《1 Introduction 》

1 Introduction

Staple food is crucial to the national economy and people’s livelihood; it occupies a fundamental and framework status in people’s dietary patterns in China. Since ancient times, the Huangdi Neijing ‧ Su Wen (the most authoritative text of early medical theory and drug therapy) has recorded the residents’ dietary structure of “five grains as the main source, and fruits and vegetables as the supplement.” According to the Dietary Guidelines for Chinese Residents (2016), the staple food is located on the first floor of the Chinese residents’ balanced diet pagoda, which is the foundation of the dietary structure and the most important food source to provide the energy needed by the human body. According to the Development Plan of the Grain Processing Industry (2011–2020), staple food is defined as the main food that can supply the residents’ consumption of three meals a day and meet their basic energy and nutrition needs. China’s traditional staple food mainly consists of noodle food and rice food, such as steamed bread, noodles, dumplings, deep-fried dough sticks, steamed buns, rice, instant rice, and instant rice noodles.

To promote the sustainable development of the traditional staple food manufacturing industry, Several Opinions of the CPC Central Committee and the State Council on Deepening the Supply-Side Structural Reform of Agriculture and Accelerating the Cultivation of New Driving Forces for Agricultural and Rural Development issued in 2017 claimed the implementation of action to upgrade the staple food processing industry and actively promote the industrialization and large-scale production of traditional staple food. Opinions on Accelerating the Supply-side Structural Reform of Agriculture and Vigorously Developing the Grain Industry Economy made specific arrangements for vigorously promoting the industrialization of staple food. It proposes supporting the industrial production of staple food products such as rice, wheat, corn, miscellaneous grains, and potatoes, protecting and exploring traditional staple food products, and increasing the variety.

In China, with the progress of the times and the acceleration in people’s life and urbanization, the staple food processing industry has rapidly developed. Driven by consumer demand, industrialized staple foods have gradually entered the public dining table. Staple food products made with rice, wheat, corn, miscellaneous grains, and tubers and manufactured by traditional or improved methods are constantly entering the market. However, China’s staple food processing industry began relatively late, basic research is still weak, and the constraining problems are relatively prominent. These problems lead to a relatively slow development of the industry. In view of this, the present study focused on the countermeasures for the development of the traditional staple food manufacturing industry, and will provide the theoretical basis for the transformation and upgrading of the traditional staple food manufacturing industry as well as the improvement of scientific and technological innovation capability of the traditional staple food.

《2 Background of developing the traditional staple food manufacturing industry 》

2 Background of developing the traditional staple food manufacturing industry

《2.1 Developing the traditional staple food manufacturing industry to ensure China’s food security》

2.1 Developing the traditional staple food manufacturing industry to ensure China’s food security

In recent years, China has made food security a top priority, providing a series of major arrangements based on the world situation, national conditions, and food situation [1]. It has become the national consensus to ensure the national food security. Staple food is the main approach of grain transformation in China; the traditional staple food manufacturing industry, which is the best market of grain products, has become an important pillar of the grain industry. In developed countries, processed foods account for approximately 90% of the total dietary consumption, while the proportion is only 25% in China [1]; this indicates that China’s staple food deep-processing industry with grain as the raw material has great development space. The development of traditional staple food manufacturing is of great significance for ensuring the national food security and promoting the transformation and upgrading of the food industry along with its rapid development.

《2.2 Innovating and upgrading the traditional staple food manufacturing industry to meet new consumer needs under the background of a healthy China》

2.2 Innovating and upgrading the traditional staple food manufacturing industry to meet new consumer needs under the background of a healthy China

Scientific consumption of staple foods greatly impacts people’s health. The food consumption of Chinese residents has been transformed from “enough to eat” to “eat well,” and is gradually moving toward “eat nutritious” because of the food industry development. Plan of Health China 2030 published in 2016 calls for promoting the construction of a healthy China and improving people’s health. Dietary Guidelines for Chinese Residents (2016) recommends that the daily intake of whole grains (including miscellaneous beans) equals to 50–150 g. At present, consumers have put forward higher demands for the nutritionalization and functionalization of staple food products; this has expanded the market for healthy and nutritious whole grain foods and functional staple food products. Thus, it is the key content for realizing the strategic planning goal of Healthy China 2030 that the staple food manufacturing industry achieves the innovation and upgrading to build a new environment for the production and consumption of nutritious and healthy staple foods.

