《1 Introduction》

1 Introduction

The development of industrial parks in China began with the reform and opening-up policy in 1978[1]. Following over four decades of development, China has established a diverse and comprehensive manufacturing industry system associated with many industrial parks, including 2543 national- and provincial-level industrial parks [2,3]. Parks have contributed more than 50% of the gross industrial output values of the entire country [4] and have played a crucial role in sustaining manufacturing industries, promoting regional economic growth, facilitating industrial agglomeration, and enhancing the open economy.

The Yangtze River Economic Belt (YEB) is one of the most prosperous and strategically significant areas in China [5]. Since the 18th National Congress of the Communist Party of China, the central government has strengthened the green transformation of the economy and designated the YEB as one of the five national initiatives for coordinating regional development. Presently, the YEB has achieved balanced growth within the regions, associated with the increased capability of high-quality development and effective resource management and utilization [6]. The national master plan for the YEB calls for substantial efforts to facilitate green development of the region, with the hallmark of promoting ecological conservation and avoiding excessive development of the entire catchment. Driven by eco-conservation priority ideology and green development, the upstream, middle, and downstream areas are coordinately running for a high-quality development paradigm [7].

It is common to settle down the manufacturing industry along rivers or ports because of convenient shipping, abundant water resources, and environmental carrying capacity compared to inland areas. Undoubtedly, the YEB has an advantage in growing manufacturing industries, contributing 50% of China’s industrial output values. The YEB has developed many leading industrial parks globally, which have played a key role in facilitating economic and social development in both local areas and neighbors. However, intensive manufacturing industries along the YEB have had heavy environmental impacts on the Yangtze River, such as pressures on local habitats, resource supply, and energy production. Some parts of the river have been overdeveloped for a long time, and the accumulated ecological and environmental impacts have overweighed the carrying capability of the local environment. Meanwhile, many industrial parks along the river also present great challenges, such as upgrading industrial structures to the high value-added end and improving environmental management.

In the National Master Plan for the Yangtze Economic Belt Development, water environment protection and improvement were explicitly outlined, and the plan also calls for efforts to control industrial pollution. While facilitating economic development in the YEB, industrial parks along the river have generated numerous environmental issues involving water, soil, and air pollution [8–10]. Industrial parks have intensive industrial activities, considerable resource and energy consumption, and high pollutant emissions. Thus, they substantially affect local ecosystems and the environment [11]. In recent years, many firms located within 1 km of the shoreline of the Yangtze River have been requested to move to industrial parks. Additional challenges will be added to industrial parks, such as increasing resources, energy, and environmental pressure and the availability of infrastructure in parks. [12].

This study aims to uncover the paradigm of the green development of industrial parks in YEB and propose policy implications for decision-making. Hence, it is necessary to assess the features of the green development of industrial parks in YEB by comprehensively analyzing economic development, spatial configuration, pillar industries, energy-environmental infrastructure, water consumption, and pollutant emissions. Consequently, we identify the main challenges for furthering the green development of industrial parks and then propose green transformation strategies for industrial parks in the YEB to underpin sustainable policymaking.

《2 Materials and methods》

2 Materials and methods

Fig. 1 shows a schematic diagram of this study. First, the features of industrial parks, their main challenges, and a roadmap for green development are explored. Second, geographic information system (GIS) technology, GIS-based databases, and multi-criteria decision-making are developed.

The database covers national- and provincial-level industrial parks in the YEB, including Hubei, Hunan, Sichuan, Yunnan, Guizhou, Anhui, Jiangxi, Zhejiang, Chongqing, and Shanghai Provinces. The database was developed based on a GIS framework.

The features of industrial parks focus on spatial configurations, pillar industries, energy-environmental infrastructure, water use, pollutant emissions, and economic-environmental performance. The main challenges to green development are identified from multiple aspects, including the spatial layout of manufacturing industries in the industrial parks, industry structure, greenhouse gas (GHG) emissions, the quantity of water use, and water security. A multi-criteria decision-making method was employed to deduce tailored policy implications for the green development of industrial parks by integrating the upstream and downstream regions in system thinking, particularly for robust pollution control in chemical industrial parks.

