《1 Introduction》

1 Introduction

In China, heavy commercial vehicles bear 78.8% of passenger traffic and 78% of freight traffic [1]. The technological innovation of heavy commercial vehicles is an important measure to implement a strategy for using manufacturing to enhance the power of the country, and has important strategic significance for economic and social innovation and development, ecological civilization construction, and energy and national defense security.

A powertrain is the core of a heavy-duty commercial vehicle, and the simultaneous improvement in its dynamism and economics, its emission control, an enhancement of its reliability, and technologies for achieving product consistency have been recognized as global challenges. Since 2005, Weichai Power Co., Ltd. (hereinafter referred to as Weichai) has taken the lead in the R&D and production of powertrain products. After more than 10 years of research, Weichai successfully developed China’s first China III electric-control common rail heavy-duty engine with completely independent intellectual property rights, namely, the Landking China III WP10/12 series. After a strategic acquisition of the Hunan Torch Automobile Group, the integration of Shaanxi Heavy Duty Truck Co., Ltd., Shaanxi Fast Gear Co., Ltd., Shaanxi Hande Axle Co., Ltd. and other high-quality assets, the world’s first “heavy-duty diesel engine + Transmission + axle” powertrain gold industry chain business model was created. At the same time, the world’s first powertrain R&D base was established, allowing China to produce a full range of large-volume, multi-variety, personalized, high-quality, heavy-duty, commercial vehicle powertrain products, achieving a leap from providing only engines to providing powertrain systems to customers. Weichai products have a domestic market share of 70%, and its production and sales volume ranks first in the world, which has driven a comprehensive upgrade of China’s heavy-duty vehicle industry and upstream and downstream industrial technologies, leading the industry to form a core competitive advantage in the international market. This has completely changed the passive situation of China’s lack of core technologies in heavy-duty powertrains, and has also reconstructed the market structure of China’s heavy-duty truck industry [2], resulting in significant contributions to energy saving, a reduction in emissions, and national defense construction.

《2 Independent innovation development process of Weichai》

2 Independent innovation development process of Weichai

《2.1 First stage: Introduction, digestion, and absorption (1983–2000)》

2.1 First stage: Introduction, digestion, and absorption (1983–2000)

In the early days of China’s reform and opening, the State Council officially approved the introduction of the complete Steyr heavy-duty vehicle project in July 1983 owing to a “lack of heavy and light industries” in China’s auto markets. Among them, the introduction, digestion, and absorption of heavy-duty engines were undertaken at that time by Weichai and the Hangzhou Engine Factory, mainly based on Weichai.

When introducing the Austrian Steyr engine technology, Weichai received drawings and parameters; however, the products produced were inconsistent with the Austrian Steyr engines and the quality level did not meet the relevant requirements. At the time, the foundation of Weichai was too weak, and the company lacked theoretical research and practical experience, the specific reasons of which were impossible to determine. After the product was put into production, the company no longer had the conditions to test its engines. Using a simple bench test, it was impossible to determine whether it could meet the needs of its customers. During the 1990s, there were few highways in China, and heavy-duty vehicles used 200–300 hp engines. The production volume of Steyr engines was small, and there were numerous problems in the quality of the products sold. In this context, the State Council implemented a bankruptcy reorganization of the former China Heavy Duty Truck Co., in 2000 for mainly two reasons: first, the capacity could not be released, and second, the product continuously had problems.

Weichai mainly produced fishery power devices before the introduction of the Steyr 10L engine. Before the reform and opening up of China, 70% of the offshore fishing vessel engines were manufactured by Weichai. During the 1990s, the depletion of offshore fishery resources led to a sharp drop in the sales of such engines. Heavy-duty truck engines were put into production by Weichai but could not be sold, and Weichai found itself on the verge of bankruptcy.