《2.3 The traditional staple food manufacturing industry contributes to the construction of the Belt and Road and promotes the spread of China’s traditional food culture》

2.3 The traditional staple food manufacturing industry contributes to the construction of the Belt and Road and promotes the spread of China’s traditional food culture

The poems of ancient Chinese, the records of a Dream of Red Mansions, and a variety of rice, wheat, corn, miscellaneous grains, and tubers in modern life reflect the culture of traditional staple food. The Belt and Road initiative constituted by the Silk Road Economic Belt and the 21st Century Maritime Silk Road focuses on the active development of economic partnerships with countries along the route, contributing to giving new development space for China’s traditional staple food manufacturing industry [2]. The Belt and Road includes countries rich in staple food products and regions in shortage of staple food products, which are highly complementary in trade. Thus, with the help of the Belt and Road, China’s staple food manufacturing industry can go international, thereby promoting the inheritance and development of traditional Chinese food culture.

《3 Development status of the traditional staple food manufacturing industry 》

3 Development status of the traditional staple food manufacturing industry

《3.1 Raw materials for traditional staple food manufacturing are in abundant supply and steady increase in output》

3.1 Raw materials for traditional staple food manufacturing are in abundant supply and steady increase in output

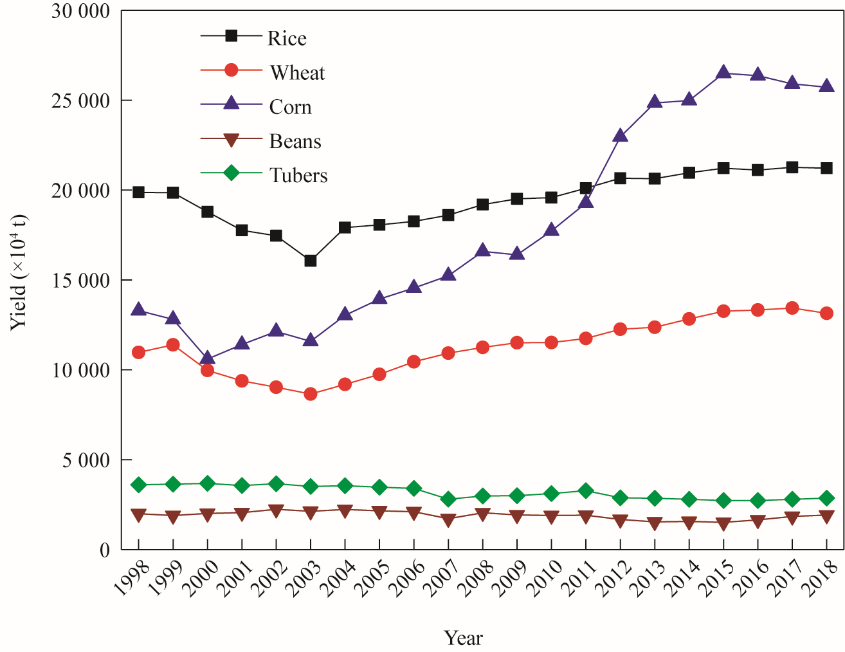

The manufacture and processing of staple food is not possible without raw materials, particularly rice, wheat, corn, miscellaneous grains, and tubers. Rice, wheat, and corn, as three main staple food raw materials in China, have shown a steady increase in the overall output in the past 20 years (Fig. 1), accounting for approximately 93% of China’s total grain output in 2018.

《Fig. 1》

Fig. 1. Changes in the yield of raw materials for China’s traditional staple food.

Source: China Statistical Yearbook (2003–2019).

Rice and its products are the most important food for Chinese residents. The overall yield of rice shows a steady upward trend. Since 2011, the annual output has reached 2.0 ×108 t, accounting for more than 30% of China’s total grain output [3].

Wheat is the main raw material of traditional flour products in China. In the past five years, the average annual output of wheat in China is approximately 1.3×108 t, and traditional flour products, such as steamed bread and noodles, consume 75% of the total wheat production [4]. Nearly 90% of the wheat is processed into flour in China, but only 25.5% of the flour is used in the processing of industrialized flour products, including instant noodles (8%), dried noodles (4.5%), quick-frozen food (6%), and baked products (7%) [5]. Therefore, raw materials for traditional staple food manufacturing are in abundant supply and steadily increase in output, but the proportion of industrialized production is relatively low.