The basic data were mainly obtained from the statistical yearbooks of different provinces and cities. We also used the industrial park database established by the Center for Cleaner Production and Industry Ecology in the School of Environment at Tsinghua University. The database of industrial parks includes basic information, geographic location, pillar industries, economy, energy consumption, pollutant emissions, energy and environmental infrastructure, land use, and other information. The list of energy infrastructures in industrial parks has a resolution of plant-level information, such as individual capacities, technology types, energy efficiency, vintages, and cooling technologies. The information on environmental infrastructure is mainly for centralized wastewater treatment plants in parks, covering capacity, technologies, load rate, pollutant removal efficiency, vintage, and geographic location. Energy infrastructures, in this study, referred to shareable utilities located within the industrial park and provided energy for the park, such as combined heat and power, heat generation stations, electricity generation facilities, municipal solid waste incineration, hazardous waste incineration, and biomass-to-energy. Additionally, data were collected through face-to-face reviews with industrial parks managers, enterprises, and infrastructure operators.

We assessed the green development performance of industrial parks in the YEB by considering their pillar industries, the capacity of energy infrastructure, pollutant emissions, diversification of water resource intake, implementation of national demonstration programs targeting eco-industrial development of industrial parks, energy productivity, water resource productivity, and green development index. Solutions for addressing resource-environment challenges were further explored on this basis.

《Fig. 1》

Fig. 1. Schematic diagram of the research procedure.

《3 Status of industrial parks development in the Yangtze River Economic Belt》

3 Status of industrial parks development in the Yangtze River Economic Belt

《3.1 Spatial distribution and pillar industries in industrial parks》

3.1 Spatial distribution and pillar industries in industrial parks

According to the industrial parks catalog released in 2018 [13], the YEB hosts 1045 industrial parks, consisting of national economic-technological development areas, national high-tech industrial development zones, and provincial-level industrial parks. These industrial parks accounted for 44% of the total industrial parks in the catalog (Table 1).

Table 1. Categories of industrial parks in the Yangtze River Economic Belt.

《Table 1》

| Category | Total numbers in the country | Numbers in the YEB | Percentage (%) |

| National economic-technological development areas | 219 | 108 | 49.3 |

| National high-tech industrial development zones | 156 | 69 | 44.2 |

| Provincial-level industrial parks | 1991 | 868 | 43.6 |

| Total | 2366 | 1045 | 44.2 |

3.1.1 Number of industrial parks increasing from upstream to downstream

We analyze the geographic distribution of national- and provincial-level industrial parks in the YEB. The upstream region (Sichuan, Chongqing, Yunnan, and Guizhou Provinces) hosts 311 industrial parks, whereas the midstream region (Hubei, Hunan, and Jiangxi) and downstream region (Anhui, Jiangsu, Zhejiang, Shanghai) host 322 and 412 industrial parks, respectively. Provincial-level industrial parks have a spatial aggregation characteristic; in particular, the eastern parts of Sichuan, Hunan, and Shanghai have a high density in industrial parks’ spatial aggregation.

Industrial parks contribute substantially to the local economic development in the Yangtze River, accounting for more than half of the industrial output values in these provinces. For example, industrial parks in Guizhou Province contribute more than 70% to both provincial industrial output values and the number of enterprises above a designated size; industrial parks in Jiangsu Province contribute more than 50% of gross domestic product, 60% of fixed asset investment, and 80% of total foreign trade.

