《1 Introduction》

1 Introduction

The automobile industry is an important national pillar industry and plays a significant role in the development of strong national manufacturing capabilities and the promotion of new supply-side structural reform processes. The Made in China 2025 plan selected ten major advantageous and strategic industries to achieve key breakthroughs, which included the energy efficient and new energy automobile industry. In 2017, the Ministry of Industry and Information Technology, the National Development and Reform Commission, and the Ministry of Science and Technology jointly published the Medium and Long-Term Development Plan of the Automotive Industry, thereby comprehensively accelerating the upgrading of China’s automobile industry. Quality is the most important core competitiveness in the automobile manufacturing industry and plays an irreplaceable role in terms of promoting the healthy development of the industry and the establishment of international competitive advantages. In view of nations with strong automobile manufacturing industries, such as the United States, Germany, and Japan, when countries reach a certain level of socioeconomic development, they adopt strategies of quality development. A thorough analysis of the status quo of the quality in Chinese auto industry, as well as proposing strategies and policy recommendations used to tackle bottlenecks, will go a long way to achieve transformation and upgrading in auto industry and improve its competence.

《2 Development and analysis of quality in China’s automobile manufacturing industry》

2 Development and analysis of quality in China’s automobile manufacturing industry

《2.1 Significant improvements in automobile manufacturing quality》

2.1 Significant improvements in automobile manufacturing quality

2.1.1 Rapid development of China’s automobile industry and stable improvements in quality

Since the beginning of the 21st century, China’s automobile industry has experienced substantial development and automobile production volume has maintained relatively significant growth. Since 2000, Chinese automobile production volume grew from 2.07 million units to 28.12 million units, a thirteenfold increase in 16 years. Since 2009, China’s automobile production and sales volumes have ranked first in the world for eight consecutive years. The automobile industry is an important contributor to Chinese socioeconomic development; according to statistics from the China Association of Automobile Manufacturers (CAAM), in 2015 Chinese automobile enterprises above a designated size achieved a total of 7.32 trillion yuan in core business revenue and generated a total of 587.2 billion yuan in taxes on profits [1].

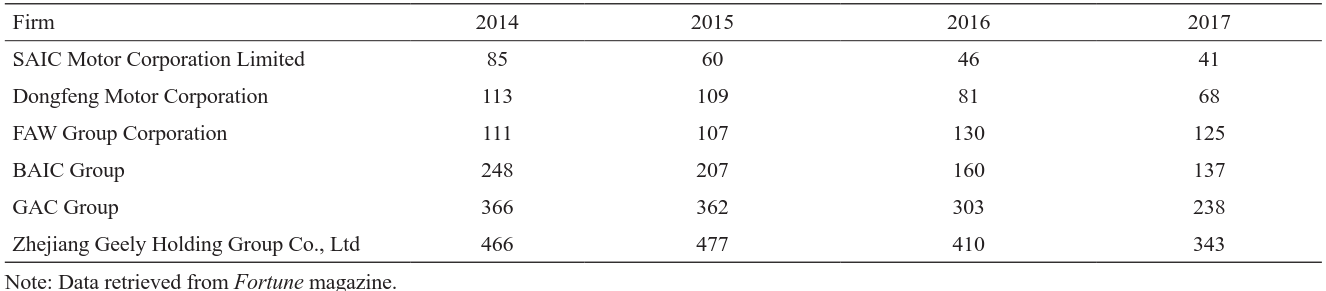

The global influence of China’s automobile industry is also gradually increasing. In 2017, the Chinese automobile company Geely ranked 472nd out of the top 500 global automobile brands, the first time that a Chinese independent automobile brand was included in this list. In the Fortune 500 ranking, rankings of Chinese automobile companies increased significantly from 2014 to 2017 (Table 1). In the 2017 version of the Fortune Global 500, six Chinese automobile companies made the list.

Table 1. Ranking of Chinese automobile firms in the Fortune global 500.

《Table 1. 》

Table 1. Ranking of Chinese automobile firms in the Fortune global 500.