As another major cereal staple food material, corn has the most obvious growth trend in annual output from 1.3 ×108 t in 1998 to 2.6 ×108 t in 2018. Corn currently accounts for 40% of China’s total grain output, and its output ranks first.

In China, miscellaneous grains are rich in varieties, including minor grain crops (sorghum, millet, buckwheat, oats, proso millet, coix seed, etc.), beans (mung beans, red beans, broad beans, peas, lentils, etc.), and tubers (sweet potatoes, potatoes, yams, taro, etc.). For the past 20 years, the yield of beans and potatoes has been steady, and reached 1.9 ×107 t and 2.9 ×107 t in 2018, respectively.

It is worth mentioning that potatoes are the fourth largest grain crop in the world and have an obvious tendency to become the raw material of staple food. Since 1993, China’s potato output has been ranked first in the world, and the corresponding output has increased from 1.4 ×107 t in 2008 to 1.8 ×107 t in 2018 (Fig. 2). In 2015, China has launched the potato staple strategy, adopting a way of making potato into rice flour, steamed bread, noodles, and other traditional staple food to accelerate the process of potato staple food [6].

《Fig. 2》

Fig. 2. Changes in potato yield in China from 2008 to 2018.

Source: The annual data of National Bureau of Statistics from 2008 to 2018.

《3.2 The staple food manufacturing industry has formed a large market scale and presented an obvious trend of industrial agglomeration》

3.2 The staple food manufacturing industry has formed a large market scale and presented an obvious trend of industrial agglomeration

In recent years, the scale of staple food processing enterprises has shown a continuous growth trend, and the economic benefits have steadily improved. In 2012, the department in charge of rural work implemented the Staple Food Processing Industry Promotion Action, piloted in some provinces and cities, and organized activities such as the identification of demonstration enterprises, the technology–enterprise docking activities, and the display of products and equipment. By 2017, five batches of Demonstration Enterprises of National Staple Food Processing Industry containing 336 companies have been recognized, playing a role in demonstration and guidance.

The number of staple food processing enterprises and their main business income have shown an increasing trend year by year, among which, the rice and flour product enterprises developed most rapidly. The number of rice, flour product, and edible oil enterprises significantly increased from 905 in 2008 to 1878 in 2018. Related main business revenue increased from 136.10 billion CNY in 2008 to 639.22 billion CNY in 2018 (Fig. 3). The gradual expansion of the market scale of staple food manufacturing industry provides a broader market space.

《Fig. 3》

Fig. 3. Changes in the number of rice, flour product, and edible oil enterprises in China and their main business income from 2008 to 2018.

Source: The annual data of National Bureau of Statistics from 2008 to 2018.

Under the guidance of national policies, provinces and cities have actively cultivated staple food manufacturing industry clusters. At present, staple food processing enterprises are gradually gathering in the main production areas of staple food raw materials, primary processing concentrated areas, and staple food sales areas. The industrial layout tends to be reasonable. The rice product processing industry has basically formed an industrial belt centered on the middle and lower reaches of the Yangtze River and the Northeast region; related enterprises are distributed around the industrial belt and Jiangxi province as the main region. Based on the advantages of staple food raw materials in different regions, the flour products processing industry has formed various staple food manufacturing industrial clusters. For example, Henan Province, the main wheat producing area, has established strong gluten-, medium gluten-, and weak gluten-noodle staple food industrial clusters in northern Henan, central Henan, and southern Henan, respectively, forming regional characteristics and providing reference for the development of other staple food manufacturing industries.

《3.3. A scientific and technological support system for the manufacturing of traditional staple foods has taken shape》

3.3. A scientific and technological support system for the manufacturing of traditional staple foods has taken shape

The discipline of grain and oil processing is an important branch of food science and technology. The scientific and technological innovation and development of the staple food manufacturing industry in China cannot be separated from the construction of the food science and technology discipline, especially the grain and oil processing discipline. At present, there are a total of 17 colleges and universities with undergraduate majors in Grain Engineering, nearly 100 institutions of higher learning and scientific research institutes with the authorization of master’s degree in Food Science and Engineering, and 37 institutions with the authorization of doctor’s degree, most of which are related to grain and oil processing. There are more than 300 colleges and universities with the major of Food Science and Engineering and courses related to grain and oil processing. These educational and scientific research institutions have provided a basic guarantee for the scientific and technological innovation and development of the staple food manufacturing industry, as well as trained high-level practitioners for the industry.

