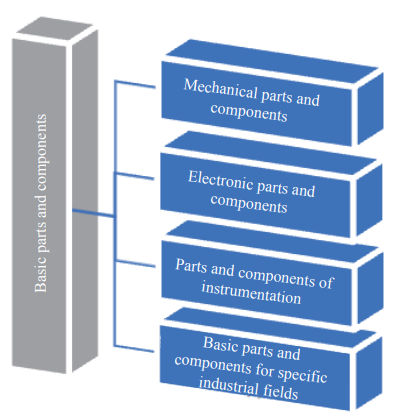

Basic industrial parts and components are the essential structure or functional units of machines that cannot be separated from the machines as a whole. According to their diverse characteristics and industrial attributes, basic industrial parts and components can be further subdivided into basic mechanical components, electronic components, and instrumentation components, as shown in Fig. 1. Their range also includes numerous basic parts and components commonly used in specific industries and fields. Basic industrial components feature a vast quantity and a wide scope. They are extensively used and are the basis and core of the manufacturing industry. The performance, level, quality, and reliability of the finished product are directly determined by the components. Their value has usually increased dozens of times over their initial cost with a strong industrial radiation capacity and wide influence. Their key technology reflects the technical level of a country’s industrial and defense equipment and occupies a very important strategic position. The development of the basic parts industry plays an important role in other related industries, and its technological progress is the precondition of the technological innovation in the downstream machine application industry.

《Fig. 1》

Fig. 1. Composition of industrial basic parts and components.

Core basic parts and components usually feature high performance, high reliability, high strength, long lifespan, and cutting edge, intelligent technology, and they are the crucial basis supporting the survival and development of an industry; its quality level directly determines the development of the industrial structure. The following three prerequisites must be met in the government’s intervention in the field of core parts and components. ① At present, the industry faces a severe hollowing out, and it relies heavily on imports; ② national economy and national defense security are influenced by basic components, and it is urgent to bolster and industrialize basic industrial components; ③ problems cannot be solved solely by the market, and government-led advancement is needed [1].

《3 Current development of basic industrial parts in China》

3 Current development of basic industrial parts in China

After decades of efforts, considerable progress has been made in China’s basic component and parts industry. A complete range of industrial systems has been formed in China’s manufacturing industry of basic industrial components, which shows a positive development trend. Over the past decade, the scale of the basic industrial component manufacturing industry has gradually expanded, research and development capabilities have been improved, and a relatively complete range of low-end products can be provided. In some fields, some high-end equipment has replaced imported equivalents. Strong support and protection are thus provided for the development of the complete machines manufacturing industry and other industries [2]. At present, the deficiency of the basic components in high-end equipment is mainly that the product performance and quality do not meet the differentiated requirements of host machines and problems such as unreliable product function and inconsistent quality have not been resolved.

《3.1 Development and achievements》

3.1 Development and achievements

3.1.1 A complete industrial system has been initially established

At present, China’s mechanical basic part products can meet the general requirements of domestic complete machines. Statistics of the industry association show that the domestic mechanical basic parts occupy about 60 %–65 % of the market share. Some mature and self-developed, low-end products have been able to satisfy bulk export. The task of providing common parts for diverse industries of national economy can be undertaken. Some products are even exported to Europe, North America, and Southeast Asia. In some high-end equipment fields such as wind turbine gear boxes and bearings, hydraulic components, and systems for mining equipment, and marine gear boxes, market share has been gradually increased and many imported products have been replaced by domestic ones. After a series of research in recent years, a number of projects were tracked, and numerous results generated in the field of instrumentation and electronic components. Industrial layout of the instrumentation industry is largely completed. According to statistics, sensors can meet 70 % of the requirements of automation instruments, 80 % of the requirements of medium-sized projects, and 60 % of the requirements of large-scale projects. Sensors feature 3 Series, 12 major categories, and 42 subcategories. Most of them have been researched, developed, and manufactured in China, and more than 12,000 various specifications of sensors are developed and manufactured domestically.

3.1.2 Industrial scale ranking among the manufacturing countries

Taking the machinery industry as an example, the sales revenue of China’s hydraulic and pneumatic sealing products ranks fourth in the world; production and sales revenue of bearings rank the third in the world; production and sales revenue of gears ranks fourth in the world; total production volume of molds ranks third in the world, and the production volume of fasteners accounts for about 1/3 of the world’s total output.