With the rapid development of China’s automobile market, the increase in automobile production and sales volumes, continuous innovation of complete automobile products, uninterrupted improvements in key core technologies, and improved precision in automobile manufacturing methods, significant progress has been made in the quality of Chinese automobile manufacturing. Along with these changes, China’s automobile industry is transitioning from a period of high-speed growth to a new era of high-quality growth.

2.1.2 Significant quality improvements of independent brands

Independent Chinese brands have significantly improved their automobile quality. Firms such as SAIC-GM-Wuling Automobile, Great Wall Motors, Geely, and BYD Company, which are representative of Chinese independent brands, are currently accumulating personal experience and technologies through continuous automobile production and have achieved breakthroughs in product quality. In 2016, sales of independent brand automobiles reached 11.971 million units, representing the first time that passenger vehicle sales exceeded 10 million units and constituting a 20.5 % year-on-year growth [2]. Herein, independent brand SUV sales performance was especially strong; in 2016 independent brand SUV sales reached 5.268 million units, ranking first among categories of passenger vehicle sales, constituting 57.6 % year-on-year growth, and accounting for 58.2 % of all SUV sales. Among the top ten SUV brands ranked in terms of sales volumes, six are independent brands.

In order to cater to the increasingly high-end demands of consumers, independent brand vehicles have accelerated their product upgrading processes and the introduction of new generations of products. Product quality and brand status have begun to shift towards the high-end of the market, as represented by the Geely owned brand Lynk & Co, and by Great Wall’s WEY. Market competition among independent brands has increased, attracting an increasing number of consumers in the process. Stimulated by relevant policies such as Made in China 2025, independent brands have attained a leading status in the new energy passenger vehicle market and have maintained rapid growth in production and sales. Currently, independent brands account for more than 90 % of the Chinese market for new energy vehicles. In 2016, all nine companies with annual sales of more than 10 000 units were mainstream independent automobile brands, most of which boast good brand and product reputations, such as BYD Company and Geely [2]. Great effort is currently being made to improve fuel cell vehicle technology and positive progress has been achieved with regard to fuel cell life-span and power [3].

In 2016, SAIC-GM-Wuling Automobile ranked fourth in China in terms of domestic sales performance, with an annual sales volume of 1 427 921 units. It was surpassed only by SAIC Volkswagen, SAIC GM, and FAW-Volkswagen Group China. At the same time as it has achieved lean, flexible, and modular development, SAIC-GM-Wuling’s Baojun production base has also established optimized routes of people flow and logistics processes and becomes a green production base that meets the highest international production standards GM.

With the execution of the “Belt and Road Initiative” (BRI) strategy, China’s automobile companies have expanded to overseas markets, established overseas factories, and have achieved self-improvement through the process of “absorptiondigestion-re-creation.” The importance with which automobiles from independent Chinese brands are viewed overseas has continuously increased, as has the influence of these brands. For example, in July 2017, SGMW Motor Indonesia, a subsidiary of SAIC-GM-Wuling, began operations in Cikarang, Java. The first vehicle produced by this operation, the Wuling Confero S, constituted the success of the Indonesian of facility program, which is an example of the new model of “wholesale venture” that consists of competitive vehicle products, low-cost operation models, and complete supply chain system.