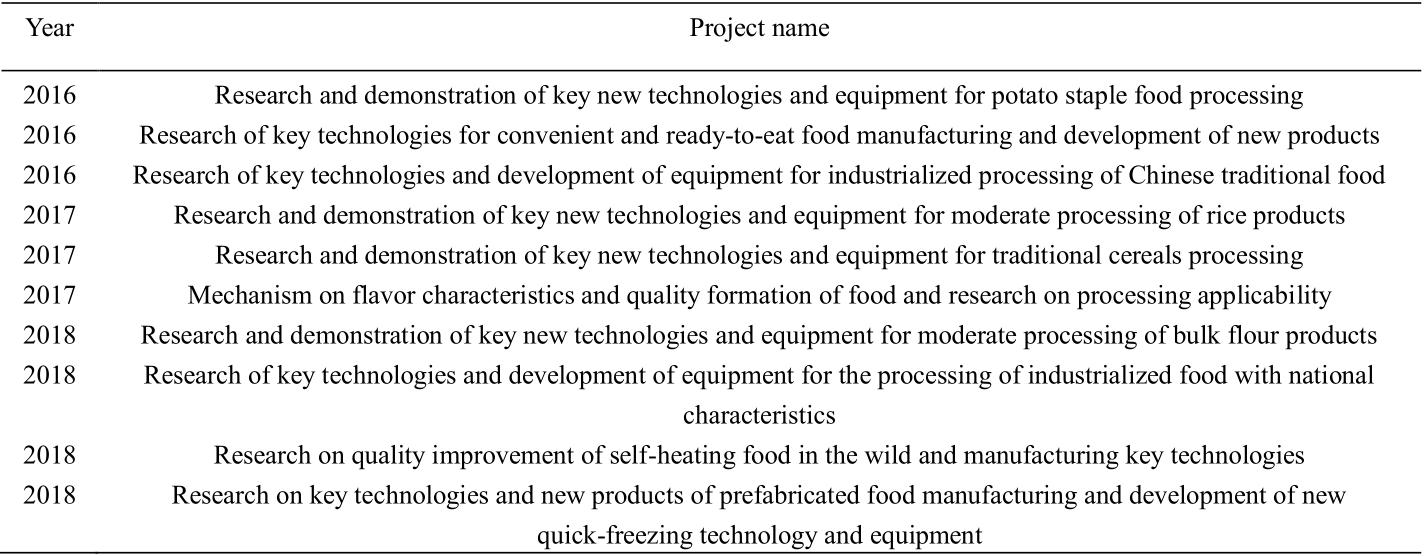

The state has maintained strong support for basic and applied scientific research on traditional staple foods. During the 13th Five-Year Plan period, the Ministry of Science and Technology approved 10 National Key Research and Development Programs of China related to staple food processing (Table 1). The total funds for the four projects in staple rice, staple flour, miscellaneous grain, and potato staple products reached 115 million CNY. The Food Discipline of the National Natural Science Foundation of China has set up three application codes for staple food processing, including C200102 for grain and oil food raw materials, C200504 for grain and oil food, C200601 for grain, oil, and product storage. In recent years, more than 100 projects have been approved under these categories.

《Table 1》

Table 1. National Key Research and Development Programs related to staple food processing during the 13th Five-Year Plan period.

With the technical support of national-level scientific research projects, the traditional staple food manufacturing industry has broken through a number of key technologies for staple food production and intensive processing. In terms of traditional rice products, the low-pressure grinding and whitening technology and equipment for embryonated rice, and the cooking and quality improvement technologies for brown rice have been developed. These technologies have been applied industrially in many enterprises. In terms of traditional flour products, the automation and intelligence level of flour making, drying, and packaging equipment has been greatly improved, and the intelligent bionic steamed bread production line has been put into operation. In the traditional processing of corn products, the key production technologies of corn dumplings and steamed bread, such as microwave-assisted biological modification, texture recombination, and aging control technologies, and the key production technologies of corn recombination rice, have been developed; the corn deep processing production line has been built. In the aspect of traditional miscellaneous grain products, the cooking and quality improvement technologies for miscellaneous grain products, the enzyme suppression technology and equipment for oat, and the processing technology and equipment of whole oat flour have been developed; a series of production lines for miscellaneous grain products have been created. In terms of potato staple food, the key processing technologies of potato mash, potato pulp, rice products, and noodles have been developed, and a series of production lines of potato staple food have been established.