China’s electronic components industry has grown into a vast one where a variety of ownership coexists with a relatively complete category and tens of thousands of enterprises. According to the statistics of China Electronic Components Industry Association, in 2013, the total sales revenue of resistor potentiometers, capacitors, magnetic materials and devices, inductance devices, electronic transformers, hybrid integrated circuits, electronic ceramics and devices, piezoelectric crystals, control relays, sensitive components and sensors, electrical connectors, micro-motors, electro-acoustic devices, optical cables, electronic protection components, printed circuit boards, batteries and 17 other segments summed up to about RMB 1.548 trillion, ranking third in China’s electronic information manufacturing industry. China has also become the world’s leading producer of electronic components with the production and sales revenue ranking in the forefront of the world. Production volume of a range of products such as resistors, photoelectric cables, electronic transformers, magnetic materials and devices, electro-acoustic devices ranks first in the world. In 2015, in the context of the global market downturn, China’s semiconductors benefited from national policy support and continuous investment in industrial capital and maintained a rapid growth. The industry size keeps growing by more than 20% and occupies a global share of about 30%.

With the further improvement of China’s industrialization level, there will be increasing demand for instruments. From 2010 to 2014, market demand in China’s industrial automation instrumentation industry continued to grow, and the compound annual growth rate was 22 %. China has become a primary manufacturer in the instrument industry. According to the statistics released by China Instruments Manufacturers Association, the total industrial output value of the industry was RMB 927.6 billion in 2014.

3.1.3 Remarkable progress in innovation, research, and development capabilities

Supported by various national and regional science and technology projects, in the fields of machine tools, automobiles, aircraft, construction machinery, transmission and transformation equipment, shield machines, wind power equipment, and highspeed trains, the research, development, and installation of key basic parts have been realized. The research of similarities and key technology has been carried out, and a system of research and development which includes the National Laboratory, the National Engineering Research Center, universities, and institutes as the core has been formed. China’s basic parts industry is moving from a stage of imitation, introduction, and learning to a stage of independent design, exploration, and innovation [3].

《3.2 Existing problems》

3.2 Existing problems

3.2.1 Insufficient attention to basic parts and components and long-term investment

Basic parts are usually produced in large batches, and there is also a wide variety of products that require high processing precision, thus requiring higher requirements for the processing techniques and equipment as well as significant investment of capital. High-efficiency and high-precision special machine production lines or flexible lines are adopted abroad to realize efficient automated production. China’s industry has long been influenced by the idea of concentrating on host machines and putting less emphasis on supporting facilities, and the investment in basic parts is not sufficient. The capacities of self-improvement of enterprises are poor. Production is basically operated at a low level. The level of innovative technique and technological equipment is not high enough. Advanced equipment is insufficient and is not coordinated; thus, consistency of the quality of products cannot be maintained, and the quality of products is influenced.

Since the reform and opening-up policy, China has attracted foreign investment to establish factories with favorable conditions. A large number of foreign-funded factories which produce mechanical parts, electronic and instrument components for the domestic assembly industry has achieved domestic matching, and the cost of the complete machines is greatly reduced. China’s manufacturing and electronic information industry has flourished, and internationally well-known brands of complete machines such as JIER Machine-tool Group Co., Ltd., Beijing No.1 Machine Tool Plant, Haier, Lenovo, Huawei, ZTE and other internationally well-known complete machine brands have been cultivated. After China’s entry into the World Trade Organization (WTO), tariffs on a number of mechanical parts, electronic components, and instrumentation components was reduced or even exempted. Foreign basic parts from that point have flooded the Chinese market. The total economic volume of industrial basic parts is smaller than that of complete machines,product specifications are diverse, leading enterprises are few, the degree of industry concentration is low, and existing technical problems are dispersed and at a low level, so insufficient attention has been paid to this industry and a vicious cycle has formed. At present, building a strong industrial base has been listed in Made in China 2025 as a core issue and has received wide attention. At the same time, China has launched projects to strengthen industrial foundations, and enterprises which produce core basic parts are supported specifically. The poor industrial base has been gradually improved.