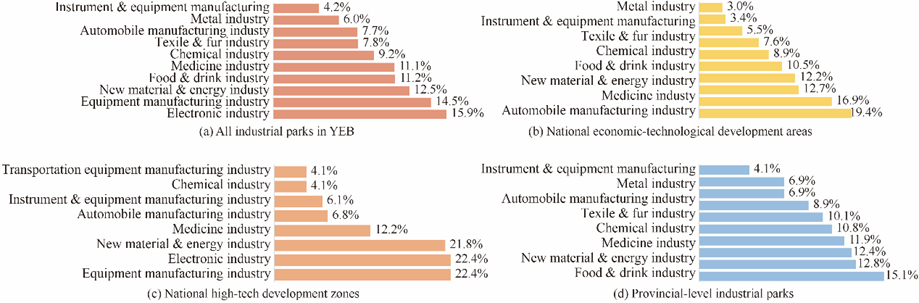

3.1.2. Similarity of pillar industries in industrial parks

We analyze the frequency distribution of pillar industries in 1045 industrial parks along the YEB. The top three industries in industrial parks are electronic device manufacturing, equipment manufacturing, and advanced materials and energy, as shown in Fig. 2a. Furthermore, the top three industries in the national economic-technological development areas are equipment manufacturing, electronic device manufacturing, and automobile manufacturing (Fig. 2b). As shown in Fig. 2c, the top three industries in the national high-tech development zones are equipment manufacturing, electronic device manufacturing, and advanced materials and energy. The top three industries in the provincial-level industrial parks are depicted in Fig. 2d, including electronic device manufacturing, equipment manufacturing, and food and beverage manufacturing. We find that equipment manufacturing and electronic device manufacturing are the pillars of the YEB; national-level industrial parks have similar features in pillar industries, whereas provincial-level industrial parks are relatively diverse in pillar industries.

《Fig. 2》

Fig. 2. Pillar industries in the industrial parks along the YEB.

《3.2 Features of in-use energy infrastructure in industrial parks》

3.2 Features of in-use energy infrastructure in industrial parks

Industrial parks utilize shared infrastructure with a long service time and encapsulate resources and environmental concerns. Infrastructure is a critical lever for promoting the green development of industrial parks. Here, we quantitatively analyze the characteristics of in-use energy infrastructure in the national- and provincial-level industrial parks of the YEB.

3.2.1 Characteristics of energy infrastructure in industrial parks

Among the 1045 industrial parks in the YEB, 386 deploy centralized energy infrastructure, such as the cogeneration of heat and power plants, electricity generation, and heating production plants within their physical boundaries. The inventory includes 1820 energy infrastructure units in service, with an installed capacity of 209 GW, accounting for 37% of the total installed capacity in the YEB. In terms of the primary energy structure, coal-fired and natural gas-fired units dominate all energy infrastructure units, accounting for 84.2% and 11.3% of the total capacity, respectively. The capacity structure of the in-use energy infrastructure units in industrial parks features a small number of large-capacity units and many small-capacity units (Fig. 3). Accordingly, the large-scale upgrading of small-capacity units in industrial parks can bring significant energy saving and emission reduction benefits.

《Fig. 3》

Fig. 3. Capacity structure of energy infrastructure units in industrial parks.

3.2.2. Performance of low-carbon transition of energy infrastructure in industrial parks

We analyze the energy efficiencies and environmental performance of energy infrastructure in industrial parks of the YEB compared with the national average and advanced levels. Consequently, we identify the development status and achievable improvements in the energy infrastructure of industrial parks. Generally, the energy infrastructure in industrial parks in the YEB has a significant impact on the local environment. The overall energy efficiency of the energy infrastructure in industrial parks is nearly equal to the national average level, whereas the environmental performance is better than the national average.

The average electricity supply efficiency of 1820 energy infrastructure units in industrial parks of the YEB is 39.0%, equal to the national average level in the same year (38.5%). From the perspective of environmental impacts, the energy infrastructure in industrial parks of the YEB delivered 860 megatons of CO2 equivalent of GHG emissions, 800 kilotons of sulfur dioxide emissions, and 1130 kilotons of nitrogen oxide emissions in 2014, accounting for 26%, 12%, and 17% of the total emissions of the Yangtze River Economic Belt, respectively. In terms of environmental performance, 99.5% of the total capacity of the energy infrastructure in these industrial parks is thermal power. The environmental performance is better than the national average level of thermal power generation.