《4 Challenges faced by the traditional staple food manufacturing industry 》

4 Challenges faced by the traditional staple food manufacturing industry

《4.1 Single structure of special varieties with good processing suitability》

4.1 Single structure of special varieties with good processing suitability

There are several varieties of raw materials for traditional staple food manufacturing. In the process of staple food manufacturing, the processing technology is likely to be different because of the variety of raw materials, years, and origins. It is difficult to control the processing and the product quality, copy and popularize practical technology, and guarantee the stability of product quality because it cannot be quantified effectively, resulting in problems such as weak market competitiveness and low economic benefits of traditional staple products.

Grain crops, such as rice, wheat, and corn, have temporary purchase and storage policies, regardless of the quality of the varieties. Farmers tend to plant grain varieties with temporary purchase and storage policies, resulting in the variety structure simplification and low quality trend of raw materials for traditional staple food manufacturing. Therefore, it is a challenge to effectively associate seed selection and breeding with staple food processing and promote the cultivation of special varieties with good processing suitability of traditional staple food.

《4.2 Low level in deep processing of staple food products and irrationality in product structure》

4.2 Low level in deep processing of staple food products and irrationality in product structure

Although the staple food manufacturing industry is developing at an adequate momentum, there remain problems such as low level of deep processing, high output of primary products, serious product homogeneity, and small and scattered processing enterprises. There are few products that can meet the needs of improving diet and nutrition, most of which lack quality standards and technical regulations.

In the staple food manufacturing industry, the proportion of finely processed cereal staple foods is relatively large, whereas that of various nutritional staple foods, such as whole grain foods, is very low. There are more ordinary and low-end staple food products, and few mid-to-high-end products. For example, ordinary staple foods, such as rice noodles, sweet dumplings, and Zongzi, account for a large proportion in the processing of rice-based staple food products, whereas the market share of intensively processed staple food products, such as nutritious breakfast cereals and functional rice noodles, is small [8]. This situation restricts the quality and efficiency improvement and the transformation and upgrading of the staple food manufacturing industry.

《4.3 Low level in the diversification and nutrient development of traditional staple food》

4.3 Low level in the diversification and nutrient development of traditional staple food

The food consumption of Chinese residents is in a transitional period from “eat well” to “eat nutritious” and the varieties of staple foods tend to be diverse. There are only over 300 varieties of traditional staple foods in China, whereas there are as many as 800 varieties of pasta and over 100 varieties of hamburger in other countries [7].

The lack of diversity in traditional staple foods has led to a significant decrease in the residents’ grain intake and a significant increase in animal food intake. The lack of food nutrients, such as the carbohydrates, dietary fiber, and vitamin B provided by staple foods, and fewer nutritional collocation are likely to cause obesity and cardiovascular diseases, which is damaging for national health. To adapt to the transition from subsistence consumption to nutritious consumption in China, several problems, such as enriching the varieties of staple foods, developing the staple food products of miscellaneous grains and whole grains, and strengthening the nutrition of staple foods, warrant urgent resolutions.

《4.4 Low application proportion in high-tech and intelligent special equipment》

4.4 Low application proportion in high-tech and intelligent special equipment

China’s traditional staple food has a long history, and has been produced mainly in the form of traditional small workshops, relying on experience and traditional methods. The relative lag in research has become the root cause of backward processing technology, and it is vital to adopt modern scientific and technological means to improve it. Developed countries have generally realized the application of high and new technologies such as ultra-high pressure, vacuum mixing of dough, and corrugated rolling, in the staple food processing industry. There is a gap between China and developed countries in this respect.

The modernization of China’s staple food industry’s processing equipment begins late. The industry generally maintains a rough processing mode and lacks professional supporting equipment. The staple food manufacturing enterprises are weakly capable of independent research and development of their equipment and lack core technology and market competitiveness. In China, with the increasing scale of the traditional staple food manufacturing industry and increasing social labor costs, independent research and development of intelligent special equipment suitable for the industrialization and standardized production of traditional staple food processing has become an urgent need for the industry. The industry needs to develop intelligent manufacturing.