3.2.2 Unestablished innovation system, insufficient innovation capability, and lack of core technologies

The independent innovation system taking enterprises as the main body and combining “government, industry, university, research, and application” has not been formed, prospective technological research and development is insufficient, independent innovation ability should be further improved, and core technology is lacking, which are reflected specifically in the following four aspects: ① scientific exploration is poor, the theoretical research foundation is weak, and the exploration and research on new principles and new phenomena are absent; ② scientific research is detached from actual production; the transformation of scientific research fruits is slow; scientific research is not closely related with actual production, which has restricted the development of research on products in terms of design technology, reliability technology, manufacturing process and procedure, and basic material performance; ③ the industry standard system is imperfect, especially the research on standard process, and test and detection method standards are urgently in need of strengthening; ④ process technology falls behind; investment in basic process research is severely insufficient, and process technology cannot be easily procured. Enterprises are mostly engaged in imitation and only seek production ability; it is difficult for them to break through and realize improvement.

3.2.3 Personnel training and management system yet to be improved and severe outflow of high-end talents.

China lacks overall planning and implementation in education system reform, subject setting, in-service personnel engineering education, and certification of technical qualifications. Curriculum arrangement of professional foundation and practical skills is critically insufficient. Engineering innovative spirit, upholding refinement, truth, innovation, refinement of designing, and proficiency in tackling difficulties is not sufficiently introduced, and internships in engineering practice are rare, which results in students unable to independently solve actual problems existing in the manufacturing process. The atmosphere for fantastic ideas and unconventional practices that encourage problem solving is difficult to achieve, the environment built for the growth of innovative talents has not been formed, and talents with innate innovative ability are severely insufficient. It still needs more time before a social environment that is open, inclusive, permitting failure, and beneficial for the growth of innovative engineering of technological talents is constructed. Permanent mechanisms of introduction and cultivation of academic leaders, leading technical talents, and urgently needed talents are lacking in key areas. A talent inspiring mechanism is not in place, the evaluation system is not reasonable, processed talents are uncomfortable, industrial talents are not appreciated, technology talents are not outstanding, and it is hard to break through the forbidden zone in talents of department ownership and company ownership. The lack of attention on high-tech talents causes severe outflow of the talents. At present, well-known transnational corporations and enterprises of other industries in China, with their strong profit earning ability, good market prospects, high wages, preferential treatment, and sound environment, are attracting talents to flow toward foreign enterprises or other areas, causing subsequent shortage of personnel and poor research capacity.

3.2.4 Restriction by the military-civilian double-track development mode, severe repetitive construction, and dispersion of capital investment

Before the reform and opening policy, as the West was imposing an embargo on China, China’s parts and components depended on independent research and development, which laid a foundation for the basic parts industry of China at present. After the reform and opening up, the civilian industry of China began to thrive. During the time when the extensive market was attracting investments of foreign funded parts and components production enterprises, the private basic parts enterprises in China also began to grow up. The previous military-civilian double-track system could not adapt to the new market situation. The products and technology of state-owned enterprises in the field of military products did not suit the needs of the market of civilian products. Most private enterprises, though fast in technological progression and fully capable of undertaking the task of the national defense industry, were not willing to enter the area, due to severe examination of products of the national defense industry, small number of orders, and long-term payment. It rendered many state-owned basic parts enterprises of China severely reliant on military industrial projects and severely deficient in technological innovation ability. Moreover, private enterprises, unable to enter high-end product areas of high profit and high attachment value, were restricted in their development. The threshold of low-end component products is not high, and low level repetitive construction is severe. Industrial concentration is low, and most enterprises suffer from problems such as “large and all-inclusive,” “small and all-inclusive,” low degree of specialization, low equipment level, inconsistent quality, insufficient scale, and low economic efficiency. The domestic competition is disordered causing a mess in the market, part of production capacity is backward and severely superfluous, the enterprise transformation and upgrading is extremely weak, industrial structure adjustment is slow, and concentration is hard to improve. Owing to lack of relevant guidance of policy, the basic parts industry is severely detached from the development of supporting industries such as materials, equipment, and parts. Some key raw materials, equipment, and parts, which cannot be produced independently, need to be imported from overseas.

Parts and components are in large quantities and cover an extensive area. In China, they belong to different departments and industries, lacking unified systematic research, scientific planning, and top-level design. The centralization of policy support is low, and centralized support of special programs is insufficient. National policy support is low in investment intensity and not centralized with a lack of continuity, and basic research is ignored [4].