In 1998, at the age of 37, I became the director of Weichai and was a small sensation in the industry. After thorough research and analysis, I believed that, to break through the predicament at the time, we needed to sell Steyr products, and thus we chose the construction machinery market as a breakthrough. The construction machinery that year was mainly dominated by a domestic enterprise, which had an absolute market advantage, and whose products were in short supply. After a considerable amount of research, we came to believe that the Steyr engine could be fully transformed for application in construction machinery. Weichai deployed all resources needed to develop engines suitable for construction machinery. After a transformation, the Weichai engine was quickly accepted by its customers and became an important transformation node of Chinese construction machinery and modern power during the late 1990s. At the same time, China’s expressway network was gradually established and improved. During the first decade of the 21st century, Weichai seized the opportunity and opened a new phase of nearly 10 consecutive years of continuous sales growth.

《2.2 Second stage: Open cooperation and innovation (2001–2005)》

2.2 Second stage: Open cooperation and innovation (2001–2005)

From 2001 to 2002, Weichai began to explore the next step of its strategy, namely, the development of a new generation of high-power and high-speed engines, the integration of global resources for such use, and achieving a breakthrough in key core technologies. Around this series of issues, Weichai chose to carry out innovative studies from the following two aspects:

The first aspect is the question of how to choose three technical routes (namely, the use of a single pump, a pump nozzle, and a high-pressure common rail) to accommodate future engine emissions requirements. At the time, the perspectives in the industry were extremely inconsistent. These three technical routes were separately adopted by certain companies. In the end, Weichai finally made an important determination to introduce high-pressure common rail into China through in-depth research and discussion. It is been proven that taking this high-pressure common rail route has made Weichai the first enterprise in China to realize the mature application of a common rail system, and is at the forefront of the entire industry.

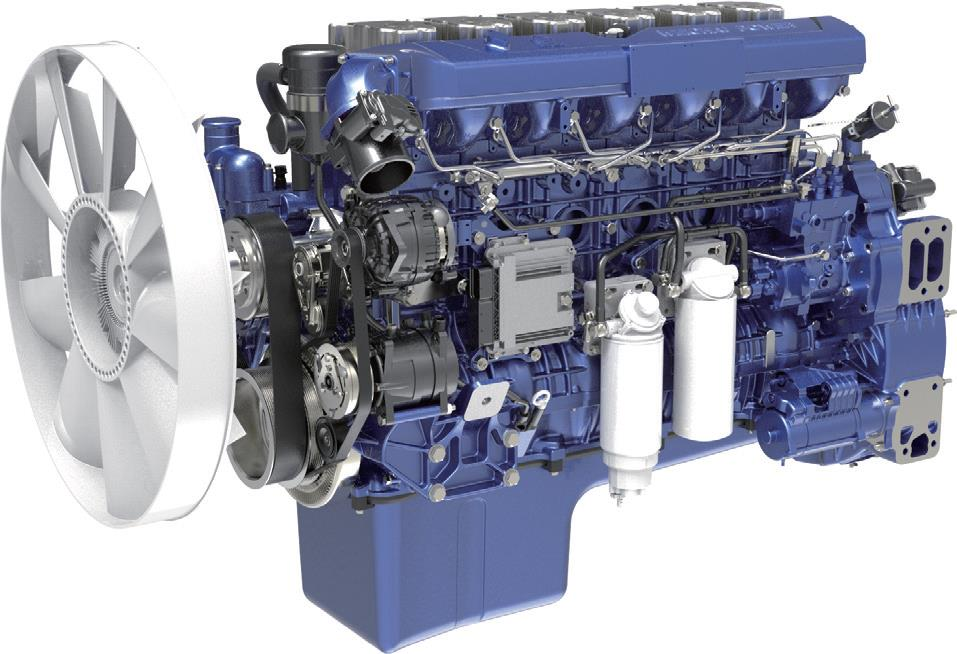

The second aspect is Weichai’s cooperation with a technology company in Austria. Weichai refused the subsidy given by the Austrian company to Weichai’s participating engineers and insisted that the engineers sent by Weichai participate in the design and testing of the entire process and enter its partner laboratory for research and development. These requirements enabled the 30 engineers sent by Weichai in 2002 to master the process and specifications for the development of high-power high-speed engines during the cooperation process. The process of innovation is not copying, nor buying, but achieving positive development through cooperation. In 2005, Weichai took the lead in the industry to release its Landking China III electronic control high-pressure common rail engine. In 2012, Weichai’s study “Key Technology and Industrialization of Heavy Duty High Speed Diesel Engine” won second prize of the National Science and Technology Progress Award. A typical product developed by Weichai is shown in Fig. 1.