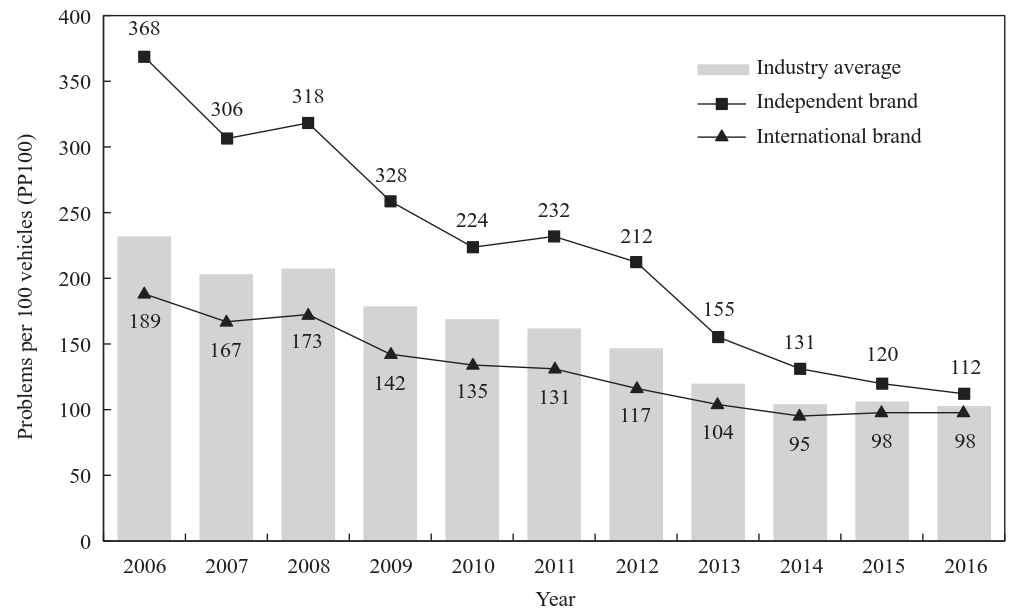

After years of development, the dependability of automobiles produced by independent Chinese brands has significantly increased, along with the quality of new vehicles, thereby further reducing the gap between these brands and leading international automobile brands. In 2016, the average overall new vehicle quality index, PP100, for independent brands was 112, and the quality index gap between independent brands and international brands declined to 14 points. In contrast, in 2006, the quality index gap was 179 points (Fig. 1) [4].

《Fig. 1. 》

Fig. 1. Quality of Chinese independent brands and international brands. Note: Data sourced from J.D. Power Asia Pacific.

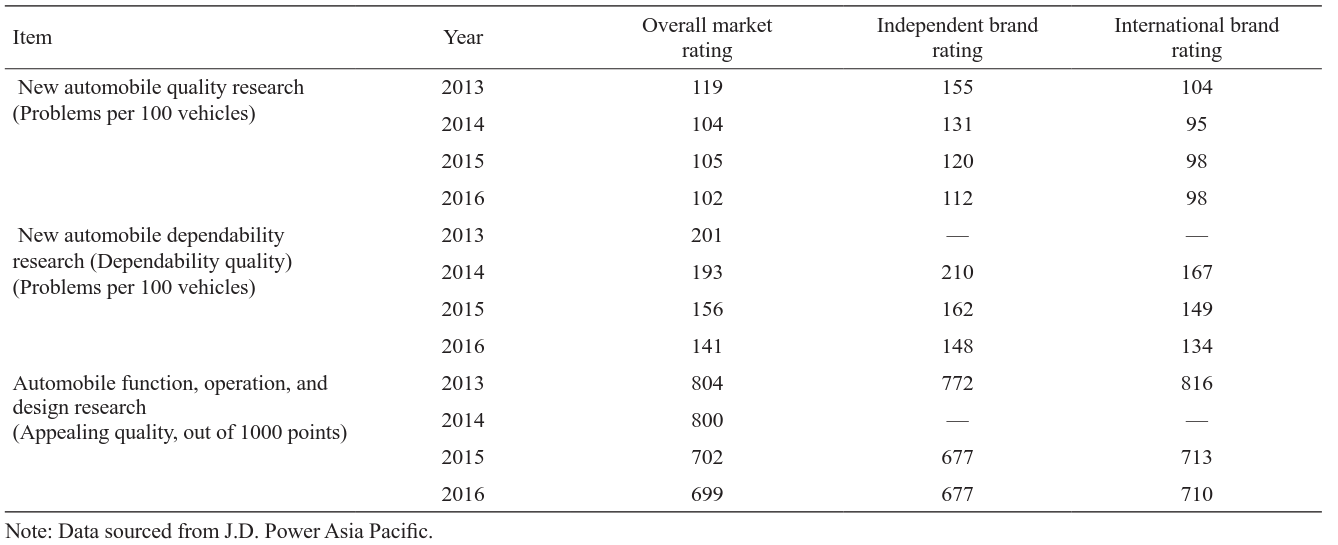

Apart from research reports on new vehicle quality, J.D. Power has also published reports from Vehicle Dependability Studies (VDS) and Automotive Performance, Execution, and Layout (APEAL) studies for the Chinese market, reflecting the dependability and appeal of Chinese vehicles. According to survey studies by J.D. Power, the quality of new vehicles produced by independent brands is improving faster than their dependability and appeal (Table 2) [5,6].