《4 Lessons and experience learned from developed industrial countries》

4 Lessons and experience learned from developed industrial countries

“Stones from other hills can serve to work on jade.” Overseas developed industrial countries, especially countries like the US, Germany, and Japan, have rich experience in basic parts development. We should make serious analysis and draw conclusions, combining the actual development of China, to set out the strategy and policy that will promote better development of basic parts in China. Thus, China can realize the 2020 objectives of the industrial foundation strengthening project, i.e., independent guarantee for key basic parts (components) and key basic materials can reach 40 %, advanced basic process promotion and application rate can reach 50 %, an industrial technology basic system can be initially established, the situation of being restricted by others can be gradually relieved, and high-end equipment manufacturing and national major projects can be achieved [5].

《4.1 Emphasis on top-level design, and guiding of industrial development》

4.1 Emphasis on top-level design, and guiding of industrial development

In basic parts fields like industrial parts and components, developed countries attach great importance to top-level design of industrial development, to determine strategic frameworks and long-term horizon, and to introduce industrial development by establishing a program, plan, or route map. The United States established appropriate policies and programs during different periods to promote industrial development in accordance with the conditions of domestic and overseas development.

Developed industrial countries promoted the development of industrial basic sections by establishing a series of policy measures and programs in different periods in accordance with the conditions of domestic and overseas development. For example, in the 1950s and 1960s, in order to introduce and push forward the development of the semi-conductor industry, Japan established a series of measures such as the policy of export credit, the policy of export rebate, and the policy of export insurance. The Japanese IC industry achieved rapid development, giving rise to a group of world top 500 enterprises like Toshiba and Sony. American industrial competitive capability suffered a severe challenge due to the uprising of Japanese industry. In 1990, the U.S. Commerce Department executed the “Advanced Technology Program (ATP),” subsidizing American enterprises in their development of those activities in technology research and development at early stages, which have high risk, but huge potential influence on national industrial competitive capability. The innovation system developed by the cooperation between the government and enterprises was built up, where enterprises were pushed forward to engage in publicity and development of high-risk cutting-edge technology. After the world financial crisis of 2008, the US proposed to achieve the returning of industry and the development of the future manufacturing industry and issued a serious strategy to boost the real economy, in the hope that by borrowing new technologies such as artificial intelligence, robotics, and digital manufacturing, its national manufacturing industry could be revived, and its hegemony in high-end manufacturing would be solidified. In 2012, in order to revitalize the US equipment manufacturing industry, a national manufacturing scientific center and a manufacturing information resource center were established, and the “Advanced Manufacturing Technology Plan” promoting the development of manufacturing technology and the “Manufacturing Technology Center Plan” pushing forward the promotion and application of the manufacturing industry were issued in succession.

《4.2 Importance to support and guarantee for technical innovation by industrial policies, laws, and regulations》

4.2 Importance to support and guarantee for technical innovation by industrial policies, laws, and regulations

In order to promote the development of industrial basic parts of their own nations, the US, Japan, and developed countries in Europe usually take the tactics of priority on the strategy of technology progression, supplemented by relevant supporting policies in fund, finance and taxation, trade, and so on. By issuing large numbers of laws and regulations, governments intend to support technology innovation, and improve the construction of technology innovative ability, with the purpose of finally achieving the promotion of industrial competitive capability. As the largest consumer in a country, the government has strong purchasing power. With unmatched influence on equipment and basic parts production enterprises compared with other procurement entities, government procurement has become a means usually adopted by governments of various countries. In government procurement the US lay heavy emphasis on the protection of its domestic industry (including instruments and equipment of scientific research). Through government procurement a group of national IT industrial giants were fostered such as IBM, HP, and Texas Instruments Corporation; in terms of support of domestic industry, it is specified that international procurement must at least include the purchase of 50 % domestic raw materials, instrument equipment, and products. According to the Federal Procurement Law, the government assets (including instruments and equipment for scientific research) occupied by the project undertaker must be reused inside federal departments to the maximum extent; and in terms of support of small-medium enterprises, it is specified that domestic small-medium enterprise suppliers can enjoy 12 % higher quotation discount than foreign suppliers with regard to the quotation. Besides, the government of each country generally adopts policies such as tax preference, and subsidy to promote the research activities of their domestic enterprises. The American government offers preferential treatment of perpetual tax credit for investment of enterprises on research and development, and it reduces the long-term investment income tax on advanced technology of small enterprises by 50 %. American taxation law also specifies that for companies entrusting universities or scientific research institutions to conduct basic research, they can offset 65 % of research cost paid in accordance with the contract from income tax, meanwhile they are provided with tax-free preferential policy in terms of intermediate prototypes of new products.