Fig. 1. Weichai Landking engine.

《2.3 Third stage: System integration and integrated design (2006–2010)》

2.3 Third stage: System integration and integrated design (2006–2010)

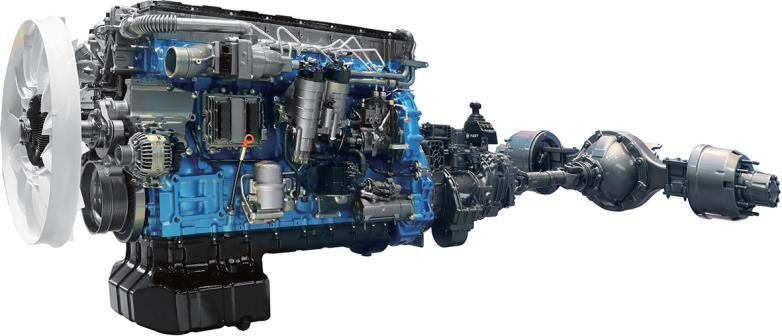

In 2005, Weichai recognized the disadvantages of being an engine-only company. The fuel consumption rate of an engine on a test bench was 187 g/kW•h, but reached 200 g/kW•h after installation in a vehicle. Weichai began to consider how to transform from an engine company to a powertrain company. At the time, the Delong incident had occurred, and the Hunan Automobile Group, which owns Fast Transmission, Hande Axle, and Shaanxi Automobile Heavy Truck, was to be auctioned. After a fierce auction, Weichai finally won the bid at a price of 1.02338 billion yuan. At the time, many people thought that the cost was too high, but later the companies in the industry praised Weichai for its powertrain integration strategy. Through the restructuring of Hunan Torch Automobile Group, Weichai turned the concept of a “powertrain” into reality [3], and comprehensively developed its powertrain system from the perspective of basic principles, and thus Weichai truly mastered the core technology of a heavy-duty vehicle powertrain. The development of commercial vehicle powertrain products (Fig. 2) has changed the ecology of China’s auto industry, allowing the self-owned brand of heavy commercial vehicles to occupy 99% of the domestic market and be exported in batches.

《Fig. 2》

Fig. 2. Weichai’s commercial vehicle powertrain.

《2.4 Fourth stage: Combination of theoretical innovation and practice (2011–present)》

2.4 Fourth stage: Combination of theoretical innovation and practice (2011–present)

After 2010, China’s infrastructure construction and market environment had advanced by leaps and bounds, its highway network had improved daily, and its logistics industry had rapidly developed. At this time, Weichai vowed to be a full-series, full-field engine supplier, forming a comprehensive development pattern to achieve an engine displacement of 2.1 to 340 L. In the past, the engine displacement range was designed by engine manufacturers to be in increments of 2 L, e.g., 10/12 L or 9/11/13 L. Such a layout is clearly not suitable for the current environment, and because the working conditions have changed, the emission requirements have developed into the China VI B stage, and there are various products such as freight trucks and logistics vehicles in the market segment. At the same time, energy savings are achieved under the premise of emissions, and thus a displacement of only 2 to 3 power segments is considered the best for customers. During this process, Weichai achieved a positive development, as well as innovation from theory to practice to method, reflecting the company’s strongly independent and innovative capability.

Weichai’s development during the past 20 years has always been based on products. Weichai has developed products and used capital to achieve a comprehensive improvement of its market competitiveness. In 2018, sales of Weichai engines reached 682,000 units, most of which are high-power products, which fully meet the needs of the market. During the Two Sessions in 2018, General Secretary Xi Jinping spoke highly of Weichai, namely, that Weichai’s 10 years of development has achieved beautiful results. All successful enterprises that climb to the top must rely on an unwavering focus regarding their main business [4].