Table 2. J.D. Power ratings of the Chinese automobile market

《Table 2. 》

Table 2. J.D. Power ratings of the Chinese automobile market

《2.2 Gaps in Chinese automobile manufacturing quality》

2.2 Gaps in Chinese automobile manufacturing quality

2.2.1 The automobile industry is large scale, but suffers from low quality and low efficiency

Due to its rapid development, the industrial scale of China’s automobile industry has been the largest in the world for several years. However, when compared to countries with strong traditional automobile industries, China faces some competitive shortcomings with regard to quality and efficiency. For example, the six Chinese automobile firms included in the 2017 Fortune Global 500 had total annual profits of 11.7227 billion USD, while Toyota had an annual profit of 16.8993 billion USD, indicating that independent Chinese automobile brand company still differ significantly from well-known global brands with regard to quality and efficiency. China’s independent brand automobile industry urgently needs to improve and develop its quality and efficiency.

2.2.2 Weak automobile quality competitiveness

The Chinese Automobile Industry Customer Satisfaction Index (CACSI), developed by the China Association for Quality (CAQ) and the China National Customer Committee (CNCC), investigates customer satisfaction with regard to product quality, after-sales service, and sales service. In 2016, the industry was given a CACSI score of 77 out of 100; independent brand satisfaction was given a score of 75, two points lower than the industry average and three points lower than joint-venture brands. With regard to product quality, the quality dependability satisfaction, function/design satisfaction, and problems per 100 vehicles (PP100) for independent brands were 3.8 points lower, 3.5 points lower, and 14 times higher than joint venture brands, respectively. Independent brands scored three points lower than joint venture brands for both sales and after-sales service in terms of service quality.

2.2.3 Insufficient supply of mid-range and high-end automobiles

China’s independent automobile brands have been positioned at the mid-to-low end of the industry value chain for a long time. As such, there is insufficient supply of mid-range and especially high-end vehicles. When analyzing the hierarchical structure of automobiles, we see that most independent brands focus on the low-end market of A-grade automobiles or lower. These vehicles have low added value and command even lower brand premiums. In 2016, of the ten brands with the highest sales of A00 grade automobiles, nine were independent brands, while three of the ten brands with the highest sales of A0 grade automobiles were independent brands. However, only one of the ten brands with the highest sales of A and C grade automobiles were independent brands, and none of the ten brands with the highest sales of B grade automobiles were independent brands. With regard to automobile pricing, independent brands tend to focus on the market for vehicles priced at less than 100 000 yuan. According to the “2016 Consumer Report for Chinese Car Brands” published by Motor Trend Magazine, the sales-weighted average price of independent brand cars was only 90 000 yuan, while the sales-weighted average price of joint venture brands and imported brands was 188 000 yuan.