《4.3 Scientific and reasonable division across the industrial chain》

4.3 Scientific and reasonable division across the industrial chain

The development of basic parts for developed industrial counties in industrial chain of equipment manufacturing is always closely related to host equipment manufacturing. From designing, testing, manufacturing, to supporting application, all of them are the results of common efforts. The concrete practice can be generalized as: in the form of legislation, guarantee the connection between production and requirements, as well as coordinated development; implement simultaneous development between host equipment and supporting basic parts, especially paying attention to the preferential development of basic parts industry; pay attention to basic parts industrial standards, and lay a foundation for the development of host machines; national defense and civilian industrial technologies are closely bound and there is no clear barrier or boundary between them. In addition, the organic binding between large transnational enterprise groups and specialized and refined particular small enterprises should be focused. Through long term mergers and reorganization, and arrangement in the capital market, a group of large-scale internationalized enterprise groups with clear superiority in capital and talents have been established in the US, Japan, and Europe. However, there still exist a group of more vigorous small and medium enterprises whose products contrast dramatically in characteristics due to their focus on the protection of intellectual property rights. Cultivating consistently in their respective market segments and products, and working on specific professional technology, they possess specialized and characteristic manufacturing process and ability, and in parts, components or unit system of sub-divisional sections they can get a relatively large market share.

《4.4 Attention to innovation and encourage investment in R&D》

4.4 Attention to innovation and encourage investment in R&D

The European, American, and Japanese governments require enterprises to make targeted investment in scientific research, keep promoting the research and development of key technologies, and facilitate technological innovation with market competitive capability as soon as possible in an effort to ensure the leading position in their respective fields. Strategically, the government has launched a series of plans and measures. For example, in 2010, Germany adopted the 2020 High-tech Strategy for German:ldea·Innovation·Growth, and put forward the goal to expand German superiority in the machinery, equipment, and parts manufacturing industry worldwide. Then it was committed to create an innovative base for the future manufacturing technology, to ensure effectively the high technical quality of German manufacturing industry and the competitive strength of its foreign trade export. Methods including mutual penetration, integration and platform building were employed to facilitate the joint participation of technical research parties, manufacturers and product users in the research and development of production technology. The United States announced in 2012 that it would set up 15 institutes of manufacturing innovation across the country to bridge the gap between basic research and technology development in the industry, each of which would have a clear technical focus to address the challenge of mass production. In 2013, the U.S. government announced the establishment of the “College of Digital Manufacturing and Design Innovation,” which will focus on manufacturing industry and the research, development and applications of electro-mechanical components and system design. In addition, the fierce market competition also urges enterprises to invest more in research and development and technological innovation, and the quantity and quality of foreign enterprises’ investment in research and development (including labor, money, and materials) are unparalleled by some domestic industries and enterprises.

《4.5 Perfection of talent training and management system》

4.5 Perfection of talent training and management system

The advantage of industrially advanced countries in the field of basic parts industry lies in their talent training and management systems. In Europe, there is a strong mobility of personnel in the field of education and industry with no strict barrier between scientific research and industry, and educational circle is almost seamlessly connected with industrial community. The application for a title of senior professional post in many engineering universities requires long-term experience in and the background in the industry. Most of the graduates with master’s degree or higher degree are engaged in major-related professional field after graduation, many of whom work directly for project partners, thus achieving a high utilization rate of talents. The talent training system of Europe, the US, and Japan is very complete with reasonable level distribution. For instance, an important reason for the strength of Germany’s traditional manufacturing industry is that it has a large number of senior technical workers who graduated from vocational and technical colleges, laying a solid foundation for high-level manufacturing. The government has a lot of sound policies and legal basis for the training of local engineers and the introduction of relevant talents from abroad and attracts a large number of talented people from all over the world through the “Talent Introduction Strategy” while strengthening local basic education, which provides the necessary intellectual security of talents for the revitalization of domestic industries.