《3 Understanding of innovative development of commercial vehicle powertrain systems》

3 Understanding of innovative development of commercial vehicle powertrain systems

Weichai is continuously focused on the development of core technologies for commercial vehicle powertrain systems to promote the overall development of China’s commercial vehicle industry. The innovation process of the commercial vehicle powertrain system can be summarized as follows:

First, in terms of product development, Weichai focuses on the actual use conditions of vehicle customers and considers the powertrain system as a whole to study a reduction in fuel consumption and emissions, and improve engine life. Relying only on the national key laboratory of engine reliability in China, Weichai is cooperating with more than 40 universities around the world to learn and improve their innovative capability through the process of cooperation.

Second, in terms of technological innovation, the main body of innovation is products, and the formation of innovation depends on the ecology. Without the ecology, innovation cannot be achieved. Weichai adheres to the principle of “self-based joint innovation,” and cooperates with global innovation resources to build a three-in-one technological innovation system of “independent innovation + open innovation + first-line innovation.” First-line workers and technicians are also important innovation elements. Without them, it is impossible to achieve perfect engineering technology. Recently, we proposed the new three-in-one technology innovation system of “Basic Research + Scientific Research + Engineering Research,” hoping to support the sustainable development of enterprises and industries for the next 20 years or even longer.

Third, in terms of R&D capabilities, Weichai must dare to invest and regard R&D capacity building as a strategic tool for enterprise development. In the research and development of heavy-duty engines, Weichai has already reached the world-class level. During the past 10 years, a total of 15 billion yuan has been invested in engine R&D, and a total of 3 billion yuan has been invested in the product laboratory. Weichai has established a sound development process and specifications. In the past, when a product was introduced into the market for customer verification, if a problem occurred, the product was modified. Now, relying on a perfect development process and system, the products developed by Weichai do not encounter large numbers of problems after being introduced into the market. In addition, Weichai is prepared to publicly release an industrialized heavy-duty diesel engine with a thermal efficiency of more than 50% in 2020.

Fourth, in terms of R&D system construction, Weichai must form its own methodology. All theories and experiments end with quality, and the management of engineering quality requires the support of quality methods and systems. Weichai has formed its own quality management model, the Weichai Operation System (WOS), by learning from advanced concepts and methods around the world, and combining the situations of actual enterprises. Quality and innovation have complemented each other. In November 2018, Weichai won first place in the highest quality award in China for the manufacturing industry, namely, the China Quality Award. In addition, in January 2019, Weichai’s “Key Technology and Application of Heavy Commercial Vehicle Powertrain” project won first prize of the China Scientific and Technological Progress Award. Thus, Weichai’s quality management and independent innovation have been fully affirmed and recognized.

《4 Prospects for the future development of commercial vehicles》

4 Prospects for the future development of commercial vehicles

In the future, the traditional energy efficiency of commercial vehicle engines is expected to reach 50%. The thermal efficiency of Weichai’s existing products has reached 46% on average. The newly developed engines have reached 48.5% on a test bench. System problems, such as a vehicle application and wind resistance, are also being researched. These days, countries are studying new energy sources. The pressure brought about by new energy sources is a reaction to traditional internal combustion engine enterprises because it also promotes better research and innovation. During the next 50 years, it will be difficult to break away from the demand for traditional energy sources, and thus, the internal combustion engine industry must produce quality internal combustion engines. It is debatable whether diesel cars should be allowed to enter a city. It needs to be resolved whether diesel and gasoline vehicles should achieve as little emissions as possible. The Euro VII standard being studied in Europe is near zero emissions, which technically indicates that zero emissions are fully achievable.

There are two main trends in the future development of commercial vehicles: new energy and an intelligent network. The new energy trend is irreversible. China is a large energy-consuming country, and thus, a way to promote the development of new energy sources and strategically adjust our consumption structure needs to be implemented. Development of new energy in the future requires careful study and consideration. Additionally, the trend of intelligence is also irreversible, and commercial vehicles are expected to continue to exert their strength in smart driving, vehicle networking, and electronic control technology. Based on an understanding of new energy, Weichai will not study lithium batteries in heavy commercial vehicles in the near future but will instead study solid oxide and hydrogen fuel cells. Weichai will maintain responsibility for the country and society and is expected to become a world-class Chinese enterprise.

京公网安备 11010502051620号

京公网安备 11010502051620号