《3.3 Environmental infrastructure and water use in industrial parks》

3.3 Environmental infrastructure and water use in industrial parks

3.3.1 Environmental infrastructure development of industrial parks

According to the national guidelines for water pollution management, industrial parks were requested to build centralized wastewater treatment facilities with automatic online monitoring devices by 2017. Industrial parks in the YEB had a completion rate of 96.8% for centralized wastewater treatment facilities and 96% for online monitoring devices. Currently, wastewater treatment in industrial parks can be divided into two distinct patterns: one is to build centralized wastewater treatment plants within the parks, and the other is to use urban wastewater treatment plants outside industrial parks. The two patterns account for 40% and 60% of the total industrial parks, respectively. For example, 209 centralized wastewater treatment plants are located inside the physical boundaries of 108 national economic-technological development areas in the YEB. Most centralized wastewater treatment plants treat industrial wastewater generated in industrial parks and are associated with municipal wastewater from neighboring communities. The annual wastewater treatment capacity is 2.97 gigaton, with industrial wastewater accounting for only 29%.

The national economic-technological development areas in the YEB show large differences in the volume of industrial wastewater discharge (Fig. 4). The annual industrial wastewater volumes generated in the upstream, midstream, and downstream regions are 110, 100, and 980 megatons, respectively. Generally, there is a positive correlation between water pollutant emissions and wastewater discharge volume. The chemical oxygen demand (COD) of wastewater from industrial parks is subject to such a correlation, whereas ammonia nitrogen is not straightforward. Industrial parks in the downstream region have a high removal rate of ammonia nitrogen because the heavy water pollution in this area drives the implementation of high-standard wastewater treatment technology [14].

《Fig. 4》

Fig. 4. Industrial wastewater and pollutants emissions from national economic-technological development areas in the YEB.

3.3.2 Quantity of water intake in industrial parks

The total water intake of the 108 national economic-technological development areas in the YEB is 5.75 billion m3, accounting for 0.95% of the national total water intake (604 billion m3). The parks’ economic output per cubic meter of water intake (also called water productivity) is better than the national average. Industrial parks have diverse sources of water intake (Fig. 5). Surface freshwater is the primary supply source, accounting for 67.5% of the total water intake, followed by tap water outside the industrial parks.

《Fig. 5》

Fig. 5. Structure of water intake sources in national economic-technological development areas.

《3.4 Assessment of green development of industrial parks in the YEB》

3.4 Assessment of green development of industrial parks in the YEB

3.4.1 Practice of national demonstration programs on eco-industrial development

The Chinese government has attached great importance to facilitating national demonstration programs targeting industrial parks, such as eco-industrial parks, green industrial parks, low-carbon parks, and circular economy industrial parks. The Ministry of Ecology and Environment, Ministry of Science and Technology, Ministry of Commerce, Ministry of Industry and Information Technology, National Development and Reform Commission, Ministry of Land and Resources, and other departments have released a series of policies promoting the green development of industrial parks. Many industrial parks in YEB have actively boosted such demonstration programs. Fig. 6 presents an overview of the diverse demonstration industrial parks in the YEB. In other words, most government-oriented demonstration industrial parks are located in the four provinces of the downstream region.

《Fig. 6》

Fig. 6. Overview of diverse demonstration programs for industrial parks in the YEB.