Throughout the development of core basic components in industrial developed countries abroad, the basic experience of the growth of basic industry in developed countries can be summarized as follows: with the guidance and intervention of the government, the incentive for enterprises to bear the risk of innovation will be increased, the protection of property rights will be strengthened, especially intellectual property rights, an open and tolerant social atmosphere as well as an innovative spirit and culture will be created, thus forming an ecological environment conducive to innovation and entrepreneurship, guiding enterprises to become the main body of real technological innovation. Enterprises attach great importance to the innovation and development of vertical industrial chain, constitute a sustained innovation support system to form a core competitive capability, establish a professional development path, and create a strong competitive advantage in the market centering on the core business.

《5 Research on the development strategy of basic parts industry》

5 Research on the development strategy of basic parts industry

The practice of host machine-oriented and neglect of supporting basic parts has already made foreign enterprises take charge of domestic high-end basic parts market, resulting in the situation that domestic mainframe equipment and basic parts cannot develop synchronously with laggard basic parts. At present, the core basic parts in China are at a critical stage rising from the middle-and-low-end to the middle-and-high-end, and the problem of synchronization between mainframe equipment and basic parts cannot be solved only by the development of enterprises themselves in the industry. “Revitalization” that does not depend on the law of market is a typical planned economy mode, which is difficult to develop in the long run. However, if without the “strategic support” of the country, it is also difficult for basic parts to succeed in the competition of a wide disparity in level with foreign countries. The development of national industry cannot be separated from equipment, while the core of the development of equipment lies in the basic parts. Meanwhile, special attention must be paid to the strategic position and the problems faced by the growth of basic parts industry in China, and the R & D and manufacturing level of basic parts should be improved so as to solve the problems of “technology hollowing” and “low added value” of domestic equipment. To realize the leap-forward development of China from a “big manufacturer” to a “strong manufacturer,” the overall layout of basic parts must be strengthened, and the independent development of basic parts should be included as a “national objective” to become a part of “national strategy.”

《5.1 Persisting in and encouraging independent innovation to promote the construction of innovation platform》

5.1 Persisting in and encouraging independent innovation to promote the construction of innovation platform

To realize the rapid development and prosperity of basic parts industry, it is essential to strengthen independent innovation ability and firmly keep the cutting-edge technologies and key core technologies in the hands of enterprises and scientific research institutions. At present, China’s industrial international competitive capability has been significantly improved, some subdivision industries have been close to or even ranked among the world’s advanced level, while some enterprises already have the ability and strength to compete with internationally renowned enterprises. The current technological reform of imitating and tracking has failed to provide enough driving force for industry and business. Introduction, digestion and absorption can only achieve the tracking of cutting-edge technologies, and transcendence can only be achieved through independent innovation. We should closely follow up and rationally judge the development trend of science and technology worldwide, recognize the gap, find out the real problems, and gather the superior strength to aim at the breakthrough and the main direction of attack. We should also adhere to independent innovation and R & D, focus on conquering a batch of key core technologies of industrial basic parts, break through originality, and occupy the technical commanding point.

Industrial generic technology is the cornerstone of the industry to improve independent innovation ability, serving as the source and guarantee of core competitive capability. We should give full play to the supporting and leading role of technological innovation, strive to solve the key generic technologies affecting the performance, quality and stability of basic parts, strengthen the construction of public R & D and service platform in the industry, and establish a system of technological innovation with enterprise as the main body and production, education and research as the combination. Through the Research Institute of Generic Technology Innovation, a distributed and networked research system of generic technology is established to fill the long-existed gap in the research of generic technology in China, and to guide the research and development of advanced technologies, basic technologies and key generic technologies in the field of industrial basic parts at a national level.

We should also establish fiscal and tax policies to stimulate innovative design, foster an environment for innovative design, and promote market promotion of innovative products. In addition, major products developed independently should be subsidized and supported by national and local finance, the protection of intellectual property right of independently designed products should be strengthened, projects with state or local government-led investment should also be encouraged to prefer selfdeveloped products, and innovatively designed products shall be incorporated into the government’s procurement list. Aiming at the demand of industry and market, national, municipal and prefecture-level innovative design competitions and design awards should be set up to motivate the whole society to invest in innovative design so as to form a social atmosphere that lays emphasis on innovation.