2.2.4 Fundamental contradictions between strong joint venture brands and weak independent brands remain unresolved

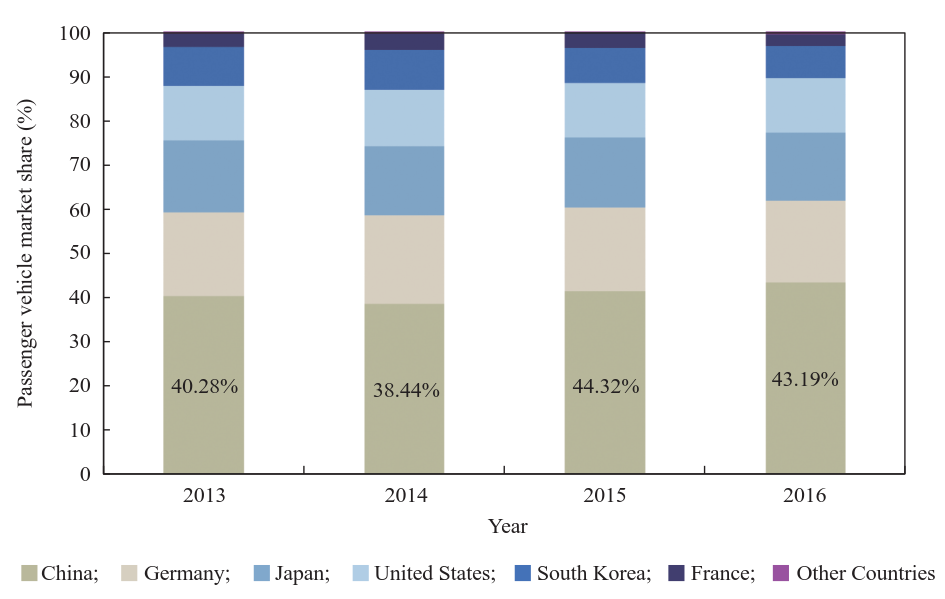

The market share of automobiles produced by independent brands remains low. Fundamentally, the contradictions between strong joint venture brands and weak independent brands have not yet been resolved. CAAM has calculated the market share of passenger vehicles produced by independent Chinese brands from 2013 to 2016, as shown in Fig. 2.

《Fig. 2. 》

Fig. 2. Chinese independent brand passenger vehicle market share. Note: Data sourced from the CAAM.

As of 2016, passenger vehicle sales by independent brands reached 10.5286 million units, or 43.19 % of sales, a 2 % increase compared to the previous year. By comparison, the share of passenger vehicle sales by German, Japanese, American, Korean, and French brands were 18.50 %, 15.55 %, 12.16 %, 7.35 %, and 2.64 %, respectively. According to the 13th FiveYear Development Plan for the Automobile Industry, the market share of independent brands should surpass 50 % by 2020. This indicates that the market share of independent brands remains low and below planned industry targets [7]. Independent brand vehicle exports are concentrated on countries and regions including Russia, South America, Southeast Asia, and Africa. The competitive advantages of independent brands tend to be reflected in pricing, giving these brands the image of producing “cheap cars.” From 2014 to 2016, average exports of complete Chinese automobiles were lower than 1 million vehicles, with annual export values gradually declining over this period. This indicates that as consumer tastes shift towards higher quality products, pricing advantages declined significantly and branding and quality weaknesses began to emerge.

Another prominent manifestation of the strength of joint venture brands and the weakness of independent brands is evident in automobile components. Among independent automobile brands, companies that manufacture complete automobiles are much stronger than component manufacturers. In fact, independent Chinese automobile component manufacturers are in a generally dire state. Currently, most suppliers of component parts for independent manufacturers of complete automobiles are still foreign brands.

《3 Analysis of problems with Chinese automobile manufacturing quality》

3 Analysis of problems with Chinese automobile manufacturing quality

《3.1 New challenges facing automobile quality》

3.1 New challenges facing automobile quality

As in other manufacturing industries, China’s automobile industry is currently facing a series of problems including the disappearance of demographic dividends, increasing manufacturing costs, and the loss of resource advantages. Compared to most other manufacturing industries, China’s automobile industry boasts definite advantages in terms of development speed and efficiency, although the acceleration of development has slackened in recent years. In the context of China’s new economic paradigm, the automobile industry must transform its concept of development, and focus on improving quality and efficiency rather than simply expanding in scale as a means of combatting the pressures of reduced development rates.