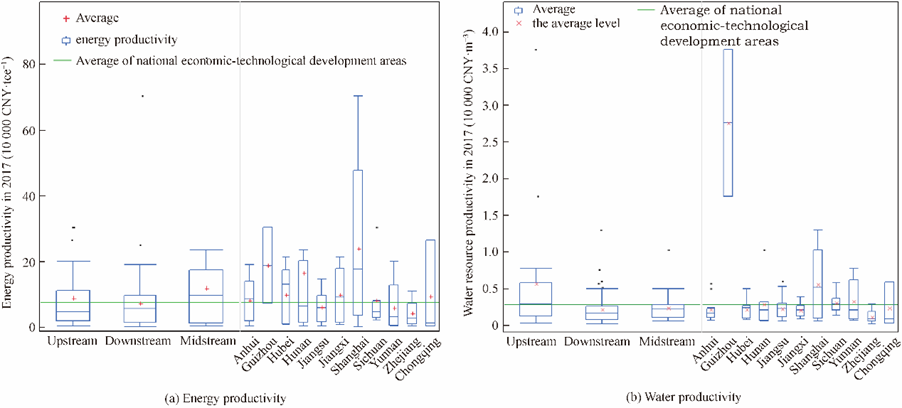

3.4.2 Assessment of green development performance of industrial parks based on typical indicators

We use typical indicators, such as energy productivity, water productivity, and pollutant emission intensity to assess the green development performance of national economic-technological development areas in the YEB. The energy productivity of these industrial parks ranges from 0.40×104 to 8.2×105 CNY/tce (Fig. 7a). Specifically, 47% of these parks have energy productivity of no less than 5×104 CNY/tce, whereas 16% have energy productivity no less than 1.5×105 CNY/tce, including four industrial parks in the upstream region of the YEB, seven in the midstream region, and six in the downstream region. The statistical distribution of the water productivity is shown in Fig. 7b. The water resource productivity of these industrial parks ranges from 0.01×104–3.75×104 CNY/m3, and there is significant heterogeneity across industrial parks [15].

COD emission per unit of GDP (COD emission intensity) in national economic-technological development areas of the YEB ranges from 1 kg/million CNY to 298 kg/million CNY, with 51% of them less than 100 kg/million CNY and 25% higher than 200 kg/million CNY. Industrial parks in the midstream and downstream regions are comparatively emission-intensive. On one hand, a large part of the parks in these regions (53%) achieved a 60% decline in COD emission intensity compared with 2015. On the other hand, 12% of the parks, mainly in the downstream region, increase COD emission intensity. Although the pollutant emission intensities in most industrial parks have decreased over the past years, the long-term challenge of emission reduction remains while considering the variation among industrial parks [15].

《Fig. 7》

Fig. 7. Energy productivity and water productivity of the industrial parks in the YEB.

3.4.3 Green development index of industrial parks in the YEB

We use the method developed in our previous work [16] to analyze the green development index of national economic-technological development areas of the YEB and then compare the index with other industrial parks (Fig. 8). The green development index of the national economic-technological development areas in the YEB range from six to 86. Industrial parks with an index higher than the average value (50) in the upstream, midstream, and downstream regions account for 13%, 22%, and 65%, respectively. Industrial parks in the downstream region generally have a higher index than those in the midstream and upstream regions. Overall, industrial parks in the YEB have a slightly higher green development index than the average performance of industrial parks across China. However, industrial parks in the YEB’s upstream, midstream, and downstream differ dramatically, and industrial parks in the upstream and midstream lag far behind those downstream in facilitating national demonstration programs on eco-industrial development. Specifically, 87%, 78%, and 35% of the national economic-technological development areas with a lower-than-average green development index are found in the upstream, midstream, and downstream regions, respectively. Therefore, achieving a green leapfrog for all industrial parks in YEB still has a long way to go.

《Fig. 8》

Fig. 8. Green development index of national economic-technological development areas in the YEB.

Note: The red line at 50 refers to the average value.

《4 Challenges for green development of industrial parks in the YEB》

4 Challenges for green development of industrial parks in the YEB

The ecological environmental pressures and risks of the YEB continually increase and exceed its carrying capacity. Based on a quantitative assessment of economic development, spatial configuration, pillar industries, energy-environmental infrastructure, water use, and pollutant emissions of industrial parks across the YEB regions, we identify four major challenges for furthering the green transformation of industrial parks in the YEB.

《4.1 Challenge to enhance the awareness of ecologicalization and strengthen the capability of technology innovation jointly》

4.1 Challenge to enhance the awareness of ecologicalization and strengthen the capability of technology innovation jointly

The nine provinces and two cities along the YEB have a wide variance in resources, economy, and transportation, resulting in considerable differences in regional development and industrial park management. Since the 18th National Congress of the Communist Party of China, the state has placed a premium on green transformation and innovative development in the industry. It has proposed a series of plans to facilitate the ecologicalization and green development of industrial parks. The documents highlight the concept of ecologicalization and green development. However, industrial parks in different regions at different developing stages have divergent understandings of “what is ecological civilization” and “how to implement it at the park level effectively.” For example, most industrial parks still put more attention on compliance with the limits of end-of pipe-emissions and did not uncover the potential of cultivating new competitive advantages of economic development by implementing ecological innovation.