《4.5 Further improvement needed for a standardized system for staple food products》

4.5 Further improvement needed for a standardized system for staple food products

A number of national and industrial standards such as Wheat Flour Steamed Bread, Wheat Flour for Steamed Bread, and Wheat Flour for Bread, have been formulated by the competent authorities of China. These standards have played an active role in promoting the standardization of China’s traditional staple food manufacturing industry. However, the traditional staple food itself has a wide variety of derivatives. Many staple food products do not have a unified product standards system and cannot truly break through the geographical restrictions. The corresponding industrialization and standardization development are restricted. Compared with developed countries, the current standard level of staple food processing in China is relatively low, and the standards system is not sound and perfect. In particular, the establishment of a standards system for healthy grains and staple foods lags behind.

《5 Countermeasures and suggestions 》

5 Countermeasures and suggestions

《5.1 Breeding high-quality varieties that are suitable for traditional staple food processing》

5.1 Breeding high-quality varieties that are suitable for traditional staple food processing

The competent authorities need to put forward requirements on the plant breeding community from the perspective of staple food processing and residents’ nutrition, and focus on key tasks such as variety breeding and planting bases. Depending on the evaluation system of suitability for variety processing, it is necessary to breed or improve the raw material varieties for staple food processing. For example, potato varieties such as fried type and starch type can be selected and bred according to different processing needs; from the perspective of nutrition, rice varieties rich in zinc and selenium can be selected to produce functional staple food products. Efforts should be made to promote these high-quality special staple food species to further enrich the planting varieties of raw materials for traditional staple food manufacturing in China.

《5.2 Adjusting the product structure as well as promoting the transformation and upgrading of the traditional staple food manufacturing industry》

5.2 Adjusting the product structure as well as promoting the transformation and upgrading of the traditional staple food manufacturing industry

Proper processing of rice and noodles should be advocated to preserve their original nutrients to the maximum. Nutritious and healthy rice/noodle staple products such as functional rice noodles and nutritious breakfast cereals need to be actively developed. The industrial production of corn, miscellaneous grains, and potato staples should be promoted to enrich the market supply and meet the diverse needs of the population. The staple food manufacturing industrial chain needs to be extended for improving the comprehensive utilization rate of by-products. In this way, deep-processing products with high-added value are developed, and the product structure of traditional staple food manufacturing is optimized, thereby promoting the high-quality and sustainable development of the staple food manufacturing industry.

《5.3 Developing whole grain foods and upgrading the traditional staple food processing toward healthy grains》

5.3 Developing whole grain foods and upgrading the traditional staple food processing toward healthy grains

The National Nutrition Plan (2017–2030) ushered in the era of “Healthy China, Nutrition first” for all people. To meet the development goal of increasing the intake of whole grains, it is recommended to strengthen the scientific research on whole grain foods, conduct science popularization, and promote the innovation and upgrading of traditional staple food processing to healthy grains and staple foods. The nutritional factors in whole grain foods need to be further explored and personalized, and precise nutrition programs should be developed according to different target groups to meet people’s nutritional health needs.

《5.4 Strengthening the research and development of technologies and equipment as well as promoting the deep integration between the traditional staple food manufacturing industry and intelligent manufacturing》

5.4 Strengthening the research and development of technologies and equipment as well as promoting the deep integration between the traditional staple food manufacturing industry and intelligent manufacturing

Investment in basic theory and applied research of traditional staple food products should be increased to drive the long-term development of the staple food manufacturing industry with scientific and technological innovation. The development of key technologies and equipment for traditional staple food manufacturing must be strengthened, with emphasis on the technical orientation featuring intelligence, environmental protection, energy conservation, emission reduction, and grain saving. High-tech and intelligent technologies such as additive manufacturing of staple food chips, intelligent fermentation, and automated packaging, can be integrated to develop industrialized, large-scale, and continuous production lines, thereby supporting the development of the traditional staple food manufacturing industry toward standardization, automation, and intelligence.

《5.5 Improving the standards system to promote the industry to be standardized and scientific》

5.5 Improving the standards system to promote the industry to be standardized and scientific

The standards system of staple food manufacturing in developed countries can be used for reference or introduced, and the specific standards and regulations must be studied and analyzed. In combination with the adjustment of national standards system framework, social organizations related to staple food manufacturing should formulate a batch of group standards aimed at promoting industrial development and technological progress. The formulation and revision of national and industrial standards should be strengthened, and relevant Chinese institutions should actively participate in the research on staple food standards of the International Standardization Organization, thus enhancing the international influence and competitiveness of China’s traditional staple food manufacturing industry.

京公网安备 11010502051620号

京公网安备 11010502051620号