Next, China’s automobile manufacturing industry must increase its supply capacity in response to rapid changes in demand. As the strength of China’s national economy grows and people’s living standards increase, consumers’ demand for automobiles has exhibited profound change and diversification and has shifted towards high-end individualized products and products aimed at younger consumers. Consumers have become more selective, and no longer only care about individual functional values of vehicles. Furthermore, as technology has progressed, and with the introduction of green travel requirements, related industrial policies have shifted towards new energy, light-weight, intelligent, and network integrated development. Changes in consumer and social demand have in fact imposed higher requirements on automobile supply capacity. In response to the new requirements of supply-side structural reforms, China’s automobile manufacturing industry must increase the quality and volume of high-end supply and strengthen the adaptability and flexibility of its supply structure in response to changes in demand.

In addition, the automobile business model has undergone profound changes; China’s automobile manufacturing industry must adapt to these new challenges. In recent years, with the development of new business formats and development methods such as the Internet, the automobile has been transformed from a tool for transportation to a large, mobile smart device, storage unit, and digital space. The production of automobiles has moved towards a fully interconnected and cooperative smart manufacturing system, where production resources are efficiently allocated across the globe. In addition, R&D and production efficiencies have significantly increased, upstream and downstream industry links have been strengthened, and consumers are now accessible to more information. With the rapid development of the sharing economy, shared vehicles have become common, which allows for maximum utilization of vehicles while also forcing automobile firms to transform and upgrade their businesses. As a result, the question of how to maintain quality while also being guided by consumer demand and adapting to new patterns and modes of business has become a key area of concern for automobile companies.

《3.2 Chinese automobile manufacturing quality bottlenecks》

3.2 Chinese automobile manufacturing quality bottlenecks

Although China’s automobile industry has developed considerably and achieved significant success over the past several years, when generally compared to countries with developed automobile industries, China still exhibits a significant gap in manufacturing quality. Prominent bottlenecks in this regard include the following:

3.2.1 Insufficient technological quality infrastructure

The quality and technological foundation of China’s automobile industry has developed along with the rapid development of the industry. However, when compared with traditional automobile manufacturing countries, China still lags significantly behind in this respect. China has successively developed automobile function testing instruments and equipment such as automobile testing and diagnostic tools, data collection and processing automation, and the ability to print test results directly. As such, it is already possible to independently produce complete suites of automobile testing equipment, such as large-scale and technologically complex chassis dynamometers, integrated engine analyzers, four-wheel alignment machines, and brake testing machines. However, the level of standardization of these instruments is low, and existing bottlenecks include the following: lack of high-precision measurement equipment, insufficient standardization of quality systems, insufficiently precise verification and testing equipment, and inadequate certification capabilities.

3.2.2 Weak industrial foundation

Due to the late emergence of China’s manufacturing industry, it is incapable of independently manufacturing many types of major equipment and has a weak capacity for the independent production of major equipment, in addition to being highly dependent on external assistance in the high-end production of equipment. As such, China’s automobile industry is dependent on imports for most high-end equipment manufacturing. Furthermore, China’s technological foundation for automobile components remains poor and its component manufacturing system is weak, suffers from serious long-term investment shortages, an irrational industrial structure, and poor product development capability. Because of their high-quality design requirements and high added value, core-technology automobile components must be imported from abroad at high prices. At present, China focuses on the introduction of smart manufacturing technologies and has yet to grasp many fundamental modern manufacturing technologies. In addition to lacking basic research capabilities and having inadequate abilities to absorb and digest technological introductions, China is also lacking in original innovation. China’s technological systems are incomplete and suffer from key shortcomings such as control systems and system software. As such, China lags behind in the development of cutting-edge fields such as advanced materials and additive manufacturing.

3.2.3 Core technology weaknesses and lack of innovation

In recent years, China’s automobile industry has advanced significantly in the field of independent innovation and has achieved important successes in this regard. However, innovation has focused on the development of complete vehicles and the production of traditional components. Independent automobile component companies have achieved a definite supportive scale but have not yet developed some core technologies and independent capacities for innovation; the problem of insufficient investment and effort towards core and key technologies remains prominent. Quality design for Chinese automobile products lacks effective theoretical, methodological, technological, and instrumental support, which leads to no systematic quality design plans during the overall R&D process. The development method of Chinese firms, which emphasizes technological introduction rather than the digestion of new technologies, is overly dependent on foreign capital and has caused the vast majority of Chinese-produced vehicles’ core components to lack any intellectual property rights owned by independent Chinese brands, meaning that the initiative to develop is out of their hands.