In some parks, the driving force for eco-industrial transformation remains insufficient because of inadequate scientific and technological innovation capabilities. As eco-transformation progresses, some new industries, such as the big data industry, smart manufacturing, and artificial intelligence-based industry, have emerged as strategic engines. However, they are mostly in the early stages of large-scale commercialization. Consequently, several critical issues need to be addressed. First, industrial parks must continuously reinforce their scientific and technological innovation capabilities. Second, it is vital to empower the stock of manufacturing industries by enriching research and development investment in enterprises. Third, it is crucial to accelerate the commercialization of new technical innovations on a large scale to underpin industrial structure upgrading.

《4.2 Challenge to reorganize the configuration and industrial structure of industrial parks along the YEB》

4.2 Challenge to reorganize the configuration and industrial structure of industrial parks along the YEB

Presently, many industrial parks in the YEB are established very close to the shoreline. The industrial structure is heavy-industry-intensive, exemplified by the high concentration of the chemical industry, equipment manufacturing, and other heavy industries. As illustrated earlier, there is a similarity in pillar industries among industrial parks, especially in the middle and downstream regions. Collaboration along the industrial, supply, and value chains of manufacturing industries in the YEB should be carefully planned. Remarkably, YEB has intensive chemical industrial parks, and the chemical industry plays a vital role in some cities in the upstream region. There are 490 industrial parks at different scales and categories in the 29 central cities along the YEB, 103 of which are chemical industrial parks. The chemical industrial output value of YEB accounts for 46% of the total national volume. The number of chemical industrial parks within 1 km of the shoreline increased from 149 in 2000 to 715 in 2017 [17]. In recent years, the petroleum and chemical industries have shifted from the downstream to the middle and upper streams of the Yangtze River. Such spatial reallocation has a positive effect on promoting industrial development in the YEB However, it also adds extra resource-environment burdens to the Yangtze River in the long term due to the ecological sensitivity and fragility of the upper stream region.

Generally, the green development index of industrial parks in the YEB is relatively better than the national average. However, there is a remarkable variation among the parks in the upper, middle, and lower streams. The parks in the upper and middle streams fall far behind those downstream in terms of implementing national demonstration programs. Given the country’s advanced economic and technological development, the YEB continues to encounter considerable obstacles in achieving a holistic stride of the green development index for all parks.

《4.3 Challenge to reduce GHG emissions from industrial parks》

4.3 Challenge to reduce GHG emissions from industrial parks

According to our previous research, 1600 national-level and provincial-level industrial parks in China emitted approximately 18% of the country’s total GHG emissions in 2014. The GHG emissions of industrial parks in the YEB accounted for 37% of the total emissions. Industrial parks are the primary source of GHG emissions and need to take robust measures targeting the national strategy of carbon peaking and carbon neutrality.

The energy infrastructure located within the park accounts for most of the park’s GHG emissions. Direct carbon emissions from the park’s energy infrastructure account for approximately 75% of the park’s GHG emissions from energy consumption. There is a total of 1820 in-use heat and power generation units in parks of the YEB, with a combined installed capacity of 209 GW, accounting for approximately 37% of the total installed power generation capacity in the YEB. Approximately 84% of these in-service units are coal-fired, and the capacity structure reflects “a limited number of large-capacity units and a large number of small-capacity units.” That is, large-capacity units with capacities of 300 MW and above account for 79% of the total installed capacity and 19% of the total units in service in parks. Meanwhile, small-capacity units with less than 30 MW account for 7% and 65%, respectively.

Generally, large-capacity units have a higher energy efficiency than small-capacity units. Upgrading the small-capacity units in parks and large-scale application of non-fossil energy will synergistically affect energy saving, water conservation, and carbon emission reduction from the perspective of lifecycle thinking. Facilitating a sharable energy infrastructure in an industrial park can also play a role in mitigating GHG emissions and improving the environmental performance of eco-industrial development.