《5.2 Combination of key breakthroughs and overall upgrading》

5.2 Combination of key breakthroughs and overall upgrading

The technological progress of basic parts and components industry needs long-term accumulation of personnel, technologies, management, etc. Moreover, it is the foundation of the whole industry, while the overall upgrading of the industrial chain of the basic parts itself is the foundation. First, there should be an authoritative and clear development plan of basic parts products approved by the mainframe equipment market, and all the investment cannot be concentrated on increasing productivity but on the key design and core manufacturing technologies in an effort to effectively solve the bottleneck problem of basic parts. The breakthrough of core technology is not only the premise of industry upgrading, but also provides the basic parts for guaranteeing the promotion of the significant development of emerging industries. An efficient cooperation mode combing “government, industry, education, research, and business” should be explored with resources concentrated on making major breakthroughs. When enterprises are formulating their own development strategies, they should pay attention to their advantages, make accurate positioning, and lay a solid foundation without blindly pursuing the high-end technologies. They should also be fully based on domestic industrial base, thus achieving innovations and breakthroughs on a sound basis. The implementation of relevant government’s supporting policies should be strengthened, and targeted support for enterprises producing the first (set of) key basic part product should be offered, thereby making these enterprises have more economic motivation and intrinsic enthusiasm. With the support of the government and the industry and after the appraisal by relevant authorities, import tax exemption and tax reduction/exemption for high-tech products are not provided any more for import products which can be domestically produced, to truly help enterprises and products of the industry to achieve key breakthroughs, and to realize the strategy of industry’s overall upgrading.

《5.3 Adhering to the government guidance under market competition》

5.3 Adhering to the government guidance under market competition

The basic parts industry is an industry full of market competition. Large international enterprises fully enter local markets and monopolize high-end basic parts with high profits being obtained by relying on their advanced technologies and long-term and rich experience in application as well as high-quality products, thus further boosting investment in research and development and constantly enhancing their competitive capability. Domestic enterprises manufacturing basic parts are small in scale but large in quantity, with less product profit, and their investment in research and development of new products and new technologies is unable to match large international enterprises, so it is difficult for these enterprises to win if simply relying on market competition. Government guidance and support are needed in the earlier development of basic parts industry, and specific measures include: ① a large and medium-sized enterprise groups of basic parts should be established through the capital market to optimize the allocation of resources. ② the international acquisition method should be made full use of to improve the speed of technological progress in China’s basic parts industry, quickly digest and absorb international advanced technologies, and realize the real introduction of technologies. The government should also vigorously support the “going out” strategy of domestic enterprises and introduce China’s basic products and standards to the world. ③ the disconnection between the basic parts products and the mainframe should be completely reversed, the cooperation of industrial chain should be strengthened through the guidance of the government so as to realize the coordinated development of host and basic parts ④ the production factors of combined industries should be optimized, with the layout and adjustment of industry being accelerated and the segmented manufacturing base for the industry being created. The specialized processing manufacturers in the eastern coastal areas or the upstream industries closely related to the industry chain shall be guided to transfer to the central and western regions based on the market. At the same time, the eastern coastal areas should accelerate industrial upgrading and guide the international advanced industries and the high-end production link of the industrial value chain to transfer to China in an effort to promote the upgrading of the whole industry.

《5.4 Strengthening the training and introduction of talents》

5.4 Strengthening the training and introduction of talents

We should adhere to the talent-oriented principle with equal attention being paid to self-reliance cultivation and overseas talent introduction. The government is also required to build a platform to cultivate skilled talents and form the multi-level talents training system. Universities, colleges, secondary professional schools, and vocational and technical schools should be guided to attach importance to the construction of basic disciplines in manufacturing. Large scientific research institutions should be encouraged to establish postgraduate education and postdoctoral workstations to foster leading talents in engineering science and technology by relying on national major engineering projects and major scientific and technological projects. Joint vocational education and on-the-job training among enterprises, schools and scientific research institutions should be promoted, the mode of cooperation between schools and enterprises to train skilled personnel should also be actively popularized. Meanwhile, through the way of order education, centralized training, orientated cultivation or commissioned training between the school and enterprise, a large number of skilled personnel are trained. In addition, large-scale enterprise groups should be an important base for training skilled personnel and accepting students to practice in the front line.

The introduction of talent and intelligence should be strengthened, with a variety of ways being adopted to actively introduce overseas leading personnel in engineering science and technology and talent as an urgent need. A research environment conducive to encouraging innovation should be created to promote the formation and development of excellent innovative talent groups

京公网安备 11010502051620号

京公网安备 11010502051620号