3.2.4 Lack of a common fundamental technological research platform

It is important to establish a shared technological platform in order to realize mutual learning and sharing of research across different fields and different levels of the market to improve product quality, independent innovation capacity, to overcome problems related to generic and key technologies in the development of the automobile industry, to optimize the allocation of technological resources, and to resolve problems related to social concerns for automobile safety and environmental friendliness. However, China’s automobile industry lacks this shared basic technological research platform, making it difficult for large automobile companies to form alliances. In this context, such firms are unwilling to share benefits or risks and cannot fully integrate technologies and resources, which limits the high-end oriented development of the industry and makes it difficult for firms to develop their own strengths.

《4 Strategic measures to improve the quality of Chinese automobile manufacturing》

4 Strategic measures to improve the quality of Chinese automobile manufacturing

《4.1 General requirements for improving the quality of Chinese automobile manufacturing》

4.1 General requirements for improving the quality of Chinese automobile manufacturing

In order to carry out the spirit of China’s 19th Party Congress, according to the overall requirements of the Guiding Opinions and the overall execution of the Medium and LongTerm Development Plan of the Automotive Industry, the primary orientation of supply-side structural reform of the automobile manufacturing industry will be centered on improving the supply quality of automobiles and the central task of the supply system will be to comprehensively improve automobile quality. The core drivers of innovation are the advocacy of innovation, coordination, environmental friendliness, openness, and shared concepts of development. It is also necessary to implement quality-oriented fundamental solutions and use new energy vehicles and intelligent and connected vehicles (ICVs) as breakthrough areas to consolidate the foundation of quality development. Furthermore, problems related to key generic technologies must be overcome, improvements must be made to quality management mechanisms and independent brand development capabilities, and quality and efficiency must be improved.

Improvements in China’s automobile manufacturing quality follow the basic principles of quality-first, being company-oriented, government-guided, and market-led. Short-term goals are as follows: achieve breakthroughs in product manufacturing and technological innovation capabilities, acquire R&D capabilities for a variety of automobile products and key assembly products, accelerate improvements in manufacturing quality, independently develop automobile products that meet advanced international standards, and form several internationally competitive independent brands. Long-term goals are as follows: gradually surpass original innovations, form a series of independent innovative capabilities, establish a leading status in the international manufacturing sector, further develop and strengthen independent brands, develop absolute leadership in the domestic market, and attain competitive advantages in the automobile markets of developed countries.

By 2020, China aims to have established a complete quality assessment system, established credibility in the domestic market, developed a number of independent automobile component companies, created several internationally well-known independent automobile brands, and to have gradually begun exporting vehicles produced by independent brands to developed countries. By 2025, China hopes that its quality assessment system will have authority in the international manufacturing sector, and that it will have significantly improved the mid-range and high-end supply of vehicles from its independent brands. For its independent brands, it will have established a dominant domestic market position and rank among the top-ten international brands in terms of production and sales. By 2035, China aims for its independent brand automobiles to rank among the best in the world in terms of quality, to have competitive advantages in developed countries’ automobile markets, and to have developed global supply capabilities for automobile components.

《4.2 Strategic measures to improve Chinese automobile manufacturing quality》

4.2 Strategic measures to improve Chinese automobile manufacturing quality

4.2.1 Strengthening the orientation of national industrial support policies towards new energy vehicles and ICVs

policies towards new energy vehicles and ICVs New energy vehicles and intelligent connected vehicles represent the future development orientation of automobiles, in addition to being consistent with the Chinese concepts of “innovation, coordination, environmental friendliness, openness, and sharing.” It is difficult to surpass traditional automobile manufacturing countries in this long-established industry and so opportunities for China to match or surpass these countries lie in the developing fields of new energy vehicles and intelligent connected vehicles. In the future, it will be necessary to redefine which nations have strong automobile manufacturing industries, meaning that the countries that succeed in the aforementioned fields will dominate. Chinese companies have already taken action in this field, but they cannot depend on the market alone. As such, the government must increase the strength of relevant industrial policies so that the automobile industry can change its development orientation and overtake others, thereby allowing the Chinese automobile industry to establish a leading status despite its late start.