《4.4 Challenge to sustainable water stewardship by managing water consumption, safety, and harmful contaminants》

4.4 Challenge to sustainable water stewardship by managing water consumption, safety, and harmful contaminants

Owing to abundant and low-cost water supplies, parks and enterprises along the YEB do not have strong indications to control the cap of water intake. The cost of water intake only accounts for a minimal share of production costs; thus, it cannot leverage parks to invest much in water stewardship. Moreover, most parks and enterprises are unaware of the direct and indirect costs and environmental impacts of water use from the lifecycle thinking viewpoint. A large room is still ahead while stringing for sustainable water stewardship from water intake to drainage.

Given the environmental infrastructure deployment, national and provincial industrial parks in the YEB have installed centralized wastewater treatment plants and online monitoring devices. However, this is just a fundamental requirement for preventing and controlling water pollution in industrial parks. Presently, industrial wastewater management in parks mainly focuses on typical indicators, such as COD and ammonia nitrogen. Many industrial parks cannot manage toxic and hazardous pollutants, persistent organic compounds, and other emerging pollutants [18,19]. It is not uncommon for some industrial parks to mix municipal and industrial wastewater for further treatment; such practices could pose potential environmental risks. Moreover, industrial parks experience additional pressure to increase emission standards and improve reclaimed water use.

《5 Green development roadmaps for industrial parks in the Yangtze River Economic Belt》

5 Green development roadmaps for industrial parks in the Yangtze River Economic Belt

Industrial parks have played a significant role in economic and social development in the Yangtze River Basin by contributing more than 50% of the gross industrial output values of the provinces along the Yangtze River. It is necessary to strengthen the strategic position of industrial parks for the robust development of the manufacturing industry in China. We propose the following policy implications for furthering the green transformation of industrial parks:

《5.1 Making a master plan for green development of industrial parks in the YEB and strengthening the demonstration role of parks in downstream regions.》

5.1 Making a master plan for green development of industrial parks in the YEB and strengthening the demonstration role of parks in downstream regions.

We suggest that the Ministry of Ecology and Environment take the lead and collaborate with other important departments (the Development and Reform Commission, Ministry of Industry and Information Technology, Ministry of Commerce, and Ministry of Science and Technology) to propose guidelines for the green development of industrial parks. It is necessary to integrate in-use policies and demonstration projects for industrial parks to create tailored regulations for parks with various pillar industries and green development performance. Local authorities are encouraged to release annual reports on the green development of industrial parks.

Particularly, well-developed industrial parks in the downstream regions of the YEB should demonstrate deep eco-transformation and ecological civilization construction. Consequently, the key is to achieve substantial improvement in the following aspects: (1) drive a coordinated development of the whole basin by building a comprehensive modern industrial system with the industrial park as the primary carrier; (2) encourage the digitalization and ecologicalization of industrial parks and enterprises; (3) optimize the relative and absolute decoupling control both for energy and water use, and facilitate the improvement of resources, carbon, and energy productivity in a doubled or tripled manner; (4) strengthen sustainable water stewardship in industrial parks and build up a multilevel water risk prevention and control system by integrating the river basin, park, enterprises, and production equipment; and (5) implement the green and low-carbon transformation of energy-environmental infrastructures and foster industrial symbiosis among infrastructure, with the aim of improving cascading utilization of energy and recovering unconventional water resources.

《5.2 Implementing comprehensive eco-transformation and building up green industrial parks from the perspective of lifecycle thinking》

5.2 Implementing comprehensive eco-transformation and building up green industrial parks from the perspective of lifecycle thinking

Comprehensive measures should be implemented to build a green industrial park throughout its lifecycle by integrating industrial production, energy, and environmental systems. In particular, four aspects should be considered. First, industrial parks should promote pollution prevention and control, ecological-environmental protection, and resource-energy management from a lifecycle perspective by integrating park-tailored countermeasures with local environmental features, managing the material and energy flow of the park, and environmental impacts thereof. Second, industrial parks should drive the green development of the entire industrial chain by innovating key technologies for cleaner production and circular economies in the pillar industries. Meanwhile, the leading enterprises and industrial parks are encouraged to play a critical role in fostering industrial symbiosis and collaboration among different products, manufacturers, and regions. Such collaboration is the key to improving the competitive advantage of the entire industrial chain. Third, measures such as reduction at source, process efficiency improvement, and source opening should be employed to reduce the quantity and intensity of energy, water, and land resource consumption in industrial parks. Industrial parks should keep improving their carbon productivity, and some are encouraged to take the lead in achieving peak carbon emissions. Fourth, the safety and environmental management regulations should be intensified strictly, transparent, and timely manner. The government should continue optimizing emission standards and strengthening ecological-environmental risk prevention, especially those caused by emerging pollutants, while effectively managing regular pollutants. Fifth, local governments in industrial parks should take effective measures to manage energy consumption and water use by integrating the park and local community and building a resilient energy supply system with a balance between combined generation and distributed clean energy. Moreover, the symbiotic network between energy and the environmental infrastructure is a useful supplement.

《5.3 Balancing chemical industrial parks development and carrying capacity of the Yangtze River by controlling pollution for the entire process precisely and scientifically》

5.3 Balancing chemical industrial parks development and carrying capacity of the Yangtze River by controlling pollution for the entire process precisely and scientifically

(1) Special regulations should be implemented to tackle pollution in chemical industrial parks and chemical manufacturers along the Yangtze River. The number of chemical production enterprises within a one-kilometer radius along the main and tributaries of the Yangtze River, in environmentally sensitive areas and densely populated urban areas, below-scale enterprises, or outside a chemical industrial park should be carefully and appropriately controlled. Local governments and industrial parks are encouraged to explore site-specific sustainable solutions. New mechanisms for reallocating resources and environmental emission caps will facilitate industrial structure adjustments and improve the threshold for additional chemical manufacturing. For chemical industrial parks and enterprises that must be moved out, tailored measures should be taken carefully in light of permanent closure, relocation, transfer to local regions or undertaking by other provinces. Consequently, the dilemma of the heavy-density chemical industry along the YEB should be addressed. It is also an excellent opportunity for industrial parks to avoid overcapacity and homogeneous competition in advance and to implement joint transformation and upgrading of chemical enterprises and receive parks. Thus, a diversified but symbiotically linked chemical industry layout in the upper, middle, and downstream regions could be achieved and coordinated with the Yangtze River ecologically and environmentally friendly.

(2) Industrial parks are encouraged to construct innovative industrial parks and enhance their capability of environmental risk prevention, emergency alerting, and response. Particularly, it is necessary for chemical industrial parks in the YEB to establish an intelligent platform for the early warning and prevention of environmental risks. The vision is to build a data-driven environment and safety management system that covers the entire process to improve the capability of an intrinsically safe chemical industrial park.

(3) Industrial parks should consolidate sustainable water stewardship by implementing high-resolution water monitoring and balance testing. The government will carry out special regulations to check sewage discharge outlets along the Yangtze River and strictly control the installation of new sewage outlets. It is suggested that only one sewage outlet be set up in each park, and online monitoring of sewage outlets should be reinforced. In an environmental accident, a multilevel water risk prevention system should be established to ensure that polluted water does not directly flow into the Yangtze River. Downstream of the sewage outlet and the area with branches flowing into lakes, a constructed wetland sewage treatment project is recommended by considering local conditions to purify the tailwater further. The main purpose is to set up site-specific emission standards and reduce or avoid effluent directly discharging to the Yangtze River.

(4) Industrial parks should keep improving the emergency response plans for significant environmental pollution and ecologically damaging accidents, formulate implementation plans for environmental risk prevention and control, make solid emergency plans for environmental emergencies in chemical industrial parks along the Yangtze River, and strengthen routine practices and trials.

《Compliance with ethics guidelines》

Compliance with ethics guidelines

The authors declare that they have no conflict of interest or financial conflicts to disclose.

京公网安备 11010502051620号

京公网安备 11010502051620号