4.2.2 Carrying out quality improvement projects

The following quality improvement projects should be undertaken: strengthening R&D for new materials and processes; making breakthroughs in key materials and “know-how” for key manufacturing processes, making rapid breakthroughs in the introduction of domestically produced equipment into the automobile supply chain, and eliminating dependence on foreign technologies; expanding the intensity of dependability design, testing, and verification; strengthening the construction of basic infrastructure related to automobile quality, improving the intensity of standards related to China’s complete automobile and automobile component manufacturing, establishing an advanced modern national measurement system, improving the national qualification assessment system, and establishing systematic service capabilities to support the development of the automobile industry. In addition, it is necessary to make use of academic organizations, associations, manufacturing companies, certification organizations, and testing organizations in order to establish a quality assessment and standard system for automobile manufacturing quality and to implement comprehensive quality improvements oriented towards automobile design development, manufacturing, and service processes. Finally, China should accelerate the application of smart manufacturing technologies such as big data and cloud computing within automobile manufacturing and establish an innovative “Internet+ quality service” model.

4.2.3 Establishing a complete and modern automobile supply chain system

In response to the current problem of China’s independent complete automobile brands being stronger than independent automobile component brands, China should strengthen the independent R&D capabilities of component producers with regard to core technologies such as powertrains, automatic transmissions, and electronic control systems in order to achieve breakthroughs in these core technologies. This will break foreign monopolies on high-end components while also strengthening China’s independent automobile supply chain system, thereby establishing mutually beneficial relationships between complete car manufacturers and components producers and achieving coordinated development between these two sectors.

4.2.4 Establishing an automobile quality assurance and tracing system

Through integration with next-generation information technologies and artificial technologies as represented by the Internet, the establishment of a production tracking control system, which allows for feedback on all stages of the process from production to after-sales will form an automobile quality assurance tracing system. By fully utilizing advanced technologies such as the Internet and big data, establishing a dynamic assessment system for vehicle quality, and continuing to improve product quality and service capabilities, China will achieve improvements in manufacturing quality assurances and brand image.

4.2.5 Implementing a globalization strategy for independent brands

In order to truly develop China’s independent automobile brands into strong and renowned brands, it is necessary to achieve breakthroughs in mid-range and high-end brands, develop in foreign markets and especially developed countries, and be subjected to the tests of developed countries’ automobile markets. In one regard, on the firm-level, it is necessary to fully understand the principles of global competition and different national laws and regulations in addition to making full use of international resource advantages such as technologies, talent, and markets in order to improve international competitiveness. In another regard, related companies with independent automobile brands must develop a sense of camaraderie, share resources, and form industrial agglomeration effects. In addition, the government should actively establish a platform to summarize the successful experiences of globalized companies and provide services to assist independent automobile brands in developing their globalization strategies.

《5 Conclusions》

5 Conclusions

During the critical period in which China is transforming from a major industrial nation to a major manufacturing nation, it is important to recognize that quality issues have already become important bottlenecks for major manufacturing countries and that quality is the key to the timely achievement of related objectives. In order to develop a strong automobile manufacturing industry and improve manufacturing quality, China must find efficient solutions to problems such as grasping core technologies, establishing a strong foundation of quality technologies, and achieving breakthroughs in automobile components. China must also coordinate research relationships between academia and industry, promote the absorption, digestion, and re-innovation of key technologies, break foreign monopolies on key production equipment, and obtain a series of high-tech modern manufacturing technologies with complete and independent intellectual property rights. In addition, China should increase the intensity of its development of independent brands, rapidly increase quality and efficiency, and improve its ability to supply top-quality mid-range and high-end automobiles, thereby allowing it to rapidly achieve the transformation from a large automobile manufacturing country to a global leader in this sector.

京公网安备 11010502051620号

京公网安备 11010502051620号